Autonomous Driving Technology for Connected Cars

Hitachi Automotive Systems, Ltd. develops a wide variety of chassis products that influence vehicle performance, and integrated vehicle control systems in which these components in turn work with a wide variety of control techniques to improve vehicle safety and comfort. This article describes progress on development that look ahead to an era of electrification and autonomous driving, and also the prospects for the future.

There is consistent demand from the public for the eradication of traffic accidents. Electronic stability control (ESC) and automatic emergency braking (AEB) have become standard features for accident prevention, with vehicles also coming on the market that are equipped with the ability to keep within their lanes on a highway with minimal steering input from the driver. Along with these advanced driver assistance systems (ADAS) and autonomous driving systems, competition is also intensifying on the development of systems for electric drive, including electric vehicles (EVs) and hybrid electric vehicles (HEVs).

Drawing on know-how built-up over many years of involvement with conventional products, Hitachi Automotive Systems has been working on adopting electronic and electrical operation for brakes, steering, and suspension, parts that influence vehicle driving, cornering, and stopping performance. The company has also been developing intelligent technologies and environmental sensing techniques that enable safer autonomous driving. Through integrated control that harmonizes the operation of these different technologies, Hitachi intends to contribute to the achievement of zero accidents and zero environmental impact by delivering a high level of comfort, environmental performance, and safety.

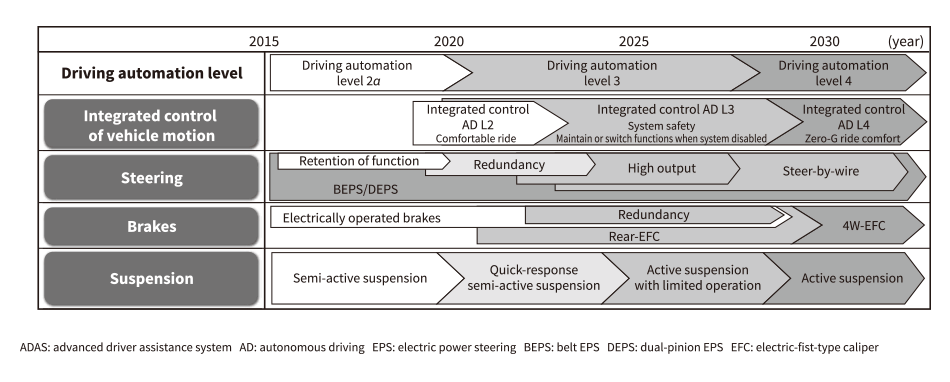

This article describes progress on the development of integrated vehicle control and chassis components as well as the prospects for the future (see Figure 1).

Figure 1 - Roadmap for Integrated Vehicle Control Along with enhancing individual components to keep pace with advances in autonomous driving, Hitachi is also developing techniques for the integrated control of these components to provide highly reliable automotive systems that provide safety and comfort.

Along with enhancing individual components to keep pace with advances in autonomous driving, Hitachi is also developing techniques for the integrated control of these components to provide highly reliable automotive systems that provide safety and comfort.

The requirement for past automotive systems has been to deliver driving, cornering, and stopping performance that faithfully responds to the actions of the driver while also maintaining comfort, with enhancements having led to improvements in the various subsystems that include the engine, brakes, steering, and suspension. However, to allow for a future in which use of electrically powered components and electric vehicles is the norm, and that includes autonomous driving in which electronic control has progressed to the point of replacing the driver, it will be essential to consider how to develop all aspects of vehicle performance in an integrated manner.

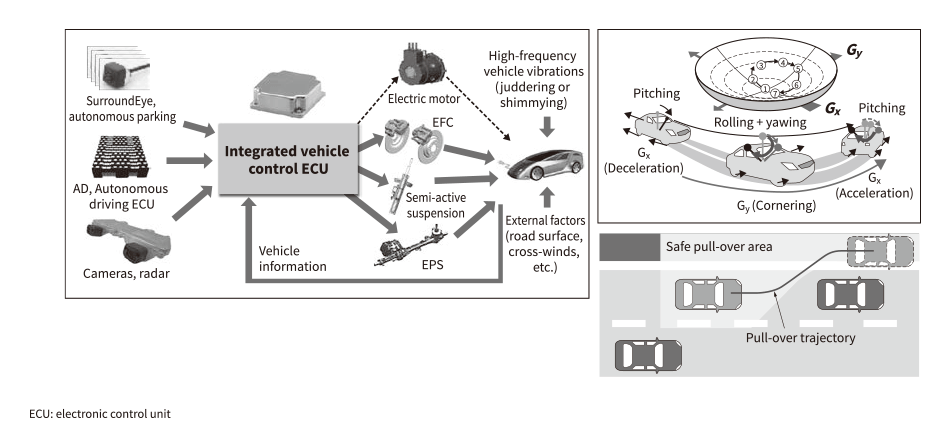

Accordingly, Hitachi is developing the controllers for integrated vehicle control that are needed to optimally control and integrate large numbers of components and supply safe vehicle systems that also maintain comfort. These controllers handle the control of numerous components by integrating control signals from the various sensors and other controllers involved in control functions that deal with sensing and decision-making. The result is the seamless provision of a comfortable ride in a variety of different situations, extending from automatic parking, where the requirement is for turning sharp corners at low speed, thorough to lane-keeping and other high-speed driving functions. The controllers for integrated vehicle control also serve to enhance reliability by taking advantage of component-level redundancy to switch over to backup components in the event of failure. They also include backup functions invoked when a supervisory controller fails. This means that, even if commands from a supervisory controller are interrupted, the controller keeps the vehicle on the intended trajectory and safely hands over control to the human driver during autonomous driving, or selects a safe place to pull over and bring the vehicle to a halt (see Figure 2). The presence of controllers for integrated vehicle control means that the supervisory controller can implement coordinated control of vehicle systems simply by specifying the desired direction, speed, and trajectory, and that a comfortable ride can be provided based on the road surface and vehicle conditions with high reliability and in accordance with the instructions.

Figure 2 - Integrated Vehicle Control The integrated vehicle control ECU controls the movement of the vehicle based on a target trajectory supplied by a supervisory controller (left). It provides safe and comfortable vehicle behavior by managing the operation of each component in an appropriate way (top right). Failure of the supervisory controller does not interrupt autonomous driving and instead the ECU follows the safest trajectory (bottom right).

The integrated vehicle control ECU controls the movement of the vehicle based on a target trajectory supplied by a supervisory controller (left). It provides safe and comfortable vehicle behavior by managing the operation of each component in an appropriate way (top right). Failure of the supervisory controller does not interrupt autonomous driving and instead the ECU follows the safest trajectory (bottom right).

Automotive manufacturers are working to develop vehicles that place a low load on the environment against a background of global warming and atmospheric pollution. Electric vehicles (EVs and HEVs) represent an effective way of achieving these environmental goals. This shift toward electric vehicles is advancing rapidly, with Europe having recently announced that sales of internal-combustion-engined vehicles will be banned by 2040.

The products of Hitachi Automotive Systems include key components for HEVs and EVs, namely motors, inverters, batteries, and controlled vacuum-less brakes. To obtain knowledge of the coordinated control of these components in combination and how to use them on the road, Hitachi has built test vehicles with front-engine/front-drive (FF), front-engine/rear-drive (FR), and 4-wheel-drive (4WD) configurations, and has developed EV drive control and coordinated control techniques to acquire knowledge about the coordinated control of electric vehicles and its on-road use.

Hitachi has demonstrated that superior vehicle performance is achieved by incorporating different types of coordinated control and integrated control in a 4WD prototype vehicle with front and back motors that has the control configuration shown in Figure 3. In the future, Hitachi intends not only to supply key components, but also to use these as a means for providing development solutions by enhancing know-how acquired in car making and improving performance evaluation, system design, and development efficiency technology.

Figure 3 - Block Diagram of Integrated Vehicle Control on Prototype 4WD Vehicle with Front and Rear Electric Motors The vehicle control module performs integrated control of the motor controller (electric power control) and brake controller (behavior control).

The vehicle control module performs integrated control of the motor controller (electric power control) and brake controller (behavior control).

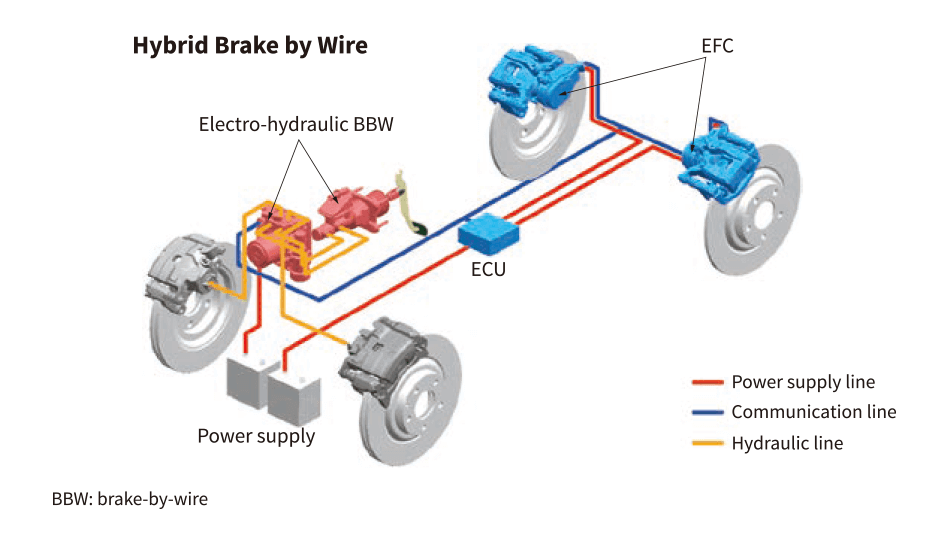

Progress is being made on the adoption of electrical brake systems with the aim of improving safety, environmental performance, and ride comfort. Hitachi has already successfully commercialized ESC, electric boosters, and electric parking brakes. To meet the demands of electric power trains and autonomous driving, two areas where rapid expansion is expected, brake systems will need higher levels of reliability, responsiveness, and control performance than ever before. Meanwhile, it is anticipated that brake-by-wire (BBW) systems that operate under the control of both the vehicle and the driver will be needed to provide customers looking for greater driving enjoyment with better brake feel, and such systems are currently under development. Although existing BBW systems include electro-hydraulic systems that work by the fluid pressure generated by electric motors and pumps, it is anticipated that electric-fist-type caliper (EFC) electromechanical brakes that use electric motors to control braking force directly will be needed to achieve responsiveness and control performance. As the precise control that is possible when using electromechanical brakes on the two rear wheels brings numerous advantages, including safety, comfort, and performance, Hitachi is developing hybrid systems with highly reliable electro-hydraulic BBW on the front wheels and precise and responsive electromechanical BBW on the rear (see Figure 4). This configuration is based on use of Hitachi's brake master cylinder (MCYL) and ESC technology on the front wheels and electric parking brake technology on the rear, and is a quick way to achieve the level of quality needed to make the system available to customers. In comparison to existing hydraulic systems, the ability of this system to harvest regenerative energy over a broad range, as well as its not requiring energy in any form other than electric power, makes it ideal for EVs and HEVs. In addition to shortening the stopping distance for emergency braking, the system is also considered to be suitable for autonomous driving because it allows for advanced vehicle dynamics control and because of the redundancy provided by having two different types of braking. The system can also take advantage of the ability of BBW to provide flexibility in brake feel to provide drivers with the feel they prefer, and to maintain a smooth brake feel without any disconcerting behavior in the transition from autonomous driving to driver control. It provides a high level of ride comfort combined with safety and consideration for the environment.

Figure 4 - Block Diagram of Hybrid BBW The hybrid system uses electro-hydraulic BBW on the front and EFCs at the rear. It achieves a higher level of brake control with coordinated front and rear braking in response to input from the driver or autonomous driving system.

The hybrid system uses electro-hydraulic BBW on the front and EFCs at the rear. It achieves a higher level of brake control with coordinated front and rear braking in response to input from the driver or autonomous driving system.

With recent years having seen a greater emphasis on environmental regulation and energy efficiency, there has been rapid progress toward the adoption of electric drive for the vehicles themselves as well as for onboard systems. This is true also of steering systems, with close to 100% of cars both small and large being fitted with electric power steering (EPS). Improvements in electronics have enabled EPS to have higher output, and this has led to its use being extended to larger sports utility vehicles (SUVs) and small trucks.

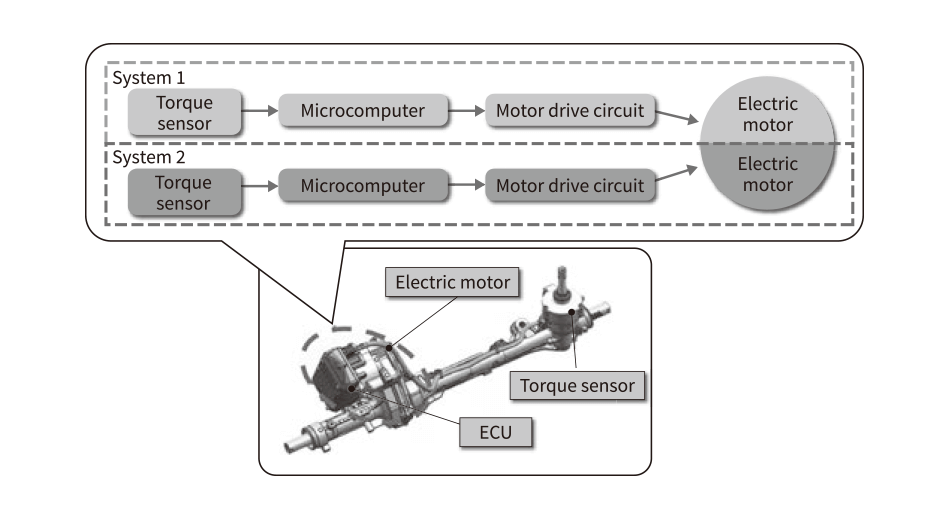

Meanwhile, carmakers are putting a lot of effort into readying autonomous driving technologies for market, with rapid progress evident in this field. To provide an EPS system suitable for autonomous driving, Hitachi Automotive Systems has, for safety reasons, proposed using a fault tolerant (FT) design system as shown in Figure 5. By providing redundancy for electrical and electronic systems, the design is able to keep EPS functioning with 50% output even if a system failure occurs (by continuing to use the other half of the system). In terms of performance, the system is capable of precise steering angle control, with the internal software in the EPS having the ability to switch over from an assist function to a steering function during autonomous driving in response to instructions from an external controller.

Figure 5 - EPS with Redundancy Duplication of electrical and electronic components used in the system means that steering function is not lost in the event of a failure.

Duplication of electrical and electronic components used in the system means that steering function is not lost in the event of a failure.

It is anticipated that this FT design of EPS systems will be widely adopted in the future(1) as autonomous driving becomes more prevalent, and development is currently directed towards bringing it into full production. Moreover, higher levels of autonomous driving in the future will demand more advanced FT design, with a requirement for systems that expect to maintain 100% of function even when a failure occurs. To satisfy this demand, Hitachi is responding to market needs by developing EPS systems with more advanced FT design.

Vehicle suspension is an important component of the chassis that plays a role in achieving ride comfort by suppressing input from the road surface, and in steering stability to improve vehicle stability while driving.

Recently, integrated control of controlled suspension and coordinated operation with controlled brake systems and EPS has begun to enter wider use as a way of achieving higher performance(2). There will also be a need for even higher performance in the near future for autonomous driving, as well as a ride experience that delivers higher levels of comfort. For mass-market vehicles, meanwhile, Hitachi is developing technology for controlled suspension with high performance and low cost, for improving the base performance of conventional dampers (a core product), and for shortening development lead times.

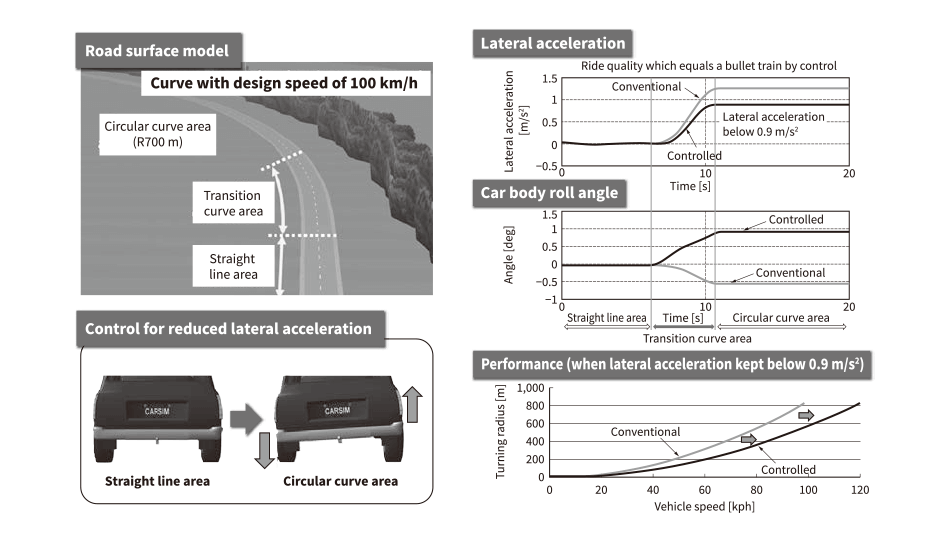

As noted above, the ride comfort in vehicles with driving automation at level 4 or higher will need to provide a superior experience. One of the issues for ride experience in current vehicles is that of front- or rear-seat passengers suffering from motion sickness. With the requirement being for levels of ride comfort like those in the Shinkansen bullet train, Hitachi is proposing to reduce lateral acceleration during cornering. The requirement in modern trains is for a lateral acceleration in curves of no more than 0.9 m/s2 (3). One realistic way to achieve this using vehicle suspension is through the control of roll angle. To reduce costs, Hitachi Automotive Systems is proposing to do this by combining air suspension and controlled suspension (see Figure 6).

Figure 6 - Reduction in Lateral Acceleration by Using Air Suspension and Semi-active Suspension to Control Roll The lateral acceleration experienced by people in the vehicle is reduced by using the air suspension to generate an opposite-to-normal roll angle when cornering.

The lateral acceleration experienced by people in the vehicle is reduced by using the air suspension to generate an opposite-to-normal roll angle when cornering.

Semi-active suspension suppresses vibration and unwanted vehicle movements by performing continuous real-time control of damping force based on things like steering wheel input as well as the car body and suspension stroke. Specifically, it controls damping force as needed, increasing it during bouncing, pitching (1 to 2 Hz), and cornering, and decreasing it for unpleasant vibrations in the 2 Hz and higher frequency range.

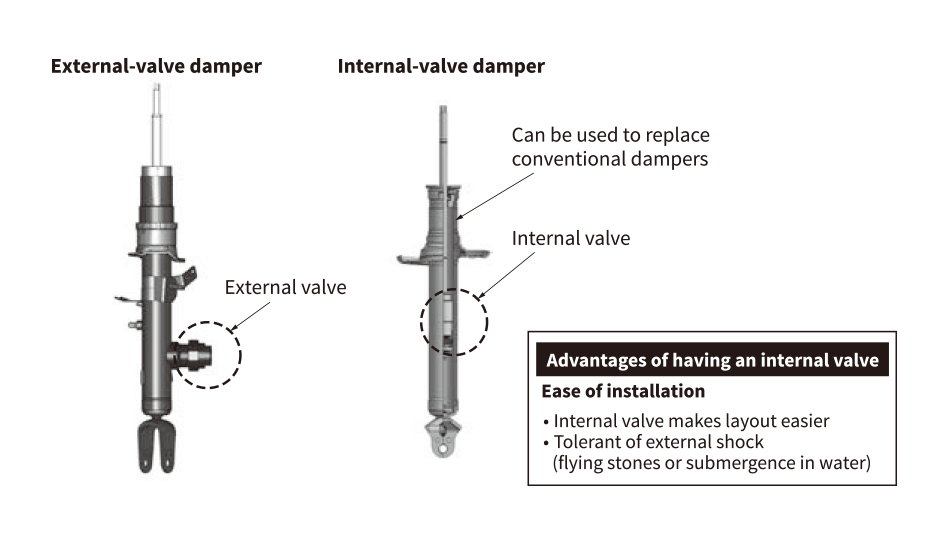

Hitachi Automotive Systems has used a proprietary valve design to develop a damper for semi-active suspension that is highly responsive and provides variable damping force over a wide range. Use of the damper is growing, primarily on high-end models. Along with anticipating increased adoption over a broad range of vehicle types in the future to provide the superior ride comfort and experience increasingly in demand for autonomous driving, Hitachi is also expecting strengthening demand for lower cost. To this end, dampers for semi-active suspension are being developed that have a built-in damping force control valve and that can be used as replacements for conventional dampers. Hitachi is also building high-performance semi-active suspension systems with a simple design, with a sensor-less control technique currently under development that does not use a dedicated acceleration or ride height sensor and which is based on a bi-linear optimal control (BLQ) suspension algorithm(4) that is proprietary to Hitachi Automotive Systems (see Figure 7).

Figure 7 - Comparison of Dampers for Semi-active Suspension (with External and Internal Valves Respectively) The damper with an internal valve has the same external dimensions as a conventional damper for easy replacement. An advantage of the valve being built-in is that it is more tolerant of external shock (flying stones or submergence in water).

The damper with an internal valve has the same external dimensions as a conventional damper for easy replacement. An advantage of the valve being built-in is that it is more tolerant of external shock (flying stones or submergence in water).

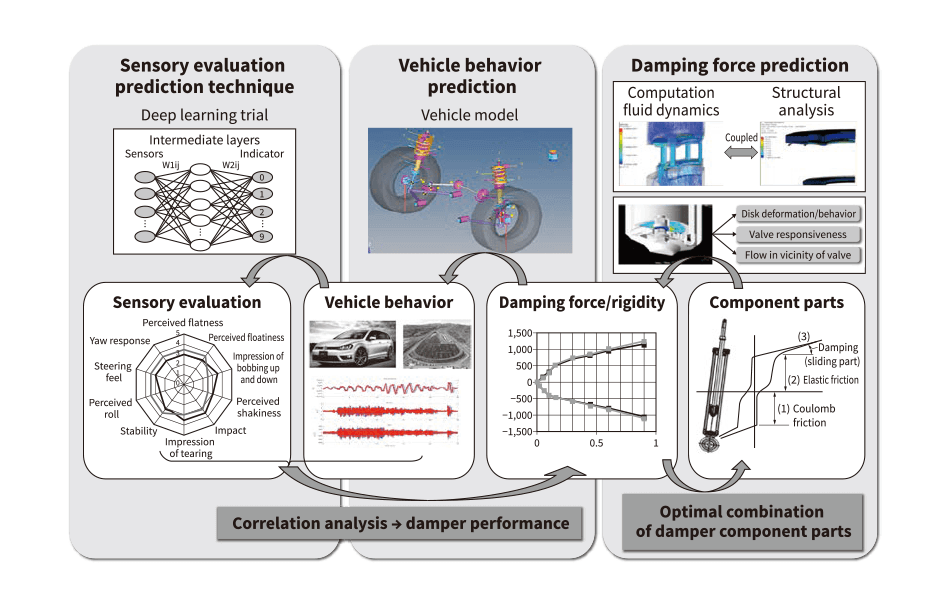

Hitachi also sees improvements to basic performance and shorter development lead times as important for improving the commercial competitiveness of its base conventional dampers. Basic performance is being improved by reassigning and optimizing the functions and performance of the various component parts. Hitachi is also using analytical techniques to develop a series of systems that can predict component part characteristics, the damping force characteristics of dampers, vehicle behavior, and the sensory evaluation of ride feel (see Figure 8). This is helping carmakers to shorten development lead times by significantly reducing the time required for design and for adapting the dampers to a particular vehicle (tuning).

Figure 8 - Analytical Damper Development System Use of analytical techniques helps shorten design and development lead times by improving prediction of damping force and vehicle performance.

Use of analytical techniques helps shorten design and development lead times by improving prediction of damping force and vehicle performance.

This article has described progress on the development of integrated vehicle control, including its use for autonomous driving and electric vehicles and in terms of brakes, suspension, and steering systems, and also the outlook for the future.

Many chassis components have an important safety role, with sub-systems requiring a high level of reliability. A high level of functional safety performance is also needed to control these in an integrated way that is coordinated with other systems. Through advances in integrated vehicle control, Hitachi intends to deliver high levels of safety, environmental performance, and comfort.