IIFES2024 Hitachi Group Booth

Stage Video

NewsPicks

"New Competitive Strategies for

Conglomerates in VUCA Times"

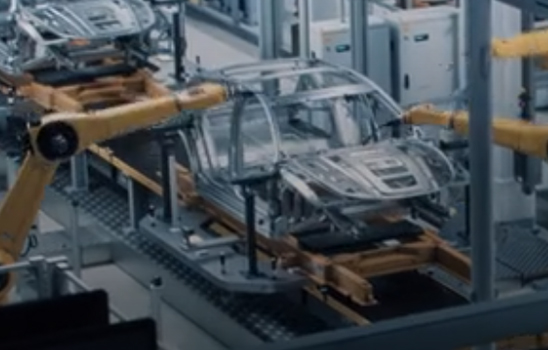

The People of Hitachi:Automating

EV Battery Production – An Engineer’s

Journey to Manufacturing Innovation

Industry

Digitally connect and optimize management,

the field, and the supply chain

One-stop solution to customer issues

We provide a Total Seamless Solution

Providing a Total Seamless Solution by connecting with digital technology, we resolve your business issues

Digitally link and optimize your entire supply chain, from management to workplaces

Hitachi Social Innovation Forum 2023 JAPAN stage video

The digital transformation of industries and cities

Realizing a sustainable society by connecting entire cities with digital technologies

Hitachi's Total Seamless Solution

We use digital technologies to connect entire manufacturing businesses, from manufacturing sites to management. This improves productivity and quality, enabling efficient manufacturing operations that can respond immediately to the changing needs of markets.

We utilize data throughout the entire value chain, from procurement to sales and after-sales services. This enhances the functionality of distribution centers and delivery, leading to optimization of the supply chain.

By collecting data and analyzing it through the use of AI, we improve the visualization of consumer needs. This makes one-to-one marketing more accurate and contributes to an increase in sales.

By providing high added value to after-sales services for the manufacturers and owners of production equipment, we contribute to increased profits, labor-saving efforts, and improved operating rates of equipment.

By making use of the knowledge and track record we have cultivated over years of experience as a comprehensive water service provider, we provide advanced water and sewage solutions that contribute to achieving a sustainable society.

Through a wide range of environment-related businesses, such as air and energy, we implement clean environments to meet our customers' diverse needs.

We provide a variety of production equipment, system, and services that are necessary for factories. We can also propose measures for tackling issues such as power and labor reduction and the improvement of production lines.

Throughout the world, we provide key products that meet the needs of our customers in the manufacturing industry and in fields such as resources and energy, and that support social innovation businesses.

A System to Visualize Expert Skills to Younger Workers

- Making passing down unexplainable skills easier

How a Japanese company is driving toward a future of factories that combine Skilled techniques and automation to deliver the best manufacturing services

Customers getting what they want, when they want it: Automated guided vehicles support the e-commerce industry

Merging JUKI production facilities with Hitachi's operation know-how to bring advances to MONOZUKURI (manufacturing) workplaces

Digitalization of quality control know-how through co-creation between Daikin and Hitachi

Hitachi pump technologies: Advancing over 100 years in pursuit of solutions to water resource problems

Centrifugal compressors: Playing a key role in the production of Brazil's offshore oil resources

Contents of this page are applicable in Japan. Total Seamless Solution is a registered trademark of Hitachi, Ltd. In Japan and the U.S.