Efforts to combat climate change include work on creating a decarbonized society. Hitachi is responding by aiming to create a hydrogen trading platform that will enable the construction of a hydrogen system providing renewable energy and green hydrogen circulation, while ensuring a good balance between decarbonization and cost-effectiveness through the use of a global ecosystem operating from centers such as Europe and Japan. The company is also working on developing a hydrogen multi-resource platform that will balance supply and demand while generating high earnings. The platform will incorporate a hydrogen production system and hydrogen-based cogeneration system that can supply low-cost and sustainable hydrogen, power, and heat. This article presents the concepts behind the hydrogen multi-resource platform and hydrogen production system that Hitachi aims to create. It also looks at the control technologies to be used in the hydrogen-based cogeneration system.

Achieving carbon neutrality by 2050 will require energy-saving measures along with greener alternatives to the fossil fuel derivatives used for power and transportation that account for over 60% of carbon dioxide (CO2) emissions. Meeting these demands will require the mass adoption of renewable energy and a switch to non-fossil-fuel-derived hydrogen that emits no CO2. Hitachi has responded by aiming to become a global pioneer through the creation of a full-scale renewable energy-based hydrogen value chain by 2030. The biggest challenge will be finding ways to reduce the total cost of renewable energy and hydrogen distribution in the phases ranging from production to storage, transport, and use. One mandatory requirement will be to create a platform for implementing an energy trading business that will make the use of hydrogen energy more cost-effective than other options. These efforts will be made possible by improving hydrogen production quantities, reducing hydrogen production costs, improving usage efficiency during the hydrogen usage phase (for power and heat), and coupling the industrial, transportation, and other sectors.

Hitachi is aiming to create two systems to enable the construction of a hydrogen multi-resource platform that will ensure profitability for renewable energy providers and hydrogen supply chain businesses. One is a low-cost hydrogen production system using power from renewable energy. The other is a low-cost hydrogen-based cogeneration system for users such as cities and mobility providers. This article looks at the development of these systems and the concepts behind them.

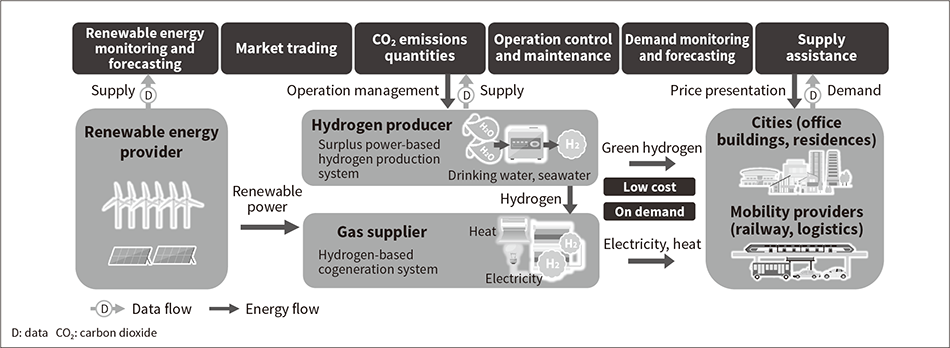

Figure 1 illustrates the concept of a renewable energy-based hydrogen multi-resource platform. By using hydrogen produced by water electrolysis equipment powered by renewable energy, the aim is to provide users (cities, plants, and mobility providers) with an operation platform for high-profit, on-demand trading of electricity and heat through a cogeneration system that uses solid oxide fuel cells (SOFCs) and other fuel cells along with mixed combustion engines. The platform will incorporate real-time Internet of Things (IoT) functions for renewable energy monitoring, market trading, and CO2 emissions monitoring. It will be possible to produce low-cost hydrogen by monitoring and forecasting renewable energy-based power and cogeneration energy supply and demand data in real time to control each piece of equipment to optimize the operation timing. The platform will also be designed to promote trading operations that generate earnings reflecting market prices by enabling low-cost electricity and heat production by providers supplying heat, electricity, and gas. Its operation will be designed to make electricity, heat, and green hydrogen available on demand to the user cities, plants, and mobility providers at a lower cost than before. The overall energy system will have new hydrogen technologies installed alongside existing technologies. To verify that it will provide a good balance of cost-effectiveness and environmental benefits when the new technology is installed, Hitachi is working on globally coordinated total energy simulations with the Fraunhofer Institute for Solar Energy Systems in Germany. Typical European models are being used to study cases that would enable the hydrogen energy supply cost for cities to be halved by 2030 by drawing on the twin benefits of improvements to the efficiency and operating ratio of renewable energy-based water electrolysis hydrogen production systems, and improvements to the efficiency of hydrogen usage systems. Below is a description of the hydrogen production system and hydrogen-based cogeneration system that will be needed for the platform’s creation.

Figure 1 — Concept of Hydrogen Multi-resource Platform  The concept of a renewable energy-based hydrogen multi-resource platform is illustrated here. The platform’s aim is to enable high-profit, on-demand trading of electricity and heat among users (cities, plants, and mobility providers).

The concept of a renewable energy-based hydrogen multi-resource platform is illustrated here. The platform’s aim is to enable high-profit, on-demand trading of electricity and heat among users (cities, plants, and mobility providers).

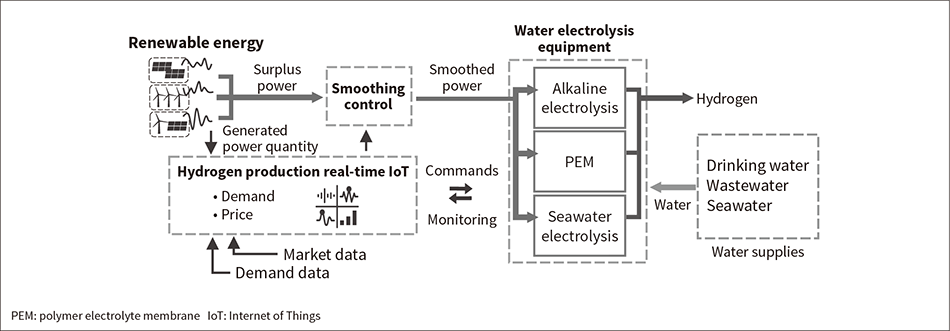

Figure 2 — Surplus Power-based Hydrogen Production System  Hitachi is aiming to create a hydrogen production control system that uses surplus power and operates in connection with supply and demand data. Drinking water, seawater, and other water supplies will be procured, and low-cost surplus power will be smoothed to improve the water electrolysis equipment’s operating ratio and to reduce costs. The surplus power will be power that was previously wasted. It will come mainly from wind and solar generation.

Hitachi is aiming to create a hydrogen production control system that uses surplus power and operates in connection with supply and demand data. Drinking water, seawater, and other water supplies will be procured, and low-cost surplus power will be smoothed to improve the water electrolysis equipment’s operating ratio and to reduce costs. The surplus power will be power that was previously wasted. It will come mainly from wind and solar generation.

To improve hydrogen production quantities and reduce production costs, Hitachi aims to create a hydrogen production control system that uses surplus power and operates in connection with supply and demand data. The system, shown in Figure 2, will be a mainly wind- and solar-powered system designed to double the hydrogen production system’s operating ratio by stabilizing the low-cost surplus power that has previously been wasted. By doubling the operating ratio, the system will aim to halve the production costs and provide hydrogen at a target price of JPY30 per cubic meter.

To enable a hydrogen production control system that operates in connection with demand data, Hitachi will create a system that presents optimized plans by forecasting demand quantities and prices, and controlling the timing of hydrogen production by water electrolysis. These operations will be done with real-time IoT technology that uses data on renewable energy-based power, cogeneration demand, and the market. A smoothing circuit will be used to stabilize the widely fluctuating surplus power generated by each site to keep output constant. By providing a stable supply of this output as the power source for electrolysis, Hitachi will increase the equipment operating ratio of the water electrolysis module array by at least 70% and develop technology enabling today’s costs to be cut in half. The module stack will be composed of elements such as polymer electrolyte membranes (PEMs) and alkaline electrolysis equipment.

Depletion of water resources is a growing risk throughout the world. Stoichiometrically, hydrogen production by water electrolysis requires 9 liters of water to produce 1 kilogram of hydrogen. In practice, more water resources will be needed to handle system specifications such as water purity and cooling. So, the switch to a hydrogen economy could be accompanied by increasingly severe water shortages. Accordingly, ensuring stable water supplies for each region’s use of both drinking water as well as seawater and industrial wastewater will be a key requirement. Hitachi is working on solving this issue and enabling the release of hydrogen production systems in a greater range of areas by using existing water treatment technologies(1), and developing water separation membrane materials and technologies that will enable water recycling systems with high efficiency and long life.

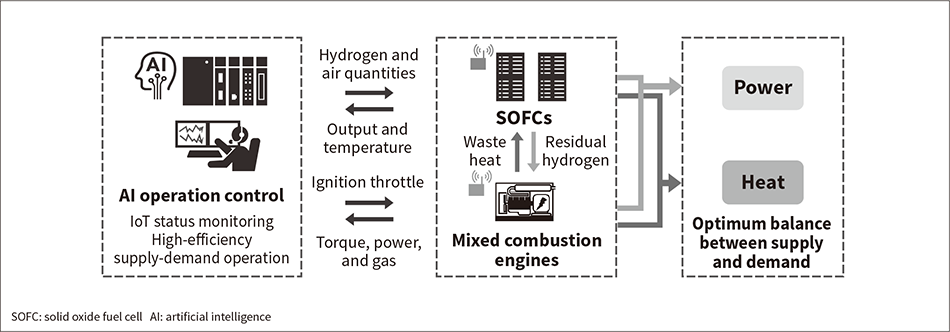

Figure 3 — Hydrogen-based Cogeneration System Driven by AI Control  A hydrogen-based cogeneration system is being developed for suppliers of energy to users (cities, plants, and mobility providers). Demand will be accommodated by building response control technology that combines SOFCs having high power-generating efficiency with mixed combustion engines having high thermal efficiency. The technology will extend the balancing range for electricity and heat supply quantities, while instantly responding to demand.

A hydrogen-based cogeneration system is being developed for suppliers of energy to users (cities, plants, and mobility providers). Demand will be accommodated by building response control technology that combines SOFCs having high power-generating efficiency with mixed combustion engines having high thermal efficiency. The technology will extend the balancing range for electricity and heat supply quantities, while instantly responding to demand.

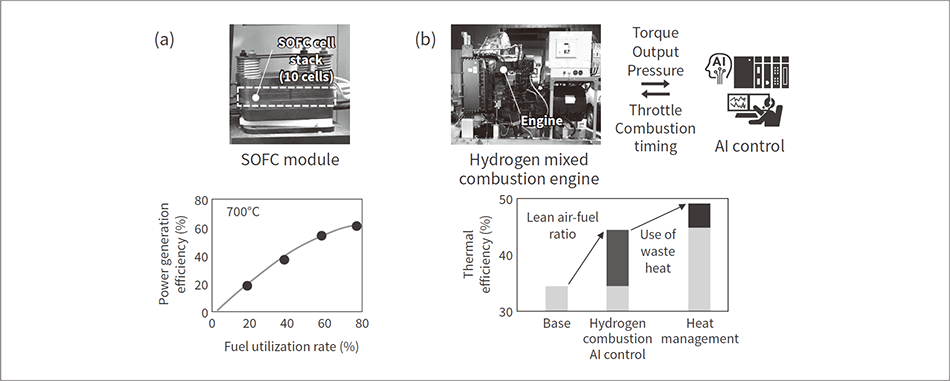

Figure 4 — High-efficiency Mixed Combustion Engine Made Possible by SOFC Stack and AI Control  Figure 4 (a) shows an SOFC module composed of 10 stacked cells. A power generation efficiency of 60% has been demonstrated by improving the fuel utilization rate. Figure 4 (b) shows a high-efficiency mixed combustion engine running on hydrogen reformed from existing multifuel engine fuel with a catalytic reaction. It has achieved a thermal efficiency of about 50% using low-concentration aqueous ethanol.

Figure 4 (a) shows an SOFC module composed of 10 stacked cells. A power generation efficiency of 60% has been demonstrated by improving the fuel utilization rate. Figure 4 (b) shows a high-efficiency mixed combustion engine running on hydrogen reformed from existing multifuel engine fuel with a catalytic reaction. It has achieved a thermal efficiency of about 50% using low-concentration aqueous ethanol.

To build a hydrogen multi-resource platform for reducing user-side CO2 emissions, Hitachi is developing a hydrogen-based cogeneration system enabling low-cost heat and electricity production and enabling highly profitable operation by supplying energy at market prices to users (cities, plants, and mobility providers). There are two key requirements for providing a low-cost energy supply. One is to accommodate demand by extending the balancing range for electricity and heat supply quantities. The other is to provide control enabling an instant response to demand. To solve these issues, Hitachi is developing an SOFC hybrid cogeneration system that combines SOFCs having high power-generating efficiency with mixed combustion engines having high thermal efficiency to enable an optimized balance of supply and demand for heat and electricity (see Figure 3). The engine waste heat is used as the SOFC startup heat source, while some of the unused hydrogen from the SOFCs is used as engine fuel. This waste-free reciprocal use of resources increases system efficiency. The operating states of each unit are continuously monitored by IoT technology, and the operating condition parameters are controlled by artificial intelligence (AI) in real time to ensure operation at the maximum efficiency for the cogeneration demand. Hitachi’s work on developing an SOFC- and AI control-based high-efficiency mixed combustion engine is described here.

Figure 4 (a) shows an SOFC module composed of a stack of 10 SOFC cells. It was developed in partnership with the International Research Center for Hydrogen Energy at Kyushu University. Also shown is the power generation characteristic at 700°C using an ethanol solution of 24 to 40 wt%. A power generation efficiency of up to 60% was achieved by reforming the fuel at 700°C and improving the fuel utilization rate to 80%. The same result was also achieved when using biofuel, enabling an improvement in power generation efficiency by controlling the fuel utilization rate of green multifuel engine fuels. Figure 4 (b) shows the AI control-based high-efficiency mixed combustion engine. The engine has been demonstrated using hydrogen reformed from bioethanol and other existing multifuel engine fuels with a catalytic reaction(2). It has achieved a thermal efficiency of about 50% using low-concentration (28 wt%) aqueous ethanol (pre-distillation water state)(3)–(5). To enable optimum operation of the mixed combustion engine, this technology incorporates AI-based mixed combustion engine combustion control technology(6). The technology detects the combustion state and learns the combustion state for each combustion type to automatically sense the fuel type and changes in composition, enabling creation of the optimum operation state.

Hitachi will continue to create AI control technologies designed to combine SOFCs with mixed combustion engines and provide data-connected operation on the hydrogen multi-resource platform.

This article has presented the concepts behind a hydrogen trading platform that Hitachi aims to create to help bring about a decarbonized society beginning in 2030. The platform will enable the construction of a hydrogen system providing renewable energy and green hydrogen distribution, while also ensuring a good balance of cost-effectiveness. Also described were a hydrogen production system and hydrogen-based cogeneration system control technologies enabling low-cost and sustainable supply of hydrogen, power, and heat. Hitachi’s hydrogen multi-resource platform will balance supply and demand while enabling high profitability. Hitachi will continue to work on this platform while aiming to create a sustainable hydrogen value chain enabling zero emissions.

The hydrogen supply chain concept and SOFC development work described in this article were greatly assisted by Associate Professor Dr. Yusuke Shiratori and Professor Dr. Kazunari Sasaki, Director of the International Research Center for Hydrogen Energy at Kyushu University. The work on coordinating hydrogen energy simulations was also assisted by the Fraunhofer Institute for Solar Energy Systems. The authors would like to express their heartfelt appreciation.