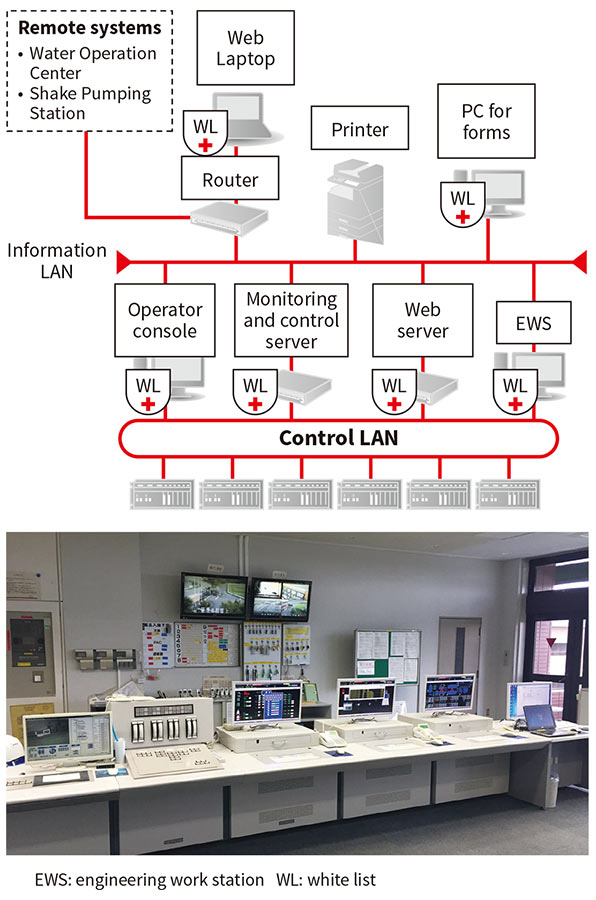

1. Kanagawa Water Supply Authority Ayase Water Purification Plant Monitoring and Control System

1. Schematic diagram showing white list being applied to the monitoring and control system (top) and Ayase Water Purification Plant's monitoring and control room (bottom)

The Ayase Water Purification Plant is a large facility that forms the core of the Kanagawa Water Supply Authority. It has a site area of 234,495 m2 and a water supply capacity of 500,000 m3 per day. The facility commenced operation in 1998. Recently, during its 17th year of operation, its central monitoring and control equipment was given a complete overhaul to improve system reliability and make operation monitoring work more efficient.

The overhaul involved constructing a web monitoring system controlled by mobile PCs installed in electrical rooms. System security measures were also provided. The web monitoring system was provided by creating a local area network (LAN) in the facility. The system lets users bring laptops into electrical rooms to do the same monitoring work they do from the central monitoring room, which is effective for maintenance, management and servicing during accidents, maintenance, and trial operation. The security measures include using a white list method for the first time instead of the common black list method, which has high load and could potentially reduce the monitoring and control system's response time. The constructed security system disables unknown malware while reducing load.