Materials development, which has traditionally involved large amounts of experimental testing combined with the experience and intuition of scientists, is now set to be transformed by the techniques of MI whereby development is directed by diverse forms of materials data. This new approach is being embraced by research and development organizations across the materials industry, both in Japan and around the world, leading to the establishment and growth of new markets. Recognizing the intensification of global competition in materials development, Hitachi launched a materials development solution based on MI in November 2017, targeting private-sector businesses in the materials industry that are looking to utilize the approach in their development work. This article describes progress to date and what the expectations are for the solution in the future.

How to develop materials more quickly and at lower cost poses a challenge amid the intensification of global competition in the field of materials development. In response, Hitachi supplies the industry with a materials development solution(1) that utilizes materials informatics (MI), a field of study that uses diverse forms of materials data to guide the direction of development. The materials development solution utilizes technologies such as databases, machine learning, and artificial intelligence (AI) to support the rapid and low-cost development of materials in ways that enable efficient material selection and performance evaluation. This article describes the current state of this solution, which has now been available for around two-and-a-half years, and Hitachi’s expectations for what the market will require in the future.

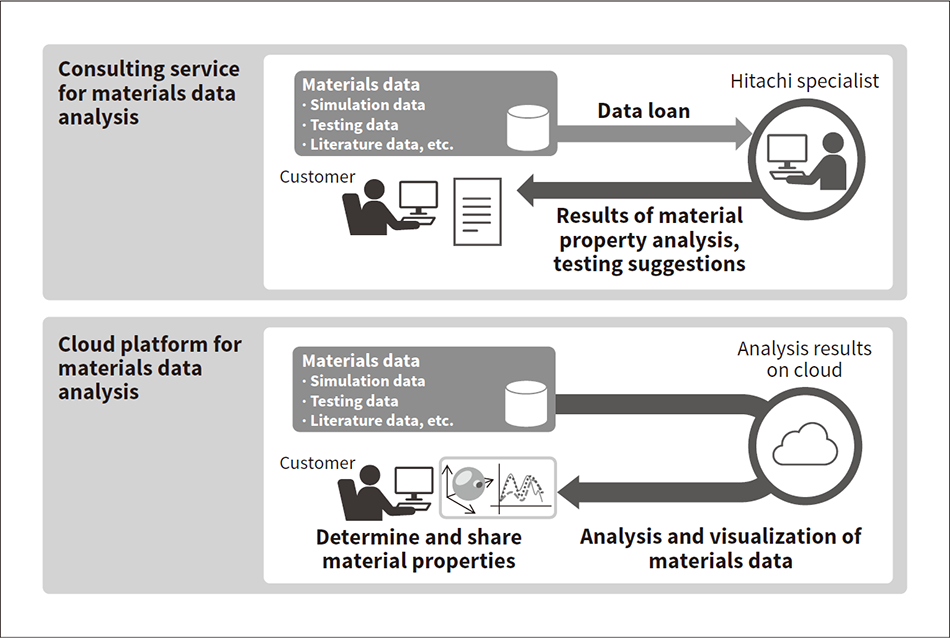

Fig. 1—Materials Development Solution Services

The two main services respectively provide consulting and a cloud platform for materials data analysis. Many customers choose to adopt the cloud platform for materials data analysis after first using the consulting service to assess the benefits.

The two main services respectively provide consulting and a cloud platform for materials data analysis. Many customers choose to adopt the cloud platform for materials data analysis after first using the consulting service to assess the benefits.

Development is the wellspring of competitiveness for companies in the materials industry. Competition in development has intensified globally in recent years, such that the ability to develop materials quickly and at low cost is an important issue for countries as well as companies.

Past practice for materials development has involved repeated experimental testing based on theory as well as the knowledge and experience of experts. Unfortunately, the field has also been beset by major problems, including a failure to establish adequate mechanisms for sharing this specialist knowledge, experience, and theory within companies, and the fact that every additional experimental test that is carried out adds to the total time and money consumed.

MI uses diverse forms of materials data to guide the direction of development, utilizing informatics technologies such as databases, machine learning, and AI to do so. While recent years have seen increased interest in the field, the obstacles to its practical use include the large investment required to train data scientists to use MI for data analysis and to build data analysis platforms that can manage and analyze a variety of data resources.

To overcome these obstacles, Hitachi launched a materials development solution based on MI in November 2017(2). As of December 2019, the solution has been adopted for 31 projects across 24 installations, most of which were at the research and development organizations of chemical companies(2), (3). The solution has the following three features.

By following this sequence of steps to the full adoption of MI, solution users can maximize the cost-benefit of their digital transformation to MI-based materials development. The following sections describe the main services available for undertaking a PoC (see Figure 1).

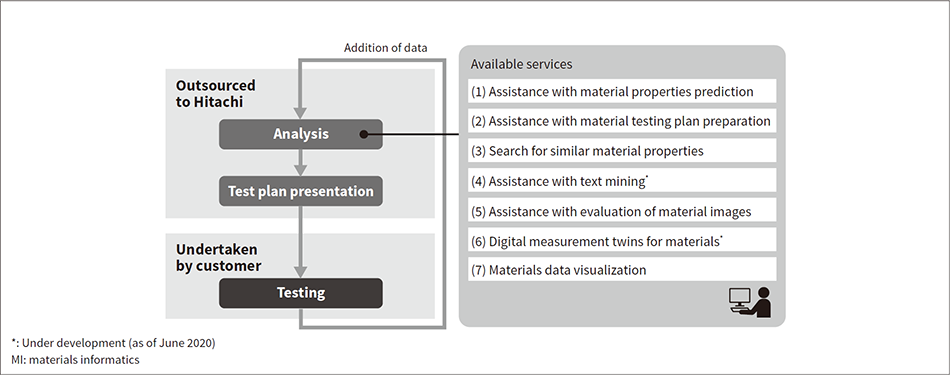

Fig. 2—Consulting Service for Materials Data Analysis

Hitachi’s MI experts undertake the analysis of past test results and the draft preparation of testing plans on behalf of customers, both of which are required for MI-based materials development.

Hitachi’s MI experts undertake the analysis of past test results and the draft preparation of testing plans on behalf of customers, both of which are required for MI-based materials development.

This involves Hitachi receiving materials data from the customer on the basis of a non-disclosure agreement (NDA)(4) and then undertaking analyses on their behalf, utilizing databases, machine learning, and AI, and providing the results in the form of reports. It addresses the needs of companies that are uncertain about where to start with MI-based materials development, or that want to train data scientists to perform analyses or want to partner with Hitachi in open innovation. The service provides the following (see Figure 2).

The service uses data from materials literature such as technical papers and patents; libraries of chemical formulae, electron microscope images, or emission spectroscopy data; and data from temperature sensors or stresses when materials are worked (material parameters). This information can be used to predict material properties using the optimal experiment planning program (OEPP), which includes use of MI analytics. The OEPP was developed based on extensive past experience and has the following three features.

The service reduces the number of experimental tests that users need to perform and the time it takes to perform them as well as the overall time and cost of materials development by enabling an experimental approach to testing that is limited to only those candidates that have material properties with a high likelihood of delivering the desired performance.

This platform enables users to undertake multifaceted analyses of a wide variety of materials data using databases, machine learning, AI, and other forms of informatics, and to present the results using three-dimensional visualization. It meets the needs of companies that want to efficiently utilize MI for their own materials development, cut the cost of data scientist training, or to participate as part of the platform in a framework of open innovation with Hitachi. The service has been well received by users with respect to the following points in particular.

Figure 3 shows the top screen of the materials data analysis platform. The user interface is designed to provide intuitive system operation. Visualization on the platform can also be done using a geographic information system (GIS). GIS software is typically used to present data and images such as maps that are spread over a wide space. Figure 4 shows an example screen. Each point on the screen represents multidimensional data that is decomposed down to three dimensions by the GIS to enable it to be shown on-screen. The user interface includes the ability to click display points with the mouse to bring up a dialog box showing the multidimensional data, providing data scientists with an intuitive grasp of data whether it be numbers or chemical formulae.

As a means of accelerating new innovation in the materials field through collaborative creation with users, the MI-related services of the materials development solution will be further enhanced and extended to help these users improve their competitiveness. Hitachi intends to continue with development during FY2020, primarily in the form of enhancements to the following functions that are in high demand from users.

Countries around the world are taking action to resolve issues associated with the sustainable development of their societies, as exemplified by the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015, with Japan undertaking measures aimed at realizing the Society 5.0 vision promoted by its government. Alongside this, the materials development solution is contributing through the materials sector to the creation of a sustainable human-centric society with a high quality of life (QoL). Achieving this will require the development of data analysis platforms that enable the collection, integration, analysis, and visualization of materials data in a more seamless manner. In the future, Hitachi intends to continue striving to resolve the challenges facing its corporate partners and improve people’s QoL by combining analytics using advanced MI with appropriate data management techniques and by developing the means of delivering these via a cloud-based platform to address the challenges that partners face in undertaking materials development more quickly and with greater cost control.