1. Outlook of Water Environment Solutions Technology

The Hitachi Group has been involved in the development of technologies that support the water environment for almost a century. We currently provide products, systems, and services in a wide range of fields including water resource preservation, flood control, water supply and sewage development, waste water treatment, and the reclamation and recycling of water. On the other hand, the Hitachi Group also proposes holistic solutions to issues concerning the water environment, and aims to provide new solutions and services that leverage IT and the strengths of existing businesses.

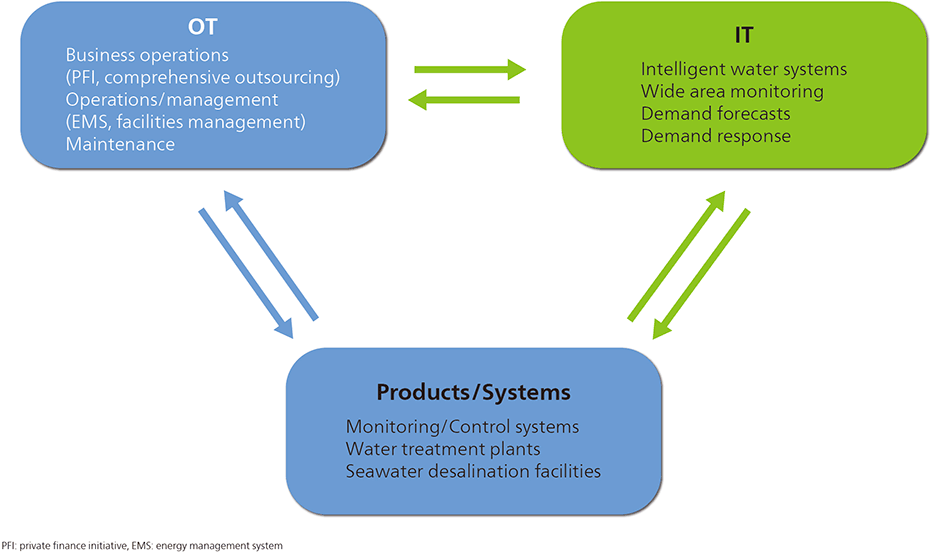

In the water environment solutions field, across-the-board optimization achieved through the linkage of products such as monitoring and control systems and water treatment plants with operational technology (OT) and IT is essential. Through collaboration over various technologies, Hitachi will continue linking innovations in water treatment and water supply management with other infrastructure such as electric power, thus ensuring the safety and security of the entire social infrastructure and contributing to its optimization and sustainable development.

1. Water environment solutions and services that leverage IT and the strengths of existing businesses