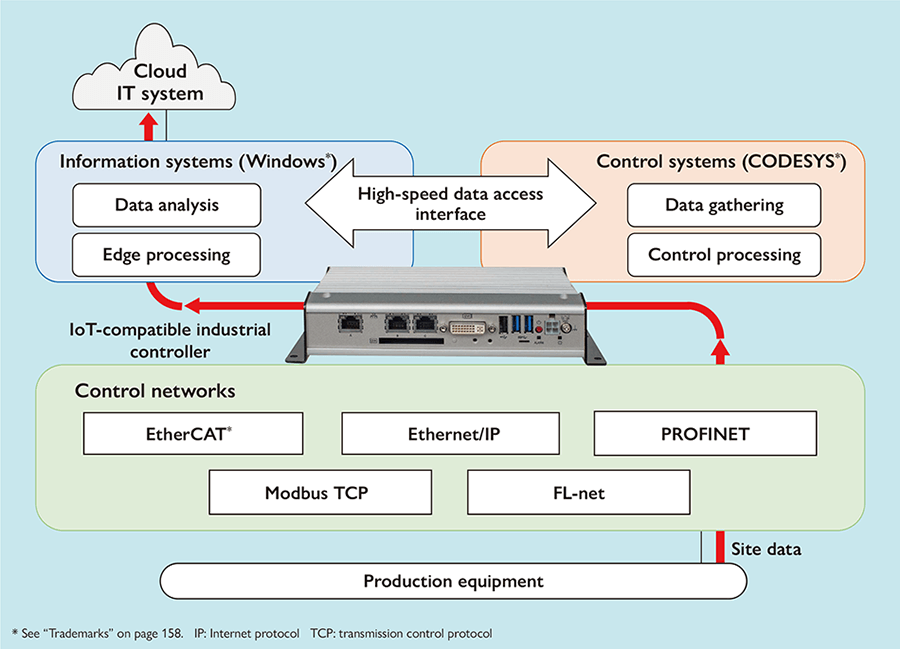

1. IoT-compatible Industrial Controllers

Factory automation systems are increasingly embracing the use of the Internet of things (IoT). The application of IoT technology to factory automation encompasses more than just control functions for controllers. Other controller functions such as collecting real-time data from sensors and other inputs, and for performing immediate data analysis and edge processing are in high demand.

To respond to these demands, Hitachi is planning to release the following two functional augmentations for IoT-compatible industrial controllers:

- Support for control networks [Ethernet/IP*, PROFINET*, Modbus*, Transmission Control Protocol (TCP) and FL-net] used to connect to various devices and gather data

- Adding high-speed data access functions for use between control and information systems to communicate control system high-speed cycle data to information systems without omissions

IoT-compatible industrial controllers connect control systems and information systems. These functional augmentations will help bring the IoT to factory automation systems.

- *

- See the list of “Trademarks.”

1. IoT-compatible industrial controllers for connecting control systems and information systems