COVER STORY:ACTIVITIES 1

Designs that Enhance Experience Value to Deliver Comfortable Mobility

Hitachi undertakes its Social Innovation Business with the aim of enhancing people’s QoL and achieving the sustainable development of society by engaging in co-creation with customers and other partners to overcome the challenges facing society. Hitachi’s Global Center for Social Innovation – Tokyo, which in 2019 established the Kyōsō-no-Mori “Collaboration Forest” as a research and development facility for accelerating innovation through open co-creation, sees product design, service design, and vision design as the three core competencies of its design platform, undertaking this work on the basis of an experience design approach that addresses such issues as user satisfaction and other aspects of experience value. For this article, Hitachi Review spoke with designers involved in projects at the forefront of this work about the initiatives they are engaged in, using examples such as rolling stock for overseas railways and elevator and escalator systems for smart buildings to discuss such matters as the design concepts they use, how these are put into practice, and their plans for the future.

Modern society faces a myriad of challenges including global warming, population growth, and urbanization. Mobility systems, meanwhile, are seen as having an important role to play in addressing these issues, including both the railways that provide public transportation with low levels of greenhouse gas emissions and the elevators and escalators that help people move around in cities. As part of the public infrastructure used by a large number of people, it is important that these products be designed in ways that take in a broad range of considerations, encompassing not only performance and functionality, but also ease-of-use, ride comfort, and aesthetic appeal.

Akira Omachi (Senior Designer, Product Design Department, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd.) made this point as follows,

“In our view, the top priority when designing products that are integral to daily life, such as trains, elevators, and escalators, or automated teller machines (ATMs), is to ensure that they integrate seamlessly into society. An important part of this is to keep up with the changes in people’s values by engaging in co-creation with stakeholders to obtain a deeper understanding of how the social environment shifts over time or across different communities.”

Hitachi has a track record of utilizing advanced design practices, including being among the first to adopt “experience design,” which means designing in ways that consider experience values such as satisfaction and emotional response. In 2015, Hitachi established its Global Center for Social Innovation as part of the Research & Development Group to serve as a facility for working with customers and other partners on the co-creation of solutions, bringing designers and researchers together with customers to devise such solutions using the NEXPERIENCE methodology that Hitachi developed specifically for this purpose.

Hitachi is undertaking its design activities seeing product design, service design, and vision design as the three core competencies of its design platform. The product and service designs that result from this work are assessed in terms of experience design with the aim of producing designs that integrate seamlessly into society. In the case of product designs for trains, elevators, and escalators, Natural Support, a design that provides public utility through efficient infrastructure to make daily life go smoothly.

Omachi also makes the point that, because the organizations that purchase these products are different from the people who use them, it is also essential to consider how value is perceived by these two distinct groups and to come up with designs that will be accepted by the public as well as integrating seamlessly into society.

To illustrate how rolling stock design happens in practice, the following section looks at two projects for overseas customers. The first is the development of the Class 800 rolling stock for the UK Intercity Express Programme (IEP) that commenced commercial operation in 2017. The second is a project currently underway to develop Intercity Electric Multiple Units (EMU) for Taiwan.

The Class 800 is based on the Class 395 high-speed train that entered service between London and Kent in 2005. Given that the Class 800 project involved more than 800 cars operating between London and other major cities, build quality, safety, and reliability were all key considerations in the rolling stock design. One of those involved in the design work was Yuichiro Kota (Senior Designer, Product Design Department, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd.). He described the concept for the train’s exterior shape as follows.

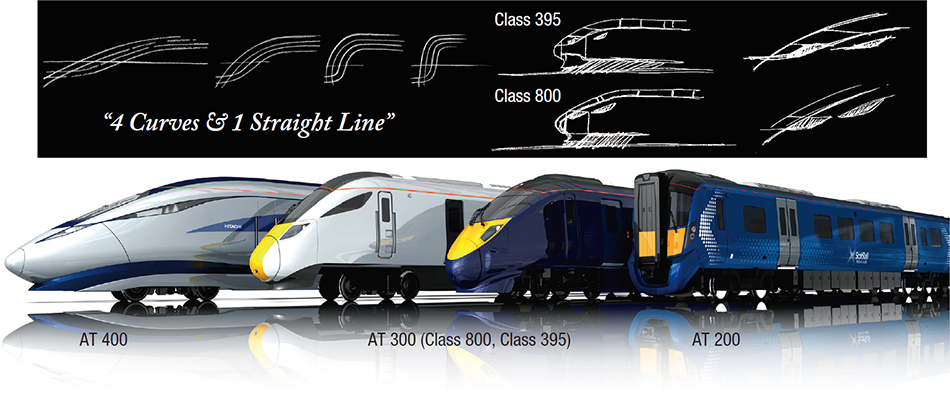

Figure 1 | Four Curves & One Straight Line Design Concept

“As Hitachi was a late arrival in the European market, our first objective was to establish the Hitachi brand. We were conscious that giving the train a distinctive visual identity was a good way to achieve an exterior design that both fit in with its surroundings and was recognizably the work of Hitachi. Our past practice had been to use what we called the “One Motion Form” design for the front-end shape of our high-speed trains. This was characterized by use of a flowing profile that took the form of a single, smoothly curving line from the front-end of the train to the body, as used on the earlier Class 395 development. The Class 800, however, took this concept a step further, adopting a design we called “Four Curves & One Straight Line” (see Figure 1). Here, the “one straight line” is the line from the bottom of the driver’s windscreen across the top of the head lights to the bottom of the side windows, and the “four curves” are, respectively, the centerline of the train, the line from the front-end of the train to the body (the “character line”), and the two curves that run from the top of the train to the front-end and encompass the headlights (in the process crossing over the centerline and character line).”

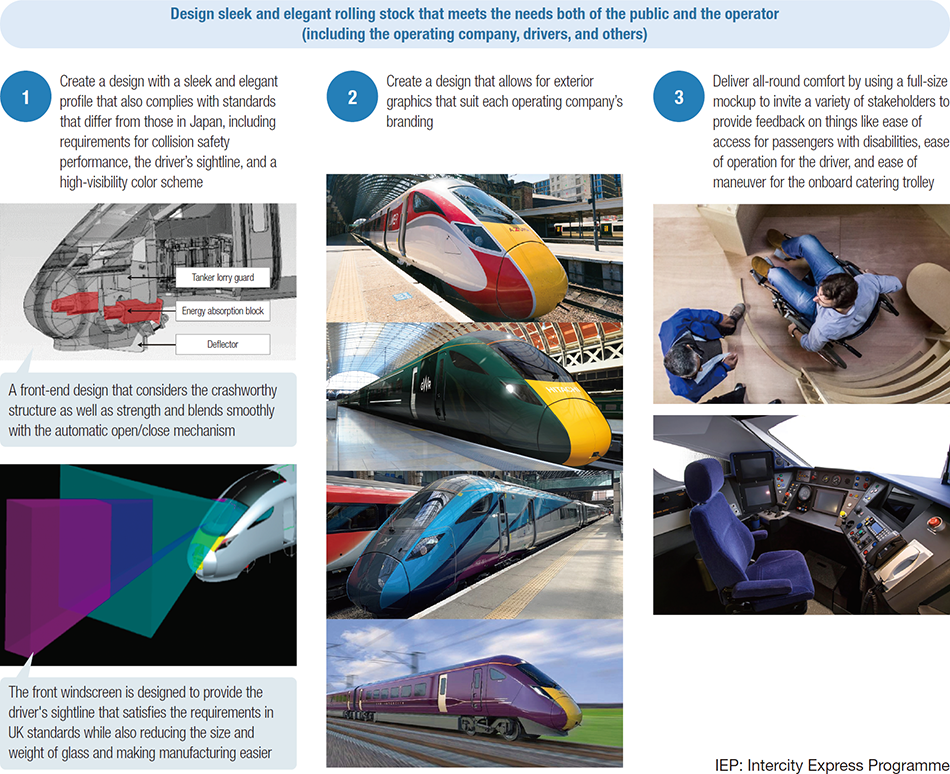

This was the basis on which the design concept was finalized. The next challenge was posed by European railway standards and requirements that were different from those in Japan, being based on a different approach to safety. Standards in Europe, including the UK, contain detailed stipulations covering things like the deceleration in the event of a collision, a space for protecting the driver, an adequate field of view for the driver, and the color scheme to use in order to make the approaching train easier for any one to see. In terms of collision safety, a sleek design that conveys a sense of speed without compromising aerodynamic performance was achieved by reducing the size of the components used in the energy absorption block located at the front-end of the train and adjusting their orientation. Similarly, the exterior design was done in cooperation with the design engineers so as to satisfy the differing requirements of the rolling stock leasing company, consultants, and operating company, while still complying with the various other standards (see Figure 2).

Figure 2 | Total Design and Development involving Class 800 Rolling Stock for UK IEP

Moreover, given that the order was for more than 800 cars, the design team also focused on ease of production and maintenance as well as on delivering an attractive appearance at the same time as complying with the strict European standards.

As Yuichiro Kota, commented, “One example relates to how, with the Class 800, we had to satisfy standards for the driver’s sightline and customer requirements for that of co-drivers. Unfortunately, making the windscreen larger to satisfy the field of view requirement conflicts with the objective of reducing weight, a desirable feature on high-speed trains. To overcome this, we determined the optimal driver position and front windscreen angle that would satisfy the requirement. We also succeeded in making production and part replacement easier by lowering the support frame from the main surface of the car body for the front windscreen.”

The Class 800 entered service in 2017. It was subsequently awarded the Imperial Invention Prize at the 2019 National Commendation for Invention. This was the first time in the history of this invention prize that it had been awarded to a design registration. The award recognized how the design was not only aesthetically pleasing, but also comprehensive in how it overcame the different standards while delivering a train that was easy for the operating company to use and also comfortable in a way that blends seamlessly into local users’ lifestyle and culture.

The work done on developing the Class 800 design was also carried over to the development of an express train for the Taiwan Railways Administration, MOTC (TRA). In preparing to bid for this work, Hitachi consulted with people in Taiwan and conducted surveys along the planned route, coming up with a proposed design that was based on its standard Class 800 (AT 300 series) rolling stock while also taking account of circumstances in Taiwan. In presentations to the customer, Hitachi conveyed the attractiveness of the design while also highlighting advanced technologies such as the energy efficiency of its control systems, a key feature of Hitachi rolling stock. This led to an order being received for 600 Intercity EMU cars in December 2018.

An initial meeting following the awarding of the contract was held in June 2019 and attended not only by Hitachi and TRA, but also by a group of design experts organized by the customer. Unfortunately, the initial design proposal was not well received. Sho Nozue (Designer, Product Design Department, Global Center for Social Innovation – Tokyo, Research & Development Group, Hitachi, Ltd.), one of those involved in the work, explains why.

“The initial design was too heavily biased toward conveying the sort of festive scenes and natural beauty that a typical tourist would expect to see in Taiwan. It became clear that we had not adequately taken onboard the desire of TRA to have a design that was representative of modern Taiwan rather than its stereotypical image. This highlighted for us just how much of a difference there was between what the customer had in mind and how Taiwan is perceived by people from other countries, so it was just as well that we were able to get our thinking aligned from an early stage.”

Having established that their objective was to create an express train that they could be proud of, the three partners (TRA, the design experts, and Hitachi) embarked on a process of co-creation. Sho Nozue recounts how the workshops they held on a monthly basis were devoted to just this task of coming up with ideas on how they could design such a train. After considering a variety of reference material such as Taiwan identity card designs and graphic designs from the National Palace Museum and other cultural sites, Nozue and his team came to the view that “an express train they could be proud of” would be one that presented modern Taiwan to the world, having settled on creating a loose and restrained design. The outcome of the discussions between the three parties was a concept that they called “Silent Flow.”

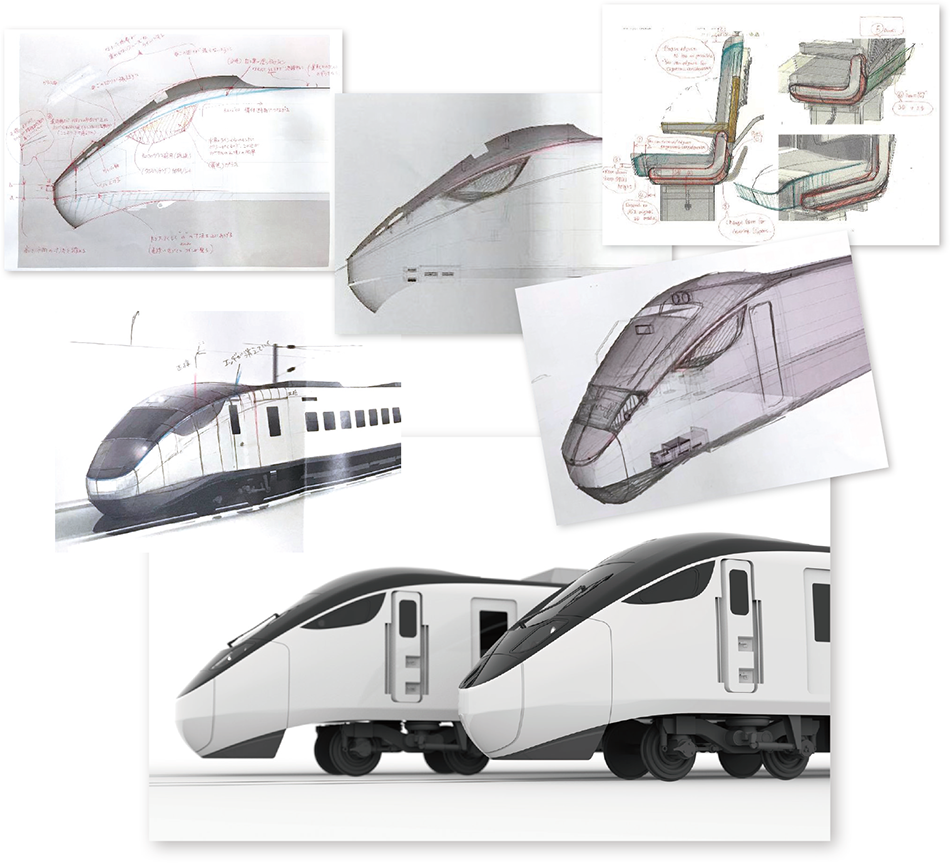

As he went on to say, “Given that the trains would be the public face of new mobility services linking Taiwan’s cities, we wanted a design that expressed quiet speed and we sought to come up with a shape for the train that, like a single curved line on blank paper, conveys elegance while still being simple. In the workshop, we used hand-drawn sketches as a basis for reviewing the design with the help of various analog and digital techniques (see Figure 3). By utilizing three-dimensional (3D) printers and virtual reality (VR), our design work took place in both real and virtual spaces.”

Figure 3 | Sketches and Computer Models of Express Train for TRA

The process of giving shape to the train while keeping to the initial concept required working closely with the design engineers. The job of these engineers was to turn the design into an actual train while at the same time ensuring that it would be easy to use for passengers and train staff. Takahisa Yamamoto (Senior Engineer, Rolling Stock Project Engineering Department, Rolling Stock Systems Design Division, Kasado Works, Railway Systems Business Unit, Hitachi, Ltd.), one of those involved in rolling stock manufacturing, explained what was discussed during these rolling stock design consultations and the important role they played.

“For example, we built a full-scale mockup of the driver’s seat and surrounding area and showed it to the drivers’ union. Whether in Japan or on overseas projects, it is valuable to go through a process of having the actual users come and take a look so that we can adjust the design to their satisfaction, and I also believe that by doing so we build a relationship of trust. Train crew also provided feedback on the conductor’s compartment and input on the needs of catering staff and the issues they have with current equipment. Likewise, consultation with passengers involved not only our telling them about usability features, but also feedback from wheelchair users and other people with disabilities and people who use the nursing room that was incorporated into the design.”

A press conference on the design of the rolling stock was held in Hualien in Northern Taiwan in December 2019, about six months after the design workshops got underway. This was followed by an exhibition of the design at Taipei Station. If the design work done up to this point could be likened to hypothesis generation, then these events served the purpose of hypothesis testing. The exhibit attracted a lot of attention, such that the initial three-day schedule was extended to 10 days. This indicated that the work done by the three-party team was on track. The project has now moved on to the rolling stock manufacturing phase and is making steady progress toward delivery in 2021.

As part of our common infrastructure, one thing that elevators and escalators have in common with trains is that the people who use them are different from the organizations that own them. As mobility systems, they differ in that trains provide horizontal transportation from city to city whereas elevators and escalators move people vertically inside buildings and are a classic example of products that people rarely give any thought even when using them. Akira Omachi offered the following comments about the thinking behind the design and development of these elevators and escalators, making reference also to how design practices at Hitachi are changing.

“In the past, the design and development of elevators has had a two-pronged focus on universal design on the one hand and harmonizing with the building architecture on the other. In fact, Hitachi elevators were among the first in the industry to adopt universal design, for which they won a Good Design Award in 2002. As these design practices became more commonplace, however, they ceased to be a distinguishing feature. That is why, since 2012, we have been working with Naoto Fukasawa, an internationally recognized industrial designer, on new concepts for Hitachi elevators and escalators and on getting products to market. Through this collaboration, we have been seeking to use design not only to make our products accessible for all, but also to help provide people with a trouble-free journey from the time they enter an office building until they reach their desk.”

Behind this philosophy was an awareness of the problems posed by new barriers that have come to the fore in recent years, namely the way that the growing sophistication of urban activity has made city neighborhoods larger with more complex travel routes, and how security measures have disrupted these routes. This gave rise to the concept of human-friendly elevators that are easy for people to use and in harmony with their behaviors, the aim being to eliminate these new barriers to movement so that people can move freely and easily from place to place without having to give the matter any thought.

As part of the development of an elevator that would exemplify this underlying concept that was announced in July 2015, Hitachi devised a user conceptual model (UCM) to identify the relationships between elevators and the people who use them. The UCM modeled the unconscious behaviors and thoughts of elevator users. The aim was to improve convenience and comfort by first understanding the actions and thinking that people unconsciously adopt when getting on or off an elevator or while inside, and then using this as a basis for resolving the associated problems. Examples of these behaviors include looking upward, standing in the back corner, wanting to be the first to get off, being conscious of baby carriages, not getting on elevators that already have passengers, and using the button indicators to track the car’s progress from floor to floor.

Omachi put it as follows. “Many people move to a corner when they get on an empty elevator so that they can lean against a wall. Recognizing this, we gave the corners a curved profile that matches people’s shoulders. Likewise, a rounded profile is used for the elevator entrance to provide an unconscious prompt that facilitates the movement of people getting on or off. We also use an upright panel for displaying the floor numbers and arrows to provide the people in the elevator with an intuitive indication of its current position. While these are all small things, our objective was to use our design skills to create an elevator that anticipates people’s unconscious behaviors.”

The HF-1 elevator is a concept model featuring a people-friendly design with enveloping curves and with close attention paid to such details as the lighting tone and the legibility and ease-of-use of the controls. It has been positively received both in Japan and overseas, including winning a 2015 Good Design Award (gold) and an iF DESIGN AWARD (see Figure 4).

Along with expanding its human-friendly concept across all products and services, Hitachi also announced an elevator management system in October 2019 that features human flow prediction.

As Omachi explained, “The system reduces waiting times during busy periods by using artificial intelligence (AI) to predict elevator user numbers based on large amounts of past data. When integrated with other functions such as building surveillance cameras or tenant identity cards, the system can make it even easier to move around inside buildings by, for example, allocating additional cars to floors where there are a large number of people waiting for an elevator. Along with improving the service quality experienced by users through the provision of an open system, our aim is also to serve building managers by helping to add value to their properties.”

In this way, by taking account of system management considerations all the way from the product itself, which was designed with users in mind, to the service as a whole, Hitachi is taking action to put its human-friendly concept into practice more widely in order to provide easier and more convenient mobility around not just entire buildings and their elevators, but also throughout the city.

Anticipating a shift from products to services along with greater use of experience design, Yuichiro Kota explains how the way in which trains, elevators, and escalators are designed will likely change in the future.

“What will remain unchanged in rolling stock design will be a focus on the functional considerations of ease of manufacturing and maintenance as well as on aesthetics that blend seamlessly into the townscapes where trains operate. Along with creating attractive designs for future orders of rolling stock, however, there will also be a need to think in terms of multiple considerations in order to deliver customer satisfaction in the form of a single integrated service that also encompasses infrastructure. Based on this approach, we are now taking our first steps toward putting the various different types of data generated from trains to use in the service as a whole.”

With regard to how companies go about design, Sho Nozue offered the following perspective from someone actively engaged in such work.

“For the exhibit of the new express train design at Taipei Station, we provided not only virtual reality and video presentations of the rolling stock design, but also a variety of other material such as preliminary sketches, notes from the development phase, and mockups. My experience of that event left me with an appreciation of how a form of corporate value arose from putting the design process on show, including all the work and effort put in by the industrial designers and design engineers. The act of making the whole process visible should in itself send a message to the public and I believe that we should make a commitment to doing so.”

Finally, Akira Omachi made the point that responding quickly to new circumstances will be more important than ever in the future.

“While the coronavirus is spreading around the world, as we move beyond the pandemic and into the post-virus world, we can expect major changes in people’s values and in what they want from products. Close contact is unavoidable in the enclosed space inside an elevator, and people riding on escalators will be reluctant to take hold of handrails. While Hitachi already offers non-touch solutions for moving around inside buildings that make use of an image analysis service and hands-free tags. I anticipate that how we go about quickly identifying these changes in people’s values will be a key factor in future industrial design.”

The pandemic is bringing about changes in how people work and interact with one another that include maintaining social distancing and making greater use of teleworking practices. Along with continuing to produce designs in harmony with society and engaging in co-creation with customers as it has in the past, Hitachi also intends to respond to changing circumstances by designing and developing mobility systems that enable travel to be safe, secure, and comfortable based on accurate assessments of the accompanying changes in people’s values.

The new express train, Laview, for Seibu Railway Co., Ltd. exemplifies Hitachi’s technical capabilities and expertise in railway vehicle manufacturing. It won the Blue Ribbon Prize of the Japan Railfan Club in June 2020, in recognition of features that include its stylish and distinctive design and functionality, accessible facilities, and measures taken to reduce its environmental impact. This article is by the internationally recognized architect Kazuyo Sejima who was responsible for the design of the new express train, Laview.

Photo by Aiko Suzuki

Kazuyo Sejima

Photo by Aiko Suzuki

Kazuyo Sejima

Graduated from Japan Women's University Graduate School in 1981. Established Kazuyo Sejima & Associates in 1987. Established Sejima and Nishizawa and Associates (SANAA) in 1995 in partnership with Ryue Nishizawa. She served as director of the 12th Annual International Architecture Exhibition at the Venice Biennale in 2010. She was awarded the US Pritzker Prize* in the same year. Notable commissions include the 21st Century Museum of Contemporary Art, Kanazawa; the Rolex Learning Center* in Lausanne, Switzerland; and Louvre-Lens* in Lens, France.

* Received on behalf of SANAA.

Our design journey started with the client’s request to come up with an express train unlike any other seen before. Although designing a railway vehicle was a first for me, I approached it in the same way as I would an architecture design, that is, to create time and space in which a wide variety of people can come together comfortably. I thought the best way to achieve this would be to produce something that blends seamlessly into the environment. This is based on my belief that comfortable space is simultaneously both private and public, which is true generally, not just of this express train.

I imagined an interior that features large windows. These bring the passing scenery into the train itself and allow for the same level of brightness inside and out. The exterior is not about the train’s form, but rather a combination of the body of the train, reflected sunlight, and passing scenery, as well as what is visible through the windows, such as the people inside and the panorama on the far side. From within, the landscape seen through the windows becomes a central part of the design. When the train arrives at a station, those waiting on the platform are given a glimpse of the atmosphere created by the people within. I hoped to create something that would blend into the diverse scenery it encounters and becomes part of it. My intention was to design a train that was less about shape and more about the atmosphere it carries with it.

Having visited Hitachi’s Kasado Works many times for meetings and reviews, I was very impressed by the sight of all the railway vehicles being manufactured. Railway vehicles are neither mass-produced like cars nor uniquely designed on a site like buildings. Learning that the trains are produced by the exquisite fusion of high-precision technologies and manual craftsmanship, my imagination was fueled and I was very inspired.