COVER STORY:ACTIVITIES2

Pioneering the Future of Mobility through Open Innovation

As the pace of evolution in railways and other forms of mobility accelerates, the challenge of how to efficiently maintain the supporting mobility infrastructure without compromising safety will come to bear sooner than other challenges such as the ageing of mobility infrastructure and the shrinking workforce. At the forefront of confronting this challenge is the Research Initiative for Advanced Infrastructure with ICT run by The University of Tokyo Graduate School of Interdisciplinary Information Studies in a social cooperation program with industry. The program aims to achieve highly developed infrastructure maintenance using data through open innovation involving industry and academia. Meanwhile, activities that look to the future of mobility as a whole are also picking up pace. The Mobility Innovation Consortium led by JR East and made up of transportation service operators and other companies and universities is undertaking surveys and research, and devising proposals aimed at achieving the best possible mobility. Some of the people involved in these collaborative activities between industry and academia share their thoughts about innovations in maintenance that use data and the continually evolving future of mobility.

Yusho Ishikawa, Ph.D.

Yusho Ishikawa, Ph.D.

Project Professor, the Graduate School of Interdisciplinary Information Studies, the University of Tokyo

The evolution of mobility is entering a new stage. A lot of work is going into next-generation technologies for greater safety and comfort. In the case of motor vehicles, this includes the emergence of connected cars and self-driving buses, while the railway industry is seeing a steady stream of new rolling stock becoming available that features faster speeds as well as improvements in ride comfort, user convenience, and energy efficiency.

In the case of Japan, however, much of the infrastructure that underpins these means of transportation, including roads and railway tracks, dates back to the post-war period of rapid economic growth, meaning that now, nearly 50 years later, much of it is approaching the end of its life all at the same time. Furthermore, because the workforce will also shrink in the future, undertaking strategic maintenance while also looking at the safety and economic considerations and continuing to utilize the existing infrastructure as capital assets of society will be essential to driving the evolution of mobility and to enhancing its value.

Having recognized this problem, initiatives are already underway that are using digital technology in the inspection and maintenance of infrastructure. One that has attracted interest is the Research Initiative for Advanced Infrastructure with ICT run by The University of Tokyo Interfaculty Initiative in Information Studies in a social cooperation program with industry.

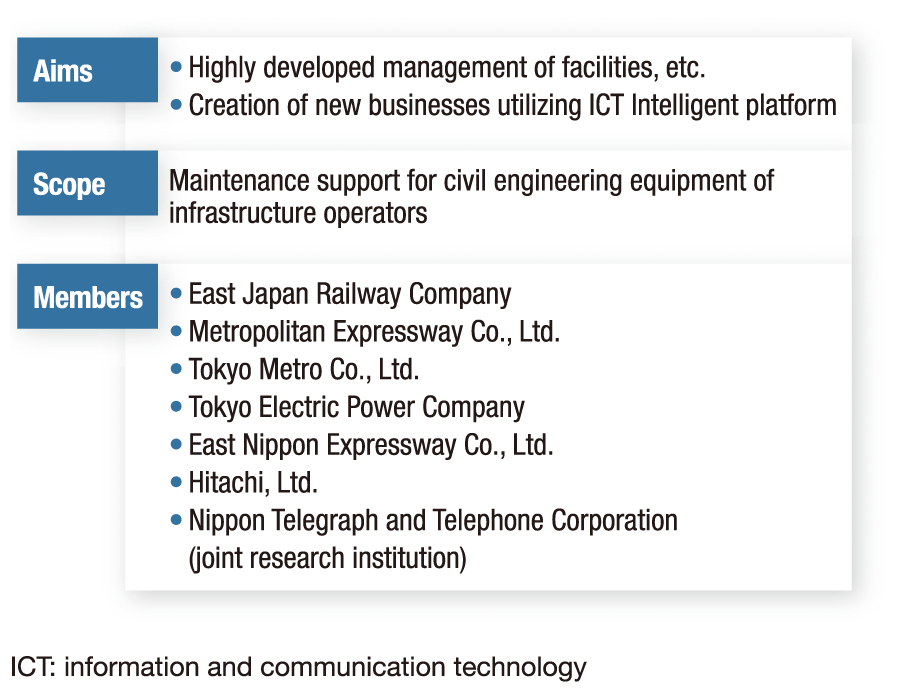

The program involves joint study with private-sector and other organizations on a range of topics that have a direct bearing on the resolution of societal issues. As well as overcoming the challenges of social infrastructure maintenance through the use of IT to perform more sophisticated management, the program also aims to achieve innovation in infrastructure through the establishment of mechanisms for infrastructure-related technical support and skills transfer. Hitachi and a number of infrastructure companies working in metropolitan regions are among the participants, as are relevant government agencies and Tokyo Metropolis who are participating as research partners (see Table 1). The program has been through two five-year phases of research work, the first commencing in 2009 and the second in 2014.

Yusho Ishikawa (Project Professor, Graduate School of Interdisciplinary Information Studies, The University of Tokyo) explains the aims behind establishing the program as follows.

“While moves to link IT and infrastructure were still rare 10 years ago, to prepare for the future, it was felt that the university should look for solutions from a long-term perspective. Furthermore, given that infrastructure companies operate similar equipment despite working in different fields, having these companies exchange their accumulated knowledge of maintenance had the potential to offer new insights and improvements. We also wanted to deepen this exchange of knowledge and become a venue for open innovation.”

Table 1—Overview of Research Initiative for Advanced Infrastructure with ICT Run by The University of Tokyo Graduate School of Interdisciplinary Information Studies in a social cooperation program with Industry

Toshimitsu Urakabe

Toshimitsu Urakabe

Director, Technology Planning Department, Technology Innovation Headquarters, East Japan Railway Company

The work involves collecting a wide variety of infrastructure-related data to predict risks, and to utilize the predictions in actual inspection and repair work.

Professor Ishikawa makes the point that, “Given the limit on the labor and costs that can be incurred, the management of risks and other factors is an important consideration in maintaining infrastructure while also combining efficiency with safety and reliability. If we can establish practices now that use data and are capable of finer-grained management than in the past, they should prove beneficial for overcoming the future challenges of infrastructure maintenance that are likely to become progressively more severe.”

While the research targeted a wide range of different infrastructure belonging to the participating companies, included ducts (for communication and power cables), tunnels, manholes, bridges, and railway trackbed, this article focuses in particular on the trackbeds of East Japan Railway Company (JR East) (see Figure 1).

Among the different infrastructure of a railway, which also includes track, bridges, signals, and power transmission equipment, the trackbed that supports rails and sleepers has a significant influence on things like ride comfort and safety. Most trackbed takes the form of crushed stone ballast that keeps the sleepers in place and distributes the load of the train. Among the problems with ballast trackbed is that it is subject to subsidence caused by the weight of passing trains disrupting the lie of the stones, resulting in rail deformation and a consequent deterioration in ride comfort. While this means that it needs to be packed or replaced at appropriate intervals, this track maintenance work can only be undertaken during the limited time when there are gaps in train operation. As JR East operates approximately 7,500 km of track, how to undertake maintenance efficiently and effectively poses a major challenge (see Figure 2).

As Toshimitsu Urakabe (Director, Technology Planning Department, Technology Innovation Headquarters, East Japan Railway Company) puts it, “Like other public services, railways are facing falls in the number of people working in maintenance at the same time as our infrastructure is ageing.” While electrical and some other equipment incorporates self-diagnostic functions that work using operational data, in other cases the only option is to conduct periodical on-site visual inspections of the equipment. Meanwhile, standard practice for remediation is to replace equipment once it reaches the end of its operating life, regardless of whether it has developed any faults, but this only adds to the labor and other costs of maintenance.

Progress is starting to be made on measures such as fitting cameras to rolling stock and using images collected during operation for inspections, or using the condition of equipment rather than time as the basis for when to replace it. It is anticipated that these practicalities of maintenance will be another factor behind the need to utilize data in the future.

Mr. Urakabe states, “While the railway industry already collects detailed data on many different parameters such as the voltages and currents of signaling equipment, voltages generated by the movement of rolling stock, rail displacement, and vibration, I believe we have yet to make the most of this. If it could be put to use in analysis, it should be possible to more accurately predict equipment condition and to optimize safety and cost. There is no doubt that the question of how to analyze and take advantage of large quantities of different types of data will be an important factor in achieving innovation in maintenance and various other technical fields.”

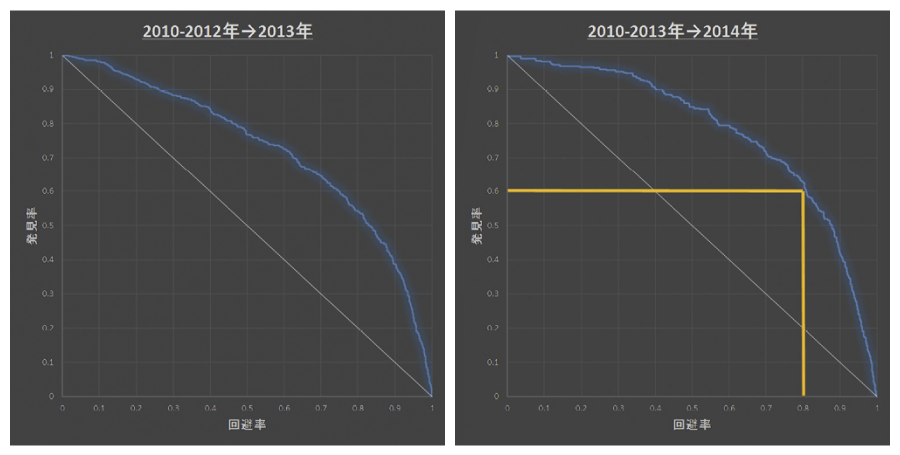

Figure 3—Examples of Equipment Damage Prediction (Prediction Result Curves) The graphs show the trade-off between the percentage of damage discovered and the extent to which inspection of undamaged equipment is avoided. The larger the area between the diagonal lines and the curves that run from the top-left to the bottom-right of the graphs, the higher the prediction accuracy. The yellow lines in the graph on the right indicate that inspecting 20% of equipment (without inspecting the remaining 80%) will identify 60% of problems.

The graphs show the trade-off between the percentage of damage discovered and the extent to which inspection of undamaged equipment is avoided. The larger the area between the diagonal lines and the curves that run from the top-left to the bottom-right of the graphs, the higher the prediction accuracy. The yellow lines in the graph on the right indicate that inspecting 20% of equipment (without inspecting the remaining 80%) will identify 60% of problems.

The data analysis technology developed by Hitachi forms the technical core of the Research Initiative for Advanced Infrastructure with ICT. This technology applies machine learning to infrastructure data to analyze the factors associated with equipment damage and thereby determine the potential for damage and predict equipment condition (see Figure 3). In the case of trackbed, the data used includes non-numeric data such as the rail welding method as well as numeric parameters such as track radius of curvature, rail displacement, and rocking acceleration. The analysis of this data can be used to predict the potential for trackbed damage in each meter of track.

Takashi Hasegawa (Senior Researcher, Customer Front Project, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd.), who played a central part in the development, explains the technical characteristics as follows.

“One aspect that is appreciated by infrastructure companies is the ability of analysis to incorporate, not only quantitative data that can be acquired in numeric form, but also qualitative data such as the weld types and materials used, or (in the case of manholes) their shape and location on the road. Meanwhile the most significant feature of the technology is that it has been honed to suit the specific circumstances, with analysis methods chosen based on the objective of predicting damage or equipment condition to improve the efficiency of infrastructure maintenance.”

What are the specific circumstances for predicting damage to infrastructure or its condition? Professor Ishikawa makes the following point.

“While talk of data analysis may conjure up images of big data, because infrastructure is an area where anomalies cannot be tolerated, data indicating anomalous conditions occur only rarely in practice and therefore they are better characterized as ‘small data.' Although there appears to be a lot at first glance, once categorized, the quantity of each type of data is small. The difficulty, then, is that collecting large amounts of data and applying machine learning is not a practical approach. The key to identifying where anomalies could potentially arise is to dig down into the small amount of data to determine the correlations and other relationships they contain, a process similar to what in mathematics is called ‘drawing an auxiliary line.'”

Whereas machine learning requires large amounts of learning data, there are many cases, not just relating to infrastructure damage, where the amount of valid data is small. Medical diagnosis is one example. Skills and knowledge in the handling of small as well as big data will be essential to the future development of the data-driven society.

Takashi Hasegawa

Takashi Hasegawa

Senior Researcher, Customer Front Project, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd.

Another feature of this analysis technology is that, rather than indicating whether or not damage is present, it produces a numerical probability (repair priorities).

Mr. Hasegawa explains that, “The function was provided in a way that facilitates its use in practice. As infrastructure repairs have to be completed within an annual budget, they are listed in order of priority so that, for example, the top 100 sites can be dealt with this year and 80 more sites next year. This provides the ability to respond flexibly to the predictions.”

The technology also provides a numerical value indicating how much each of the different types of data used in the analysis contributed to the results. This means that field staff can draw on their own knowledge to suggest that certain data should be given more weight and the calculation can be revised accordingly. As Mr. Hasegawa notes, “Providing the ability to incorporate knowledge gained from experience into the predictions without black-boxing the technology not only improves prediction accuracy, but also helps gain acceptance for it in the field.” This suggests that incorporating human knowledge into data analysis and artificial intelligence (AI) will play an important role in the coming data-driven society.

Although the second phase of the Research Initiative for Advanced Infrastructure with ICT will come to an end in FY2018, participating companies have started assessing the value of utilizing its prediction results in practice, and some companies have even gone on to revise in-house manuals based on the results. Having concluded from this that the program has achieved its objectives, Professor Ishikawa comments that, “The participating companies have indicated that the program was worthwhile as a venue for sharing information, among other things, and that they would like to keep it going in some form. Among the measures we would like to pursue are the establishment of a framework for risk assessment, after first identifying those elements that are common to a wide range of infrastructure, and also to work on suggestions for how to update maintenance rules to keep up with advances in technology.”

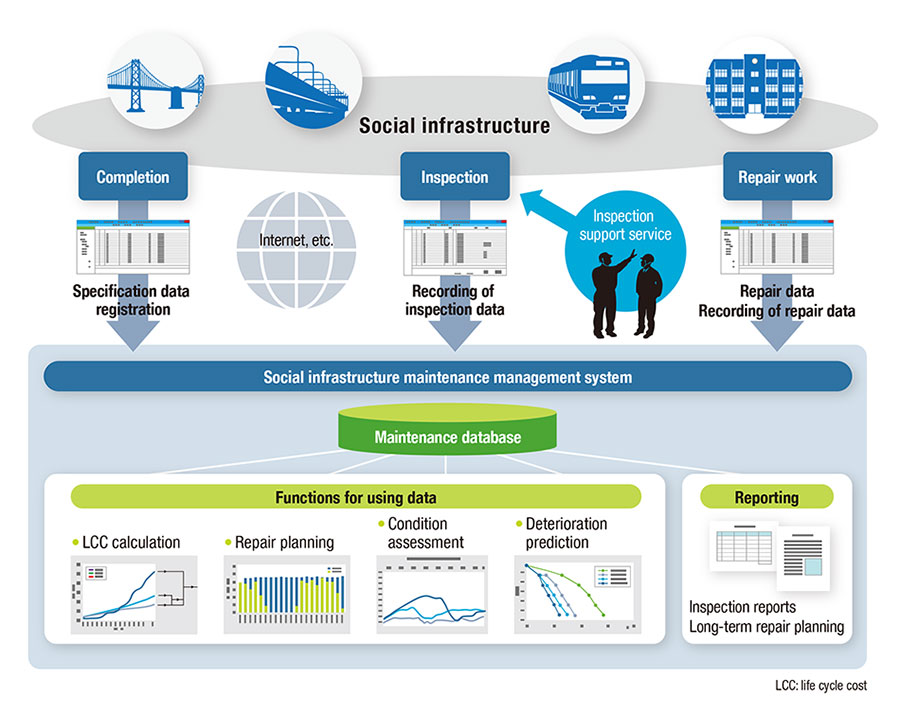

It is anticipated that the new data analysis technology will prove its worth in a wide variety of practical applications in the future, including its incorporation into the CYDEEN social infrastructure maintenance management system of Hitachi Systems, Ltd. (see Figure 4).

Figure 4—Overview of the CYDEEN Social Infrastructure Maintenance Management System The system provides maintenance and management for a wide variety of social infrastructure, supporting the formulation of optimal repair schedules. It can also exchange data with open data platforms.

The system provides maintenance and management for a wide variety of social infrastructure, supporting the formulation of optimal repair schedules. It can also exchange data with open data platforms.

Asked about the future of mobility at a time when the use of data is bringing about a new stage in infrastructure maintenance, Mr. Urakabe responds by saying, “Looking to the future of railways, our aim is to bring about a mobility revolution with greater use of data not just in maintenance, but also in other areas such as improving service and providing greater safety and peace of mind.”

Mr. Urakabe chairs the steering committee of the Mobility Innovation Consortium, which seeks to resolve social issues by getting suppliers, universities, research institutions, and other organizations to work together, with JR East playing a central role. He sees the future of mobility as follows.

“In a future characterized by the integration of many different forms of data, including information about the weather as well as railways and other forms of transportation, JR East aims to deliver value to customers on the basis of ‘Now, Here, Me.' That is, we want to offer comprehensive support tailored to individual customers. Guided by this vision, the consortium aims to provide seamless door-to-door mobility from the point of departure until arrival at the destination, while also getting more involved in the use of robots in public transportation. Whereas people currently need to adapt their movements to public transportation, what we would like to achieve in the future is the optimization of travel where different forms of mobility work together based on what the user wants to do.”

This idea of taking a fresh look at mobility from a human-centric perspective also fits well with the Society 5.0 vision being promoted by the Japanese government.

Professor Ishikawa also shares his hopes for work aimed at innovation in mobility.

“How Japan goes about overcoming the major social challenges it faces due to an ageing population and very low birthrate will, I believe, be watched closely by other nations around the world that will be confronting the same issues. Being essential to the functioning of society, mobility, along with other forms of infrastructure, requires innovations that treat the current situation in a positive light. I look to the Mobility Innovation Consortium to provide such a vision, and our collective hope is to work with people from the private sector to contribute to overcoming these challenges.”

Advanced data analysis technology and open innovation will pioneer the future of mobility.