1. ZX135USX-6 ICT Hydraulic Excavator

ZX135USX-6 is a hydraulic excavator designed for use in small construction projects that incorporates information and communication technology (ICT). It has been released for the Japanese market and complies with the 2014 standards specified in Japan's Off-road Act. It was designed as a refinement of the ZX135US-6 (a hydraulic excavator with a small turn radius) and comes with Hitachi's solution linkage assist system. This system uses data to assist work operations and provides the same machine guidance and machine control features as the ZX200X-6. The excavator's main features are as follows:

- The machine guidance system displays position relationships and posture information for the excavator body and work objective. It has an easy-to-use dedicated touch panel monitor and highly responsive posture sensors.

- The machine control system uses work objective data to provide semi-automatic control of the excavator body. Its main function prevents over-digging of the work objective by controlling the bucket. It also has a bucket angle lock mode that keeps the bucket angle constant. The precision of these features has been improved through market feedback about user needs received for previous models.

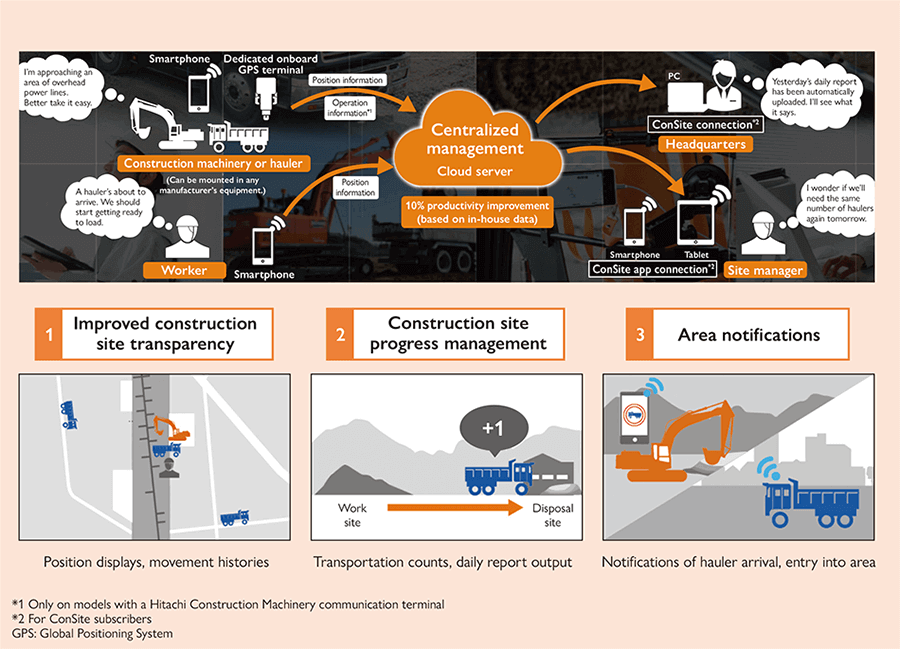

- The excavator is connected to solution linkage cloud, a cloud service from Hitachi Construction Machinery Co., Ltd. (a provider of optimum solutions for the i-Construction* initiative led by the Ministry of Land, Infrastructure, Transport and Tourism). The service enables access to applications useful for ICT-based construction work.

(Hitachi Construction Machinery Co., Ltd.)

- *

- See the list of “Trademarks.”