The novel coronavirus pandemic is confronting the world with the difficult task of maintaining economic activity while preventing the spread of infection. Meanwhile, Hitachi has been putting digital technology to work alongside its comprehensive capabilities that bring together products, OT, and IT to establish new value chains that transcend the barriers between companies and industries. This section describes work toward making life in the emerging “new normal” both secure and convenient, including technology for supply chains that places an emphasis on being non-contact and reducing the number of people involved, technology for regenerative medicine, and collaborative creation programs that deliver the maximum possible value to customers amid an uncertain business environment.

It has been said that dramatic changes in the environment in which people live, including global warming and accelerated globalization, have heightened the threat that pandemics pose for humanity.

With COVID-19, the world is faced with the difficult dilemma of how to prevent the spread of infection while maintaining economic activity. On top of the pandemic, the uncertain economic outlook is a cause of considerable disquiet for people.

The shrinking workforce was a pressing issue even before novel coronavirus arrived on the scene, with considerable research going into automation and labor-saving technologies, some of which have already entered use. The pandemic has only made the need more urgent. Encouraged as part of working style reform, the practice of remote working was already becoming established before the pandemic brought a sudden upsurge in its adoption. Necessity drastically changes people’s attitudes and behaviors, and technology follows in its wake.

Along with sustaining economic activity while also preventing the spread of infection, industry is being called on to provide a way of life in the new normal that is secure and convenient, not only for consumers, but also for workers.

Since its founding 110 years ago, Hitachi has continued to fulfill its Corporate Credo (Mission) of “contributing to society through the development of superior, original technology and products” while demonstrating the Hitachi Founding Spirit (Values) of “Harmony, Sincerity, and Pioneering Spirit.” In manufacturing in particular, Hitachi is seeking to boost social, environmental, and economic value simultaneously by working alongside its customers to support the activities on which society functions, especially the supply chains that encompass things like design, procurement, production, and distribution. By doing so, it is helping to increase the corporate value of its customers.

Meanwhile, the arrival of the new normal brought about by the spread of COVID-19 has made it difficult to continue contributing to enhancing customer value through existing means. There is a need to address uncertainties in the context of newly emerging risks.

The Japanese government, meanwhile, released its White Paper on Manufacturing Industries (Monodzukuri) 2020(1) in May 2020 with initiatives that Japanese manufacturers should strengthen. The white paper referenced the idea of dynamic capability* and identified a need to strengthen companies’ capacity for innovation. In this strategy, the term “dynamic capability” refers to the ability of companies to transform themselves when confronted with a changing environment, something that requires the following three competencies.

The white paper identified digitalization as an effective means of strengthening companies’ capacity for reform in these ways.

As an IT business and through its own activities in the manufacturing industry, Hitachi has achieved digital transformation (DX) through collaborative creation (co-creation), drawing on customers’ own strengths to create value as it works on finding solutions to the diverse management challenges that they face. At the same time, it also recognizes that the coming of the new normal demands a deeper involvement in advancing digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data.

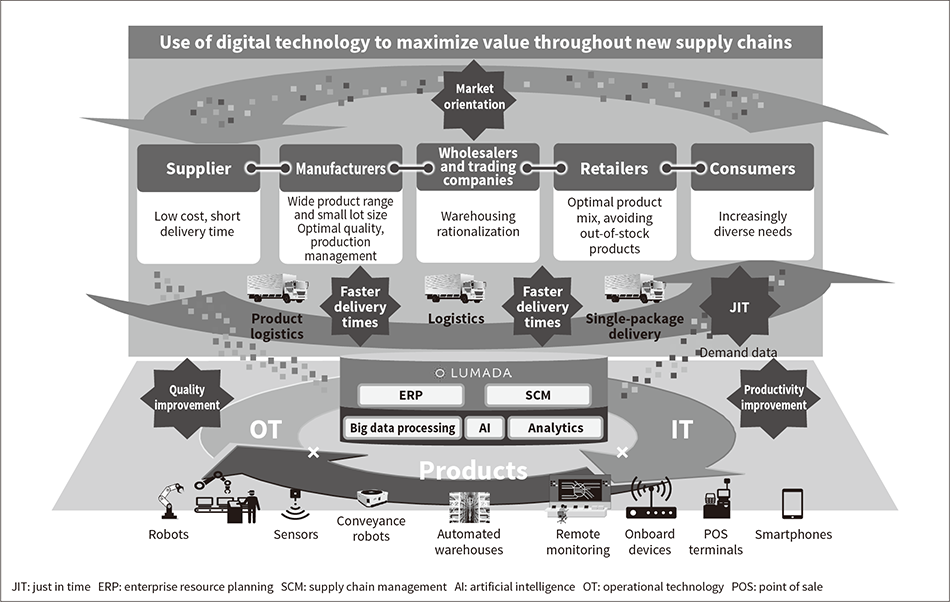

The role that Hitachi is being called on to play in an industrial sector facing rapid change amid an emerging new normal is to deploy its combined capabilities in products, operational technology (OT), and IT to break down the barriers between companies and industries and to maximize value, not just for specific customers, but across the entirety of new supply chains (see Figure 1).

Figure 1 — Expectations for Hitachi’s Role in Industry under the New Normal  Amid the rapid changes demanded by the new normal, Hitachi is using Lumada as a platform for deploying its combined capabilities in products, OT, and IT to maximize value throughout entire supply chains.

Amid the rapid changes demanded by the new normal, Hitachi is using Lumada as a platform for deploying its combined capabilities in products, OT, and IT to maximize value throughout entire supply chains.

The way in which logistics services are delivered is in urgent need of reform in order to maximize value across entire supply chains by addressing people’s increasingly diverse lifestyles and the labor-intensive structure of supply chain operations. This section describes the future of logistics and Hitachi’s role in achieving it.

Along with rising demand due to people staying at home during the current COVID-19 pandemic, the distribution industry is also experiencing an exacerbation of the existing challenges posed by labor shortages and the increasingly diverse range of services and products it handles. Measures for dealing with these are urgently needed. In particular, the work of people in the distribution industry is still based around personal contact even amidst calls for refraining people from going out, and they have had to go on performing this hard manual work in an environment where infection risk is a major concern.

To address these issues, Hitachi has put a high priority on enhancing distribution centers and the work of transportation and delivery. It has improved logistics operations by resolving these issues through the supply of solutions, platforms, and services together with system integration (SI) that combines products, OT, and IT.

At distribution centers, for example, where operations are increasingly complex, Hitachi has responded to the new normal by helping to avoid the “Three Cs” of closed spaces, crowded places, and close-contact settings, utilizing robotics for automation and labor saving to overcome the challenges posed by labor shortages and greater diversity in the services and products being handled. Other initiatives include an integrated warehouse control system (WCS) that provides seamless control of entire warehouses and a simulator that facilitates rapid and optimal warehouse automation design. In devising and implementing these in ways that make the most of products, OT, and IT, Hitachi is drawing on its comprehensive capabilities that encompass technologies from IT to products.

One example is an autonomous picking robot system developed by Hitachi to enable systems that meet site requirements to be put in place quickly, without being hardware-dependent and without the need for “teaching” (the process of specifying the robot’s detailed movements in advance) (see Figure 2). Hitachi plans to develop this technology further as it accumulates experience with its commercial deployment.

Figure 2 — Picking Robot Equipped with Autonomous Picking Robot System  Robots equipped with Hitachi’s Autonomous Picking Robot System can perform picking at distribution centers in much the same way that a human worker sees an object and reaches out to pick it up, without the need for teaching.

Robots equipped with Hitachi’s Autonomous Picking Robot System can perform picking at distribution centers in much the same way that a human worker sees an object and reaches out to pick it up, without the need for teaching.

Enhancements to the transportation and delivery of goods are vital for meeting the explosive growth in demand. The delivery business is one where there is a particular need for rapid digitalization in order to make its operations more efficient, being characterized by a large number of small players who are kept busy just completing their routine work. As a result, the industry had been slow to adopt digitalization even before novel coronavirus. Through the Hitachi Digital Solution for Logistics, Hitachi provides the ability to collect and analyze workplace data for greater operational visibility in real time, including inward and outward goods processing, delivery scheduling and instructions, and safety practices.

With regard to enhancements to distribution centers and the transportation and delivery of goods, both workforce and management recognize the potential benefits of providing operational visibility through the collection and analysis of workplace data, and the solutions that this makes possible. While distribution center operations, delivery planning, and the balancing of delivery efficiency and driving safety have in the past been underpinned by the experience and intuition of drivers and other long-serving workers, the collection and analysis of data to provide a quantitative view of what is happening in the workplace makes it possible for the entire organization to reach a consensus on the issues workers face. Moreover, systematic delivery planning and operational management that has been designed on the basis of data from the workplace can make a major contribution to reducing the workloads not only of managers, but also of onsite workers.

Hitachi intends to press on with enhancements to the logistics business by maximizing value through the use of digital technology to link together the many customers and industries that make up supply chains.

This section shifts focus somewhat to look at what Hitachi has been doing in the field of regenerative medicine. The current pandemic has refocused attention on the importance of health management and medical institutions. One phenomenon that has left a particular impression is that of the many patients who put off treatment or tests needed for their health condition out of fear that visiting a hospital will put them at risk of infection. The new normal calls for dramatic advances in healthcare as people show greater concern for their own health in order to prepare for another pandemic that could come at any time.

Regenerative medicine refers to therapies that utilize cells or tissue taken from the patient or a donor. It is seen as a way to maximize therapeutic efficacy and minimize side effects by providing therapies that are tailored to the patient’s individual characteristics and state of health, with especially high expectations that it might be able to cure diseases that are otherwise difficult to treat.

Because regenerative medicine deals with cells and tissue, a value chain needs to be put in place that is managed separately from that for existing pharmaceuticals, which are primarily chemical substances, encompassing material procurement and handling as well as special manufacturing processes.

Regenerative medicine and related products are seen as having great promise among the other new medical technologies and drugs currently in the pipeline. Hitachi supplies three DX solutions that help manage the associated value chain.

Of particular note is the DX platform for supply chain management in the regenerative medicine industry, a common service platform that is available for use by stakeholders in the field of regenerative medicine and related products, including medical institutions, drug companies, distributors, and manufacturers. The solution has been designed in a way that takes account of the fact that it is handling patients’ confidential personal information. Hitachi is supporting DX for a wide range of value chain activities in ways that transcend the barriers between the different companies and industries involved in healthcare.

This final section looks at the work being done in partnership with customers to identify new value amid the uncertain future of the new normal, and then to realize it in practice. Using the NEXPERIENCE methodology(4) that was developed by Hitachi’s Global Center for Social Innovation – Tokyo and first announced in 2015, Hitachi has been participating in work that involves expressing customers’ vision for the future and jointly coming up with new solutions.

Hitachi has engaged in this co-creation with more than 1,000 corporate customers to date. Along with the tangible outputs from the work, customer feedback has also included comments about how meaningful and enjoyable they found the discussions, and how they had never before come together in such a way to talk about their business and about where they should be heading in the future.

As for Hitachi’s own in-house initiatives during this era of the new normal, the holding of fully online (non-contact) workshops proved to be very worthwhile in terms of uncovering valuable input that would otherwise be buried within the company. This was thanks to the skills of the facilitators and their ability to draw out people’s genuine opinions and enliven the discussion.

Given the unforeseeable future of the new normal, it is more important than ever that the company bring forth these unspoken beliefs from workers and get them working together to envisage the future.

Social transformation is being accelerated by the arrival of the new normal. Accuracy and speed in management decision making are the keys to corporate development. Through the supply of a wide variety of DX solutions, including those applications presented in this issue of Hitachi Review, Hitachi intends to support the capacity for change in companies and industries as it takes up the challenge of pioneering new supply chains.