Innovation for Next-generation Energy

[ⅲ]Energy Management

Hitachi has completed a study of a microgrid designed for greater power resilience in times of crisis. It is part of a system that will use the SGET Ashikita Otachimisaki Megasolar facility (1,980 kW) currently operating in the town of Ashikita, Kumamoto Prefecture as its main power source. The system will supply power to five area recipients such as evacuation sites. To lower the cost of constructing private lines, the microgrid will use existing distribution lines of the Kyushu Electric Power Transmission and Distribution Co., Inc. for power transmission from the Otachimisaki Megasolar facility to power recipients. This article focuses on technical study of the microgrid’s configuration and control and protection system. It reports on the system handling needed for actual system construction, and the challenges for operation.

The destruction caused by the Hokkaido Eastern Iburi Earthquake in 2018 and by typhoons Faxai and Hagibis in 2019 has reinforced the importance of improving power system resilience(1). At the same time, there are growing expectations for local power supply systems with integrated supply and demand that use local renewable energy(2). But power supplied over private lines is the core of conventional local power supply systems, making the cost of private line construction one obstacle to creating these systems.

Hitachi has responded by completing a study on a power supply system for use in times of crisis that will rely on a microgrid that uses an existing distribution grid to lower costs. Since it will be a new system unlike conventional facilities, the system was studied with help from partners such the local government (the town of Ashikita, Kumamoto Prefecture) and a distribution system operator (DSO) (Kyushu Electric Power Transmission and Distribution Co., Inc.) to cover areas ranging from technical questions to power scheme-related issues. The system will use an existing 1,980 kW megasolar facility as the microgrid’s main power source, and use new storage batteries for power balancing control.

The system’s main power source will be the SPARX Green Energy & Technology (SGET) Ashikita Otachimisaki Megasolar facility (1,980 kW) currently operating in Ashikita, Kumamoto Prefecture. The area selected as the microgrid service area will contain five locations that require power in times of crisis, such as designated evacuation sites. Existing distribution lines of the Kyushu Electric Power will be used to transmit power from the SGET Ashikita Otachimisaki Megasolar facility to the power recipients.

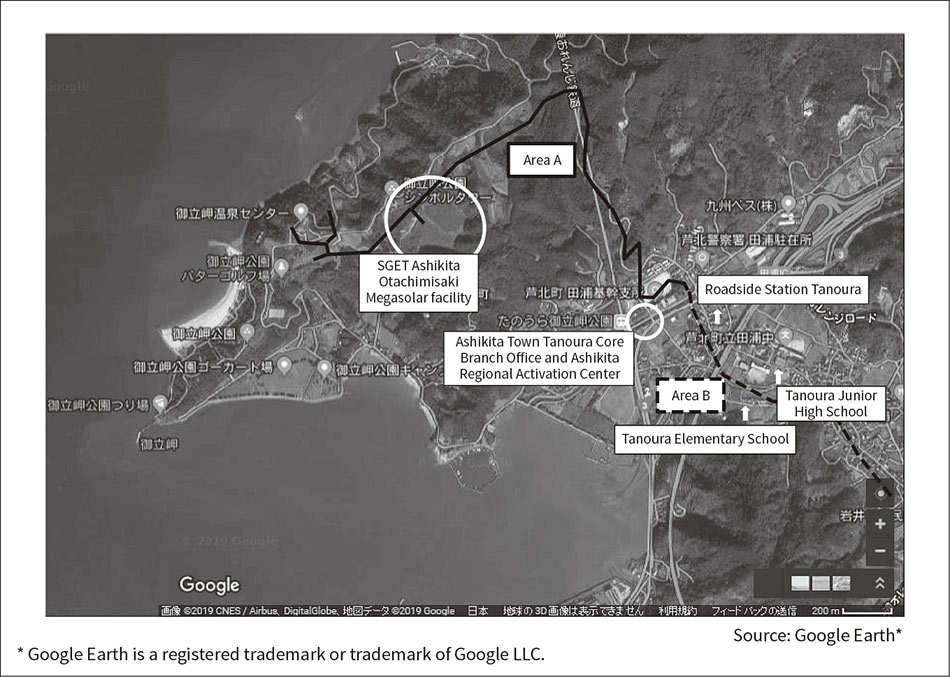

At the request of the town of Ashikita, a total of five locations were selected as microgrid power recipients—the Ashikita Town Tanoura Core Branch Office (a civil defense center), along with the Ashikita Regional Activation Center, Tanoura Elementary School, Tanoura Junior High School, and Roadside Station Tanoura (designated evacuation sites). Figure 1 depicts the megasolar facility and these power recipients, along with the existing distribution lines connecting them. This area is the microgrid service area.

In terms of distribution grid operation, this area consists of Area A, enclosed by the solid lines in Figure 1, and Area B, enclosed by the broken lines. Area A, which is connected to the megasolar facility, and Area B, which is connected to the power recipients, will be operated as separate grids during normal operation, so the boundary zone switches normally open during microgrid operation will be closed. For branch lines that are not involved in supplying power to evacuation sites, it was decided to turn off the zone switches of branch points. It was also decided that operations such as turning these switches on or off will be handled by Kyushu Electric Power as part of the microgrid construction operations done during power failures.

In addition to evacuation sites, the microgrid constructed by the operations above will also connect to general power consumers. The area’s power demand during normal operation will have a day/night average of about 600 kW. Since the megasolar facility serving as the main power source will not be able to generate power at night or when it is raining, reducing the power demand of general power consumers without disruptions will be a key issue. Enabling this demand reduction without installing terminals or other equipment at each power consumer site will require operation-based techniques.

Fig. 1—Microgrid Service Area The main power source during microgrid operation will be the SGET Ashikita Otachimisaki Megasolar facility, and there will be five power recipients such as designated evacuation sites. Existing distribution lines (Area A and Area B) of the Kyushu Electric Power will be used for power transmission.

The main power source during microgrid operation will be the SGET Ashikita Otachimisaki Megasolar facility, and there will be five power recipients such as designated evacuation sites. Existing distribution lines (Area A and Area B) of the Kyushu Electric Power will be used for power transmission.

Fig. 2—System Configuration The megasolar output is weather-dependent and highly variable. The supply and demand balance in the microgrid will be controlled by a 500 kWh storage battery system. The storage batteries will enable use as an emergency power source if power generation from the megasolar facility shuts down.

The megasolar output is weather-dependent and highly variable. The supply and demand balance in the microgrid will be controlled by a 500 kWh storage battery system. The storage batteries will enable use as an emergency power source if power generation from the megasolar facility shuts down.

The microgrid’s main power source is an existing 1,980 kW megasolar facility. The megasolar output is weather-dependent and highly variable. Since stable microgrid operation will require balancing capacity to absorb this megasolar output variation, Hitachi is planning to install storage batteries to provide balancing capacity.

Figure 2 shows the system configuration incorporating the storage batteries. The site of the Ashikita Town Tanoura Core Branch Office (also serving as a civil defense center) was selected as the storage battery installation location for a number of reasons. For example, the storage batteries will enable use as an emergency power supply if the megasolar facility becomes inoperable during a crisis. They can also be used effectively during normal operation. The storage batteries and megasolar facility will require coordinated operation, so communication equipment will be installed to connect them.

Recovery from the blackouts caused by the Hokkaido Eastern Iburi Earthquake that occurred in 2018 took 44 hours and 48 minutes(3). Hitachi used this amount of time as a guideline to install capacity that would enable the bare minimum supply of power for 3 days (72 hours) in times of crisis from the storage batteries alone. The bare minimum power supply was estimated at 93 kWh/day based on a prior study of Ashikita, and a storage battery capacity of 500 kWh was set to provide a margin of safety.

The output rating of the storage battery power conditioning system (PCS) was set based on the required balancing capacity and maximum power demand. The maximum megasolar output is 1,980 kW, and the maximum balancing capacity needed is also 1,980 kW, but this figure would require excessive equipment. Hitachi therefore decided to reduce the required balancing capacity by controlling the maximum megasolar output in response to the supply and demand conditions, and the state of charge (SOC) of the storage batteries. The maximum power demand was estimated at about 500 kW, based on the assumption that it can be reduced using operation-based techniques such as gaining broad-based prior knowledge of the power demand of general power consumers. For these reasons, the output rating of the storage battery PCS was set at 500 kW.

Fig. 3—Controlling Supply and Demand Balance The storage batteries start charging when the megasolar output becomes high, and start discharging when the megasolar output becomes low. The maximum megasolar output is reduced to keep the storage battery SOC at the right level.

The storage batteries start charging when the megasolar output becomes high, and start discharging when the megasolar output becomes low. The maximum megasolar output is reduced to keep the storage battery SOC at the right level.

The storage battery PCS operate as a voltage source to maintain a constant grid voltage and automatically controls the power in response to the deviation between the megasolar output and the demand. If high megasolar output creates an oversupply, the storage batteries start charging. If the megasolar output falls below the demand, the storage batteries start discharging. The right amount of excess charge/discharge capacity must be ensured to enable the storage batteries to maintain this type of balancing capacity, so the maximum megasolar output will be controlled in response to the storage battery SOC. Figure 3 shows how this control will be performed.

Distribution grids are usually protected against ground faults and short circuits by protective relays installed in the DSO’s distribution substation. But, since the system’s distribution grid will be isolated from the substation when the microgrid operates, the megasolar facility and storage batteries will need their own protective functions. So the megasolar facility and storage batteries will be provided with the protective relays labeled 27 and 64 in Figure 2. These relays will detect and protect against ground faults and short circuits. When a fault is detected, they will automatically shut down both the storage batteries and the megasolar facility to protect the distribution grid.

Fig. 4—Example Supply and Demand Balance Control Simulation Results Shown here are the results of a supply and demand balancing simulation for three consecutive days with a cloudy weather power generation pattern. The supply and demand balance is controlled by having the storage batteries control their charging/discharging in response to the megasolar output. The storage battery SOC is kept within its maximum and minimum value range, indicating the system is being operated stably.

Shown here are the results of a supply and demand balancing simulation for three consecutive days with a cloudy weather power generation pattern. The supply and demand balance is controlled by having the storage batteries control their charging/discharging in response to the megasolar output. The storage battery SOC is kept within its maximum and minimum value range, indicating the system is being operated stably.

To demonstrate the effectiveness of the supply and demand balance control described in the previous section, a supply and demand balance control simulation was carried out using the Otachimisaki Megasolar facility’s typical power generation conditions and demand conditions. Past operation data was used to select typical clear- and cloudy weather days as power generation conditions for the megasolar facility. To anticipate multiple demand patterns, three days of consecutive operation were targeted for simulation. Stable operation would be indicated by the storage battery SOC remaining within a range of about 10% to 90% with the charge/discharge power never exceeding the 500 kW rating over the entire period.

The simulation showed that stable operation can be achieved if the maximum megasolar output is properly controlled, demonstrating the effectiveness of the basic control. Demand needed to be restricted in cloudy weather or at other times when the megasolar facility’s generated power output was inadequate. Figure 4 shows an example simulation using the most demanding conditions—cloudy weather resulting in maximum supply capacity in the morning of the following day.

Fig. 5—Example Voltage Variation Analysis Results Shown here are the results of voltage variation analysis done using a grid analysis simulation tool. The percentage values shown are the voltage values at each location relative to a rated voltage of 100%. This analysis demonstrated that the voltage values at each location remained within ±6% of the rated voltage.

Shown here are the results of voltage variation analysis done using a grid analysis simulation tool. The percentage values shown are the voltage values at each location relative to a rated voltage of 100%. This analysis demonstrated that the voltage values at each location remained within ±6% of the rated voltage.

Japan’s Electricity Business Act (Enforcement Regulation) demands distribution grid voltage to be kept within ±6% of the rated voltage. Deviation from this range may result in electrical product malfunction or failure. The system’s voltage will vary depending on the demand distribution in the microgrid, and the relative load allocations of the megasolar facility serving as the main power source, and the storage batteries handling supply and demand balancing. Accordingly, Hitachi used a grid analysis simulation tool to analyze the voltage values during microgrid operation for each area with a zone switch in the microgrid. For every operation pattern modeled, the simulation results showed grid voltages within ±6% of the rated voltage, demonstrating the system’s ability to ensure quality. Figure 5 shows example results.

The work done on this study gave Hitachi an overview of the basic technical aspects involved in a microgrid. Future work on creating this system will involve studies that incorporate detailed aspects of controlling the coordination of the storage batteries and megasolar facility, and the use of power generation output forecast data. The study described in this article has elucidated both technical issues and operation issues. Its major findings are as follows:

Hitachi is planning further studies to create the microgrid described in this article. This work will include handling technical issues, operation issues, and power scheme-related issues.

This study was ordered by SGET Ashikita Otachimisaki Megasolar, LLC., an organization commissioned to create the master plan for the microgrid construction assistance project as part of a FY2018 Ministry of Economy, Trade and Industry (METI) subsidy for storage batteries enabling renewable energy power supply in times of crisis. The study was assisted by SGET Ashikita Otachimisaki Megasolar, LLC. and Sparx Green Energy & Technology Co., Ltd. The authors also received data and advice from the town of Ashikita and the Kyushu Electric Power Transmission and Distribution Co., Inc. The authors would like to express their heartfelt appreciation to all those involved.