1. IoT-compatible Industrial Controllers

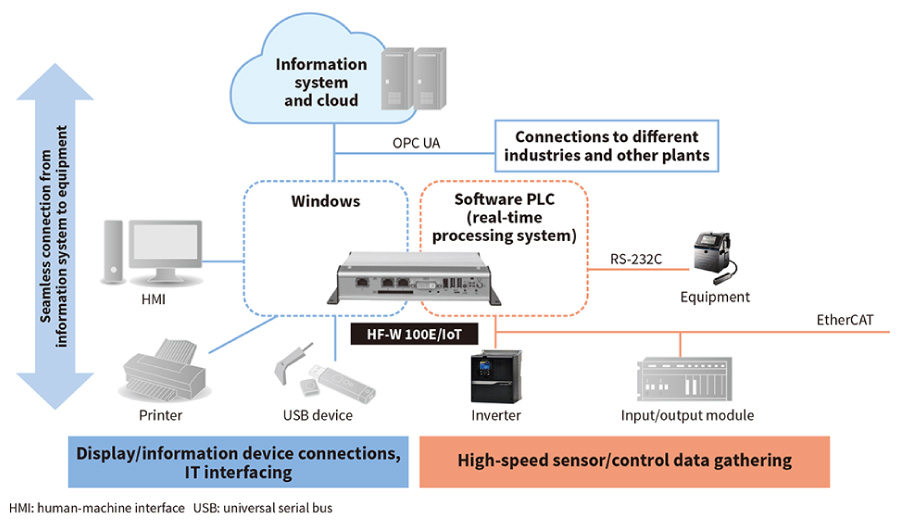

The use of Internet of Things (IoT) applications is becoming increasingly widespread among automation systems. Seeking to be among the first to capitalize on this trend, Hitachi released a series of IoT-compatible industrial controllers in 2015. The latest model in this series, was released in 2017. This model makes it easy to seamlessly connect information systems to equipment.

The main features are as follows.

- Programmable logic controller (PLC) functions are integrated into a highly reliable industrial computer with long-term availability, enabling a single device to handle processes for both the information system (Windows*) and control system (PLC).

- EtherCAT* compatibility enables the creation of a field network that provides high-speed communication with less wiring.

- OPC UA* server functions are provided, enabling platform-independent data sharing.

- To help reduce user development time and cost, programming languages that conform to the IEC 61131-3 international standard are supported, improving the reusability of PLC programs and enabling storage of vendor-independent PLC software assets.

- *

- See the list of “Trademarks.”

1. IoT-compatible controller series supporting industrial IoT applications