1. Design and Construction Authorization for Kashiwazaki-Kariwa Nuclear Power Plant Unit 7

Conformity assessments made under new regulatory standards apply criteria that reflect the lessons learned from the Fukushima Daiichi nuclear disaster when handling approval for installations (changes), applications for design and construction plan authorization, and safety standard reviews.

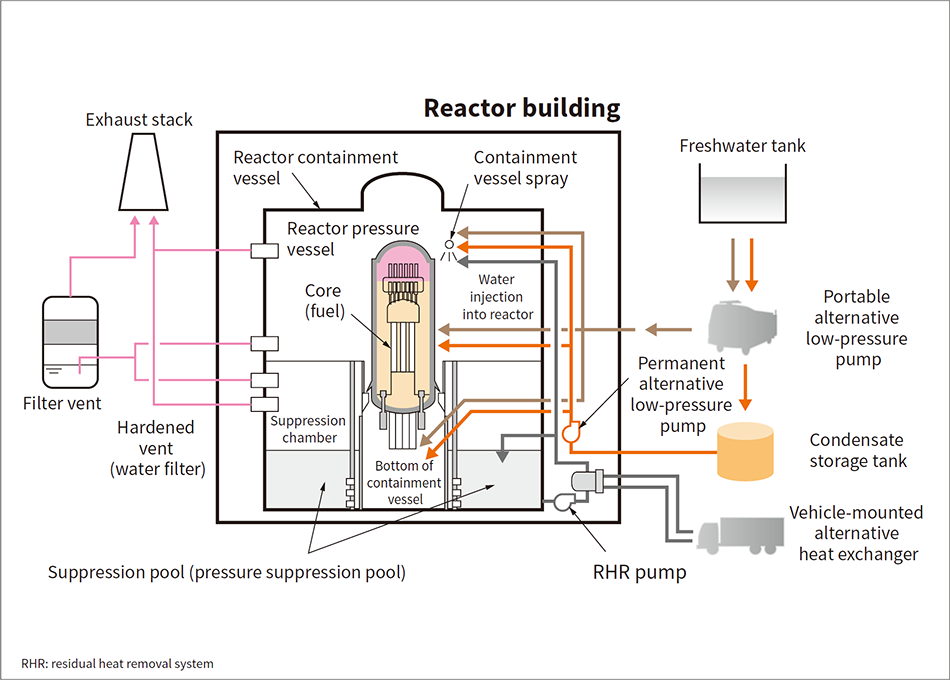

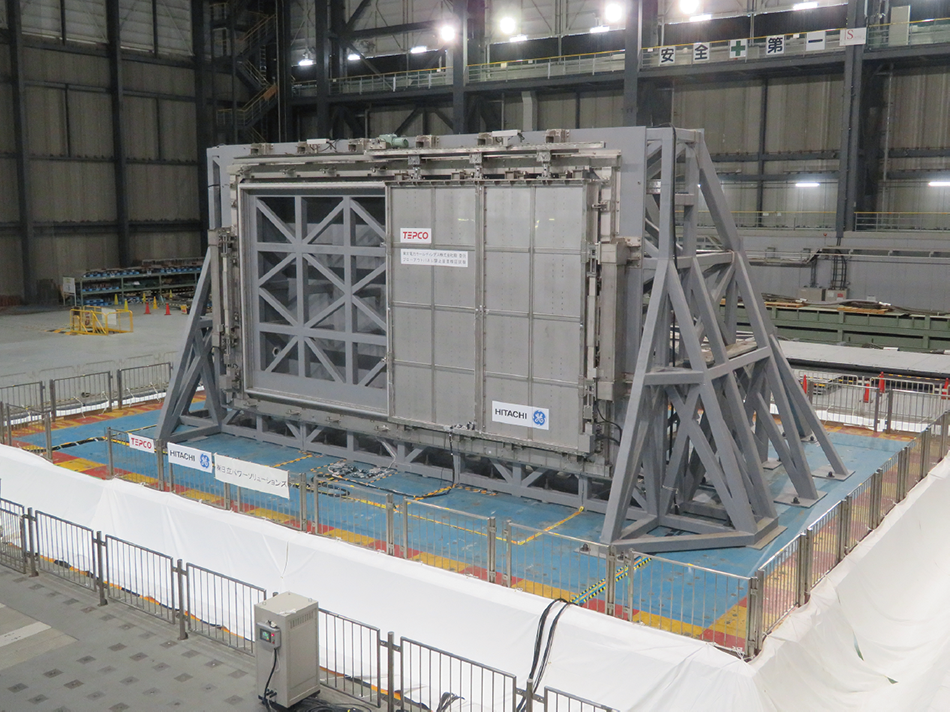

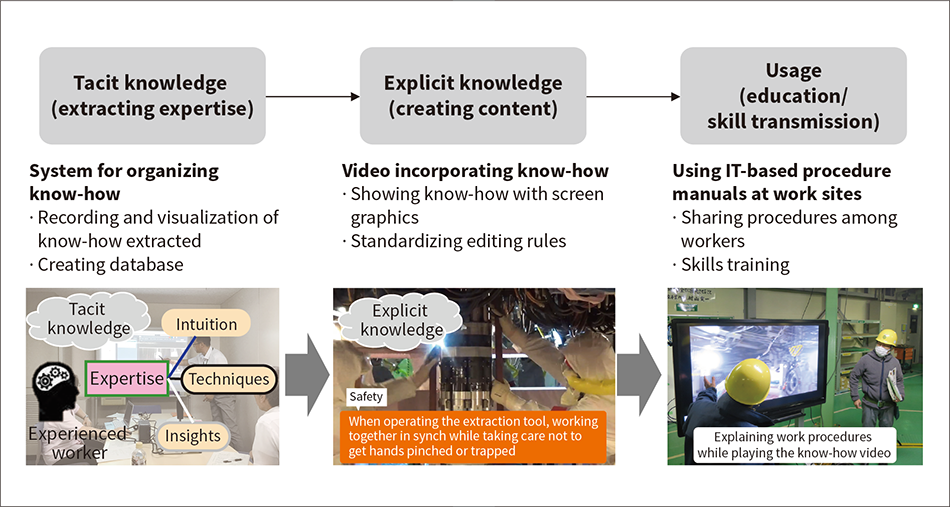

To ensure conformity with the new regulatory standards and further improve safety, Hitachi is rapidly working on a number of measures for a boiling water reactor (BWR) plant that is now in the review phase of the application for design and construction plan authorization. These efforts primarily consist of preparing for natural disasters by improving the seismic resistance of key facilities, etc., making filter vents and other equipment more resistant to major accidents, and taking steps to combat terrorism such as preparing for aircraft collisions. The Hitachi Group has made a concerted effort to prepare for this broad spectrum of severe disasters, working on everything from new technology development to design and construction.

Japan’s Nuclear Regulation Authority recently approved a revised application for design and construction plan authorization for Kashiwazaki-Kariwa Nuclear Power Plant Unit 7, which is owned by Tokyo Electric Power Company Holdings, Inc. The design and construction plan has now been authorized, and the final phase (operator inspection before use) is underway before conformity is verified by the Nuclear Regulation Authority. The Hitachi Group will continue to contribute to subsequent BWR plant conformity assessments and develop safety technologies to help increase the safety of nuclear power plants.

[1] Measures to prevent core or containment vessel damage in BWR plants