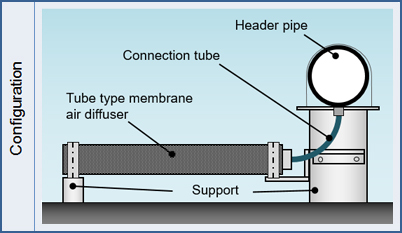

This cylindrical device suits various air diffuser layouts.

| Element size | Φ93×1000mm |

|---|---|

| Bubbling area | 930cm2 |

| Aeration volume | 40~400L/min/membrane |

| Membrane | EPDM |

| Support | SUS304 or SS400(Painted) |

| Connection tube | SUS304 |

| Header pipe | FRP |

In the case of HMD-T10S standard element.

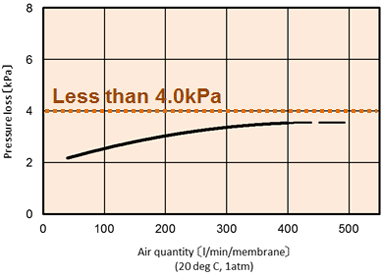

| Pressure loss | Ceramic plate | Tube membrane |

|---|---|---|

| Initial | Approx. 2kPa | Approx. 4kPa |

| Aging | Max. 8kPa | Max. 3kPa |

| Total | Max. 10kPa > Max. 7kPa | |

Comparison of pressure loss

Change of pressure loss

(In the case of HMD-T10S standard element.)

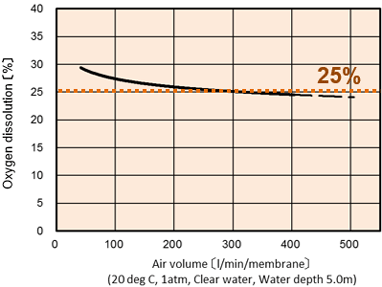

Change of Oxygen Dissolution

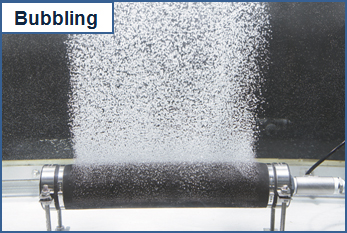

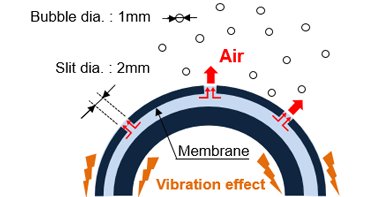

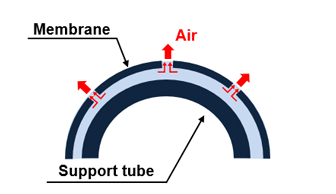

Air passes only through the slits (2mm).

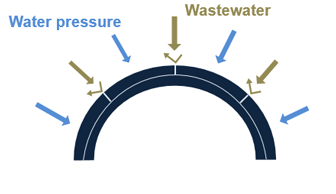

Membrane adheres to the support tube by water pressure.

→Adverse tide is prevented.

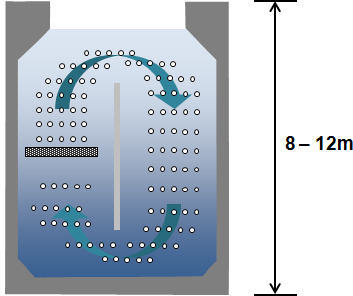

Regular aerobic tank

Deep aerobic tank

| Applications | Number of installation sites | Total number of membranes |

|---|---|---|

| Sewage treatment | 11 | 8,297 |

| MBR* | 1 | 128 |

| For rural communities | 14 | 532 |

| Septic tanks | 1 | 100 |

| Sludge carbonization | 1 | 152 |

Many installations have been completed in Japan.