Seeking to achieve a sustainable society, the Sustainable Development Goals (SDGs) set forth by the United Nations (UN) call for solutions to global environmental issues, solutions to societal challenges, and quality-of-life improvements for people around the world. These goals are also the goals of Hitachi's Social Innovation Business, and the source of ongoing growth. Hitachi Group companies are looking into several key topics for initiatives (materiality topics), extracting them from sources such as the UN's 17 SDGs. For example, Hitachi High-Technologies Corporation is examining materiality as it relates to areas such as (1) contributing to a sustainable global environment, (2) contributing to healthy, safe, and secure lives, and (3) contributing to the sustained development of science and industry. It hopes to help achieve the UN's SDGs by solving the challenges related to these areas. The growth of measurement technologies used for applications such as visualization and quantifying various phenomena will play a key role in overcoming these challenges.

Seeking to achieve a sustainable society, the Sustainable Development Goals (SDGs) set forth by the United Nations (UN) call for solutions to global environmental issues, solutions to societal challenges, and quality-of-life improvements for people around the world. These goals are also the goals of Hitachi's Social Innovation Business, and the source of ongoing growth. Hitachi Group companies are looking into several key topics for initiatives (materiality topics), extracting them from sources such as the UN's 17 SDGs. For example, Hitachi High-Technologies Corporation is examining materiality as it relates to areas such as (1) contributing to a sustainable global environment, (2) contributing to healthy, safe, and secure lives, and (3) contributing to the sustained development of science and industry. It hopes to help achieve the UN's SDGs by solving the challenges related to these areas. The growth of measurement technologies used for applications such as visualization and quantifying various phenomena will play a key role in overcoming these challenges.

The Hitachi Group has been developing pioneering technology and products since the 1940s, starting with electron microscope-based miniature-scale measurement techniques. It has since expanded into areas such as optical and ultrasonic measurement and analysis technologies, while providing equipment and services that help make modern life possible in areas as diverse as biohealthcare, electronic devices, and new materials development. Recently, it has been working more actively on measurement data and measurement data digitalization to enable the collaborative creation of high added value by providing services and solutions. Many of its products also address needs specific to client usage conditions such as in situ measurement. This issue presents the latest trends in cutting-edge measurement technologies, along with some examples of Hitachi's work on overcoming societal challenges.

Figure 1—First Commercial Transmission Electron Microscope (TEM) Produced in Japan The practical electron microscope (HU-2) was delivered to Nagoya Imperial University in 1942.

The practical electron microscope (HU-2) was delivered to Nagoya Imperial University in 1942.

Measurement technologies help advance technology as a whole, and advances in measurement technologies lay the groundwork for new scientific discoveries. The electron microscope is one example, having been a key measurement tool for measuring miniature shapes. The first electron microscope was developed at the Technical University of Berlin in 1931. Hitachi developed a magnetic field-based electron microscope (HU-1) in 1941. The following year, it developed a practical electron microscope (HU-2), delivered it to Nagoya Imperial University (now Nagoya University), and helped release the first commercial transmission electron microscope (TEM) in Japan (see Figure 1). In 1958, it developed a variable-magnification electron microscope driven by permanent magnet excitation. The microscope won a Grand Prix award at the Brussels World's Fair in the same year. It established Hitachi's reputation as a world technology leader, which it has kept until the present day. In 1978, Hitachi's researchers were the first to perfect a holography electron microscope enabling electromagnetic field measurement of nanoregions, and used it to work on explicating physical phenomena such as demonstrating the Aharonov-Bohm effect. To enable further work in these areas, Hitachi completed a research facility in April 1990 that provides a dedicated facility constructed on the firm bedrock found in the region around Hatoyama, Saitama Prefecture. Its world-class research equipment has been allocated to practical use. This equipment can be used to explicate the behaviors of electric and magnetic fields in microregions with sizes on the scale of atoms. It can greatly assist the acquisition of knowledge useful for developing next-generation materials and devices with new functions. Hitachi is working on applying artificial intelligence and other cutting-edge technologies to work on analyzing phenomena, while using open innovation to combine several different areas of knowledge.

Hitachi also uses high-energy facilities to provide ways of measuring the crystal structure of matter and the operating conditions of functional parts such as electronic devices. Using powerful, highly directional X-rays produced by synchrotrons and other accelerators, it is possible to dynamically identify the growth of semiconductor device defects and observe the behaviors of reactions within lithium-ion batteries. Hitachi is actively pursuing the use of synchrotron radiation for research. Hitachi's Photon Factory site began operation in 1982 (in Tsukuba, Ibaraki Prefecture), and the company has created a dedicated research facility in collaboration with 13 other private-sector companies at the large SPring-8 synchrotron site created in 1997 (in Sayo District, Hyogo Prefecture).

To enable efficient energy use, silicon carbide (SiC) devices are becoming increasingly promising due to the higher voltage resistances and operating temperatures they enable relative to conventional silicon (Si) devices. But SiC substrates are more prone to the presence of crystal defects and defects caused by processing damage during cutting or polishing than Si substrates. This drawback has been a major obstacle standing in the way of Si devices becoming a practical reality. For many years, Hitachi has drawn on electron microscopy to create various measurement technologies driven by electron beams. One of the results of this work is a technology that enables measurement by charging defects with ultraviolet rays. It works by using the effect that the electric potential of the substrate surface has on the emitted electron beam. The difficulty of defect detection during manufacturing processes has previously been a hindrance for manufacturing, and Hitachi's technology has made major strides in overcoming this challenge.

The rise of electric vehicles and increasingly advanced automotive electronic control are creating a growing demand for 100% inspections of electronic parts done by nondestructive methods. Ultrasonic measurement is an effective method for detecting internal defects in parts such as large-scale integrated (LSI) modules. Hitachi has also developed practical technologies that use higher frequencies to enable micron-order sensitivity improvements, and use signal processing for faster separation and measurement of signals from multiple surfaces.

Quality control in manufacturing processes is a crucial requirement for pharmaceuticals manufacturers and others in the biohealthcare industry. The water used in manufacturing must be subjected to microbial testing. To rule out the existence of any quality problems, manufacturers previously needed anywhere from a few days to more than ten days to culture and test microbial samples. With the biomedical product industry expected to see growing demand in the coming years, there are concerns that the time needed for sample culturing could impact even drug efficacy itself. The culture method is also used for tests of antimicrobial properties and sterilization performance, so rapid inspection methods are needed to enable effective quality control.

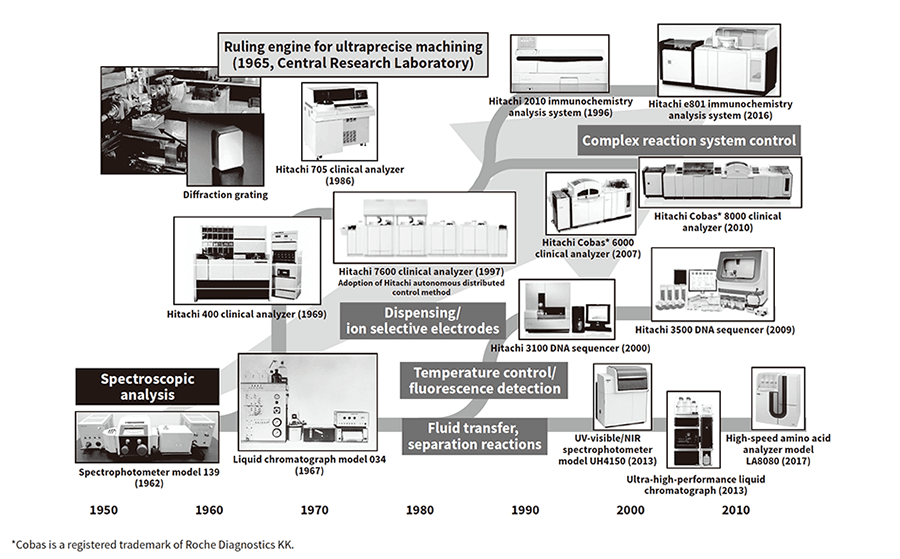

One widely-known method of detecting the presence of microbes is to detect the light emitted by the reaction of a reagent with the adenosine triphosphate (ATP) present in the cells of all organisms. But microbial testing for the objectives mentioned above requires measurement of very minute changes. Drawing on optical measurement technologies arising out of spectrophotometry, Hitachi has released a clinical analyzer for blood that automatically measures the chemical reaction of ATP with a reagent (see Figure 2). The use of these technology platforms has enabled analysis of extremely minute component quantities.

Figure 2—Milestones in Spectroscopy and Optical Detection Technologies Spectroscopy and optical detection technologies use a number of different analysis systems such as biochemistry/immunohematology clinical analyzers, amino acid analyzers, and DNA sequencers.

Spectroscopy and optical detection technologies use a number of different analysis systems such as biochemistry/immunohematology clinical analyzers, amino acid analyzers, and DNA sequencers.

Many regions around the world are tackling challenges in the natural environment such as soil or river pollution. The Hitachi Group has released a large number of measuring instruments for applications such as metal element concentration measurement and analysis. They are used to ensure security and safety in the environmental and food industries. In 1974, Hitachi released the world's first polarized Zeeman atomic absorption spectrophotometer. It is used to identify pollutants such as mercury, lead, and arsenic. Over 10,000 units have been shipped to date. Our polarized Zeeman atomic absorption spectrophotometer model 170-70 has been registered under the Heritage of Analytical and Scientific Instruments certification program created by the Japan Scientific Instruments Association and Japan Analytical Instruments Manufacturers' Association (see Figure 3).

The EU's Restriction of Hazardous Substances (RoHS) directive for electrical products first went into effect in 2006 and was amended in 2013 to, in principle, restrict the use of hazardous substances in all electronic devices. Starting in 2019, phthalate esters will be added to the list of previously regulated substances such as lead and mercury. Manufacturers will need to periodically control the hazardous substances contained in their products on a site-by-site basis. The affected manufacturers will range from set manufacturers of products such as vehicles and electrical appliances, to parts manufacturers and raw materials producers. Hitachi High-Tech Science Corporation provides systems that perform detailed analysis tailored to the screening of these regulated substances and the screening results(4). These measurement technologies can also be applied to reliability inspections of vehicle-mounted batteries, helping overcome societal challenges (see Figure 4).

In situ observation is highly effective for resource exploration applications at mining sites such as materials analysis and metal reuse. A recently perfected analysis method called laser-induced breakdown spectroscopy (LIBS) focuses and emits a laser beam onto a specimen, and uses spectroscopic analysis to analyze elements in minute quantities of atoms emitted from the specimen. The use of small lasers and highly sensitive semiconductor detectors has enabled the release of handheld measuring instruments that are proving to be effective.

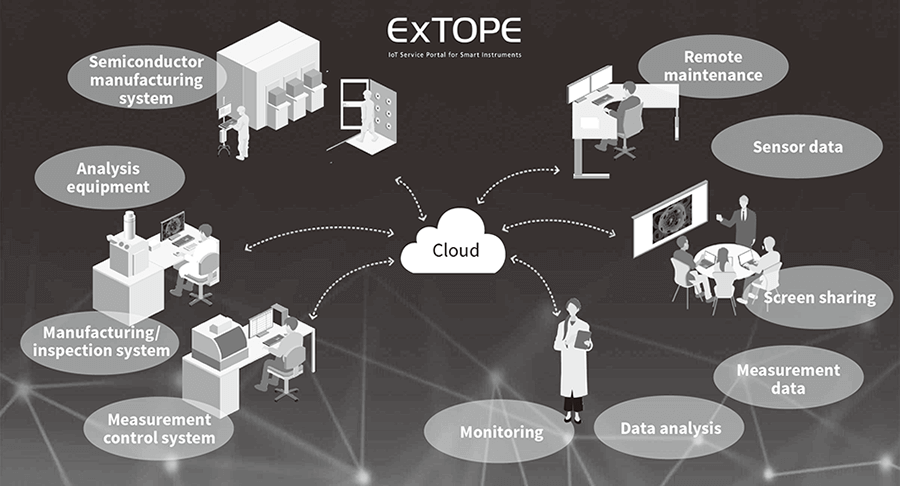

Hitachi is creating value from various types of data that are currently expanding in volume at an accelerating pace, and is using its Lumada digital innovation platform to work on collaborative creation activities with clients. Just as with other systems used for these activities, measurement systems can also store measurement results as data to enable a number of benefits. Acquired knowledge can be used for analysis, optimum measurement conditions retrieved from other cases can be presented as examples, and measurement results from multiple systems can be used to perform multifaceted analysis. To enable use of this data, the Hitachi High-Technologies Group has developed an Internet of things (IoT) service portal called ExTOPE (see Figure 5). By collecting measurement results from sources such as electron microscopes, analyzers, and semiconductor inspection systems and placing them on the cloud to enable unified management, ExTOPE is expected to enable the utilization of data via an IoT platform. Sharing data on networks should help improve client value through collaboration, open innovation, integrated analysis using multiple devices, or simplified operations made possible by group control of multiple devices.

Figure 5—Conceptual Diagram of ExTOPE IoT Service Portal Data is collected and placed on the cloud for unified management, enabling integrated analysis by a wide range of measuring instruments. Group control of multiple devices should also facilitate operations, while online data sharing will promote collaboration and open innovation.

Data is collected and placed on the cloud for unified management, enabling integrated analysis by a wide range of measuring instruments. Group control of multiple devices should also facilitate operations, while online data sharing will promote collaboration and open innovation.

To help overcome societal challenges, the Hitachi Group will continue to develop and release cutting-edge measurement technologies and easy-to-use systems tailored to client needs. By providing a service portal, it plans to further expand the benefits of digitalization, acquiring new knowledge and using the acquired knowledge to help find ways of achieving a sustainable world.