Work on Resource Recycling in Hitachi

Creating a Hitachi Groupwide Plastic Recycling Scheme

Plastics have been used for many years in household appliances and many other Hitachi Group products for benefits such as their low weight and lack of rust and corrosion. But these benefits turn into drawbacks when it comes to disposal, and waste plastic is linked to worldwide environmental problems such as soil and ocean pollution, and global warming caused by CO2 emitted when burned. To help solve environmental problems while drawing on the benefits of plastic, Hitachi is working on creating a scheme for recycling the plastics used throughout the group, centered on home appliances. This article provides a detailed look at the scheme, presenting the issues to be tackled in the years ahead.

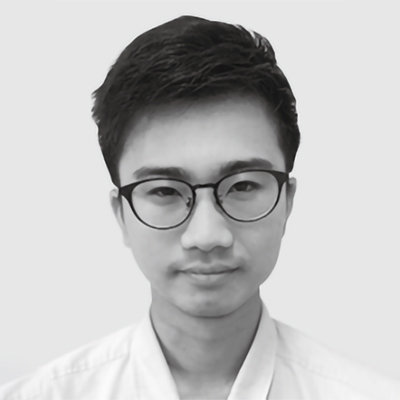

Figure 1 — Amount of Plastics Used in Typical Home Appliances Plastic materials make up about 40% of a typical home appliance overall.

Plastic materials make up about 40% of a typical home appliance overall.

Japan’s Act on Recycling of Specified Kinds of Home Appliances (‘Home Appliance Recycling Law’) went into effect on April 1, 2001. It is designed to promote efficient use of resources and reduce waste through the recycling of plastics and other useful parts and materials from four types of home appliances disposed of by households and offices. The four product types are air conditioners, televisions [cathode-ray tube (CRT), liquid crystal display (LCD), and plasma types], refrigerators and freezers, and washers and driers.

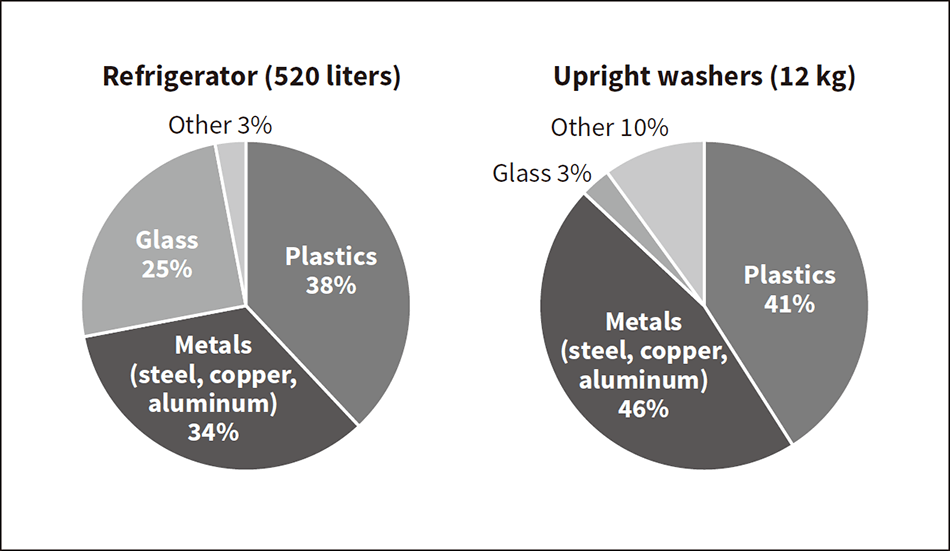

The use of plastics in home appliances is widespread and extensive. A typical refrigerator or washer construction is about 40% plastics for example, underscoring the importance of these materials (see Figure 1). Plastics are made from crude oil, so their market prices are affected by macro factors (politics, economics, and speculation) in addition to supply and demand. As shown in Figure 2, world economic growth and rising demand for crude oil have given crude oil prices a long-term upward trend, making stable procurement of plastic materials more difficult every year.

Hitachi is responding to this issue by promoting plastic recycling in Japan and abroad. Meanwhile, due to the difficulty of maintaining recycling quality overseas and the lack of recycling schemes, the company has begun with Japan-led efforts to promote the use of recycled materials. Hitachi has created a set of long-term environmental targets entitled Hitachi Environmental Innovation 2050 that presents a vision for a ‘resource efficient society.’ The targets include a 50% improvement in resource usage efficiency by 2050 (relative to FY2010). To help achieve that target, the company is using home appliance recycling projects to recycle its own plastic resources. This article describes these activities.

Figure 2 — World Supply and Demand for Crude Oil, and Crude Oil Prices Shown here are the world supply and demand for crude oil from 2000 to 2020 (left), and WTI crude oil prices from 2000 to 2021 (right).

Shown here are the world supply and demand for crude oil from 2000 to 2020 (left), and WTI crude oil prices from 2000 to 2021 (right).

The Home Appliance Recycling Law requires home appliance manufacturers to recycle collected used appliances. Consumers are also asked to do their part by paying an appliance retailer or mass merchandiser a collection fee and recycling fee when disposing of home appliances subject to the act. These fees are used mainly to cover the cost paid by home appliance manufacturers when outsourcing recycling work to recyclers. Collected appliances are brought together at centers run by recyclers in each area of the country. They are recycled by manual disassembly along with processes such as crushing and sorting. At the same time, refrigerant and insulator fluorocarbons contained in appliances such as air conditioners and refrigerators/freezers are also collected and destroyed. Home appliance manufacturers are divided into Groups A and B as shown in Table 1(1). They collect and recycle four types of used appliances throughout Japan. Hitachi belongs to Group B, and owns stakes in three appliance recyclers—Kantou Eco Recycle Co. Ltd., Hokkaido Eco Recycle Systems Co. Ltd., and Tokyo Eco Recycle Co. Ltd. The first of these three operates within the Tochigi Works of Hitachi Global Life Solutions, Inc., where it was established (see Figure 3).

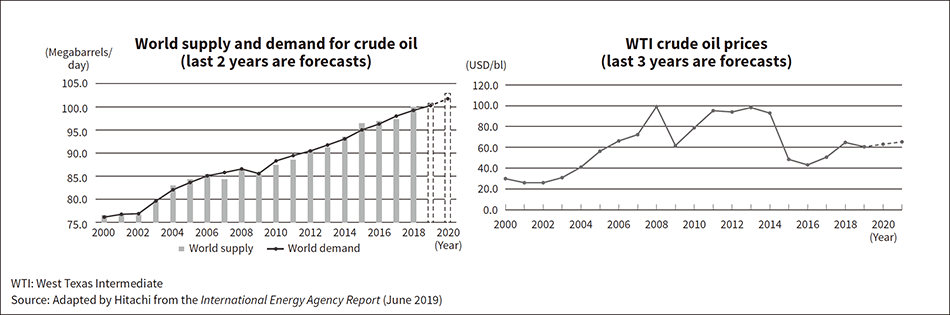

Figure 4 — Major Collectable Plastic Materials for Recycling The major plastic materials that can be collected for recycling are listed here along with their collection rates.

The major plastic materials that can be collected for recycling are listed here along with their collection rates.

Three substances account for 70 to 80% of the plastic materials used in home appliances—polypropylene (PP), polystyrene (PS), and acrylonitrile butadiene styrene (ABS). Figure 4 shows the plastic items that nearly every recycler in Japan collects from used home appliances. Collected items and collection methods vary from recycler to recycler, depending on factors such as the available workforce, crushers, and space.

Since PP and general-purpose polystyrene (GPPS) enable easy identification of parts to recycle, their collectable materials and coloring make them easy to recycle and give them high added value. These materials are therefore collected individually after being crushed in small dedicated crushers. Other mixed plastics first undergo a mixed crushing process along with disassembled parts that can’t be collected individually. Materials are then collected after being sorted according to individual material properties such as magnetism (ferrous metal sorting), specific gravity, eddy current (nonferrous metal sorting), and color. However, today’s home appliances contain a growing amount of PP and GPPS parts that are difficult to recycle, such as plastic parts with insulating urethane or glass wool bonded to them, or parts containing a fixed quantity of glass fibers for reinforcement. Another problem is that some crushers have difficulty generating plastic pellets* from crushed parts if the grain size of the collected parts is not within 10 to 50 mm2.

Figure 5 — Waste Plastic Exports from Japan This graph shows Japan’s waste plastic export quantities from 2016 to 2018. Stricter importing regulations overseas significantly reduced exports in 2018.

This graph shows Japan’s waste plastic export quantities from 2016 to 2018. Stricter importing regulations overseas significantly reduced exports in 2018.

Mixed plastics are mixtures of various types of plastic parts collected from mixed crushing processes. They also contain contaminants such as copper wires and urethane grains that could not be removed during sorting. Some mixed plastics were previously exported to China where the sorting cost was low. However, stricter Chinese environmental regulations have prohibited imports of used plastic parts since January 2018. Since then, Thailand, Malaysia, Vietnam, and Taiwan have accounted for about 80% of all waste plastic exports from Japan. Since environmental awareness is now on the rise there also, import standards are becoming stricter and will make it difficult to continue exporting on the same scale in the future (see Figure 5). A growing number of manufacturers have responded by working on speeding up mixed plastic sorting processes in Japan by installing sorting equipment that can separate mixed plastics into materials such as PP, PS, and ABS. Separation is done mainly by water-based wet methods (specific gravity separation) or non-water-based dry methods (electrostatic separation). Both approaches require high capital investment and maintenance costs, which create barriers to widespread adoption. Japan’s Ministry of Economy, Trade and Industry (METI) has responded by leading a growing nationwide movement toward voluntary waste material export regulations, with support being provided through measures such as subsidies for Japanese companies that install new equipment.

Thermoplastic materials such as PP, PS, and ABS can be reused indefinitely by heating and melting them. On the other hand, to maintain the physical properties demanded, recycled plastic materials (‘recyclables’) require additives such as antistatic agents and antioxidants for preventing thermal degradation. White colorants such as titanium dioxide are also crucial components in recyclables used in the white-colored parts seen extensively in home appliances.

Just counting the members of the Japan Plastic Recycle Association, there are about 150 recyclables producers in Japan. But recyclables are mainly used in products where their use does not greatly affect color or performance, such as pallets, hangers, and plastic products for civil engineering. For general-purpose PP enabling use in home appliances, there are few companies in Japan that can produce and provide quality control for recyclables with controlled physical properties. Hitachi Appliances Techno Service, Ltd. (HAPTS) is a Hitachi Group member that produces recycled pellets (see Figure 6).

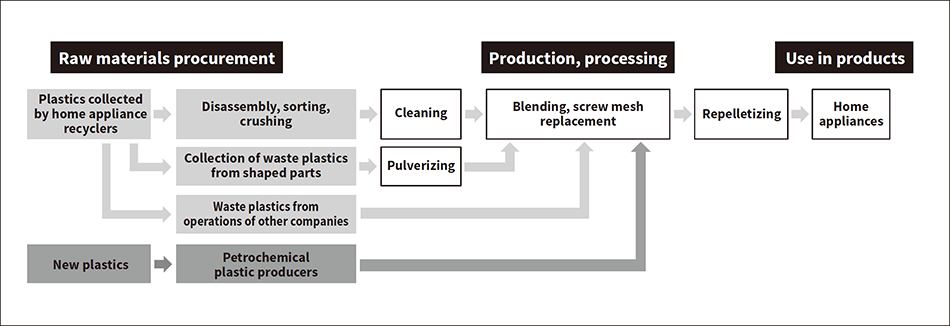

Figure 6 — Flow for Manufacturing Products Using Recyclables Hitachi Appliances Techno Service repelletizes and processes recyclables while maintaining their quality to enable use in home appliances.

Hitachi Appliances Techno Service repelletizes and processes recyclables while maintaining their quality to enable use in home appliances.

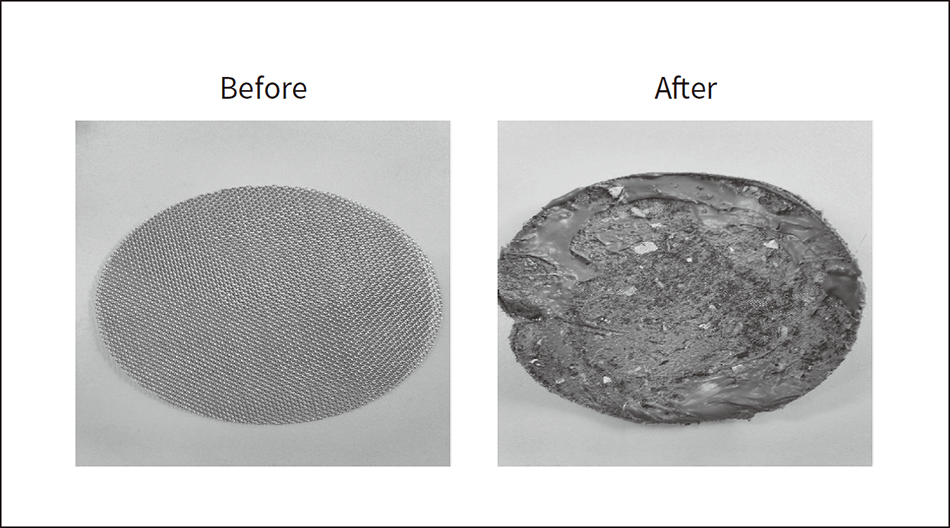

Figure 7 — Screw Mesh Before and Aft er Use Pictured here is a screw mesh before (left) and after (right) use.

Pictured here is a screw mesh before (left) and after (right) use.

The issues facing HAPTS when pelletizing recycled plastics are described below.

To address these problems, HAPTS handles issues with crushed part size and raw material contamination by taking corrective measures when the processes done at its home appliance recycling plant take place. These corrective measures bring together the compound and recycling technologies the company has accumulated over many years. Its low-cost and environmentally conscious recyclables can be used in a wide range of product areas. The quantity of HAPTS recyclables made from used home appliances and used in new products has grown by a factor of about 2.7 over the past 10 years.

Many of the mixed plastics collected from sources such as home appliances can also be recycled through use of polymer alloys (bonding different resins together by adding a resin compatibilizer). Meanwhile, there are concerns over quality, raw material costs, and the costs of manufacturing and pelletizing. To reduce the environmental pollution of plastics, producers will need to tolerate the higher cost of polymer alloys and search for new ways of using recyclables.

Procurement activities for plastic materials have been challenging for some time. In addition to price variations caused by crude oil market conditions, procurement is also affected by supply restrictions imposed by Japanese producers of PP and other plastic materials. These restrictions stem from high demand, aging production equipment and plant problems. These conditions are helping promote greater use of recyclables in the home appliance segment, where sales volumes are high, and discounts are extreme. Meanwhile, in terms of colors, production yield and other areas, new materials are still superior to recyclables. The next section discusses future issues and solutions for recyclables, looking at the example of their use in refrigerators (which grew significantly in FY2018).

The issues encountered by Hitachi when using PP recyclables in refrigerators are described below.

Concern for plastic recycling has been on the rise as developments such as the Basel Ban Amendment to the Basel Convention (regulating the international movement of hazardous waste) have brought the problem of waste plastic to the attention of the public. Meanwhile, despite this growing demand for recyclables, increasing their use will require responses to the following issues.

Unlike products from the bygone era of large home appliances, today’s appliances have functionality and designs that are tailored to diverse lifestyles, which make’s them harder to recycle. Hitachi has responded by proposing the following environmentally conscious design approaches:

Degradation of recyclable physical properties is caused by infiltration of glass or rubber contaminants, or different types of plastic materials. To prevent this degradation, recyclers need to ensure high-accuracy collection of recyclables and adequate contaminant removal.

However, in practice, differences in crushing equipment and workloads result in discrepancies arising between appliance recyclers even for materials collected individually, so that everything except the bare minimum of individually collected parts gets crushed together and ends up as mixed plastics. So finding ways to increase individual collection would yield greater quantities of recyclables.

Procurement and operation issues need to be addressed as described below.

Manufacturers previously only procured recyclables when they were cheaper than new materials that had varied in price due to crude oil price movements. The recycling suitability of recyclables like white PP materials collected from used home appliances also creates high demand, making it difficult to find new suppliers for them. As previously mentioned, the Hitachi’s procurement activities go beyond just dealing with recyclables producers. The Value Chain Integration Division of Hitachi, Ltd. and Hitachi Global Life Solutions work together to visit home appliance recyclers and deal with them directly. Since future business growth will require more sources for raw materials procurement, Hitachi will be looking into procuring materials from other home appliance recyclers throughout Japan, and using recyclables from sources other than home appliances.

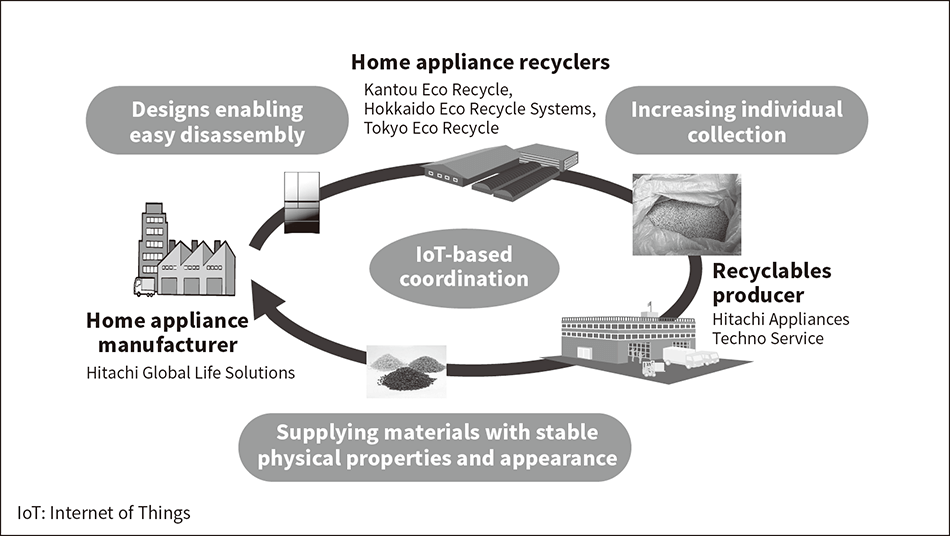

Figure 8 — Scheme Used for Recycling Plastic Material Resources within Hitachi Hitachi’s home appliance recyclers, recyclables producer, and home appliance manufacturer are the key requirements for promoting resource recycling and improving the rate of recyclables use within Hitachi.

Hitachi’s home appliance recyclers, recyclables producer, and home appliance manufacturer are the key requirements for promoting resource recycling and improving the rate of recyclables use within Hitachi.

Among companies with high rates of recyclables reuse, home appliance recyclers, recyclables producers and home appliance manufacturers are coming together to work on recycling their own resources through comprehensive technology development and quality control. Figure 8 illustrates the scheme used for recycling resources within the Hitachi. In the years ahead, Hitachi is going to work on recycling its resources by using the Internet of Things (IoT) for better information-sharing and coordination among business units.

Hitachi has consistently recycled the resources it uses by collecting plastic from used home appliances. These efforts have continued to this day, enabling the company to use more recycled PP materials in its refrigerators. The recycled PP content of its refrigerators was at one time about 20%, and had risen to about 50% in FY2018. The group plans to continue working on raising this figure, eventually getting it near 100%. It also plans to use more recyclables in other home appliances, to recycle other plastics such as PS and ABS, and to use more recyclables in other Hitachi products such as automotive parts. Hitachi will also help promote sustainability by looking into areas such as greater use of environmentally conscious and readily recyclable plastics, and use of the biodegradable plastics that are attracting interest today.