Accelerating Social Innovation through Global Open Collaborative Creation

Case Studies from Japan, China, and Southeast Asia

The wave of digitalization engulfing fields such as the Internet of Things, artificial intelligence, and robotics is also washing up against the manufacturing industry. Digitalization is bringing a transformation in dealings with customers away from the past approach of seeking to optimize individual functions and toward practices that seek to optimize the entire value chain. In regions such as China and Southeast Asia that are experiencing rapid growth, it is extremely important to identify customer needs quickly and to deliver the optimal solutions that customers want in a timely manner. In recognition of these trends, this article describes examples of collaborative creation with customers in Japan, how Hitachi is utilizing its spaces for collaborative creation with customers in its approach to the Chinese and Southeast Asian markets, and what is happening in the innovation hotspots of China where Hitachi hopes to be involved in the future.

Manufacturing and Inspection Research Department, Center for Technology Innovation – Production Engineering, Research & Development Group, Hitachi, Ltd. Current work and research: Monozukuri research on manufacturing and inspection technologies. Society memberships: The Japan Welding Society (JWS).

Strategic Planning & Management Office, Hitachi (China) Research & Development Corporation. Current work and research: Planning and implementation of research and development strategies in China. Society memberships: The Institute of Electrical Engineers of Japan (IEEJ).

Open Innovation Project, Hitachi (China) Research & Development Corporation. Current work and research: Planning and implementation of open innovation strategies in China.

Planning Office, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd. Current work and research: Planning and implementation of research and development strategies in the field of global customer co-creation.

Customer Front Project, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd. Current work and research: Customer co-creation project in the industrial field. Society memberships: The Japan Society for Precision Engineering (JSPE).

Advances in digital technologies such as robotics, artificial intelligence (AI), and the big data generated by the Internet of Things (IoT) are bringing major changes to corporate business activity and to society as a whole. In the manufacturing industry, these digital technologies are being utilized to create new ecosystems through collaborative creation with partner companies that goes beyond the boundaries separating different sectors. The creation of these ecosystems enables a rapid response to changes in the marketplace and optimization of the entire value chain, making management more efficient and enhancing competitiveness.

Hitachi supplies its Lumada platform service to underpin this work. Lumada is a platform for collaborative creation with customers that consolidates in one place the operational and information technologies (OT and IT) that Hitachi has built up over many years. The platform helps customers overcome challenges and create value by using operational information from equipment in the field to collect and collate information on the movement of people and goods, sales data, and various other forms of data associated with business operations. This information is then analyzed using AI and other state-of-the-art technologies and the results used as feedback. In the industrial and distribution sectors, Lumada makes it possible to visualize and share information from end-to-end across the entire value chain, achieving system-wide optimization that extends from design to procurement, production, logistics, sales, and maintenance, instead of focusing on each area individually(1).

Hitachi aims to rapidly identify the increasingly diverse needs of the manufacturing industry, develop digital solutions in response to new challenges, and expand its global business. To this end it is accelerating global collaborative creation with customers with the aim of optimizing the entire value chain in the industrial and distribution sectors.

This article presents examples of collaborative creation with customers in Japan aimed at value chain optimization and describes how Hitachi is utilizing its collaborative creation spaces in its approach to the Chinese and Southeast Asian markets, and describes what is happening in the innovation hotspots of China where Hitachi hopes to be involved in the future.

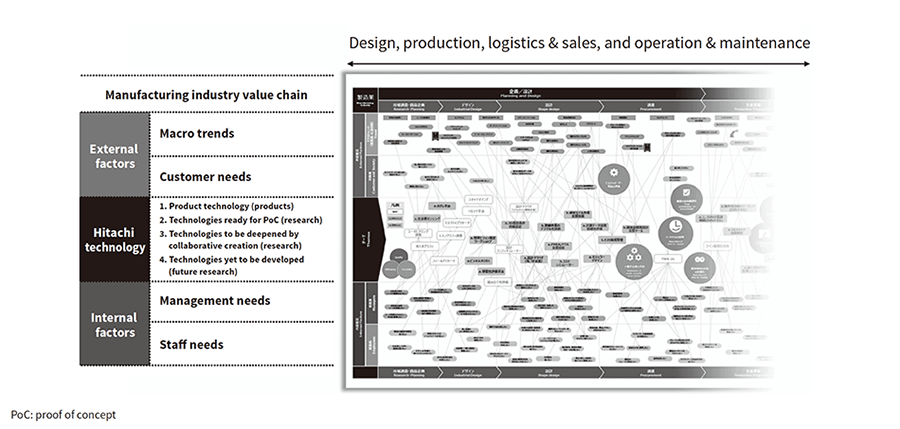

When engaging in collaborative creation with customers in the industrial and distribution sectors, it is important to first map out the customer's vision of their long-term growth strategy and business model, and to produce a roadmap for getting there. The formulation of a long-term strategy requires an investigation of stakeholder ecosystems made up of the customer's trading partners and suppliers, sales partners, and technology vendors such as Hitachi. This involves producing a “full value chain map” that shows how the management issues (internal factors) and societal issues (external factors) across the entire value chain are understood together with an overview of a proposed solution for achieving the optimization of the entire chain (see Figure 1)(2). This full value chain map is then used in collaborative creation workshops with the customer, leading to further phases including devising solutions to the identified issues, designing business models, developing prototypes, evaluating business viability, and testing solutions in practice.

Figure 1—Example Full Value Chain Map Full value chain maps are used in workshops with customers, after being prepared beforehand by plotting management issues, societal issues, and solutions against the manufacturing industry value chain represented by the horizontal axis.

Full value chain maps are used in workshops with customers, after being prepared beforehand by plotting management issues, societal issues, and solutions against the manufacturing industry value chain represented by the horizontal axis.

Figure 2—Collaborative Creation Workshops Workshops were held at Fujinomiya Works to consult with all of the departments associated with production about the work they do, and a workflow map was produced showing the current practices.

Workshops were held at Fujinomiya Works to consult with all of the departments associated with production about the work they do, and a workflow map was produced showing the current practices.

This section describes a collaborative creation project aimed at value chain optimization that was undertaken with AMADA CO., LTD. a manufacturer of sheet metal fabrication machinery.

The manufacturing industry has been confronting several challenges in recent years, including a shrinking workforce due to the aging population and low birthrate, staff shortages resulting from the retirement of experienced staff who have been the mainstay of practical manufacturing, a focus on efficiency in response to intensifying international competition, and a lack of “system-wide optimization” (meaning improvements that extend across different companies and industries rather than being limited to a more localized scope).

It is against this background that AMADA has set out to reform its manufacturing practices while also strengthening and expanding its user-oriented V-factory* IoT solution, initiatives that form part of its medium-term management plan.

Meanwhile, Hitachi has been building up experience in its own manufacturing business with digital solutions that overcome challenges such as how to improve productivity and business efficiency through collaborative creation with a wide variety of customers, utilizing its leading-edge research and development capabilities and the Lumada platform service that combines OT and IT based on experience and know-how built up over many years.

AMADA and Hitachi both have expertise in manufacturing and together have been combining their respective know-how at Fujinomiya Works (the primary manufacturing facility where AMADA manufactures sheet metal fabrication machinery) to embark on collaborative creation aimed at using the IoT to optimize the entire value chain from production onwards(3).

To enable discussion of the entire value chain at AMADA, the collaborative creation involved consulting with all of the departments associated with production at Fujinomiya Works about the work they do and producing a workflow map of current practices. Collaborative creation workshops were then held to identify the issues of concern and a full value chain map was used to debate ideas for solutions. This was summarized as a long-term vision showing what Fujinomiya Works wanted to become in the future (see Figure 2).

Specifically, this involved formulating a plan that seeks to optimize the entire value chain, including the exchange of production information with suppliers in Japan and overseas and also building an advanced production system, the scope of which extends from optimization of production at Fujinomiya Works to a manufacturing dashboard that presents a unified view of the key performance indicators (KPIs) for the workplace.

The intention for the future is to expand the scope to include AMADA manufacturing sites in Japan and overseas as a step toward transforming Fujinomiya Works into a smart factory.

Figure 3—Guangzhou OAL The OAL was established to provide a venue for collaborative creation with customers in China and to serve as a showroom for Hitachi’s mix of OT and IT.

The OAL was established to provide a venue for collaborative creation with customers in China and to serve as a showroom for Hitachi’s mix of OT and IT.

China is an important market for Hitachi, with total sales exceeding one trillion yen (in FY2017). Many manufacturers in China are moving to incorporate the IoT and it is no exaggeration to describe their IT capabilities as already being world-class. One feature of the Chinese market is that companies use demonstrations and other practical measures to show customers their capabilities, preferring the approach of building a prototype first and then working on it with the customer.

With the aim of expanding its involvement in the Chinese market, especially manufacturing, Hitachi opened an Open Automation Laboratory (OAL) in December 2017 in Guangzhou, Southern China, a place that is home to many automotive and other manufacturers (see Figure 3).

The Guangzhou OAL was established as a place where Hitachi could engage in collaborative creation with customers to deliver optimal solutions. The laboratory is made up of: (1) a discussion area that uses digital content to encourage collaborative creation, (2) a demonstration area where a model production line is used to provide a closer look at OT, and (3) a control area that combines data from the other two areas to show people the value that is created by combining OT and IT in a way that is easy to understand.

Hitachi has similar collaborative creation spaces in Yokohama, Bangkok, and Munich where it gathers information about customer needs specific to their respective locations and offers optimal solutions to those customers.

Of particular note is the Lumada Center Southeast Asia, another collaborative creation space, this one located in the similar market environment of Southeast Asia. The Lumada Center is equipped with the same model production line as the Guangzhou OAL, so the two facilities can work closely together in ways that include shared inter-site needs and demo content.

The model production lines at the Guangzhou OAL and Lumada Center are equipped with Hitachi products so that customers can see Hitachi technologies in action for themselves. One such example is the kaizen activity support system from Omika Works described below.

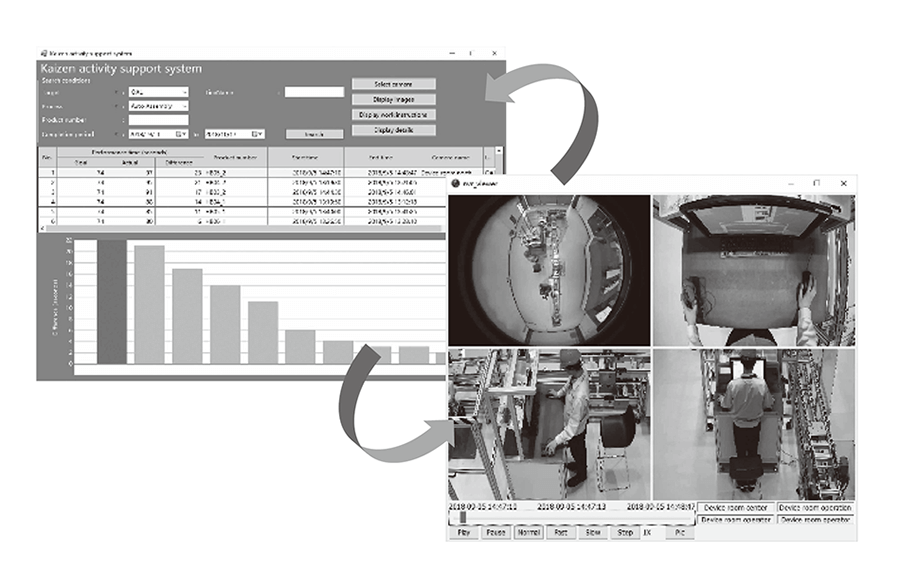

Hitachi was an early adopter of the IoT at its production lines at Omika Works and has succeeded in improving production efficiency by installing next-generation production systems and using them to collect and analyze data on people and things in the production process. One of these is the kaizen activity support system that analyzes work steps using video of how line workers do their job, cross-referencing this with the work instructions and thereby providing a view of line productivity (see Figure 4). This makes it easier to identify which steps in the production line are causing bottlenecks, with the result that the system has delivered significant benefits in terms of being able to choose the best candidates for improvement and of making those improvements in a timelier manner.

Demonstrations using this system at the Guangzhou OAL and Lumada Center present Hitachi technologies and products and show how the IoT can be introduced in a way that is easy to understand even by those customers who did not previously have a clear sense of what the IoT is about.

Among the other systems being used for collaborative creation with customers are a 2.5-dimensional camera surveillance system from Hitachi Industry & Control Solutions, Ltd. that provides a three-dimensional overview of the movements of workers and things on the production line, and a sensing technique that uses electric current to determine the operational status of legacy equipment from which data cannot be collected directly.

While the extent to which the IoT has been adopted varies widely from company to company in Chinese manufacturing, the use of image analysis and other such techniques for providing a view of what is happening has had a large impact. Along with using the products installed at the Guangzhou OAL and Lumada Center to acquire this view from a mix of OT and IT, Hitachi also aims to expand its customer base among Chinese manufacturers and to come up with new innovations by working collaboratively with its other collaborative creation spaces around the world.

Figure 4—Kaizen Activity Support System  The model production line at the Guangzhou OAL is equipped with the same systems as Omika Works.

The model production line at the Guangzhou OAL is equipped with the same systems as Omika Works.

As in the USA, China has a lot of capital available for investing in startups, with many “unicorn” companies (unlisted companies with a current valuation of more than one billion US dollars). In particular, Zhongguancun in Beijing and Shenzhen in Guangdong Province are both recognized as being among the world's innovation hotspots.

Hitachi believes that, in regions like these, the use of open innovation as a way of innovating to grow will be among the essential requirements for achieving sustainable growth through greater business involvement. Innovation hotspots are home to ecosystems that foster this innovation and it is important either to become part of these or to establish win-win relationships.

Shenzhen is the site of considerable innovation based around the manufacturing industry. This has in recent years expanded beyond hardware-based products to also encompass new innovations that mix IT and hardware. The existence of a flexible manufacturing ecosystem is one of the factors making this possible. The ability to rapidly build product prototypes to custom specifications allows the cycle of trial-and-error testing in the marketplace to run more quickly. The aim is to rapidly come up with valuable solutions by working quickly through the cycle of prototyping and testing factory production equipment and devices that incorporate sensors for collecting information from this equipment based on what matters to the customer. Moreover, establishing mutually supportive relationships with the other companies involved in the work also helps expand business though collaborations.

As the large workforces in Zhongguancun and Shenzhen cover a wide range of areas, these places give rise to a steady stream of new ideas for innovation based on leading-edge technologies and market trends. There should also be scope within these ideas for Hitachi to contribute to their realization, and activities are ongoing aimed at working on them together to bring them to fruition. One such example is the use of ideathons and hackathons to devise new ideas and create value, a practice that has seen use in a wide range of sectors over recent years. Drawing on manufacturing technology and know-how built up over many years, Hitachi intends to plant the seeds of innovation in Chinese manufacturing through discussions with companies that form part of the manufacturing ecosystem in China; leading technical staff with expertise in AI and the IoT; and people from venture capital, accelerator, and other organizations involved in supporting manufacturing business startups.

In the manufacturing sector, Hitachi has drawn on its strengths in OT built up over many years to become a leader in international markets, while improvements in the manufacturing capabilities of China and Southeast Asia have been driven by the rapid pursuit of digitalization. Along with utilizing manufacturing solutions built up by Hitachi to achieve optimization across the entire value chain in these growth markets, the intention is also to rapidly put together new solutions capable of responding flexibly by taking on an understanding of regional needs and commercial practices acquired through collaborative creation spaces in different parts of the world.

Through collaboration with innovation hotspots and leading local companies, Hitachi also aims to build solutions that incorporate viewpoints unlike those of the past.