1. High-efficiency Operational Support Technologies for Industrial Plants

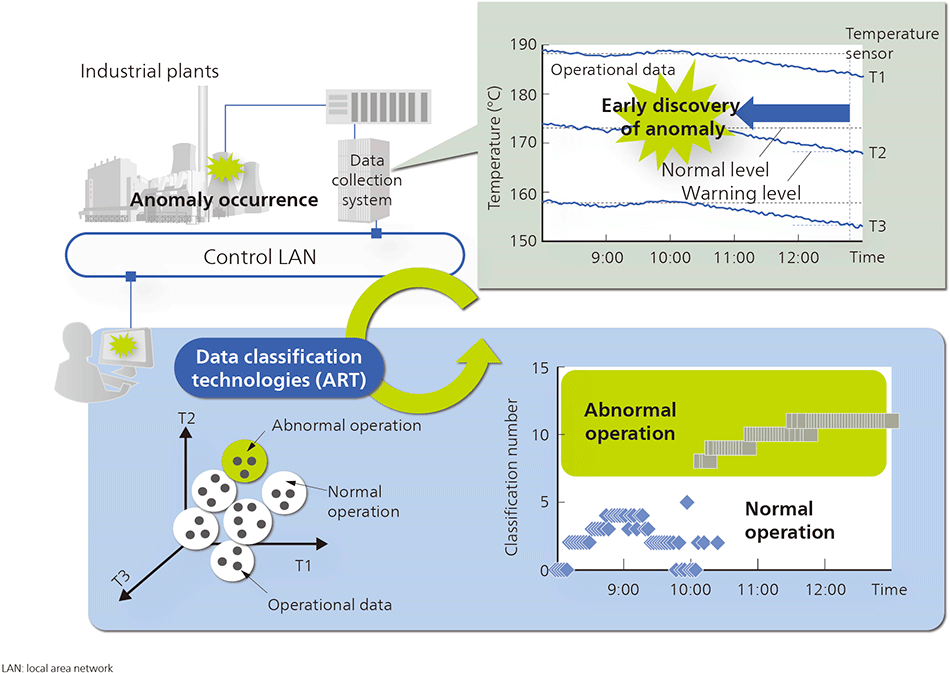

Power generating facilities and industrial plants need to maximize operational efficiency by optimizing operating conditions based on fuel and raw material lot changes, aging deterioration of equipment, and so on. Hitachi has developed high-efficiency operational support technologies for industrial plants that detect equipment anomalies and inappropriate operating states early on and provide guidance towards optimum conditions, and verified the effectiveness of the technologies in a joint effort with the Universiti Teknologi PETRONAS.

With conventional anomaly diagnosis technologies that are based on initial conditions, as fluctuations within normal operating ranges are also determined to be “anomalous,” the application of these technologies in places where the conditions considered appropriate can change on a daily basis has been difficult.

On the other hand, Hitachi’s newly developed technology employs a sequential learning-type data classification technology known as adaptive resonance theory (ART). Since ART can teach a system the “normal” conditions that correspond to a wide range of operating states, anomalies can be detected accurately.

A pilot plant for distillation towers, a key piece of equipment used in crude oil refining plants, was used to verify the system. Even when the composition of the raw materials changed, it was demonstrated that anomalies such as malfunctioning flow adjustment valves and sensor drift could be detected.

Moving forward, Hitachi will demonstrate loss cost reductions at customer plants through this technology.