1. Service Value Simulator NEXPERIENCE/Cyber Proof of Concept

The digital transformation triggered by artificial intelligence (AI), robotics, and Internet of Things (IoT) has been changing the exiting industrial structure radically while complicating issues that faced by corporations and communities. As to create new services in such era, it is required to plan acceptable businesses with a consideration of stakeholders’ profitability and businesses’ feasibility.

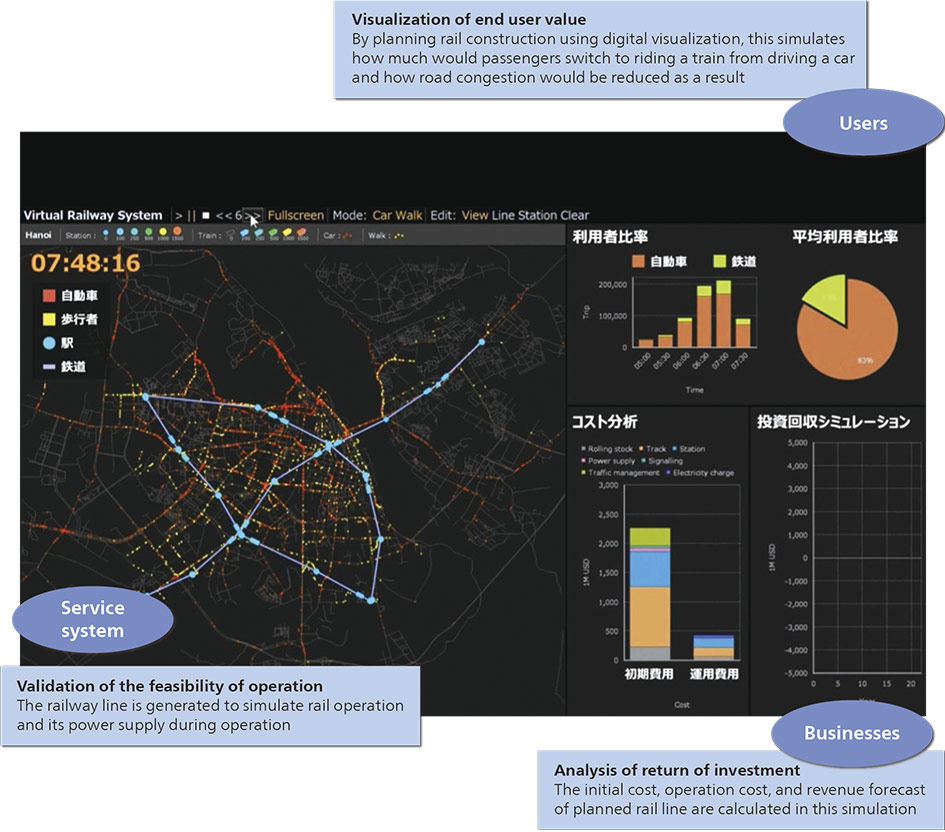

Hitachi has systematized the approaches, IT tools, and space, which are used for extracting issues, creating ideas, and validating hypothesis with customers and partners, as NEXPERIENCE for conducting customer co-creation. One of these features is Cyber-Proof of Concept that is a service value simulator to analyze the effectiveness of service intuitively and quantitatively. This allows customer’s management team to make investment decision efficiently. This service value simulator is capable of letting users to interactively modify the value of design parameter and simultaneously simulate the operation costs of required investment and service, behaviors change of end-user along with service, and revenue differences from customized service charge plan.