1. Transmission Line Protector Using Ethernet Communication from Chubu Electric Power

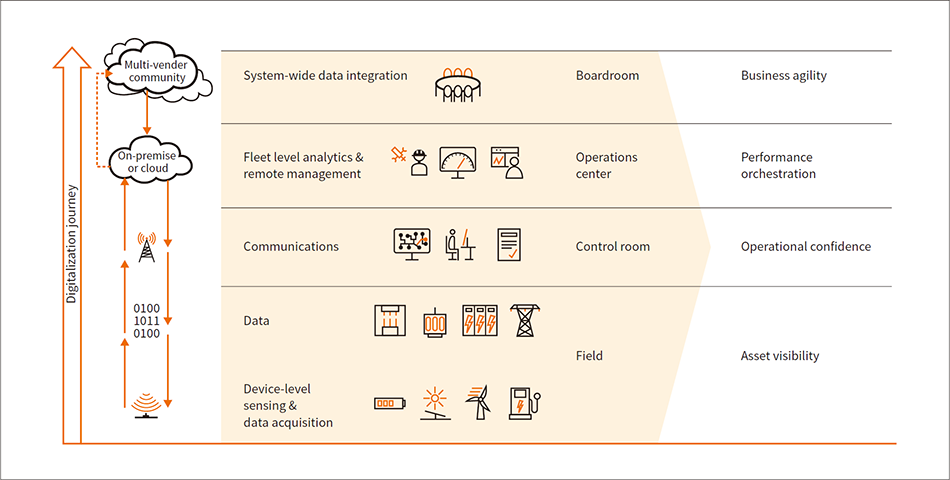

The rapid advancement of the information-oriented society in recent years has resulted in increasingly advanced communications network technology. For example, general-purpose communications technologies that enable high-speed, high-capacity communications such as Ethernet communications and the Internet Protocol (IP) are becoming increasingly commonplace.

Pulse code modulation (PCM) current differential relays are protective relay devices for transmission lines. They transmit current data back and forth between terminals and calculate the differential current to detect whether a failure has occurred in the applicable line interval. These devices were developed about 30 years ago, and have always used power company communications equipment for data transmission.

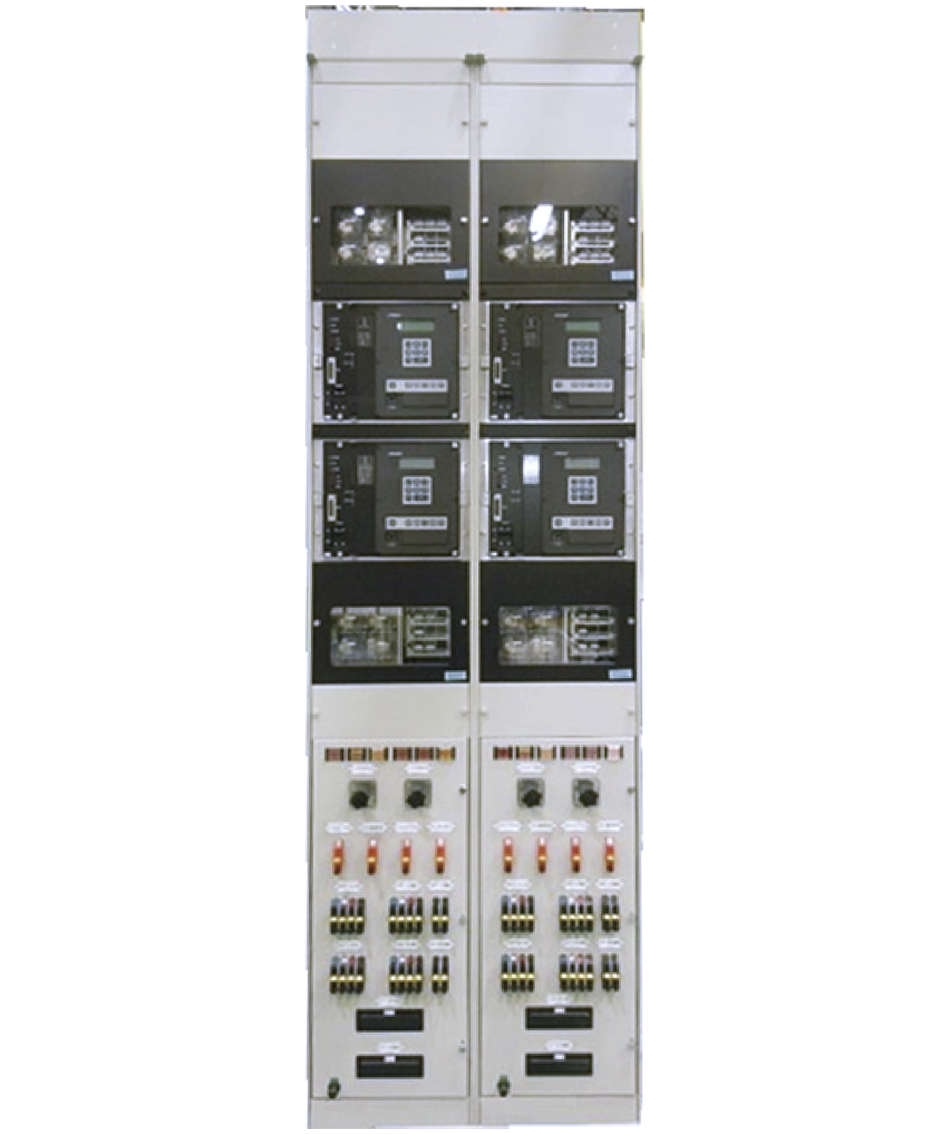

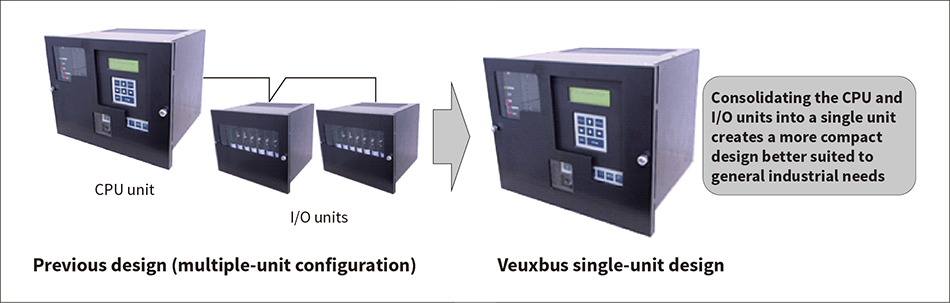

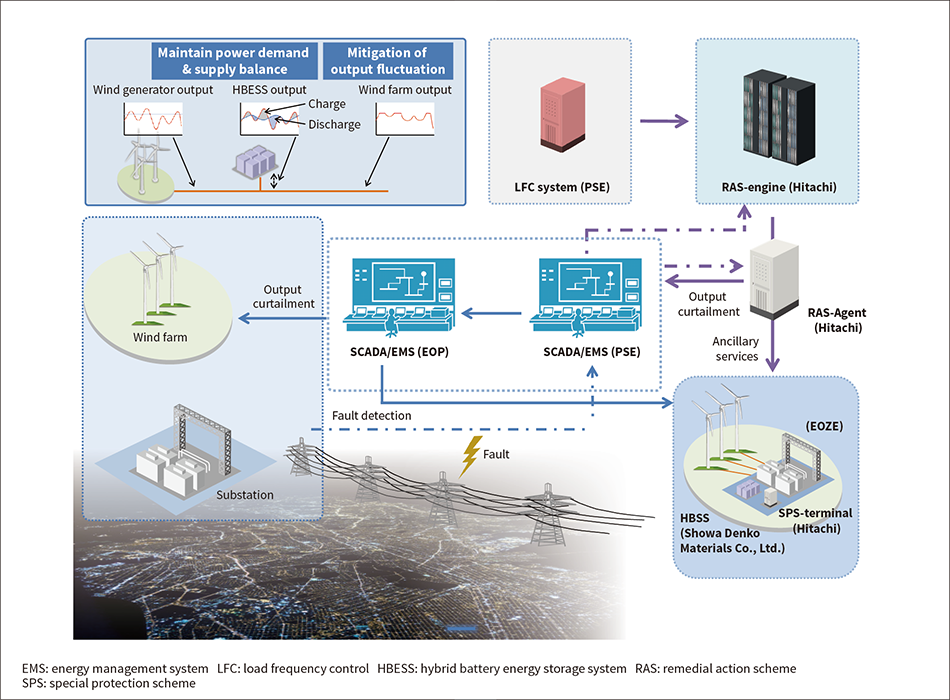

The plesiochronous digital hierarchy (PDH) communications method has conventionally been used along with a dedicated communications control board mounted on the protective relay device. Hitachi has recently developed a transmission line protective relay device that uses a layer 2 (L2) switch (a general-purpose Ethernet communications device), making it possible to use a general-purpose Ethernet interface instead of a dedicated communications board. By replacing dedicated communications equipment with general-purpose Ethernet, the developed device enables a greater degree of freedom in transmission line configurations and helps lower overall protection relay system cost.

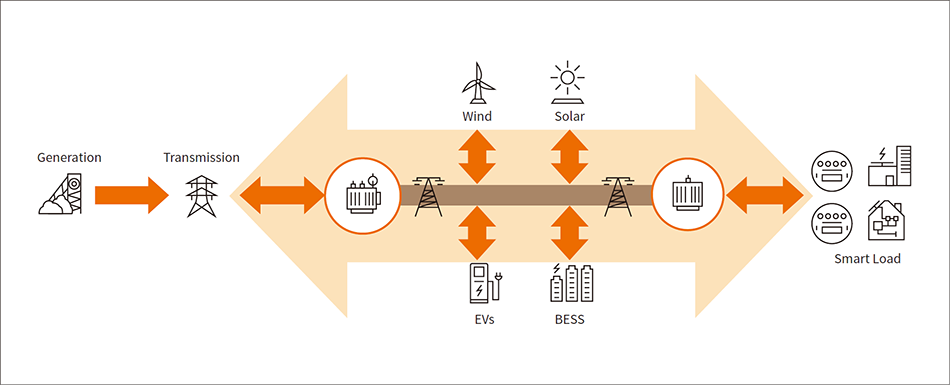

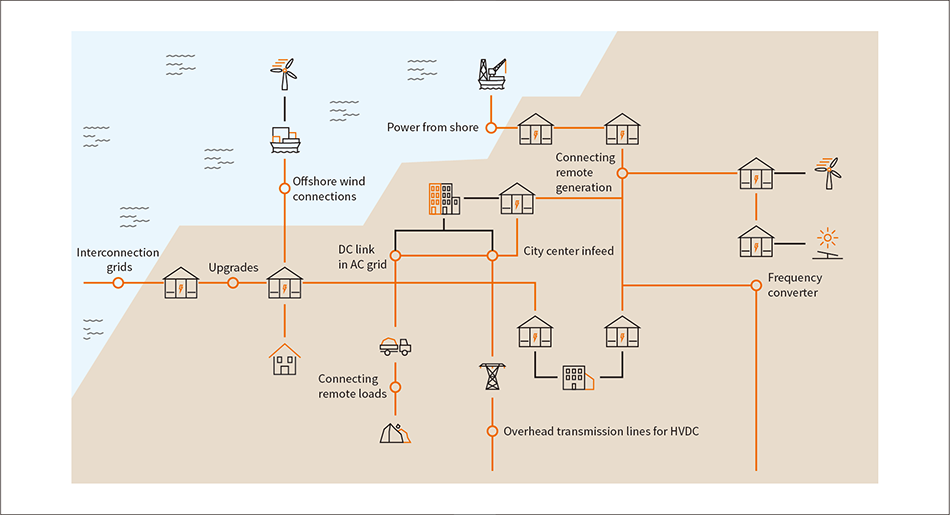

Grid connection of renewable energy-based power sources is expected to grow in the coming years. However, when connected within line intervals protected by transmission line protective relays, these power sources could generate outflow currents causing unneeded operation of transmission line protective relays when external failures occur. So, a new function for preventing unneeded operation has been provided.

The device was developed as a resistance-grounded transmission line protective relay device. Its configuration uses separate lines and supports up to eight terminals. Hitachi started making successive shipments to power stations starting in July 2020, and the first unit began operating in September 2020.