Water Environment Solutions Based on Advanced Technology and Comprehensive Capabilities

For water supply and sewerage to develop sustainably, it will be necessary to overcome challenges such as aging infrastructure, falling population, etc. This article describes Hitachi's maintenance support technologies using online data from monitoring and control systems to detect anomalies in equipment and systems, and an information system that supports the routine operation of water supply and sewage infrastructure. It also describes the development of ways of using artificial intelligence to support the future rationalization of plant operation.

Process Engineering Research Department, Center for Technology Innovation – Materials, Research & Development Group, Hitachi, Ltd. Current work and research: Development of water treatment and control technologies. Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage. Society memberships: The Society of Environmental Instrumentation Control and Automation (EICA).

Process Engineering Research Department, Center for Technology Innovation – Materials, Research & Development Group, Hitachi, Ltd. Current work and research: Development of water-related IT technologies. Society memberships: EICA.

Environmental Systems Department, Matsudo Research Center, Industry and Water Business Administration Division, Hitachi, Ltd. Current work and research: Research and development of water treatment systems, both inside and outside Japan.

Media Systems Research Department, Center for Technology Innovation – Systems Engineering, Research & Development Group, Hitachi, Ltd. Current work and research: Research and development of speech and acoustic processing. Society memberships: The Institute of Electronics, Information and Communication Engineers (IEICE) and the Acoustical Society of Japan (ASJ).

Public Global Business Department, Government & Public Corporation Information Systems Division, Government, Public Corporation & Social Infrastructure Business Unit, Hitachi, Ltd. Current work and research: Global business development of intelligent transport systems. Society memberships: The Information Processing Society of Japan (IPSJ).

Facing diverse challenges, including aging water supply and sewage infrastructure, a dwindling technical workforce, and falling usage revenues, local government agencies throughout Japan are finding it increasingly difficult to conduct sustainable operations using existing practices. Among the numerical indicators of the state of water supply management are a reduction of around 30% of its workforce compared with 30 years ago and a forecast 40% reduction in demand over the next 40 years or so(1). In both “visions” it summarized for a new water supply and new sewerage, the government has proposed policies for overcoming these challenges to deliver water supply and sewage services in ways that keep the business operating smoothly(2), (3).

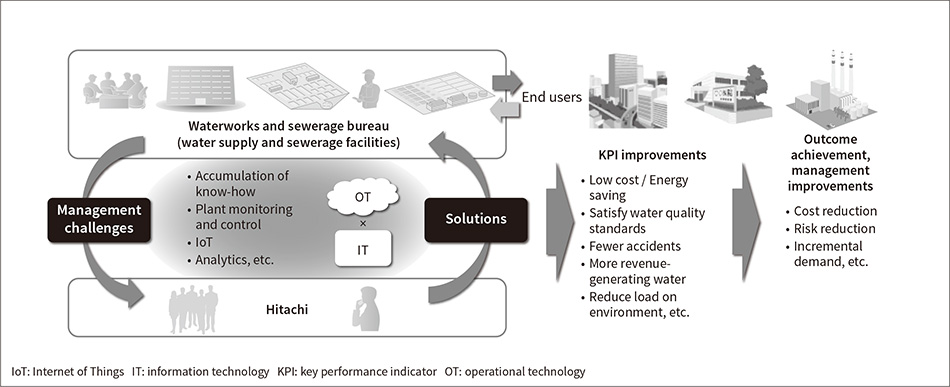

Hitachi is responding to these urgent management challenges by proposing solutions that utilize the operational technology (OT) and information technology (IT) it has built up over time to help improve the key performance indicators (KPIs) and management of the water supply and sewage business. These technologies include plant monitoring and control, the Internet of Things (IoT), and analytics (see Figure 1).

This article looks at maintenance support technology aimed at risk reduction, one of the industry's key outcome indicators. Specifically, it describes anomaly diagnosis technology for components and systems that is aimed at keeping equipment in healthy condition, a digital device that assists with both routine and non-routine operation management, and future technologies that will support rational plant operation.

Figure 1—Solutions that Contribute to the Sustainable Development of Water Supplies and Value Provided Hitachi proposes solutions to management challenges utilizing OT and IT, to deliver KPI improvements, and to achieve desired outcomes.

Hitachi proposes solutions to management challenges utilizing OT and IT, to deliver KPI improvements, and to achieve desired outcomes.

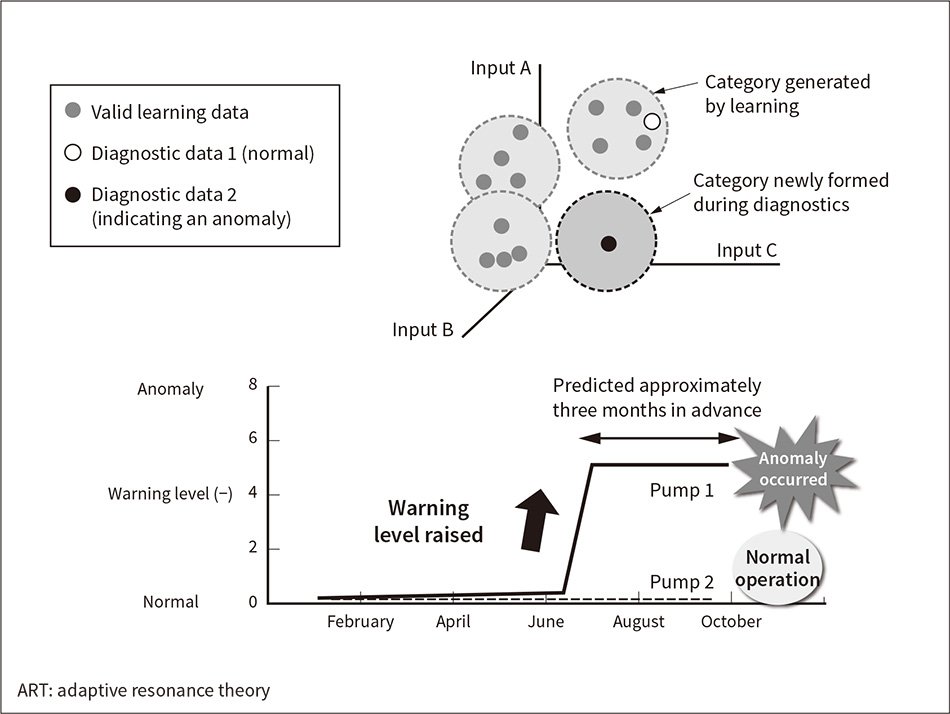

Figure 2—Principles of Anomaly Diagnosis Using ART and Results Achieved ART treats diagnostic data as normal if they fit a category generated from learning data representing normal conditions, but as indicating a potential anomaly if they form a new category. ART predicted an anomaly in pump 1 approximately three months in advance based on an increase in warning levels.

ART treats diagnostic data as normal if they fit a category generated from learning data representing normal conditions, but as indicating a potential anomaly if they form a new category. ART predicted an anomaly in pump 1 approximately three months in advance based on an increase in warning levels.

Anomalies in the equipment and devices used in water environment infrastructure can result in significant harm to the public and to industry. To prevent this, it is important that anomalies are detected before they happen and dealt with quickly. Past ways of doing this have included responding when operational measurements go outside their permitted range and when inspectors identify problems by observation. To make this process more efficient, Hitachi has developed a technique that predicts potential anomalies automatically based on operational data from equipment and devices.

The core technology is a form of machine learning called adaptive resonance theory (ART). A feature of this statistical data processing is that, after first learning what constitutes normal conditions based on the relationships between a large number of input variables, it can then identify anomalies at an early stage by detecting small deviations from these conditions. This provides a way to prevent equipment anomalies before they happen. It can also minimize the disorders that such anomalies cause for other equipment and the operation of the overall system.

This technique has been applied at water treatment and seawater desalination plants and has demonstrated its ability to predict damage to pump shafts and clogged reverse osmosis membranes.

Figure 2 shows an example of the analysis results for a disorder that damaged a pump shaft. The actual anomaly occurred in the shaft of pump 1 after the data for October (shown on the right) were collected. Pump 2 continued to operate without disorders. The ART evaluation results are consistent with the actual anomaly and predicted the anomaly approximately three months before it occurred.

The broad applicability of the new technique means it can be used for applications such as detecting abnormal water quality or operation as well as equipment and device anomalies. The aim is to utilize it in a variety of different water environment infrastructure elements in the future to help maintain more reliable operation and to reduce maintenance costs.

Hitachi has developed a support system for putting accumulated maintenance know-how to use on site to improve the efficiency of routine operations and to ensure that an appropriate emergency response is mounted to deal with disturbances. This section describes a practical implementation of augmented reality (AR) and the development of “navigation” (operational instructions) to facilitate the adoption of standard practices.

In providing outsourcing services for operational maintenance to customers such as water supply and sewage utilities or industrial plants, Hitachi uses “skill-free” maintenance practices to ensure that even staff with limited experience can operate equipment and perform their work properly. To achieve this, it has adopted cloud maintenance support systems that can improve the efficiency of outsourced work (including the collection and archiving of data on equipment operation), and an operation and maintenance (O&M) navigation system that combines AR and mobile devices(4), (5) (see Figure 3).

To further improve workplace practices, Hitachi has also built the following support technologies using the core functions of its IoT platform Lumada.

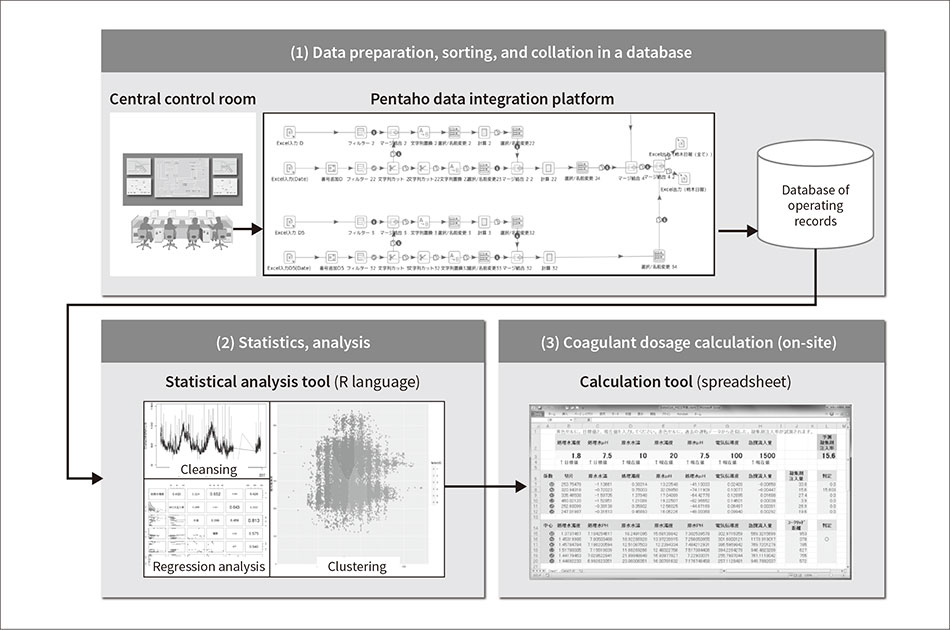

The water quality prediction system and coagulation monitoring system used in operational management adopt the Pentaho data integration and analysis platform to update monthly and quarterly time-series operation logs, and use K-means clustering in the R statistical programming language to perform multiple regression calculations. Hitachi has also developed a compact coagulant dosage calculation tool in a spreadsheet. This tool, which commenced trial use in FY2017, can determine the appropriate amount of coagulant to use based on current operating conditions while prioritizing ease of operation by using historical operation data as a basis for determining how difficult it will be to adjust water quality. It is anticipated that this will keep the plant operating close to its target treatment turbidity.

Using an M2M monitoring system to manage the deterioration of equipment over time, Hitachi is performing continuous automatic measurement of vibrations and other data to verify how easy it is to monitor device conditions, the continuity of data collection, the expandability of the scope of device monitoring, and the robustness of systems when operated continuously. By obtaining data from these verification results, which can be used to detect potential anomalies, Hitachi hopes to utilize the system for improving and simplifying maintenance and operational planning with the aim of shifting from schedule-based to condition-based maintenance.

The aim for the future is to continue making operation, maintenance, and service activities more efficient through operational improvements and further investigation into technologies to support operators on site.

Figure 3—Operational Management Using the Water Quality Prediction System The coagulant dosage calculation tool for the statistical analysis of operating records helps improve efficiency.

The coagulant dosage calculation tool for the statistical analysis of operating records helps improve efficiency.

Regional coordination is one critical measure for the sustainability of water supply services. Along with issuance of guidelines(6), there have also been many examples of operational mergers that have been implemented in practice. While water utilities already face a variety of risks, including water contamination incidents and the aging of the water supply infrastructure, regional coordination brings new risks that arise from the interoperation of the infrastructure used to get water from the source to end users and from the hydrologic cycle within a catchment area. Hitachi already markets management systems that utilize water safety planning practices, and has now embarked on the development of a support tool that helps these functions smoothly in the maintenance workplace.

The features of this tool are that it takes account of standard operating procedures (SOPs) when setting up workflows, and that it builds a database of operational rules in which the granularity and number of variables is in line with the implementation measures for the water safety plans. As shown in Figure 4, the right side of the left screen in the sequence displays the work to be done and the checks to perform in each step. Links are also provided to a detailed manual that contains information of equipment operation, measurement and analysis procedures, and the materials required. With regard to what constitutes a typical SOP, Hitachi has developed provisional SOPs that cover the non-routine work performed during emergencies such as earthquakes or power outages. These SOPs were prepared on the basis of a survey that covered things like published water safety plans, and the format and contents of manuals from small- and medium-sized utilities.

This partial standardization of work in the form of SOPs can be expected to help facilitate data visualization and the adoption of common management indicators while also simplifying situation assessment and minimize errors when a few remotely located staff serve as advisors. In the future, Hitachi aims to make this support tool part of its solution menu by testing its practicality when applied to work on actual water supply infrastructure.

Figure 4—Use of Standard Practices Database to Provide Instructions Operational standards for non-routine situations are determined from the analysis of water safety plans, operation manuals, and other material.

Operational standards for non-routine situations are determined from the analysis of water safety plans, operation manuals, and other material.

Artificial intelligence (AI) has made rapid progress in recent years. This section describes an example in which AI is used to support the operation of water treatment plants.

Hitachi first began utilizing expert systems, neural networks, and other forms of AI in the water sector in the 1990s. Examples include using AI technology to represent plant operational know-how and conducting tests utilizing an AI to control the operation of an actual plant. However, given the constraints on the type and quantity of available data, the AI had limited capabilities and the work did not result in practical applications.

In recent years, however, technical advances in sensors and the IoT have been making it possible to collect and archive greater volumes of operational records and sensor data than in the past. Meanwhile, the rapid progress of AI technology has opened up possibilities for AIs to control operations with a level of efficiency equal to or better than that of humans.

Hitachi is currently focusing on research in the fields of pattern-recognition, question-and-answer, and optimization and decision-making AI. Pattern-recognition AIs perform image or voice recognition, or generate predictions from time-series data. Question-and-answer AIs use text and web data to assist with decision-making by generating suggestions. Optimization and decision-making AIs show future decisions by using large quantities of historical data to automatically identify and make use of the factors that influence target indicators. The Hitachi AI Technology/H is an example of an optimization and decision-making AI.

Hitachi intends to use these AI techniques in the future to implement solutions to run on Lumada that will extend from collecting data via the IoT to using an AI for optimization and decision-making support.

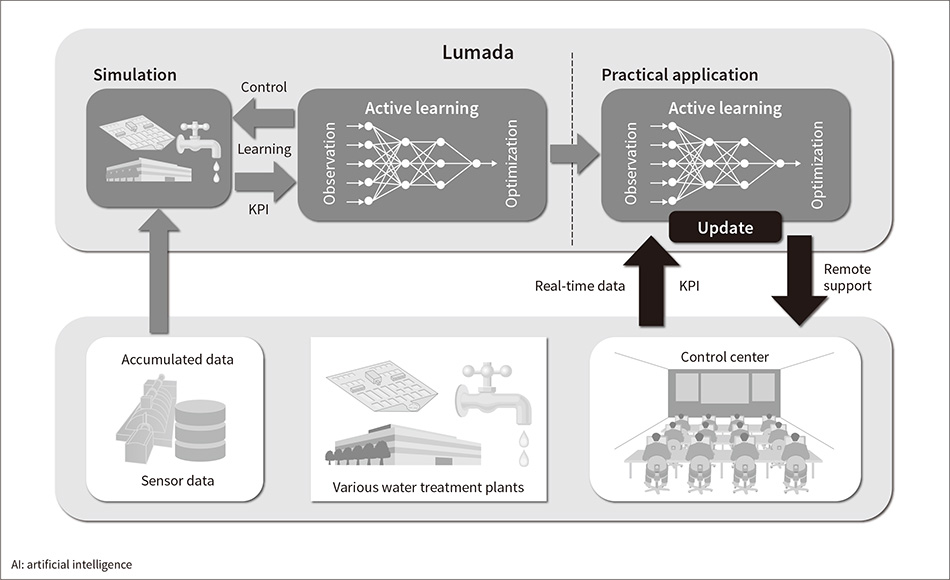

This sub-section describes the use of active learning (a form of optimization and decision-making AI) to support the operation of a water treatment plant. The technique uses a form of machine learning called reinforcement learning whereby the AI actively learns to make better operational decisions through trial and error.

Figure 5 shows an overview of how the technique was applied to a water treatment system. The AI used by the system inputs sensor data and outputs operational decisions. By using KPIs to evaluate how well the plant operates when controlled by these decisions, the AI is taught to select good decisions over bad ones. This makes the choice of KPIs an important factor. In the case of a water treatment plant, efficient operating rules that also maintain water quality and safety can be learned by including management indicators like operating costs along with water quality and safety indicators in the KPIs.

Because of the risks associated with controlling an actual plant based on the decisions output by the AI while it is at the trial-and-error learning stage, a simulator is used instead. The simulator predicts the effect that operation and control measures will have on the KPIs under given conditions and was built by using a pattern-recognition AI to learn rules from a large amount of stored data. After first conducting active learning on this simulator, the AI was then applied to the actual plant.

As unexpected events can happen in a real-world environment, the intent is for the decisions produced by the AI to be used for reference only, with the final decision on plant operation being left up to humans. Nevertheless, it is hoped that the operational support from the AI will enable operators with limited experience to make operating decisions at a level similar to experienced staff.

As it is anticipated that developed countries will face lower water revenues in the future due to falling populations, along with rising costs for the maintenance and upgrading of aging infrastructure, the operation of water supplies needs to become more efficient. Hitachi intends to use AI to both assist in handing on operational know-how and implement technologies for plant operation that will boost efficiency to raise management indicators to higher levels.

Figure 5—Overview of Operation Support for Water Treatment Plants Using Active Learning The system outputs operation decisions using sensor data as inputs. By assessing the results in terms of KPIs, the AI can learn which control actions are desirable.

The system outputs operation decisions using sensor data as inputs. By assessing the results in terms of KPIs, the AI can learn which control actions are desirable.

This article has described technologies that support the maintenance of water supply and sewerage.

Although these technologies can be used on their own, Hitachi also believes that the integration of these technologies can help build systems that are better suited to regional management. As water supply and sewerage are important parts of critical social infrastructure, Hitachi's intent for the future is to continue contributing to the continuity of this business and to improving service.