Water Environment Solutions that Facilitate Ongoing Use of Water Resources

As an important part of the urban infrastructure concerned with water in cities, sewerage systems are tasked with preventing flooding, improving public sanitation, and protecting the water quality of public waterways. In addition to these roles, the systems have also been subject in recent years to rising expectations for energy efficiency and efficient operational management. Hitachi is actively working to develop technologies and supply solutions that meet these needs. Among recent such activities is the development of operational support and control technology for preventing urban flooding and discharges of untreated sewage, the aim being to reduce the risks of flooding and water pollution during rainfall events. In this way, Hitachi is seeking to contribute to the sewerage industry as it takes on an even greater importance both in Japan and elsewhere.

Internationally, Japan is one of the countries that has achieved a high level of success in dealing with sewerage, including by maintaining high standards of treated water quality and reliability of operation. Moreover, utilities and relevant government agencies are seeking to maintain standards by pursuing future-oriented measures that address changes in both the business and natural environments, including the increasing need for equipment upgrades, rising public expectations, fewer young engineers entering the profession, and climate change in the form of more frequent heavy rainstorms.

In response to these trends, Hitachi is putting considerable effort into developing technology and systems that are tailored to the latest needs of the water sector, including sewerage, and is delivering solutions with a view to overseas applications as well as domestic users.

This article focuses on what Hitachi is doing in the field of operational support and control technologies that can help reduce the risks that stormwater poses to sewers in particular.

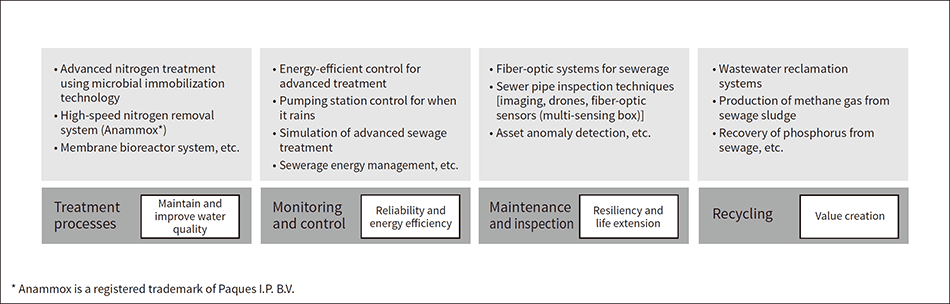

The sewerage industry is one in which Hitachi has long been working on technology development. In order to supply a wide range of solutions encompassing all four areas listed in Figure 1, namely treatment processes, monitoring and control, maintenance and inspection, and recycling, Hitachi has developed process monitoring and control technologies and simulation techniques for the evaluation and prediction of the processes involved, making use of these in products both directly and indirectly. This has included the recent development of a technique used in the ammonia removal process of sewage treatment that controls blower flow rates so as to reliably achieve the target water quality while also reducing power consumption and maintenance workloads. This technique was trialed as part of the Breakthrough by Dynamic Approach in Sewage High Technology Project (B-DASH Project) run by the Ministry of Land, Infrastructure and Transport from FY2014 to FY2015, with the ministry’s National Institute for Land and Infrastructure Management having published draft guidelines on how to introduce this technology(1).

Figure 1 — Hitachi Solutions for Sewerage Hitachi supplies a wide range of solutions that create value and reduce the load imposed on the environment by sewerage. Note that the figure includes solutions that are current under development or testing.

Hitachi supplies a wide range of solutions that create value and reduce the load imposed on the environment by sewerage. Note that the figure includes solutions that are current under development or testing.

One new initiative involves developing ways of dealing with rainfall, something that is expected to become more essential than ever as a consequence of climate change effects such as heavy rainfall events. Along with flooding risks such as inland flooding or the inundation of sewage treatment infrastructure, another concern associated with rain is the risk of city waterways being polluted by combined sewer overflows (CSOs) or the discharge of partially treated effluent from sewage treatment plants. Measures for addressing these stormwater risks in the past have mainly involved physical infrastructure, such as installing reservoirs or means of redirecting flows(2). It is also anticipated that operational measures such as improving practices at the pumping stations, sewage treatment plants, and other infrastructure used to deal with sewage will also increasingly be adopted given that such methods are more economical. Hitachi is working on digital solutions for addressing stormwater risks that also make use of technologies developed in the past. The following sections describe the progress of this work.

This section describes a sewage pumping station solution that addresses the risks of floods, inundation of equipment, and water pollution within the service area.

As sewage pumping stations that form part of combined sewers (sewers that handle rainwater runoff as well as other forms of wastewater) need to deal with a number of different risks due to inflows being higher when it rains, keeping track of these everchanging inflows is an integral part of their operation. While their primary priority is to prevent surface flooding by quickly draining away the storm rain that falls in their sewage service area, their operation also needs to take account of risks that vary with the amount of rainfall. These include the inundation of sewage pumping stations and environmental pollution caused by discharges of untreated effluent.

Hitachi has developed a dynamic simulator for sewage pumping stations that enables these stations to operate in ways that take account of these risks(3). The simulator is made up of a set of separate models that replicate in detail the specifications of the pumping stations and their equipment. Taking the predicted inflows to the pumping stations as its input, the simulator quantitatively assesses the risks (flooding within sewage service area, inundation of pumping stations, higher discharges of pollution, higher energy consumption, and so on) associated with controlling the pumps using the different techniques available (feedforward control based on inflows, control of flows into intercepting sewers, and the coordination of control with the volume of wastewater receiving high-level treatment). This provides valuable support for determining pump start/stop timings and discharge levels during rainfall events when on-the-spot decisions must be made.

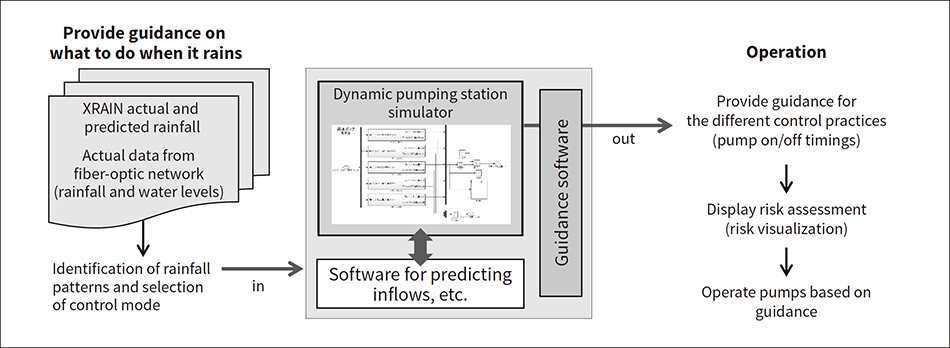

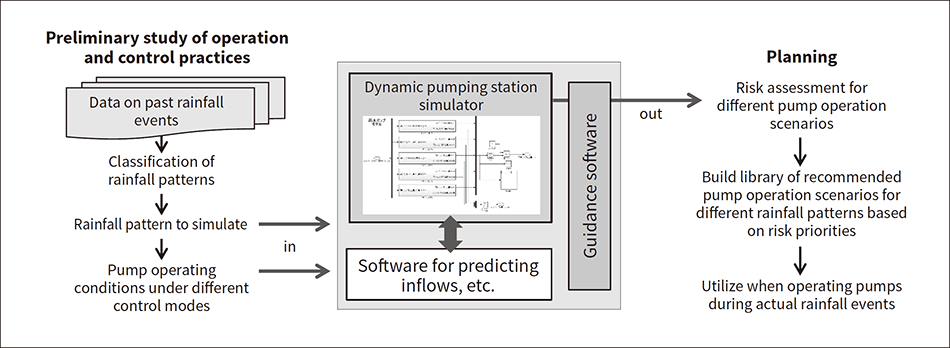

A guidance system currently under development uses the dynamic simulator described above to provide a digital solution for sewage pumping stations. The system has two functions: (1) Operational guidance and (2) Planning and training exercise guidance. The operational guidance function uses online data such as inflows and drain water levels that is transmitted over the sewer’s fiber-optic network to advise on how best to operate the pumps under the everchanging conditions (pump start/stop timings, changes to discharge levels, and so on). The planning and training exercise guidance function is also based on the dynamic simulator, using it to determine the operational outcomes of adopting different control techniques. To do so, it makes use of past data such as records of stormwater and of actual pumping station operation.

Figure 2 shows an overview of the operational guidance function. The intended inputs include predicted and actual rainfall from the XRAIN* rain radar data as well as actual data on rainfall and trunk sewer water levels transmitted over the sewer’s fiber-optic network. The dynamic pumping station simulator is run using these inputs and guidance software used to generate operational advice. The plan for the future is to integrate the function with external software for sewer inflow prediction or flood simulation.

Figure 3 shows an overview of the planning and training exercise guidance function. The inputs include the assumed rainfall pattern and the pump operating conditions under the different control modes (pump start/stop timings, discharge levels, and so on). The dynamic pumping station simulator is run offline using these inputs and the guidance software used to generate advice for planning or training. Preemptively simulating possible rainfall patterns and operating conditions provides a way to build up a library of recommended pump operating practices under different rainfall scenarios. This facilitates a prompt response to actual events and the preemptive assessment of stormwater risks, providing key information for decision-making such as the limits on what the infrastructure for dealing with stormwater can cope with and equipment upgrade plans.

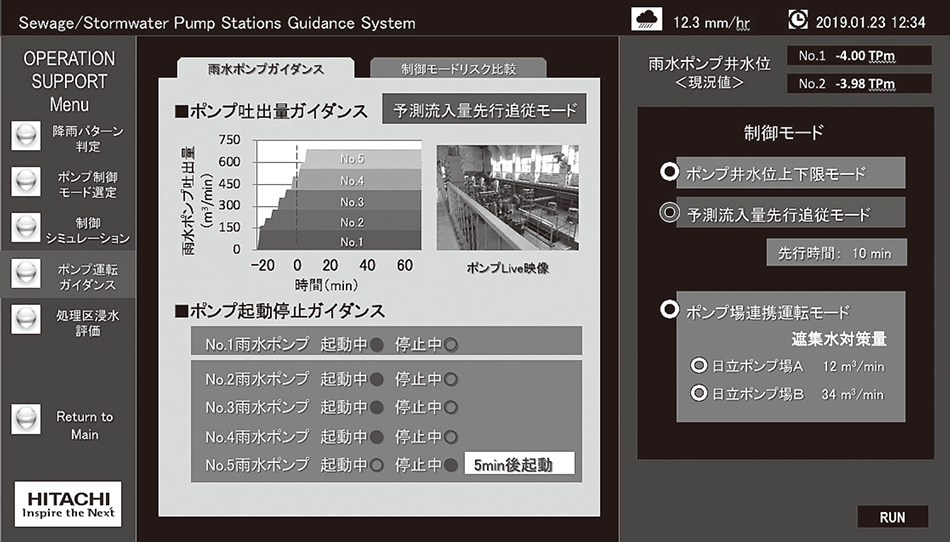

Figure 4 shows one of the system’s pump operation guidance screens. The screen can be used to select which control mode to use for stormwater pumps while viewing data such as rainfall amounts or current pump parameters. Once other required control settings have been entered, the screen can also be used to run the dynamic simulator and display the results in the guidance area (central region of the screen). In this case, the information clearly displayed on the screen includes recommended stormwater pump discharge rates to use over the specified time period and details of the pump start/stop timings. Along with providing suitable advice on decisions about pumping station operation, it is hoped that the guidance function will also prove useful for the transfer of operational expertise.

Figure 2 — Overview of Operational Guidance Function Information on rainfall data, trunk sewer water levels, and so on are input to the dynamic pumping station simulator and guidance software is used to generate operational advice.

Information on rainfall data, trunk sewer water levels, and so on are input to the dynamic pumping station simulator and guidance software is used to generate operational advice.

Figure 3 — Overview of Planning and Training Exercise Guidance Function A library of recommended operating practices can be built up by simulating different rainfall patterns and pump operating conditions before they occur.

A library of recommended operating practices can be built up by simulating different rainfall patterns and pump operating conditions before they occur.

Figure 4 — Pump Operation Guidance Screen Along with displaying information on rainfall and plant operation, the screens provide useful support for operational decision-making by showing the results of simulating different control modes.

Along with displaying information on rainfall and plant operation, the screens provide useful support for operational decision-making by showing the results of simulating different control modes.

As instances may occur in which the higher inflows experienced by sewage treatment plants during rainfall events results in some of the effluent being discharged without first undergoing biological treatment. The challenges, then, include how to prevent unsanitary conditions and improve water quality in the waterways into which the effluent is discharged. Measures for dealing with these challenges include reducing the amount of discharge by ensuring that as much of the effluent as possible is also treated in bioreactor tanks (secondary effluent)(4). As the final settling tank becomes a bottleneck when there is an increase in the amount of secondary effluent, Hitachi is developing a technique for controlling wastewater treatment during rainfall events that helps maintain stable operation by minimizing sludge outflow from this tank.

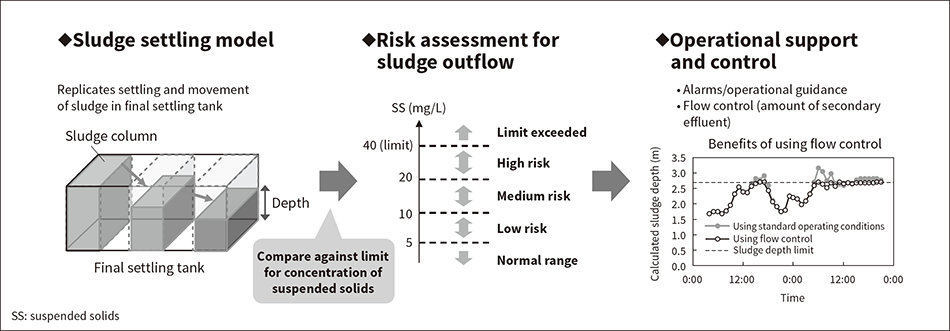

This technique uses a model of the sludge settling process in the final settling tank to assess the risk of sludge outflow and modifies how the operation is managed and controlled accordingly (see Figure 5).

The sludge settling model defines the mass of activated sludge flowing into the final settling tank per unit time as one sludge column. The system simulates the movement and settling of sludge columns in the final settling tank and calculates the sludge depth at the end of the final settling tank to use as an indicator of the risk of sludge outflow. Alarms and operational guidance are updated based on this risk and it is also used in control of how much secondary effluent there is.

Control of how much secondary effluent there is works by calculating an upper limit for this amount that ensures that the calculated sludge depth obtained by the sludge settling model does not exceed its own limit. This reduces discharges of pollution by maximizing the amount of secondary effluent while minimizing sludge outflow from the final settling tank.

Figure 5 — Overview of Operational Support and Control System for Sewage Treatment During Rain This uses a sludge settling model to assess the risk of sludge outflows from the final settling tank and utilizes this information for operational support and control. The aim is to reduce pollution discharges while also minimizing sludge outflow.

This uses a sludge settling model to assess the risk of sludge outflows from the final settling tank and utilizes this information for operational support and control. The aim is to reduce pollution discharges while also minimizing sludge outflow.

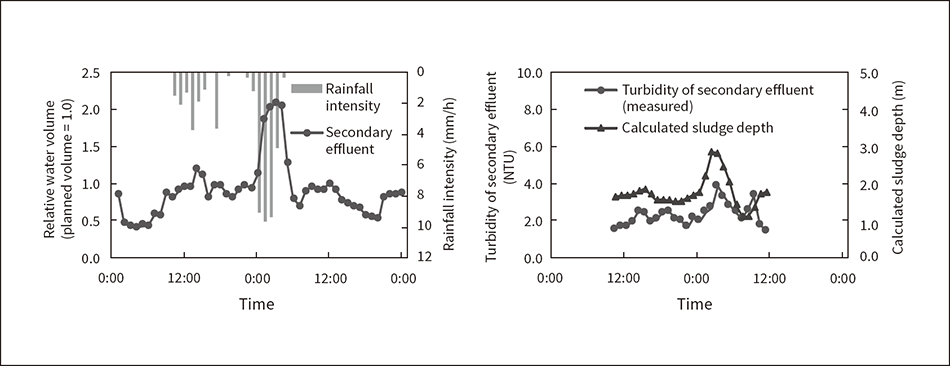

Figure 6 — Results of Sludge Settling Model The results indicate that the sludge depth calculated by the sludge settling model can be used to detect potential sludge outflows (increased turbidity of secondary effluent)(5).

The results indicate that the sludge depth calculated by the sludge settling model can be used to detect potential sludge outflows (increased turbidity of secondary effluent)(5).

A desktop study of the sludge settling model and control logic was undertaken using actual data from the operation of sewage treatment plants during rainfall events(5).

Figure 6 shows an example of plant data and sludge depth calculated by the sludge settling model for a particular sewage treatment plant. The turbidity of secondary effluent increases as the volume of wastewater rises, and this is accompanied by a rise in the calculated sludge depth. This indicates that the sludge settling model can be used to detect potential rises in the turbidity of secondary effluent.

Similarly, the results calculated with flow rate control enabled show that this reduces the risk of sludge outflow, with the sludge depth remaining below the limit as indicated in Figure 5. The calculations also demonstrated that changes to operational settings such as the recirculation rate can amplify the benefits in terms of reducing discharges.

In the future, Hitachi intends to establish control techniques that will help maintain water quality, reduce discharges, and improve the efficiency of wastewater treatment during rainfall events by collecting data from operating plants and testing on pilot systems.

For all that the circumstances under which it operates may continue to change with the times, the importance of sewerage infrastructure remains a constant. Hitachi continues to develop solutions that contribute to the safety, reliability, and efficiency of sewerage systems while keeping pace with changes in the business and natural environments. The aim for the future, meanwhile, is to further lift its involvement in the urban water cycle through its work on monitoring and control technology and digital solutions by putting even more effort into technology development.

The sewage pumping station solution described in this article formed part of independent research by the Hiroshima City B-DASH project and the control technique for sewage treatment during rainy weather was part of joint research with the Laboratory of Professor Hiroaki Tanaka, Graduate School of Engineering, Kyoto University. The authors would like to express their deepest thanks to everyone involved.