1. Use of 3D Laser Measurement to Improve Efficiency of On-site Surveys and Rationalize Spatial Design

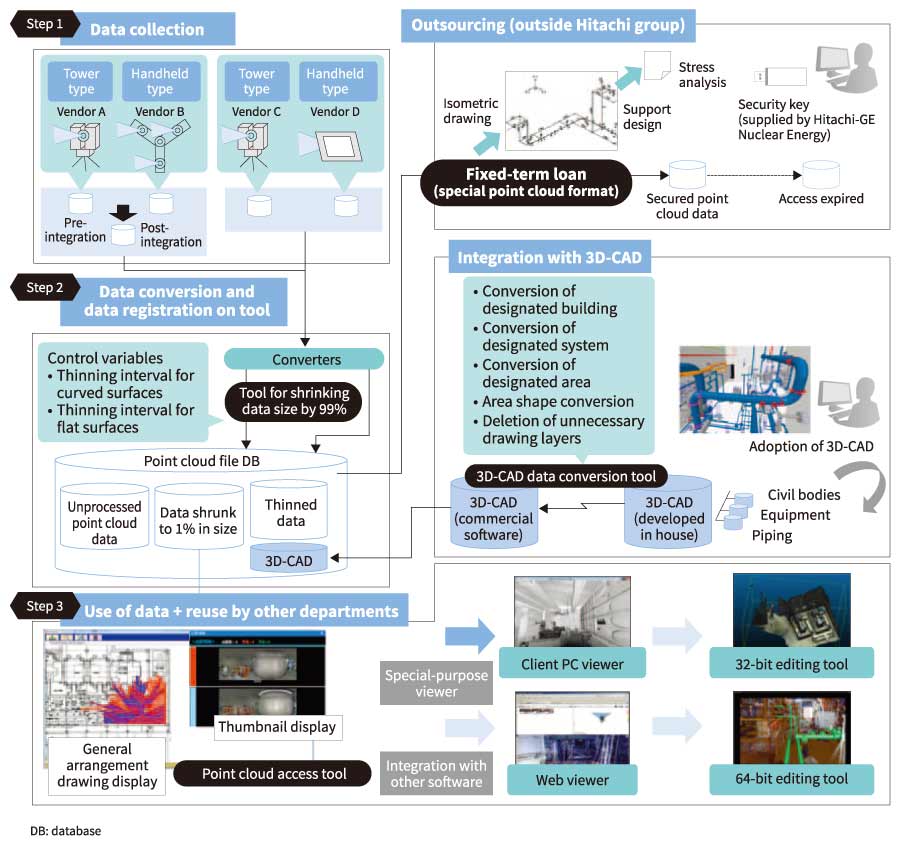

The engineering, procurement and construction (EPC) business for nuclear power plants of Hitachi-GE Nuclear Energy, Ltd. uses point cloud data for purposes that include the dimensional design of new piping installations at plants, the adoption of three-dimensional computer-aided design (3D-CAD), and fabrication work drawing preparation. While use of point cloud data has been limited to individual design departments in the past, Hitachi is now seeking to minimize radiation exposure during on-site work and boost the efficiency of design work by making point cloud data available across multiple departments at Hitachi-GE Nuclear Energy and other group companies.

As part of this, it has developed a point cloud access tool to provide the infrastructure for shared access to point cloud data across different departments. The tool supports the many different ways in which users utilize point cloud data by consolidating management of data in a variety of formats on a server, and is equipped with a special-purpose viewer and functions for integration with other software. Interfaces have also been enhanced by the development of the following techniques that allow users to access large amounts of point cloud data.

- 3D-CAD data conversion tool with a part extraction function that can overlay on point cloud data

- Tool for shrinking the size of point cloud data by 99% so users can utilize large amounts of the data without loss of productivity

- Special formats that ensure high security when work is outsourced to other companies

(Hitachi-GE Nuclear Energy, Ltd.)