Water Environment Solutions Based on Advanced Technology and Comprehensive Capabilities

While the overall planetary cycle of water resources maintains a balance between seawater and fresh water, readily available fresh water makes up only 0.01% of this total. Given that the demand for water is rising year on year due to factors such as population growth, rising living standards, urbanization, and industrial development. Hitachi has been responding to these problems by marketing and supplying wastewater recycling and seawater desalination systems. This article reviews past work in this field and describes the next generation of systems for producing fresh water efficiently.

Global Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Overseas water business. Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage.

Engineering Department, Global Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Overseas water treatment projects.

Engineering Department, Global Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Overseas water treatment projects (desalination systems). Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage.

Business Development Department, Global Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Overseas water treatment projects. Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage.

Engineering Department, Global Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Overseas water treatment projects (desalination systems).

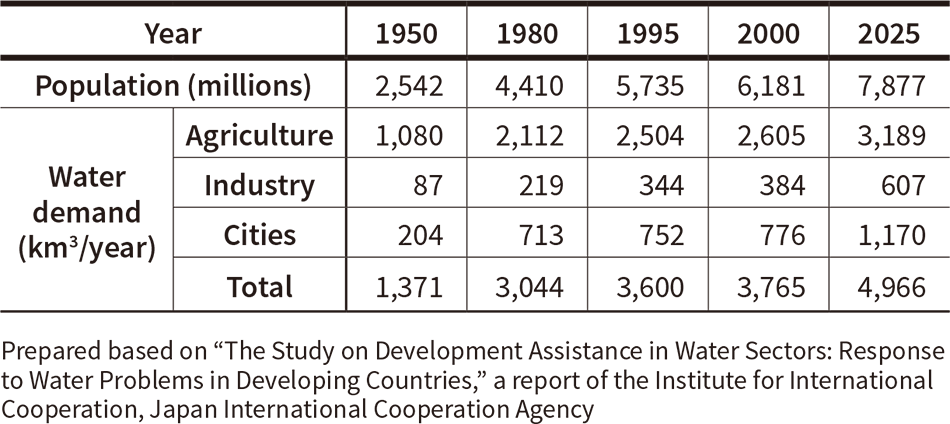

Table 1—Trends in Water Use Water use is increasing annually and is expected to reach approximately 3.6 times 1950 levels in 2025.

Water use is increasing annually and is expected to reach approximately 3.6 times 1950 levels in 2025.

The Earth has finite water resources, with the balance of seawater and fresh water being maintained by the planetary water cycle. Of an estimated total of 1,386 million km3 of water, oceans account for 97.5% and fresh water makes up only the remaining 2.5%. Most of this is in the form of ice, so the percentage of water resources in the environment that are readily available for human use is only 0.01% of the total.

As water availability is significantly influenced by factors such as climate and geography, it depends on the natural environment during any given year and there is a limit to how much effect people can have. This means that large fluctuations in the amount of available water as well as chronic water shortages are problems for societies.

Meanwhile, water is put to a wide range of uses, including drinking water, industrial water, and agricultural water, with the amounts required rising year by year due to population growth, rising living standards, urbanization, and industrial development. By 2025, water use is expected to have increased by approximately 3.6 times in the 75 years since 1950 (see Table 1 and Figure 1).

Against this background, Hitachi has been marketing and supplying systems for many different fields and applications, including wastewater recycling systems that can make effective use of finite fresh water resources and desalination systems that utilize the seawater that makes up the bulk of the Earth's water resources.

This article reports on example implementations of these systems as well as the next generation of technologies for resolving these water problems.

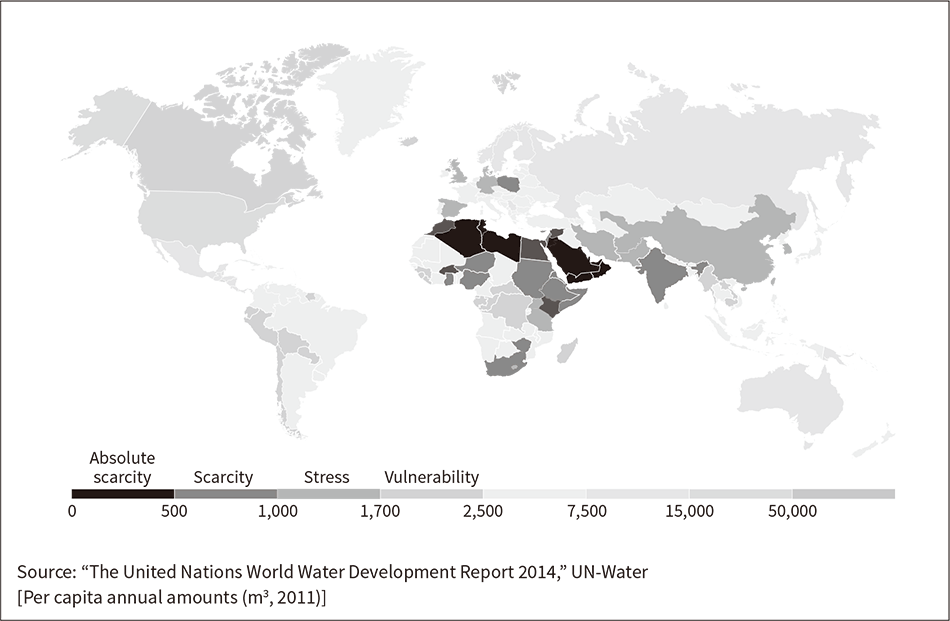

Figure 1—Global Water Environment: Available Water Resources The map shows the degree of water stress as of 2011, meaning the water demand per person relative to the available resource.

The map shows the degree of water stress as of 2011, meaning the water demand per person relative to the available resource.

This section describes examples of a wastewater recycling system for industry and a seawater desalination system for producing drinking water that Hitachi has supplied in recent years.

Hitachi has recently expanded its water treatment solutions business into Asia in response to the diverse needs of Japanese companies. More than 10 such systems have been supplied through its local subsidiary in India, including to a Japanese electricity company and automotive business. This section describes the supply of a total solution system for water treatment in 2017 to a Japanese car plant in northern India that included equipment for drinking water, wastewater treatment, and recycling.

Undertaken as part of a plan to increase water supply capacity to cope with higher vehicle production amid strict government-imposed limits on things like the amount of water able to be drawn from aquifers, it involved the supply of a total solution system designed to have zero discharges. By building a treatment system tailored to the characteristics of the wastewater so that it could be recycled, the project optimized the factory water supply and wastewater handling to reduce the amount of water taken from the aquifer. Figure 2 shows an overview of the water treatment solution.

With rising demand for water around the world, Hitachi intends to continue with its contribution to making better use of limited water supplies by drawing on its extensive experience and track record to build social infrastructure designed to alleviate water shortages and protect the environment, and to supply total solutions for water treatment.

Figure 2—Water Treatment Solution Hitachi supplied a total solution system for water treatment that included equipment for drinking water, wastewater treatment, and recycling to a Japanese car plant in India. The system helped increase vehicle production by reusing wastewater, thereby reducing use of water from an aquifer with strict limits on how much water could be taken.

Hitachi supplied a total solution system for water treatment that included equipment for drinking water, wastewater treatment, and recycling to a Japanese car plant in India. The system helped increase vehicle production by reusing wastewater, thereby reducing use of water from an aquifer with strict limits on how much water could be taken.

Around the world, severe water shortages exist in places with low rainfall, such as the Middle East, and in countries that lack rivers or other sources of fresh water, such as island nations. These countries have for a long time included seawater among their sources of water for domestic use. Whereas the past practice was to use distillation to obtain pure water, this presented significant difficulties that included the required fuel and other costs, and the space taken up by the equipment. The development of membrane technology in recent years, however, has seen growing use of reverse osmosis (RO) membrane desalination as a way to alleviate these problems, and Hitachi has supplied such systems to a number of countries.

This involves first filtering out any debris or suspended matter from the salty intake water (typically seawater), and then using an RO membrane to remove the salt (see Figures 3 and 4). Hitachi has installed desalination systems in more than 100 countries or regions to serve a variety of applications, and is currently building a facility in the Republic of Iraq able to produce approximately 200,000 m3/day of fresh water.

As the RO membrane desalination systems that are now becoming the norm require a filtration pressure high enough to match the osmotic pressure of the salty source water, high-pressure pumps are essential. Because this means that they consume a lot more electric power than systems that produce water from a fresh source, there is strong demand for ways of overcoming this problem of high water production cost.

This section describes a number of desalination systems developed to meet this customer need.

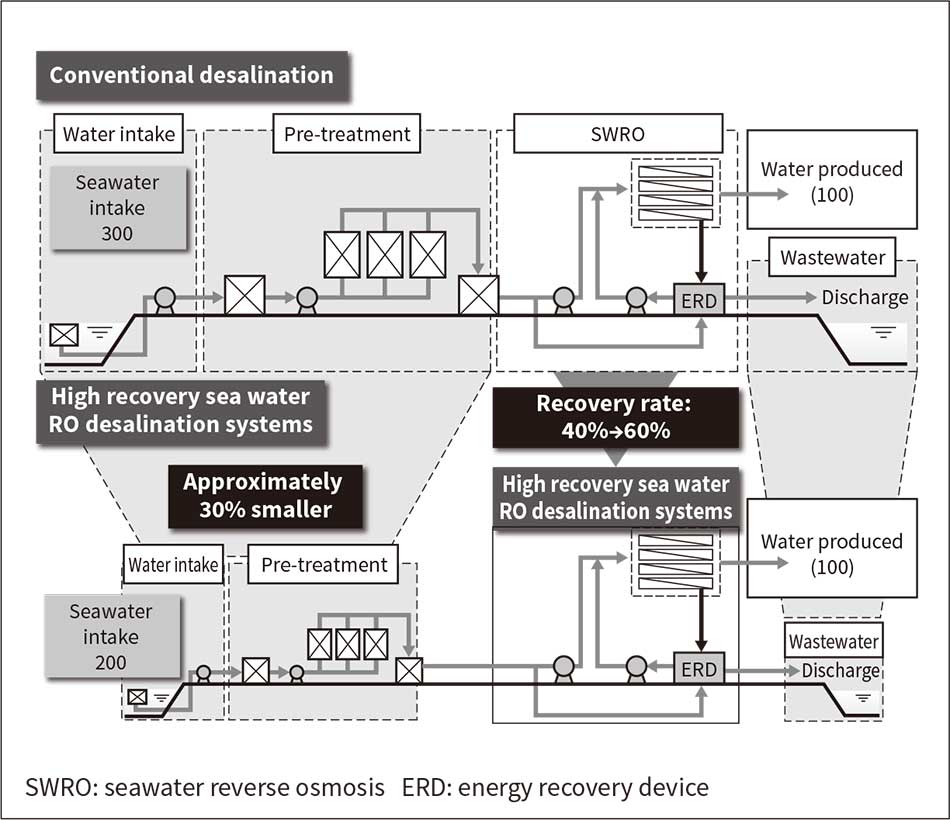

Figure 5—Comparison of Equipment Used in Conventional and Hitachi's High-recovery Seawater RO Desalination Systems The high-recovery seawater RO desalination system not only saves energy, it also reduces the load on the environment by taking less water from the sea and using a smaller quantity of pre-treatment chemicals.

The high-recovery seawater RO desalination system not only saves energy, it also reduces the load on the environment by taking less water from the sea and using a smaller quantity of pre-treatment chemicals.

With demand for water rising, the seawater desalination market is pursuing a variety of technical developments with aims that include making systems larger, using less energy, and imposing less of an environmental impact. These include hybrid technologies that combine distillation and RO membrane processes, energy-efficient RO membranes, and highly efficient energy recovery devices. Hitachi has developed a high-recovery seawater RO desalination system. Performance testing has already been conducted on a prototype (with a capacity of approximately 500 m3/day), confirming its reliability for long-term operation in the Middle East. Hitachi has also begun marketing commercial plants, and development is ongoing with a view to utilizing the technology at large plants in locations such as the Middle East or North Africa.

The recovery rate of conventional RO systems for seawater desalination has been around 40%. The problems that have prevented this from being increased in practice are the rise in power consumption and concerns about the risk of membrane fouling due to the significantly higher flux through the upstream RO membrane. Hitachi's high-recovery system increases the recovery rate to 60% by splitting up the series of vessels based on the specifications of the RO membranes so as to control and balance the flux through each one. Moreover, because higher recovery rate reduces the seawater intake, the capacity of the pre-treatment and post-treatment equipment was able to be reduced by about 30%. Meanwhile, a proprietary energy recovery system reduces the load on the high-pressure pumps in the RO system. Together, these measures not only reduce energy use at a desalination plant (by approximately 15%), they also reduce the system's environmental impact by conserving the source seawater and reducing the use of pre-treatment chemicals.

Figure 5 shows a comparison of the previous technologies and Hitachi's high-recovery system.

Membrane manufacturers have been working in recent years on the development of products with special features, such as low-pressure seawater RO membranes and membranes able to selectively remove particular ions. By combining these new products with its high-recovery system, Hitachi believes it can contribute to the diverse requirements of different industries and regions by further improving energy efficiency and offering a wide variety of water production systems.

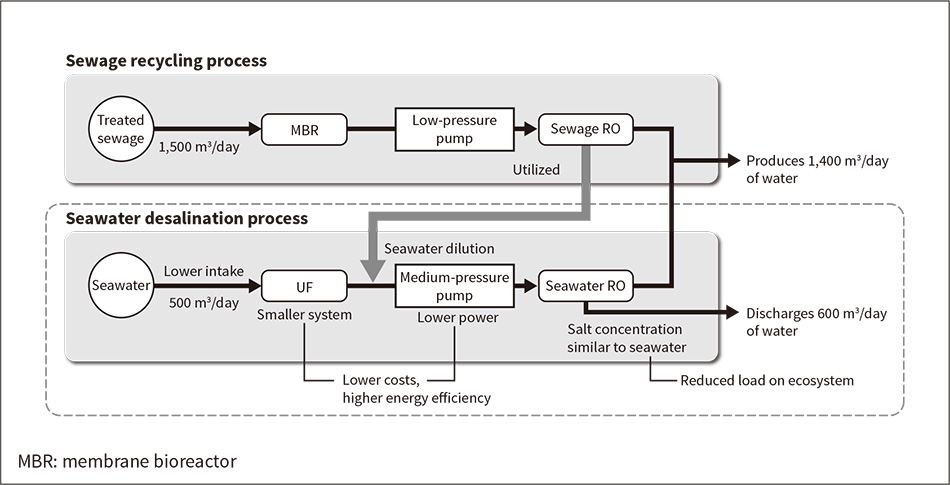

This integrated system of seawater desalination and sewage treatment is the only one of its type in the world that combines seawater desalination with wastewater recycling* (see Figure 6).

Conventional seawater desalination systems produce fresh water by highly pressurizing seawater to force it through the micropores of RO membranes, thereby removing the salt. In existing plants with RO membranes, the cost of running the pumps accounts for roughly half of all operating costs. This is because, the higher the concentration of salt, the higher the pressure needed to force water through the RO membranes and therefore the higher the pump running costs.

In contrast, Hitachi's integrated system of seawater desalination uses treated sewage to dilute the concentration of salt in the seawater before filtering it through the RO membranes. This significantly reduces operating costs compared to conventional seawater desalination. Moreover, while the brine discharged by the conventional seawater desalination process is recognized as a problem for the environment, because the system uses seawater that has been diluted with treated sewage, the concentration of salt in the discharge from the sewage recycling process can be kept down to a level similar to seawater, thereby reducing the load on the marine environment.

Hitachi and Toray Industries, Inc. played a central role in promoting this system to the New Energy and Industrial Technology Development Organization (NEDO) as a way of performing energy-efficient seawater desalination with a low impact on the environment. This led to it being adopted as part of the Water Saving and Environmentally-friendly Water Recycling Project. In 2010, a demonstration project was undertaken in collaboration with City of Kitakyushu at the Water Plaza Kitakyushu facility built by the Global Water Recycling and Reuse Solution Technology Research Association (GWSTA), of which Hitachi and Toray Industries are core founding members. The three years of trials running up until November 2013 demonstrated energy savings of more than 30% compared with a conventional seawater desalination plant.

The Republic of South Africa has to deal with a difficult water environment. Not only is its mean annual rainfall only about 450 mm, roughly half the global average, but it also lacks major rivers and the utilization of groundwater is made difficult by the land area being covered with hard rock. A number of provinces have severe water shortages, including KwaZulu-Natal, where Durban is one of the major cities. Moreover, electricity supplies are tight due to aging infrastructure and rising demand on the back of population growth and economic growth, with prices having risen at an annual rate of 20% since 2008.

Prompted by these circumstances, Durban city officials showed considerable interest in Hitachi's integrated system of seawater desalination and sewage treatment when visiting Water Plaza Kitakyushu and requested that Hitachi carry out a pre-feasibility study on installing such a system in their city. Subsequently, Hitachi was contracted by the Japan International Cooperation Agency (JICA) to undertake a project to encourage the adoption of private-sector technology in September 2014 and, with support from JICA, took active steps to present the integrated system to the relevant agencies in Durban and South Africa. In parallel with this, Hitachi was contracted again by NEDO to undertake the International Project for Energy-saving and Environmental Friendly Desalination Project in February 2015. After a preliminary study, this led to a demonstration project being commenced in October 2016. The project involved conducting overseas demonstrations of the integrated system for which operational know-how had been gained at Water Plaza Kitakyushu, with a one-year trial operation scheduled to finish in November 2020. The aim is to use the demonstration facility to operate a water supply business after the trial completes, with Durban expressing a desire to feed the water it produces into the city water supply for use as drinking water.

One challenge specific to the project was that the water be used for drinking. In the Water Plaza Kitakyushu trial, the water produced was used to supply the boilers at the Shin Kokura Power Station of Kyushu Electric Power Co., Inc. Although analysis showed that the water quality satisfied the requirements for tap water, this was the first attempt at using water from the integrated system. An advanced oxidation process unit will be installed at the downstream end of the integrated water treatment system to mitigate the risk of restricted organic material remaining in the water, and a study was conducted on the treatment of contaminants such as organic material that does not easily break down.

Figure 6—Flowchart of Hitachi's Integrated System of Seawater Desalination and Sewage Treatment In addition to lower pump power and reduced environmental load due to brine, the smaller system size thanks to the lower seawater intake also helps reduce lifecycle costs.

In addition to lower pump power and reduced environmental load due to brine, the smaller system size thanks to the lower seawater intake also helps reduce lifecycle costs.

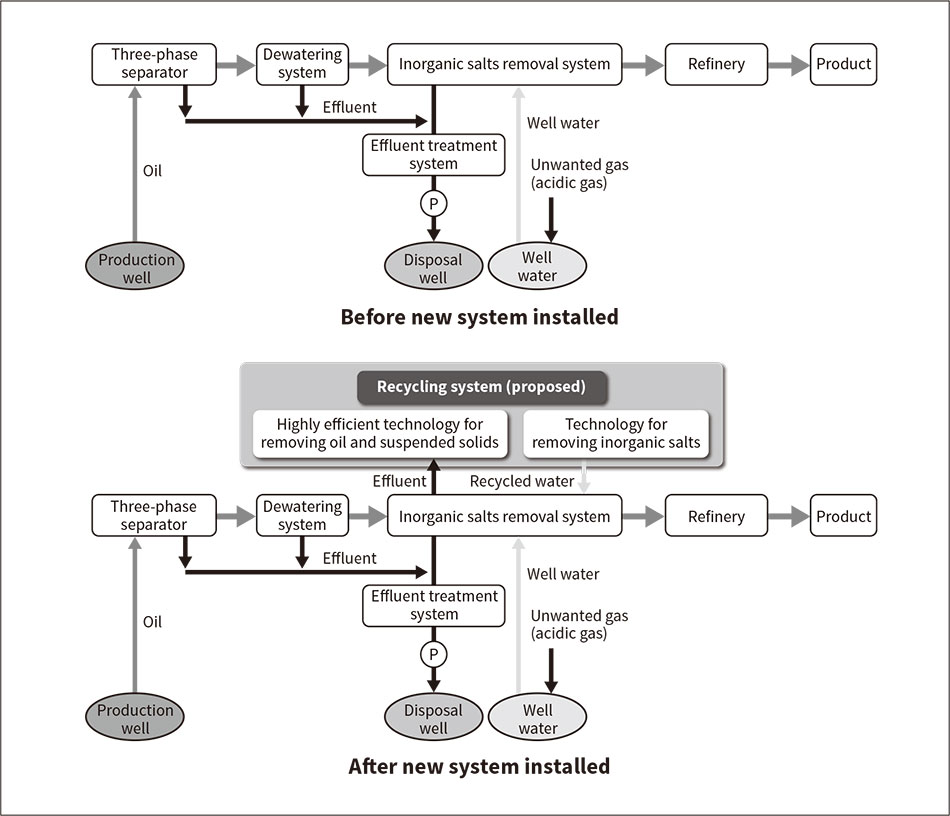

Figure 7—Before and After Installation of the New System Hitachi has proposed a new membrane-based wastewater recycling system that uses heat-tolerant RO membranes so that it can also work with high-temperature wastewater. Installation of the new system should help save energy and reduce the load on the environment.

Hitachi has proposed a new membrane-based wastewater recycling system that uses heat-tolerant RO membranes so that it can also work with high-temperature wastewater. Installation of the new system should help save energy and reduce the load on the environment.

Concerns about energy efficiency and the environment over recent years have led to the adoption of advanced wastewater recycling technologies that use membrane technology, including by the private sector. While this began on a small scale with individual treatment processes, it has since expanded to the factory level and is being utilized for comparatively large-scale wastewater treatment such as that associated with crude oil production wells (what the oil industry calls “upstream”). The recycling of treated wastewater has led not only to an expansion in treatment capacity, but also to the adoption of treatment systems that use RO membranes, with steady demand for advanced forms of treatment such as the elimination of dissolved ions (inorganic salts).

However, because the maximum operating temperature for RO membranes is typically 45°C, heat exchangers or other such technologies are required to lower the temperature when treating water that is hotter than this, with major cost implications. The wastewater from upstream oil and gas production in particular tends to be comparatively high (50°C or more), and with most oil and gas production taking place in arid regions where the air temperature is also high, meaning that heat exchangers cannot operate efficiently, this poses an obstacle to greater recycling of wastewater because the cost cannot be justified.

In response, Hitachi has investigated equipment for removing salts in upstream production and has developed a system for recycling this wastewater.

To remove inorganic salts dissolved in the trace amounts of water that remains in crude oil, the inorganic salts removal system works by injecting water with a low concentration of inorganic salts into the crude oil and shaking it in the presence of an electric field causing the water molecules to clump together. This efficiently separates the inorganic salts from the crude oil along with the water. Because this process requires a large amount of water with a low concentration of inorganic salts, there is very strong demand for the recycling of wastewater that has been treated to have its concentration of inorganic salts reduced from 20,000 mg/L to several thousand mg/L. However, because this wastewater is at a high temperature of 55 to 60°C and contains a high concentration of hydrogen sulfide as well as oil, suspended solids, and heavy metals, it has not been possible to remove inorganic salts efficiently using a mix of existing technologies.

Hitachi has developed an innovative system for use in upstream production that combines highly efficient technologies for removing oil and suspended solids (including heat-resistant microfiltration membranes) and for removing salts (including heat-resistant RO membranes) (see Figure 7). The maximum operating temperatures of the membranes used in the system are 70°C for the microfiltration membranes and 65°C for the RO membranes. The system has cost advantages because it does not require heat exchange. Other potential benefits include saving energy and reducing the load on the environment because it is no longer necessary to inject wastewater back into the ground via disposal wells.

These two new high-temperature-resistant membranes have potential for use as a core technology for water production in a wide range of industries and applications beyond just the oil and gas industry.

Everybody is aware that water is essential for both living things and industry. However, water shortages brought about by rising demand due to factors like population growth and industrial development are emerging as a problem that puts these under threat.

Along with pursuing the wider adoption of desalination systems that can help resolve water shortages, Hitachi is taking an international approach to greater customer needs and challenges, and is actively engaged in the development of technology to help improve the water environment on a global scale.

Institute for International Cooperation, Japan International Cooperation Agency, “The Study on Development Assistance in Water Sectors Response to Water Problems in Developing Countries” (Nov. 2002).