Environmental and Safety Considerations are Changing the Very Nature of Automobiles

The automotive industry is going through major changes, with the public demanding stricter environmental regulations and technical innovations for enhanced safety. As vehicles fitted with automatic braking become increasingly common, the prospect of fully self-driving vehicles is feeling increasingly real. This raises hopes for resolving some of the challenges facing society, including the elimination of congestion and traffic accidents, assistance for mobility among the elderly, and helping the distribution industry deal with its shortage of drivers.

Toshiharu Nogi (Corporate Officer, General Manager, Technology Development Division, Hitachi Automotive Systems, Ltd.) put it as follows (see Figure 1).

Figure 1 - Trials Using Actual Vehicle at Test Course

Driving trials are routinely conducted on the test course at Hitachi Automotive Systems' Sawa facility, a major center for automotive technology development.

Driving trials are routinely conducted on the test course at Hitachi Automotive Systems' Sawa facility, a major center for automotive technology development.

Toshiharu Nogi

Toshiharu Nogi

Corporate Officer, General Manager, Technology Development Division, Hitachi Automotive Systems, Ltd.

“To achieve smart mobility, we are accelerating development based on particular safety and environmental considerations, namely the adoption of electrification for environmental performance and the use of autonomous driving and connectivity to improve safety by reducing accidents. For electrification, the motor, inverter, and battery are critical, and there is a need to make each of these both smaller and more efficient. To achieve this, we are pursuing technical innovations in components that utilize core technologies, such as double-sided cooling of power modules to efficiently remove the heat generated by the inverter and providing the ability to use highly efficient silicon carbide (SiC) chips. Meanwhile, the use of sensing to determine what is happening around the vehicle plays an important role in the digital safety systems that ensure safety. To this end, we have developed a 360-degree sensing system that combines stereo cameras, a SurroundEye system with multiple monocular cameras, and millimeter-wave radar, and are also working to develop safe and highly efficient connected power train systems that combine electrification, autonomous driving, and connected technologies.”

Work is also proceeding on a smart cockpit that can serve as a human-machine interface (HMI) for safe and comfortable self-driving vehicles. The cockpit is fitted with a variety of functions such as one for automatically calling the emergency services if necessary. This works by monitoring cameras and sensors embedded in the driver's seat to detect when the driver is distracted or is having trouble breathing. Nobuyasu Kunii (Executive Officer, CTO, and Manager of the Technology Strategy Division at Clarion Co., Ltd.) had the following to say about the further possibilities of HMIs (see Figure 2).

Figure 2 - Roadmap for Integrated HMI

Clarion plays a leading role in the HMI components and systems business, supplying comprehensive solutions that draw on the resources of the wider Hitachi group.

Clarion plays a leading role in the HMI components and systems business, supplying comprehensive solutions that draw on the resources of the wider Hitachi group.

Nobuyasu Kunii

Nobuyasu Kunii

Executive Officer, CTO, and Manager of the Technology Strategy Division at Clarion Co., Ltd.

“While HMIs tend to be thought of as displays for presenting information visually, our aim is to develop a ‘Intelligent HMI.' Providing a comfortable environment inside the vehicle will likely be more important than ever once future self-driving vehicles reach autonomy levels 4 or 5, at which point drivers will be freed from having to focus on driving. Along with utilizing sound and vibration to ensure that the necessary information is conveyed, we are also considering the potential for more concierge-like HMIs in which a wide range of services are delivered by agents that use artificial intelligence (AI) and other techniques based on data in the cloud.”

Four User Values Targeted by Hitachi

Hiroyuki Mano

Hiroyuki Mano

Chief Engineer at the Technology Development Division of Hitachi Automotive Systems, Ltd.

The development of automotive technologies at Hitachi is based on four user values: safety-no collisions with people or objects; comfort-stress-free driving with good ride quality; environmental performance-low fuel consumption; and time-quickly reaching the destination, and accurately predicting the arrival time. The aim is to achieve a good balance between these four values.

The HMI developments described above are targeted at the user values of comfort, time, and seamless utilization of information. One example of such a function would be a car navigation system providing directions to a destination the user entered into his or her smartphone, including how to walk to the particular shop the user wanted to visit, in the case of a trip to a shopping mall.

With regard to the automation of driving to provide safety and comfort, in anticipation of fully autonomous driving, Hitachi has adopted an approach that considers both the application scenarios and how to increase the level of autonomy. Hiroyuki Mano (Chief Engineer at the Technology Development Division of Hitachi Automotive Systems, Ltd.) describes the roadmap for this technology as follows.

“In working toward safe and comfortable driving, we have started from autonomy level 2, which relates to specific roads such as highways or freeways. The plan is progress to autonomy level 3 on highways and ordinary roads. In parallel with this, we are also working on driverless operation in specific areas, such as automatic, remote, or valet parking. As an extension of this, we also see potential for bringing forward the achievement of autonomy levels 4 and 5 in specific areas and are working on ways of doing this. In terms of technologies, in addition to using data processing to bring greater sophistication to the individual operations of recognition, detection, and judgment, we also intend to incorporate AI technologies to enhance the achievement of autonomy level 2 and to provide capabilities for autonomy levels 3 and higher.”

Research and Development Based on a Global One Team Structure

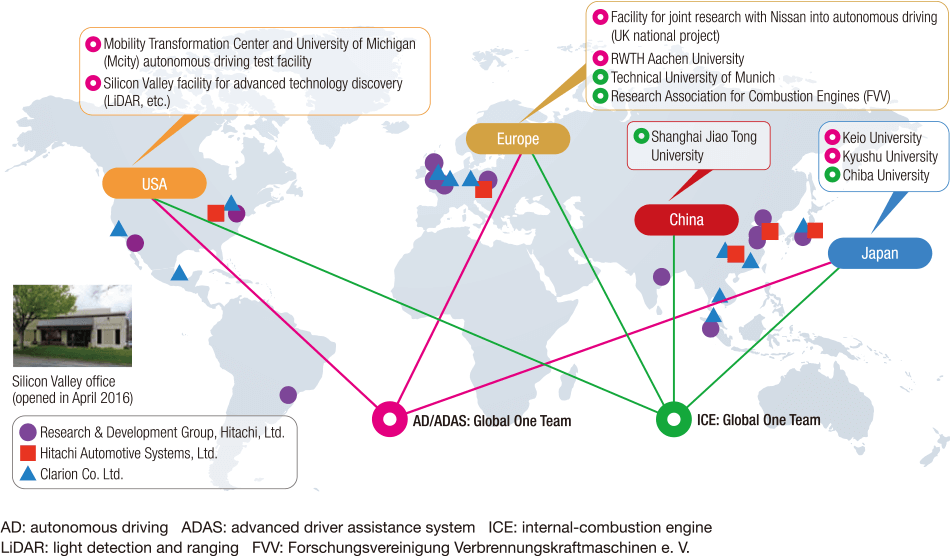

Hitachi has established a “Global One Team” structure for working with overseas sites on the research and development (R&D) of advanced technologies like these autonomous driving systems (see Figure 3). This involves initiatives that combine the different characteristics of each region, such as the establishment in April 2016 of a facility in Silicon Valley, a recognized center of innovation for autonomous driving and the connected car, and also the utilization of work done on engines and electric power train systems at facilities in Europe.

Figure 3 - Global One Team Structure

In addition to building up its product development capabilities for autonomous driving and the connected car, Hitachi is actively utilizing the resources of venture businesses and engaging in collaboration with industry, government, and academia.

In addition to building up its product development capabilities for autonomous driving and the connected car, Hitachi is actively utilizing the resources of venture businesses and engaging in collaboration with industry, government, and academia.

George Saikalis

George Saikalis

Senior Vice President and CTO, Hitachi America, Ltd.

In the field of autonomous driving, an experimental project at the University of Michigan called Mcity* began tests in 2015 aimed at driving on ordinary city streets, and has since built on this by embarking on R&D that looks to a near future made possible by the innovation that autonomous driving represents. George Saikalis (Senior Vice President and CTO, Hitachi America, Ltd.) quotes certain work being done by the company's Big Data Laboratory and the Automotive Products Research Laboratory (APL).

“The Big Data Laboratory develops big data and analytics solutions for a wide variety of fields, including energy and healthcare as well as the mobility sector. The Automotive Products Research Laboratory develops advanced driver assistance system (ADAS)-related technologies and evaluates their performance on local roads. In the automotive industry, the growing adoption of telematics and advanced driver assistance systems (ADASs) is giving rise to a diverse range of new services. In recognition of this trend, we are working on the development of a digital platform for optimizing transportation systems that is targeted at companies that supply services like advanced fleet management systems, autonomous driving solutions, and usage-based insurance (UBI).”

- *

- Mcity is a trademark of Regents of the University of Michigan.

Using Collaborative Creation to Drive Development

Ken Mitamura

Ken Mitamura

Assistant Manager of the Digital Safety Systems Division of Hitachi Automotive Systems, Ltd.

Meanwhile, a lot of effort is also going into using demonstrations, on-road trials, and exhibits at international expos to create opportunities for informing the public about the technologies being developed. This has included testing an autonomous driving (AD) system on public roads in Ibaraki, Japan in September 2016, and also testing the operation of 11 advanced functions for autonomous driving that were implemented on an electronic control unit (ECU) at Hitachi's Tokachi test course in Hokkaido in December 2016. Hitachi demonstrated remote parking at the 2017 Consumer Electronics Show (CES 2017), which also serves as a venue for exhibiting the latest cars, with a valet parking demonstration planned for 2018.

These have prompted an increasing number of system developments based on collaborative creation with customers, and not just with vehicle manufacturers in Japan, but also with global ones. It is difficult for a single automotive manufacturer to develop all key enabling technologies of systems that incorporate many associated components and technologies, particularly those for autonomous driving. Takeshi Mitamura (Staff to Division Director and acting department manager, Safety and Information Systems Division of Hitachi Automotive Systems, Ltd.) described one such example that is currently in progress.

First of all, an AD system should operate in a confident manner so that the driver can rely on the AD system. Beyond such a basic performance level, we believe vehicles also need to demonstrate human-like behavior so that other road users, including drivers and pedestrians, can anticipate what the vehicle is going to do next. Developing the complex systems and technologies that incorporate all the different technical elements associated with this sort of human-like AD systems will likely require a broader R&D partnerships than ever before. Fortunately, the UK government has granted us research funding for the development of human-like AD and we are currently working on a research project as part of a consortium including a vehicle manufacturer, universities, and other relevant companies.

Importance of Localization to Global Operations

John Nunneley

John Nunneley

Senior Vice President, Design Engineering, Hitachi Automotive Systems Americas, Inc.

The main targets of Hitachi's automotive business in markets outside Japan are America and China, with the latter experiencing rapidly growing demand. Along with strengthening sales of key components such as controllers and actuators in America, Hitachi is also seeking greater participation in the Chinese market.

Mr. Mano said, “In China, where wider adoption of electric vehicles (EVs) is being promoted by government policy, we are strengthening our marketing to Chinese OEMs through measures that include establishing the infrastructure for testing electric products. We are also conducting trials of autonomous driving at a variety of locations and considering ways of collaborating with regional governments and Chinese suppliers of parts, IT, and services.”

John Nunneley (Senior Vice President, Design Engineering, Hitachi Automotive Systems Americas, Inc.), who is working on the localization of designs within Hitachi's global operations, describes the importance of this as follows.

“The things customers are calling for include our working with them as a supplier on joint development in order to shorten development times, and also handling everything from design to manufacturing and quality assurance locally. Along with satisfying distinctive requirements based on differences of law or culture that vary between countries and regions, shorter lead times and cost reductions are also important. As a result, we have appointed separate global account managers to deal with each vehicle manufacturer and are expediting the establishment of a global design and development infrastructure centered on Japan.”

Of course, reforming development processes and manufacturing is also essential. Of particular importance in the case of development is how to go about testing the ECUs that control engines, brakes, steering, and other sub-systems. Hitachi has adopted virtual hardware-in-the-loop simulation (vHILS) systems whereby the vehicle is modeled in a computer and used for real-time testing. This proprietary technology allows development to proceed efficiently in parallel with various forms of safety testing (see Figure 4). Another useful tool is an autonomous driving simulator that replicates the circumstances of vehicle accidents in virtual reality, the sort of testing that would be impossible in the real world.

Figure 4 - Advanced Technology Center

The new Advanced Technology Center was established at Hitachi's Sawa facility in 2017 to enable integrated development from individual parts through to complete systems. Along with the existing hardware-in-the-loop simulation (HILS) room, the plan is to progressively install a range of the latest test equipment at the center.

The new Advanced Technology Center was established at Hitachi's Sawa facility in 2017 to enable integrated development from individual parts through to complete systems. Along with the existing hardware-in-the-loop simulation (HILS) room, the plan is to progressively install a range of the latest test equipment at the center.

In the case of manufacturing, Hitachi is working on innovations that use the Internet of Things (IoT). Specifically, this involves achieving continuous availability of production equipment by making information available about what is happening in the workplace while also enabling the same level of manufacturing quality at plants around the world. Hitachi also intends to utilize its Lumada IoT platform to further optimize production.

Spreading the Inherent Value of Connectivity

The changes and innovations currently happening in the automotive sector have the potential to initiate change in society itself. EVs connect to electric power via the grid and connected cars connect to the outside world via data. Also inherent in this connectivity is the potential to spread services more widely.

As Mr. Kunii said, “Along with the expansion of business opportunities into vehicle-using industries such as distribution, competition is also becoming more intense due to the growing number of new market entrants, including IT companies. One example from the vehicle-mounted information systems business is our supplying a UBI service to a car insurer in the USA. Other examples from Japan include a next-generation telematics platform for courier companies and a solution for taxi companies that incorporates demand predictions into a vehicle dispatch system.”

It has also been noted, however, that these benefits come with the risk of cyber-attacks. Another cause for concern is the growing size of software as vehicles become more intelligent. Moreover, with greater personalization expected in the future, post-sale upgrades to software functions will likely be essential.

With the expectation that more time will be spent connected to networks, Hitachi aims to meet this need by using robust over-the-air (OTA) upgrades. This involves using wireless communications to perform software upgrades, with differential upgrades used to compete these more quickly. Hitachi intends to protect against threats by incorporating secure distribution techniques that maintain security from the OTA center that issues the program update all the way to the vehicle, drawing on security techniques acquired through its work in other areas, such as infrastructure development.

There is no doubt that the connection of vehicles to both people and infrastructure will make everyone's way of life richer and more convenient. Hitachi intends to deploy its comprehensive capabilities to help achieve smart mobility in ways that provide even greater improvements in usability and to resolve challenges facing society without compromising safety.

COLUMN

Using Collaborative Creation to inject “CELEBRATE DRIVING”

Daisuke Umetsu

Daisuke Umetsu

Stability Performance Development, Vehicle Development, Mazda Motor Corporation

Makoto Yamakado

Makoto Yamakado

Professor, Department of Vehicle System Engineering, Faculty of Engineering Creativity, Kanagawa Institute of Technology

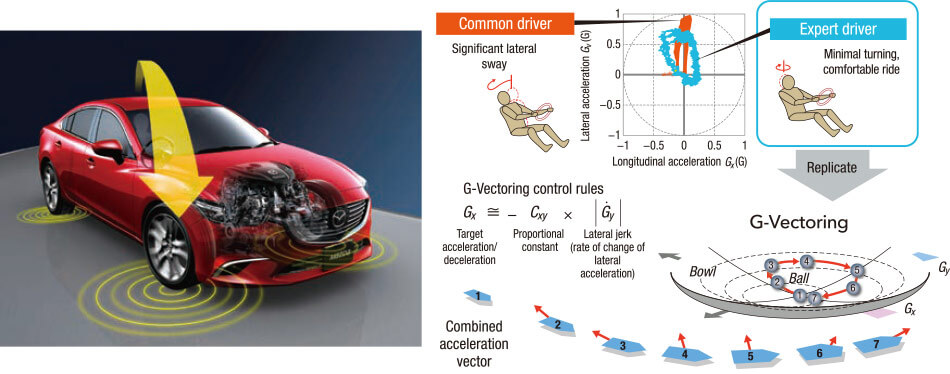

G-vectoring control (GVC) developed by Mazda Motor Corporation is the world's first control technology (in production vehicles as of June 2016, based on research by Mazda). GVC is a Vehicle Control technology that achieves smooth and efficient vehicle dynamics by optimizing the weight on all four wheels. It is used with variable engine torque based on the driver's steering for integrated control of both lateral and longitudinal acceleration (G) (which were previously controlled separately).

The implementation of GVC was developed by Mazda based on Hitachi's G-Vectoring control algorithm. Daisuke Umetsu, one of those involved in joint development, commented on the collaboration with Hitachi as follows.

“Our association with Hitachi went beyond the relationship between supplier and car maker with our joint development being accompanied by discussions based on academic research about how best to go about vehicle dynamics control. The goal was the successful incorporation into commercial vehicles with uniquely Japanese technologies that represented a major step forward in achieving “Jinba-Ittai” (Rider and horse as one). The technology is currently being offered in various models as a standard feature.

And the benefits it provides have been well-received around the world, include making smooth driving and making passengers less exposed to sway or motion sickness.”

The joint development by the two companies also benefited from the involvement of academia, in the form of close industry-academia collaboration with the Kanagawa Institute of Technology. Makoto Yamakado, one of the originators of G-Vectoring, described the process as follows.

“During the time I spent with Hitachi, I worked on the development of control algorithms inspired by driver behavior with the aim of improving routine driving performance and eliminating anomalous feeling. It was the observations of expert driver behaviors that we made during this work that gave rise to GVC. I was extremely delighted to see the two companies go on to put the technology into practice.”

Close Partnership to Satisfy Requirement for Local Manufacturing

Ed Kaiser

Ed Kaiser

Technical Specialist and BFO - Electric Motors General Motors Global Propulsion Systems

The new Chevrolet Volt sold by General Motors Company (GM) of the USA uses a fully electric drive system. Based on GM designs, Hitachi Automotive Systems developed manufacturing processes for both generators and electric drive motors.

Ed Kaiser of GM made the following comment emphasizing the importance of a close partnership between vehicle manufacturer and supplier.

“Hitachi and GM have built an excellent relationship over many years of collaboration on the development of automotive traction motors, sharing knowledge with each other on things like design and manufacturing. With this Chevrolet Volt project, the challenge has been to achieve a significantly higher manufacturing rate when compared to the first generation. Hitachi staff continue to be reliable partners who are always by our side providing support. The success of this motor development project has impressed upon me just how important it is to have a strong partnership with a supplier that has deep design, quality, and manufacturing experience.”

Thanks to a variety of innovations in the manufacturing process, the efficiency of motor production was improved by approximately 54%. To satisfy the requirement for local manufacturing, the motors are built at a motor factory in Kentucky and supplied to GM in Michigan.