1. Coupled Simulation of EV Motor Control and Electromagnetic Vibration

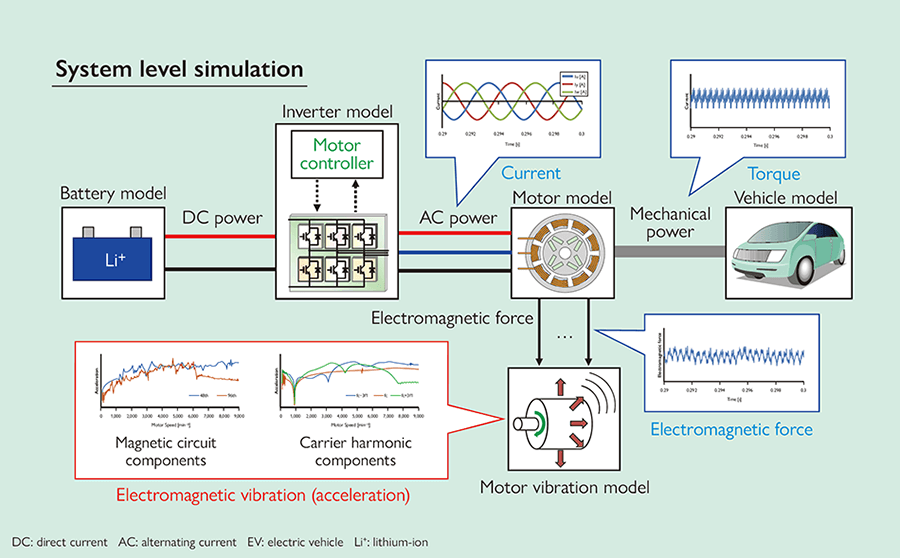

Quiet operation is one of the main benefits of automobiles such as electric vehicles (EVs) that are powered by an electric motor. Noise arises when vibrations propagate through the air, with vibration in turn being influenced by the design of the motor and the performance of the inverter used to control it. Given the lack of any existing methods for assessing vibration at the design stage, Hitachi has developed a technique that can help reduce vibration by performing a coupled analysis of the motor and its control, having first modeled the motor and inverter characteristics.

Vibration is determined by the exciting force (the source of the vibration) and mechanical resonances. The primary exciting force in the motor comes from the electromagnetic components that are in turn determined by the design and are proportional to motor speed. The second source of vibration arises from the harmonic current pulses from the inverter as they flow through the motor. Mechanical resonances, meanwhile, occur in the motor case and vehicle chassis. While vibration has previously been subject to three-dimensional analysis, the high computational load has made it difficult to perform a coupled analysis that includes control.

The new method uses an excitation model in which the electromagnetic forces present between the motor's rotor and stator are represented as unidimensional characteristics. The model includes both of the vibration sources described above. As simplifying the model to a single dimension reduced the amount of computation required, motor vibration can be analyzed under close to real-world conditions, including the control system.

In the future, Hitachi intends to utilize the new technique in the design of electric drive systems that include measures to minimize vibration.

(Hitachi Automotive Systems, Ltd.)

1. Coupled simulation of EV motor control and electromagnetic vibration