Achieving a super smart society will require logistics optimized at a global level that brings innovation to the value chain end-to-end. Hitachi is setting out to overcome these challenges by introducing global logistics services that utilize cyberspace, in the form of technologies like artificial intelligence, as well as robotics and other activities that take place in physical space.

Business Development Division, Business Incubation and Development Division, Social Innovation Business Division, Hitachi, Ltd. Current work and research: Development of new business and solutions for SCM / logistics. Certifications: Certified Logistics Master.

Business Development Division, Business Incubation and Development Division, Social Innovation Business Division, Hitachi, Ltd. Current work and research: Development of business using big data. Society memberships: IEEE.

Value Chain Logistics Department, Business Development Division, Business Incubation and Development Division, Social Innovation Business Division, Hitachi, Ltd. Current work and research: Development of new business and solutions for SCM/logistics. Certifications: Certified Logistics Master.

With the spread of smartphones and social networks as well as advances in digital technologies like artificial intelligence (AI) and blockchain, the penetration of smart technology into society has been proceeding at an astonishing pace over recent years. The activities associated with commercial transactions involving music, books, and currencies, etc., which in the past took place in physical space (the real world), are increasingly being replaced by cyberspace (the online world).

Yet, even as we enter such an era, there is no chance that logistics (the movement of physical goods) will disappear, so there is a need for further improvements in convenience along the entire value chain from production to consumption that overcome the constraints of time and place. Logistics, meanwhile, has been expanding globally in ways that transcend borders in recent years, and is becoming more complex.

On the other hand, in pursuing the quality and convenience of logistics, the growing complexity of the operating sites that support logistics is beginning to put it under strain in every market, with “working style reform” becoming a major social problem.

The global logistics proposed by Hitachi for bringing innovation to the value chain aims to achieve end-to-end (E2E) optimization to improve convenience and deal with this complexity and difficulty, while also achieving the goal of “delivering the required goods in the required quantities to the required people at the required time” in the super smart society being advocated by the Japanese government as Society 5.0.

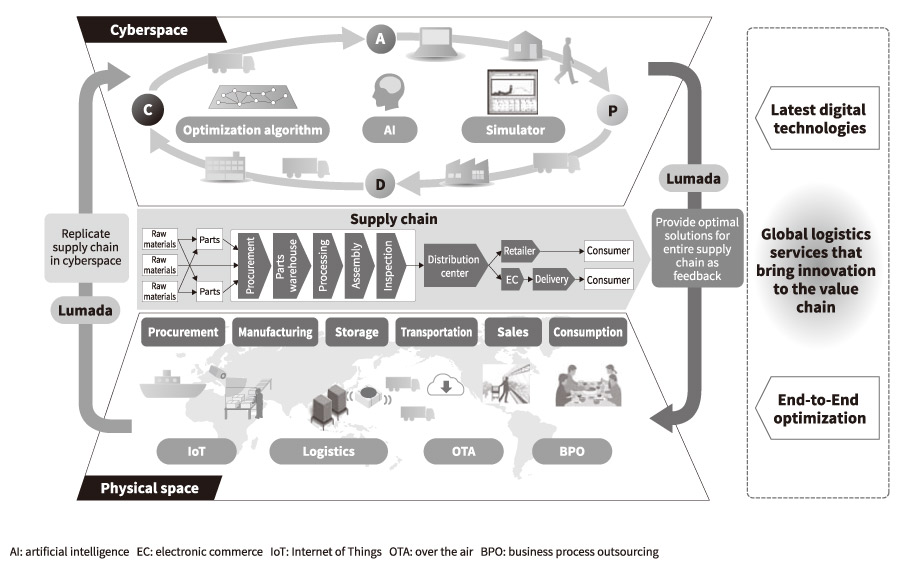

Hitachi has been working to realize this idea of global logistics bringing innovation to the value chain by reforming logistics through collaborative creation with customers and also the initiatives of its Hitachi Smart Transformation Project. Even higher levels of optimization are achieved by using the Lumada Internet of Things (IoT) platform to replicate in cyberspace the “real” elements of physical space, such as business process outsourcing (BPO) and the Racrew* and other forms of robotics, and by providing the optimal solutions derived in cyberspace using optimization algorithms, AI, and other information technology (IT) back to the physical world as feedback (see Figure 1).

This article notes the societal changes and challenges currently facing logistics in Japan, and also uses practical examples to describe how these global logistics services that bring innovation to the value chain have been able to overcome the management challenges facing customers. The article also looks at where Hitachi plans to go next in this field.

Figure 1—Concepts behind Global Logistics Services Supplied by Hitachi for Value Chain Innovation Global logistics services that bring innovation to the value chain optimize the entire supply chain from end to end (E2E), from procurement and production to sales. These services use the latest digital technologies to replicate the supply chain in cyberspace and provide optimal solutions as feedback to physical space.

Global logistics services that bring innovation to the value chain optimize the entire supply chain from end to end (E2E), from procurement and production to sales. These services use the latest digital technologies to replicate the supply chain in cyberspace and provide optimal solutions as feedback to physical space.

Japan is currently going through a period of major change in its social circumstances and environment. Along with chronic labor shortages as a result of continued aging of the population and a low birthrate, consumers are also seeking ever greater convenience through electronic commerce (e-commerce). Meanwhile the public adoption of the Internet is shortening the product lifecycle, including certain products that experience sudden bursts in popularity only to go out of fashion just as quickly.

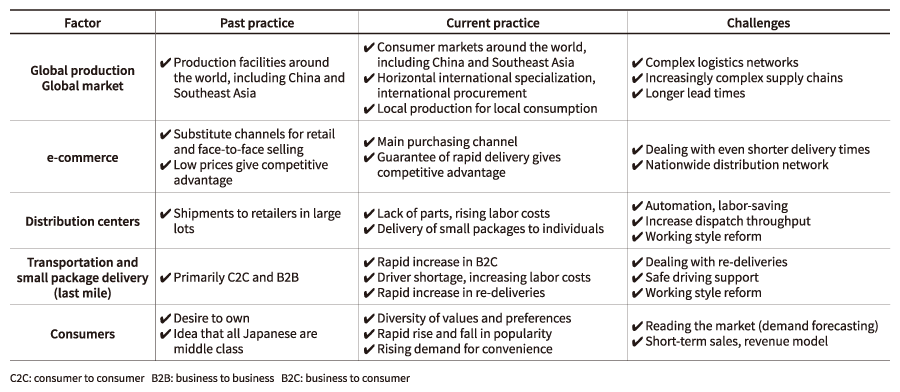

These changes in the social environment and the challenges they pose for manufacturing and logistics have been collated in terms of global production and the global market, e-commerce, distribution centers, transportation and small package delivery, and consumers (see Table 1).

Table1 —Changes in Social Environment and Challenges in Production and Logistics The table lists changes in the social environment and the challenges they pose in terms of production and logistics in manufacturing and distribution.

The table lists changes in the social environment and the challenges they pose in terms of production and logistics in manufacturing and distribution.

In this section, the term “global logistics” is used to mean the flow of goods between sites for the procurement of raw materials and parts, production, distribution and retailing, and consumption, which are traded globally beyond borders.

Japanese manufacturers have been expanding their focus since around 2000 when they moved into China, “the world’s factory,” and are now extending into the “world markets” of India and other parts of Asia. Furthermore, they seek to change to a business model of local production for local consumption throughout the world. In the process of making this change, logistics networks are becoming more congested and complex at a global level such that increases in both logistics costs and inventory assets have started to become management challenges for many Japanese companies.

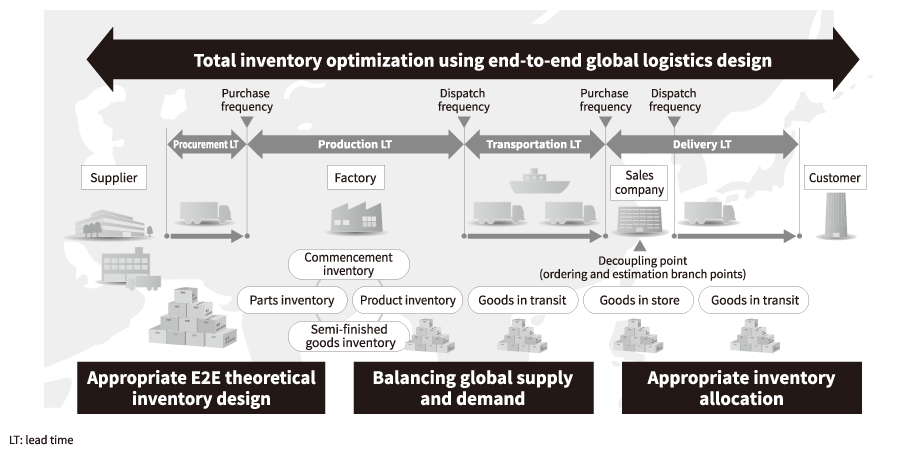

Along with the existing activities of the Hitachi Smart Transformation Project, Hitachi has also been accelerating its work on creating digital solutions using its Lumada IoT platform since FY2016, seeking to commercialize the knowledge and tools acquired through this work and apply it to solutions for other companies in the form of use cases. By adopting an E2E approach to the design of global logistics, it is reaping the benefits of work on total inventory optimization (see Figure 2).

Work in the global logistics sector on establishing services for procurement logistics, primarily in China, are described in the article, “End-to-end and Optimization of Inventory and Supply Chains in Asia.”

Figure 2—Total Inventory Optimization by Using Global Logistics Design By taking an E2E approach to designing the entire supply chain from procurement to manufacturing and sales, Hitachi is seeking to optimize and enhance global logistics networks to reduce inventory by cutting logistics costs and shortening lead times.

By taking an E2E approach to designing the entire supply chain from procurement to manufacturing and sales, Hitachi is seeking to optimize and enhance global logistics networks to reduce inventory by cutting logistics costs and shortening lead times.

The fusion of the online and real worlds is opening up new aspects of the international logistics market, bringing a transformation all along the flow from companies to consumers. In retail, competition in e-commerce is growing worldwide, with instances in which the sales hierarchy of real-world and online stores is being overturned.

In e-commerce, it is possible to cut inventory to an absolute minimum by operating without brick-and-mortar stores, cutting costs in logistics and improving cashflow. Such businesses have grown in size by adopting a core strategy of delivering to customers what they want, when they want it, and by using guarantees of rapid delivery and greater convenience to gain advantage. Underpinning this e-commerce is a platform of enhanced logistics comprised of nodes (distribution centers) and links (the delivery network).

The distribution centers that are a component of this platform and handle product storage, picking, and dispatch require very high throughput (agility) to rapidly dispatch large volumes of various products as orders come in.

Meanwhile, the delivery network that is another component of the platform is facing a major problem in that delivering small-packages over the last mile requires re-delivery in as much as 20% of cases. Moreover, as greater use of e-commerce continues to drive up the number of items to be delivered, the logistics industry is facing a shortage of labor to handle this volume growth. With a shortage of drivers and labor unions that demand transportation companies provide better working conditions, measures such as increasing delivery prices or suppressing delivery volumes are starting to be considered.

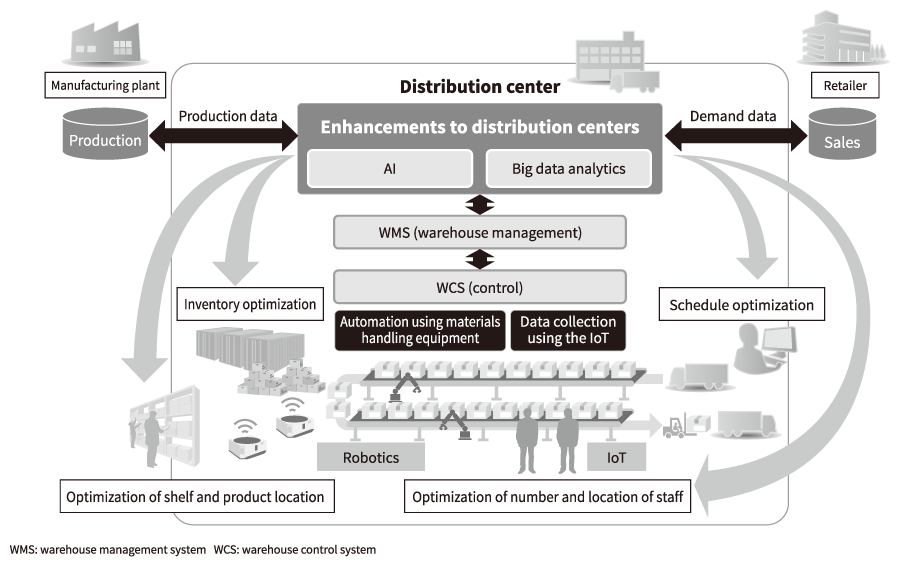

With transportation volume increases inevitable due to the expectation of continued explosive growth in e-commerce sales and delivery, the achievement of greater efficiencies in delivery is emerging as a major challenge throughout the logistics industry. The article entitled, “Enhancing Distribution Centers Using Robotics and Digital Solution Technologies” describes the work being done to address these challenges by customers and Hitachi at distribution centers that are utilizing the latest digital technologies for AI, the IoT, and robotics to perform optimization, boost efficiency, and adopt automation (see Figure 3).

Another Hitachi initiative for delivery networks is the over-the-air (OTA) technology that it jointly developed with Clarion Co., Ltd. Whereas in the past, software updates required vehicles to be brought to a dealer or depot when updating the onboard devices on trucks and other vehicles, using OTA technology means that software can be installed or updated as needed via the mobile network, even when the vehicles are in operation. Used in conjunction with onboard devices developed by Clarion, it can also help make delivery operations more efficient and support safe driving through the real-time transmission and use of the operational data collected by these devices. These Hitachi initiatives for (last-mile) delivery are described in the article, “Development of Technology for Safe Goods Distribution for Use in Small Package Delivery.”

Figure 3—Enhancing Distribution Centers Using the Latest Technologies Demand data based on customer and sales data and production data from the factory are used to enhance the operations of distribution centers through optimization using AI and the IoT and using the latest technologies such as robotics.

Demand data based on customer and sales data and production data from the factory are used to enhance the operations of distribution centers through optimization using AI and the IoT and using the latest technologies such as robotics.

One effective solution for efficiently “delivering the required goods in the required quantities to the required people and at the required time” in a super smart society is to know in advance what will be “required,” and to store inventory at an appropriate location. To achieve this, it is vital that, along with the manufacturers who produce the goods and the retailers who deal with customers, the distributors (intermediaries) who stand in between them and balance supply and demand are also included, and that the various parties share information with each other. Advances in digital technology mean that methods are being implemented whereby sales figures and customer information held by retailers are disclosed in advance to the upstream wholesalers and manufacturers, and used together with predictions to determine the volume of incoming and outgoing orders.

It is also possible to minimize loss and unnecessary work, eliminating inventory at all steps along the supply chain and reducing waste or loss of freshness due to overproduction, by acquiring critical information that influences supply and demand from end to end, including information on what might generate demand (such as sales promotion activities by retailers) and on what might constrain supply (such as manufacturing capacity).

Methods used to achieve this in the past have included marketing promotions to control demand, demand forecasting based on product sales figures, and various types of causal data (factors influencing sales). However, there is a limit to what the conventional rule-based logic can achieve in analyses that seek to acquire the customer insights that underlie product sales performance.

The article, “AI Technology for Boosting Efficiency of Logistics and Optimizing Supply Chains” describes Hitachi’s activities on digital marketing technologies and demand forecasting techniques using AI, and how they are to be utilized in supply chain optimization planning using these data.

Similarly, the article, “Development of Cutting-edge Technologies for Next-generation Logistics Services” describes the research and development behind the global logistics services Hitachi is promoting to bring value chain innovation.

While Japanese manufacturers, in looking for a way to survive in the global market, have already extended their operations overseas, especially to China and Southeast Asia, it remains the case that the land, sea, and air transportation infrastructure remains inadequate, particularly in Southeast Asia, a region with many countries and islands. Not only do the factors affecting trade, such as legal and taxation systems, vary from country to country, they are also becoming increasingly complex, something that companies are struggling to deal with.

Hitachi is working on global logistics reforms that include overseas subsidiaries as part of in-house activities. In the future, Hitachi intends to utilize this expertise acquired in its role as a manufacturer to deploy global logistics services that bring innovation to the value chain, primarily in the Asia region.

This article has described how the logistics sites that support the distribution of goods are facing many challenges, such as the wider adoption of e-commerce, in a modern society that is striving to transform itself into a super smart society. In response, Hitachi is working to develop global logistics services that bring innovation to the value chain by utilizing the latest digital technologies for AI, the IoT, and robotics.

Drawing on its experience working on products, systems, and services in the logistics sector over many years, Hitachi intends to continue contributing to enhancing logistics for a super smart society.