1. ECUs for Autonomous Driving

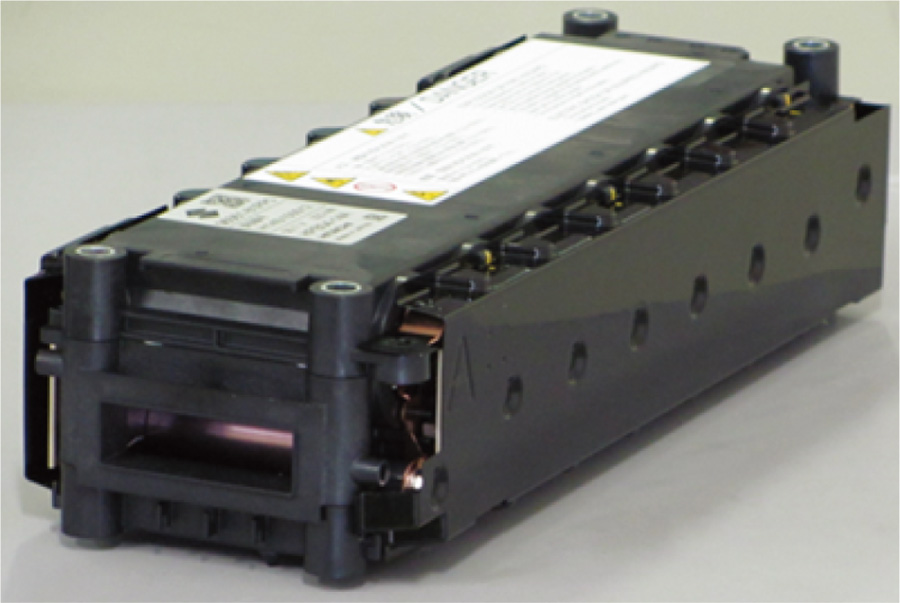

Hitachi Automotive Systems, Ltd. has commercialized stereo cameras for use in Subaru Corporation's EyeSight* and electronic control units (ECUs) for advanced driver assistance systems (ADASs) such as ProPILOT*, an autonomous driving technology designed for highway use in single-lane traffic that is installed on the Nissan Serena* made by Nissan Motor Co., Ltd. The company is also working on developments aimed at autonomous driving, which is expected to be a key technology for future public mobility.

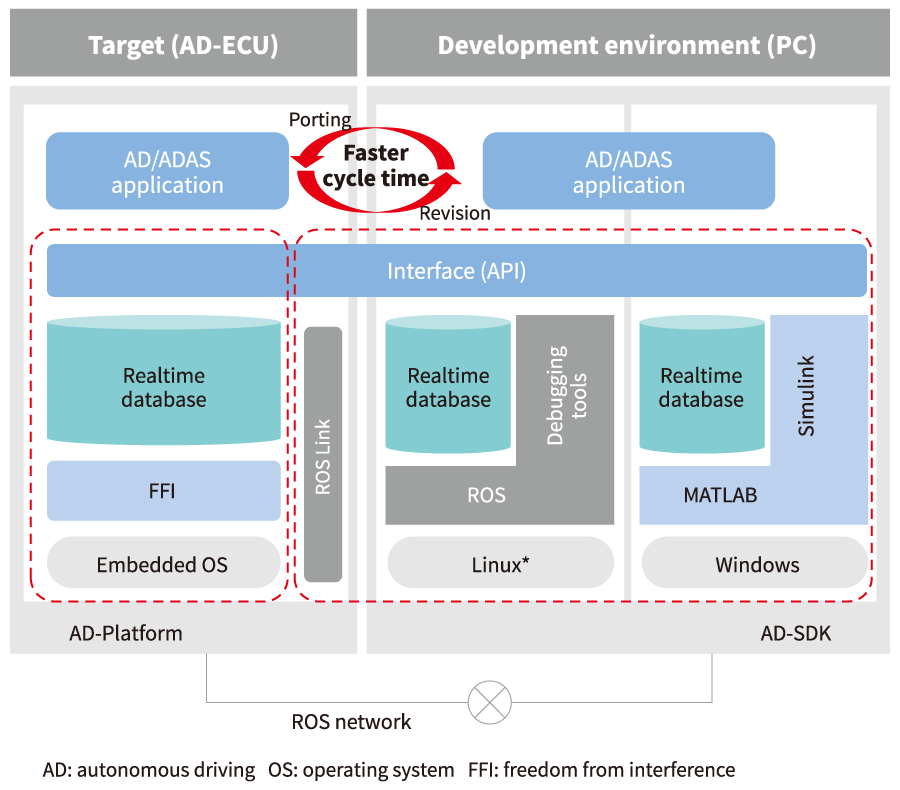

As ECUs for autonomous driving require a higher level of processing performance together with the ability to support advanced security and ever larger and more complex software, developments by Hitachi Automotive Systems include the use of field-programmable gate arrays (FPGAs), software platforms with excellent portability and scalability that support application plug-in, and over-the-air (OTA) techniques for the wireless updating of software.

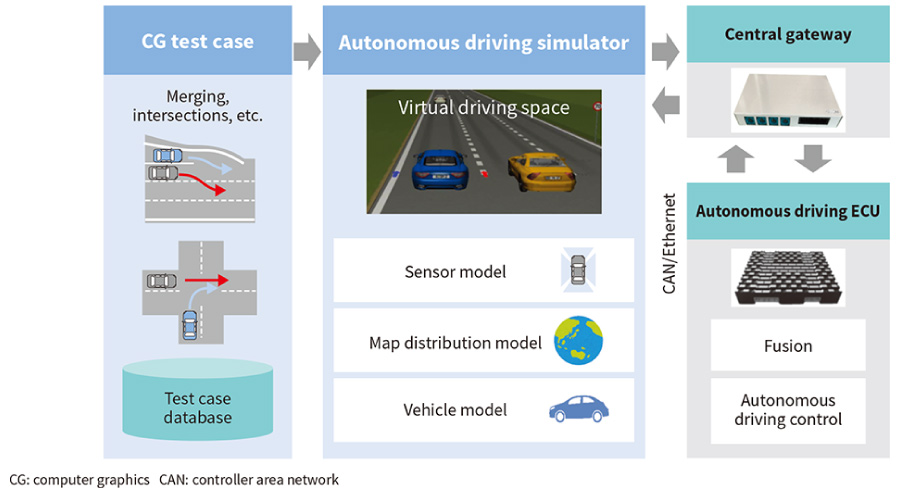

With the aim of becoming a system supplier for autonomous driving systems, Hitachi is also developing a wide variety of other ECUs required for vehicles capable of advanced autonomous driving, including gateway units that manage onboard and external communications and security, telematics control units for external communications, and high-definition map units.

(Hitachi Automotive Systems, Ltd.)

- *

- See the list of “Trademarks.”