Smart Life Solutions for People Everywhere

Environmental measures have risen in importance in recent years, with companies taking active steps to help achieve the Sustainable Development Goals and operate their businesses in accordance with environmental, social, and governance criteria. Based on its corporate mission of “contributing to society through the development of superior, original technology and products,” Hitachi has, since it was first established, sought to build a sustainable society by focusing its efforts on its Social Innovation Business for resolving societal challenges. Moreover, it has also committed itself in its 2021 Mid-term Management Plan to operating its business in a way that prioritizes social, environmental, and economic value. Meanwhile, as an early starter in the field of home appliance recycling, Hitachi has been involved in the recycling business on its own account as well as through its pursuit of technology development based on government direction and industry collaboration. This has also included the re-use of plastic from home appliance recycling in new home appliances(1). This article describes the work Hitachi is doing on home appliance recycling as it seeks to bring about a resource-efficient society.

The Act on Recycling of Specified Kinds of Home Appliances (Home Appliance Recycling Law) was enacted in June 1998 and came into full force in April 2001 after an initial phase-in period. Applying to four categories of appliances (refrigerators and freezers; washing machines and clothes dryers; room air conditioners; and cathode-ray tube, liquid crystal, and plasma televisions), the law seeks to ensure that used appliances are disposed of appropriately and that the materials they contain are put to good use. It asks consumers to play their part in the recycling process by returning unwanted appliances to a retailer and paying fees for recycling, and for collection and transportation. It also imposes an obligation on appliance manufacturers to recycle the returned products and to turn them into useful goods. Collected appliances are taken to regional recycling plants for processing into new products, a process that includes dismantling, crushing, and sorting. Along with separating and collecting the valuable materials such as steel, copper, aluminum, and plastics from the unwanted appliances, this also includes extracting the freon coolant from refrigerators and air conditioners so that it can be disposed of safely.

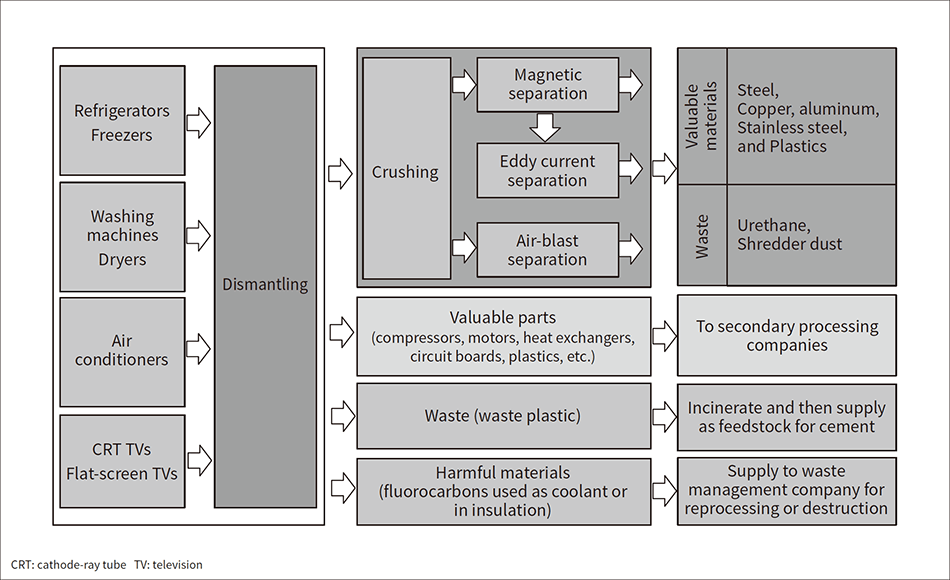

Home appliance recycling in Japan got its start with a project entitled “Development of Integrated Recycling System for Used Home Appliances” in which the Association for Electric Home Appliances (AEHA) invested a total of 5 billion yen over the four years from 1995 to 1998, receiving funding from what was then the Ministry of International Trade and Industry. This project sought to develop systems for the efficient collection of useful materials using processes that are both safe and non-labor-intensive. To achieve this, a pilot plant for home appliance recycling was established in Naka-machi (now Naka City) in Ibaraki Prefecture to operate on a trial basis, handling all of the steps from receiving the used appliances to dismantling, crushing, sorting, collection of valuable materials, and ensuring that the remaining materials are rendered harmless(2). Hitachi was contracted by AEHA to lead the project and design the overall process, and also to develop and test techniques for collecting fluorocarbons from the insulation in refrigerators, a measure for protecting against ozone layer depletion. The recycling plants now found around Japan make use of this work in a variety of ways and the process has been broadly adopted nationwide(3) (see Figure 1).

Fig. 1—Home Appliance Recycling Process Used appliances are recycled through a process that includes dismantling, crushing, and sorting. Along with separating and collecting the valuable materials such as steel, copper, aluminum, and plastics from unwanted appliances, this also includes extracting the freon coolant from refrigerators and air conditioners so that it can be disposed of safely.

Used appliances are recycled through a process that includes dismantling, crushing, and sorting. Along with separating and collecting the valuable materials such as steel, copper, aluminum, and plastics from unwanted appliances, this also includes extracting the freon coolant from refrigerators and air conditioners so that it can be disposed of safely.

Home appliance recycling in Japan is handled by two separate groups of companies. Group A includes Panasonic Corporation and Toshiba Corporation, and Group B includes Hitachi Global Life Solutions, Inc., Mitsubishi Electric Corporation, Sharp Corporation, Sony Corporation, and Fujitsu General Limited. Appliance manufacturers join one or another of these groups to fulfill their recycling obligations and outsource the actual recycling to the plants belonging to their particular group. There are currently (as of the end of June 2019) 47 of these plants located around Japan (28 operated by Group A, 17 by Group B, and two operated jointly). While most of the Group A recycling plants are existing facilities run by major industrial waste processing companies, the Group B recycling plants are largely run by newly established operating companies set up by the main Group B member companies.

Hitachi has been actively engaged in the development of processes and other technology for home appliance recycling and has also contributed to the commissioning and operation of the Group B plants. This has included not only its active participation in the recycling business, but Hitachi has also established Hokkaido Eco Recycle Systems Co., Ltd., Kantou Eco Recycle Co., Ltd., and Tokyo Eco Recycle Co., Ltd. with a view toward commercializing technologies that it has developed and tested at recycling plants (see Figure 2). Together, these three companies process 1.34 million used appliances annually, representing about 10% of the total of 13.63 million appliances(4) processed by all of the Group A and B plants across Japan (figures are for FY2018).

Fig. 2—Hitachi’s Appliance Recycling Centers The map shows the locations of Hitachi’s appliance recycling centers run by Hokkaido Eco Recycle Systems Co., Ltd., Kantou Eco Recycle Co., Ltd., and Tokyo Eco Recycle Co., Ltd.

The map shows the locations of Hitachi’s appliance recycling centers run by Hokkaido Eco Recycle Systems Co., Ltd., Kantou Eco Recycle Co., Ltd., and Tokyo Eco Recycle Co., Ltd.

The Home Appliance Recycling Law sets legal criteria for the percentage of appliances that are recycled (defined in terms of the total weight of recycled material as a percentage of the weight of used appliances that enter the recycling process). In the case of washing machines and dryers, for example, appliance manufacturers are obliged to achieve a recycling rate of 82% or more. To achieve this, Hitachi makes an effort to design its products in ways that make them easy to recycle by undertaking life cycle assessment (LCA) during development, also striving to comply with the legal requirements by means of annual tests of recycling rates conducted at all of the Group B recycling plants.

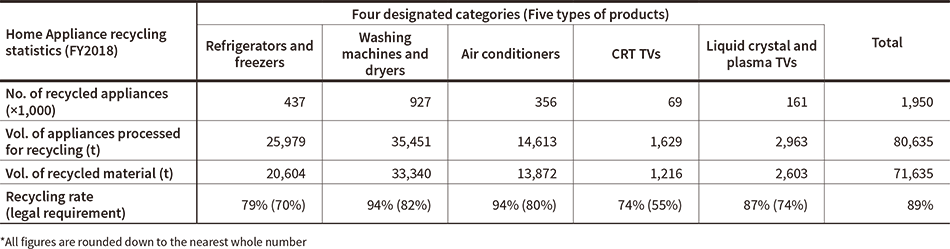

In FY2018, Hitachi (in the form of Hitachi–Johnson Controls Air Conditioning, Inc. and the now merged companies of Hitachi Consumer Marketing, Inc. and Hitachi Appliances, Inc.) processed a total of about 1.95 million used appliances in the four applicable categories with a total weight of about 81,000 t, from which about 72,000 t was recycled into useful materials. The recycling rates exceeded the legal criteria for all four product categories (see Table 1).

Table 1—Home Appliance Recycling Statistics for FY2018 While “recycling” in this context means both material recycling (transformation into a form that can be supplied as parts or materials, with or without monetary value) and thermal recovery (burning to obtain thermal energy), the recycling percentage required by law refers to material recycling only.

While “recycling” in this context means both material recycling (transformation into a form that can be supplied as parts or materials, with or without monetary value) and thermal recovery (burning to obtain thermal energy), the recycling percentage required by law refers to material recycling only.

Hitachi has continued to pursue the pre-emptive development of environmental technology based on the techniques developed at the pilot plant for home appliance recycling. This section describes one example of this work: an apparatus for removing glass wool.

Since around 2004, the traditional urethane insulation used in refrigerators has been augmented by vacuum insulation panels that offer higher levels of thermal insulation. As a consequence, the volume of refrigerators equipped with these panels entering the recycling stream has slowly increased. Unfortunately, whereas the urethane insulation stripped out of refrigerators at recycling plants can be used as a solid fuel, the presence of the glass wool used in vacuum insulation degrades fuel quality. Overcoming this problem required the development of a way to remove the glass wool from the collected urethane insulation during recycling.

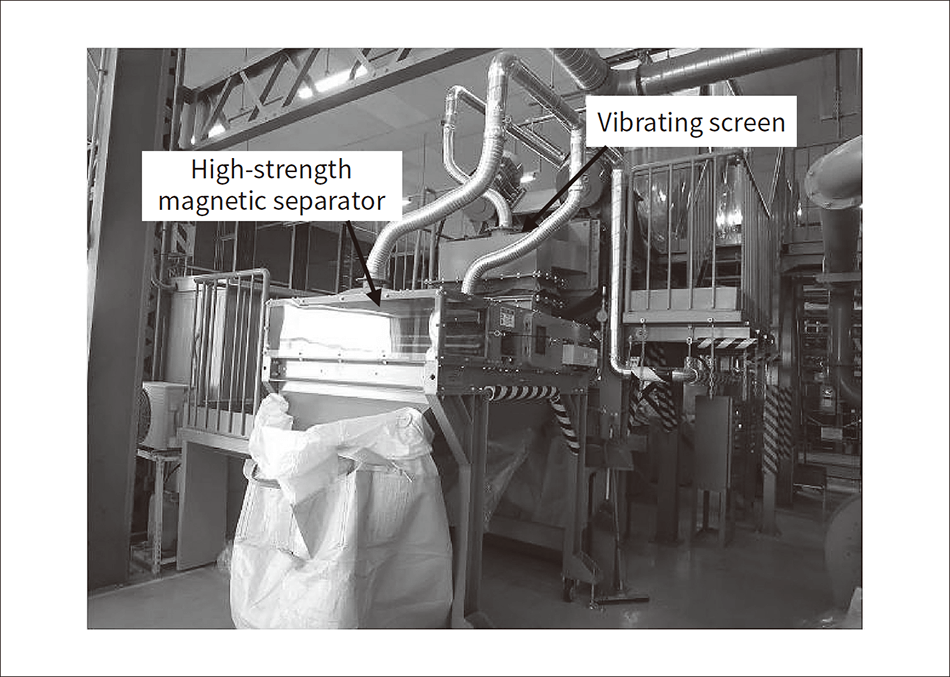

The apparatus developed for this purpose uses vibrating screens and magnetism to efficiently separate the urethane insulation and glass wool, exploiting the fact that iron filings become lodged in the glass wool during the process of dismantling the appliance (see Figure 3). The vibrating screens use perforated sheet metal (with φ2-mm holes) to remove the granular glass wool, with the glass wool then being collected by magnetic separation performed using a high-strength magnetic pulley at the end of the belt conveyor that produces a magnetic field of 0.8 T at the surface of the conveyor. Passing through these two mechanisms removes the glass wool from the urethane. The urethane produced by this process is compressed and extruded through a metal die perforated with φ8-mm holes to form it into solid fuel granules. The end product is called refuse-derived paper and plastics densified fuel (RPF). Although being a thermosetting plastic makes urethane difficult to re-use, its high calorific value means that RPF made largely from urethane is classified as a class A fuel under Japanese Industrial Standards (JIS) (see Table 2) and it can be utilized as a high-quality solid fuel. Development of the apparatus was undertaken jointly with technical assistance from the Water Solutions Division of Hitachi’s Water & Environment Business Unit and installation of the apparatus at Kantou Eco Recycle.

Fig. 3—Apparatus for Removing Glass Wool The apparatus removes glass wool (part of the vacuum insulation) from the urethane extracted from dismantled refrigerators.

The apparatus removes glass wool (part of the vacuum insulation) from the urethane extracted from dismantled refrigerators.

Table 2—RPF Quality The criteria below are from the JIS (JISZ7311).

The criteria below are from the JIS (JISZ7311).

This article has described what Hitachi has been doing in the field of home appliance recycling to bring about a resource-efficient society. That the Home Appliance Recycling Law has become part of the framework of a resource-efficient society since entering full force in April 2001 is attributable to the efforts made to comply with its provisions and undertake higher-level initiatives by the various parties that play important roles in the operation of the law. Hitachi intends to continue contributing to creating a circular economy and resource-efficient society by continuing to work on recycling technologies in pursuit of better performance and high quality.