9. Virtual Power Plants

The growing adoption of renewable energy sources such as photovoltaic or wind power is posing a variety of challenges for electricity grids. Hitachi is working on virtual power plant (VPP) solutions that utilize distributed energy sources such as electric vehicles (EVs), batteries, or heat pumps to perform demand response (DR), using information and communication technology (ICT) for aggregation*1, planning, and control so as to combine these distributed energy sources in such a way that they can be controlled and utilized in much the same way as a conventional power plant.

Hitachi has engaged in the trial operation*2 of VPPs for use in grid operation that combine distributed energy sources as part of two programs in Hawaii in the USA.

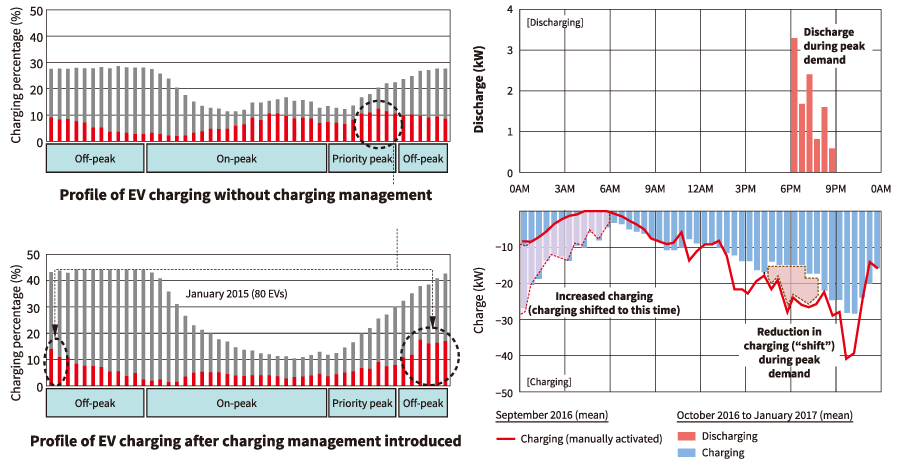

The first was a DR program that involved fast-acting direct load control (DLC) of key household loads such as EVs and water heating for emergency load shedding during grid overloads and the preparing of schedules for load adjustments based on supply and demand planning. The program demonstrated that using DR in a way that takes account of the usage settings for each EV can succeed in cutting peak demand in a power system (see left of Figure 9.1).

9.1. DR program (left) and use of VPPs to manage charging and discharging (right)

The second was a VPP program, a further development of the DR program described above, in which the VPP operated to balance supply and demand by aggregating large batteries with the capability to provide reverse power flows to the grid. The basic operation involved using power conditioning systems (PCSs) with a vehicle-to-grid (V2G) capability installed in homes with EVs to perform charging during times when excess supply is available, such as at night or when a large amount of photovoltaic power is being generated, and to discharge during times of peak demand such as the early evening. The solid red line in the graph on the right of Figure 9.1 indicates the mean actual power consumption when the EVs are charged conventionally. In contrast, the bars in the graph that indicate charging or discharging show how charging and discharging were performed while the VPP program was running. These show that charging took place overnight, except during the power system's peak demand hours (from 6 to 9 PM), whereas discharging occurred during those peak hours.

These two trial programs demonstrated that the adjustment capacity provided by DR and VPPs can be utilized as a resource for grid operation.

A smart community demonstration project*2 in Greater Manchester in the UK involved working with project partners to use a VPP made up of stored energy sources located at customer premises to conduct service trials of VPPs for providing services in a liberalized electricity market.

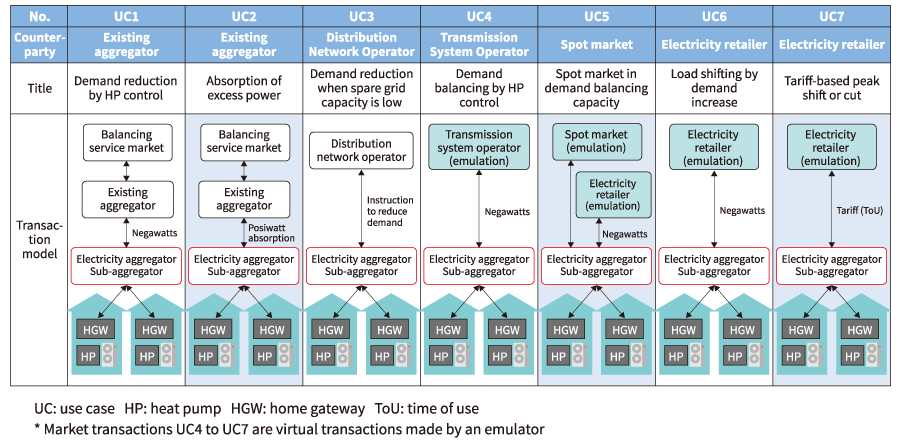

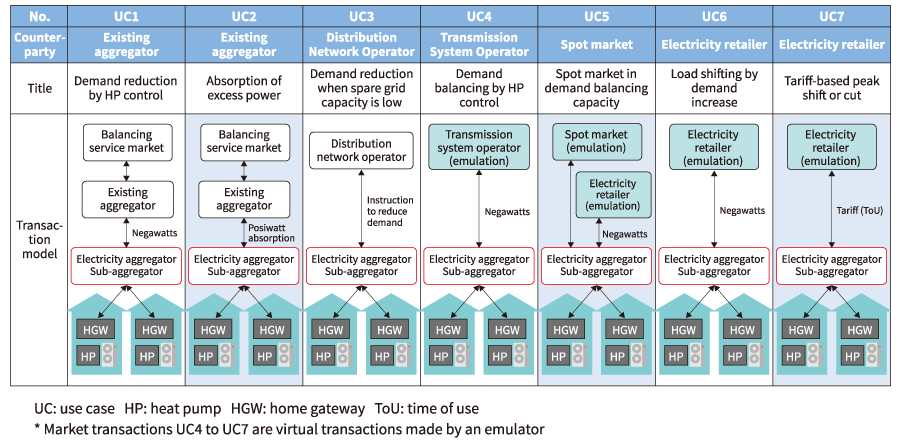

One of these trials was a VPP program that aggregated the load adjustment capabilities of 550 heat pumps installed in customer homes and traded the combined load adjustment capability on the electricity trading market or with electricity industry participants such as electricity retailers and grid operators. By incorporating functions to protect users and maintain convenience by automatically cutting out the DR program if there is a divergence of more than 2°C from the temperature set by the user or if the user operates the system manually, the trial found that more than 83% of users were able to use electric power without having to think about DR. Seven different use cases are available for utilizing the adjustment capabilities (see Figure 9.2). The trial achieved the initial target for the amount of negawatts made available and confirmed that DR satisfies the regulations when trading with aggregators.

9.2. Service use cases

A second trial involved a telecare service in the form of a data utilization program in which data acquired from the VPP business was utilized for the purposes of differentiation, customer acquisition, and revenue improvement. The trial demonstrated that improvements in the efficiency of telecare service operations and the benefits of data utilization services for enhancing business viability could be achieved by adopting IT. This included using electric power and temperature as well as data from door, motion-detection, and other special-purpose sensors to determine the situation in the home; the use of automated voice telephony to perform checks; and functions for chatting with care managers and collating care records.

These two programs demonstrated the viability of providing services using VPPs to electricity utilities in a liberalized electricity market.

The electricity business is undergoing a staged liberalization as it approaches the third stage of Japan's electricity market reforms due to be introduced around 2020. Developments in 2017 included the launch of a negawatt market, grid operators beginning to take bids for adjustment capacity, and encouragement for the introduction of VPPs that included the Ministry of Economy, Trade and Industry offering funding for demonstration projects involving VPP implementation. With the competition unleashed by liberalization having also led to rising demand for customer acquisition solutions, Hitachi intends to draw on operational know-how and the results of trials in overseas countries where electricity market liberalization is more advanced to take on the needs and challenges of the electricity business with VPP and data utilization solutions that are likely to be used by grid operators, retailers, and aggregators.

- *1

- Combining a group of distributed energy sources.

- *2

- A demonstration project funded by the Ministry of Economy, Trade and Industry and the New Energy and Industrial Technology Development Organization (NEDO)