[ⅱ]Information and Control Systems for Industrial Process Control

Among the features incorporated by Hitachi into its systems for the water supply and sewage industries are planning support functions that use AI and big data for long-term water demand prediction, VPP projects that take advantage of DX in the water and electricity sectors, use of AR for smarter on-site maintenance practices, and security solutions that facilitate digitalization. While being an important part of the social infrastructure and essential to both daily life and industrial activity, water and sewage nevertheless face a variety of challenges. In response, Hitachi is addressing these challenges by contributing to sustainable growth and greater efficiency in the planning, operation, and maintenance of water and sewage services. This article describes recent examples in which the various solutions are being put to use.

COVID-19 has reinforced the important role played by the water and sewage industries in maintaining public sanitation through the supply of clean water for maintaining personal hygiene. Unfortunately, the water and sewage industries in Japan face issues of aging infrastructure, the rising cost of upgrading that infrastructure, shrinking revenues as depopulation reduces demand for water, and the difficulty of handing on skills due to the loss of experienced workers. While COVID-19 has prompted an acceleration of digitalization in both public and commercial activity, there remains considerable scope for digitalization to improve the operational efficiency of the water and sewage industries where the operation, planning, and maintenance of infrastructure is still largely undertaken by human staff.

In response to this situation, Hitachi supplies total solutions that utilize digital transformation (DX) to help overcome the challenges facing the water and sewage industries by enhancing operational technology (OT) for control and operations.

This article presents examples of DX in planning, operation, and maintenance. The first of these describes support for infrastructure planning through the use of artificial intelligence (AI) and big data to predict future water demand. Another looks at how, as major consumers of electric power, water supply businesses can also participate in the energy sector as virtual power plants (VPPs), enhancing operating practices to provide the ability to vary their electricity use as required. Hitachi is also using digital data to make improvements to its own operations. On-site commissioning or maintenance work needs to be done in a way that avoids closed spaces, crowded places, and close-contact settings. A third example describes how such practices are being enhanced by the use of augmented reality (AR). Security, meanwhile, is a crucial issue that cannot be overlooked in this use of digital data. The final section of this article looks at security solutions and a cybersecurity training facility.

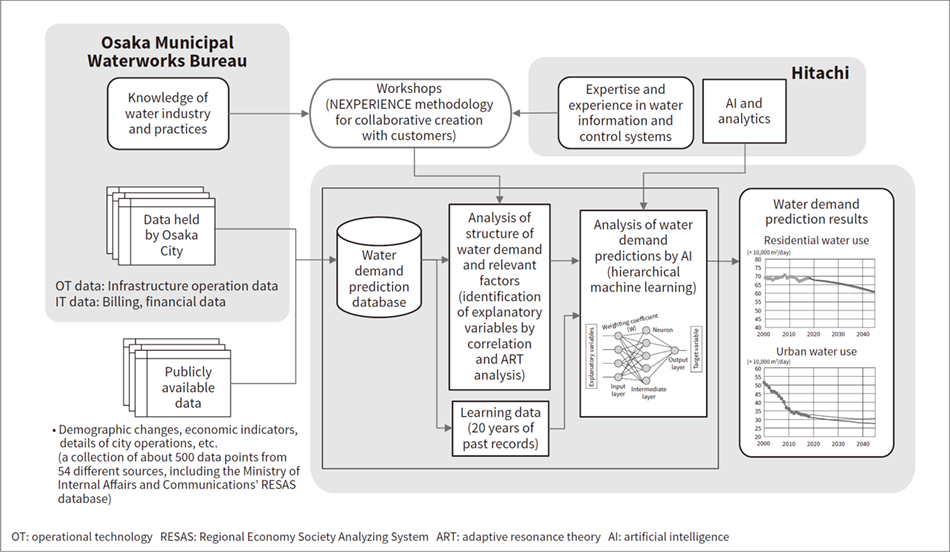

Figure 1 — Block Diagram of Long-term Water Demand Prediction Hitachi combines its expertise in information and control systems for water supply with AI and big data analytics and the Osaka Municipal Waterworks Bureau’s knowledge of the water industry to predict water demand on the basis of city data and public data from open sources.

Hitachi combines its expertise in information and control systems for water supply with AI and big data analytics and the Osaka Municipal Waterworks Bureau’s knowledge of the water industry to predict water demand on the basis of city data and public data from open sources.

Factors such as rising environmental awareness and changing lifestyles are behind a gradual decline in the demand for water experienced by water supply utilities. Meanwhile, factors relating to the economic growth of cities have also influenced water demand over recent years, including a rise of inbound visitors, major sports events, an expo, and the promotion of integrated resorts. Moreover, it remains uncertain what long-term changes will result from the impact of COVID-19 on social and economic activity. These circumstances have expanded the range of data that is relevant to water demand prediction. While the rapid expansion in the availability of open data sources calls for this data to be included, the concern is that there is only so much that can be done by human analysis given its huge volume and frequent updating.

Hitachi combines expertise in AI and big data analytics with its role as a full-service provider to the water industry, where it has built up experience and expertise from many years of working on the associated information and control systems. It has now developed a new technique for long-term water demand prediction. The technique is being used in joint research into the use of AI and big data for water demand prediction with the Osaka Municipal Waterworks Bureau, another organization with knowledge and expertise in demand prediction. Using the method shown in Figure 1, this has involved a case study in which water demand was predicted for approximately the next 20 years to provide a baseline from which to estimate future water supply revenues and infrastructure requirements.

As an example of how long-term water demand prediction might be used, Figure 2 shows the potential for formulating optimal plans for future water supply infrastructure (reservoirs, pipes, and so on) through the use of techniques that assist with equipment consolidation and asset management, including equipment ledger and piping management systems that hold information on existing infrastructure.

Future plans include conducting similar case studies in other cities and improving the accuracy of water demand prediction. Hitachi also plans to contribute to continuity and progress in the water supply sector by providing comprehensive support for operational decision making, using long-term water demand prediction as a means of facilitating planning for the ongoing reliable supply of water that is clean and trusted, and including it among the range of services it offers for resolving the upcoming challenges confronting water supply utilities.

Figure 2 — Application to Planning Using Long-term Water Demand Prediction Combining long-term water demand prediction with equipment ledger and piping management systems enables planning, such as the downsizing of pipe diameters or the consolidation or decommissioning of reservoirs and pumping stations.

Combining long-term water demand prediction with equipment ledger and piping management systems enables planning, such as the downsizing of pipe diameters or the consolidation or decommissioning of reservoirs and pumping stations.

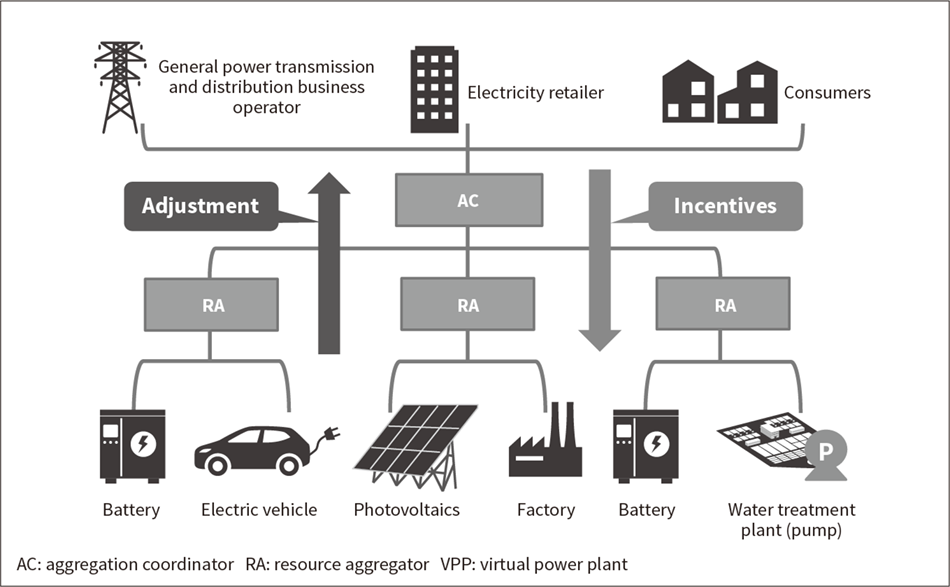

Figure 3 — Structure of VPP Market Consumers vary how much electric power they supply or consume in response to instructions from the AC and RAs, for which they are compensated with financial incentives.

Consumers vary how much electric power they supply or consume in response to instructions from the AC and RAs, for which they are compensated with financial incentives.

Photovoltaic power generation and other forms of renewable energy have become more common in recent years. However, the reliance of such energy sources on nature makes it difficult to ensure a reliable supply of electric power and VPPs have been put forward as one way of addressing this problem. A VPP takes a range of energy storage devices, such as batteries or electric vehicles, that are spread across electricity consumers and bundles them together as one large power source. As their name suggests, VPPs operate as a virtual source of electric power, discharging when the supply of power from the market is low and charging up again when there is an excess of available power, thereby providing a way to buffer the supply and demand for electricity. As shown in Figure 3, a VPP is made up of consumers with their own batteries or other energy storage resources, resource aggregators (RAs) that control these resources, and an aggregation coordinator (AC) that allocates over- or under-supply of electric power from the market to the RAs and monitors their performance. Consumers charge or discharge their resources in response to instructions from the AC and RAs, thereby keeping supply and demand in balance and earning revenue (incentives) in accordance with the amount of adjustment they provide.

What makes water infrastructure suitable for use as a VPP is that water utilities use large amounts of electric power for pumping water and operate reservoirs for the purpose of water storage. This means they are able to operate their infrastructure in a way that mimics a battery, halting pumps and relying on the existing stored water in reservoirs when there is a need to reduce electricity use, and then starting the pumps and topping up the water in the reservoirs when electricity is available again. As VPP operation requires a large adjustment capability across the system as a whole, the comparatively large capacity available from water utilities makes them a prime candidate for this role when set against the small capacity available from batteries owned by individual consumers.

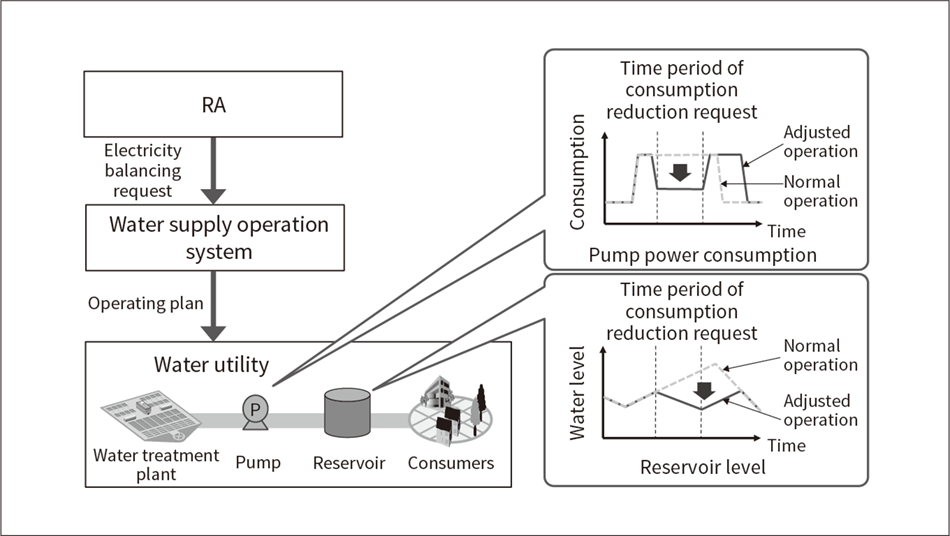

Figure 4 — Use of Water Infrastructure for Electricity Balancing Pump operation is controlled in response to requests to reduce electricity consumption in a way that maintains reservoir levels.

Pump operation is controlled in response to requests to reduce electricity consumption in a way that maintains reservoir levels.

The objective of utilities is to maintain a reliable supply of water. Because operating as a VPP involves varying reservoir levels, the purpose of which is to serve as a buffer to maintain steady water supplies, there is a risk that this will compromise supply reliability. Accordingly, there is a need to plan pump operation in a way that keeps reservoirs above a certain level, thereby ensuring that the supply of water is not disrupted.

Hitachi supplies operation systems for water infrastructure. These systems formulate daily operating plans for pumps, reservoirs, and other infrastructure based on predicted demand on the day concerned. The prediction of water demand is based on the weather forecasts, day-of-week, and past demand records. The system then uses these predictions to formulate plans based on the capacities of the water treatment plants, reservoirs, and pumps. These plans consider criteria such as filling reservoirs during the morning hours and minimizing the number of times pumps are turned on or off.

VPP operation receives requests from the AC and RAs specifying when and how much balancing capacity is needed. These are incorporated into the system’s planning criteria referred to above to generate plans that satisfy both the AC and RA requests and the requirement for reliability of supply (see Figure 4).

To establish practices for VPPs that incorporate the operational planning of water infrastructure, Hitachi participated during both FY2019 and FY2020 in the Virtual Power Plant Construction Demonstration Project that Utilizes Demand-side Energy Resources tendered by the Ministry of Economy, Trade and Industry(4). Work undertaken as part of this project has contributed to national VPP projects.

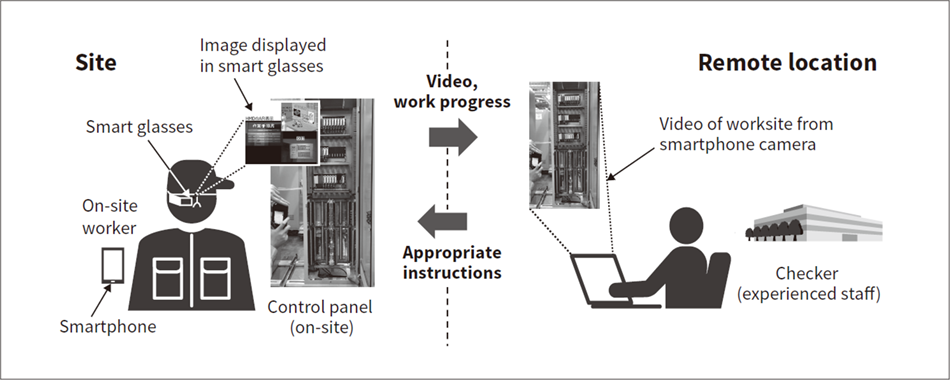

Figure 5 — Overview of Remote Operational Support System Remote support is provided by connecting to the site via a commercial telecommunications network.

Remote support is provided by connecting to the site via a commercial telecommunications network.

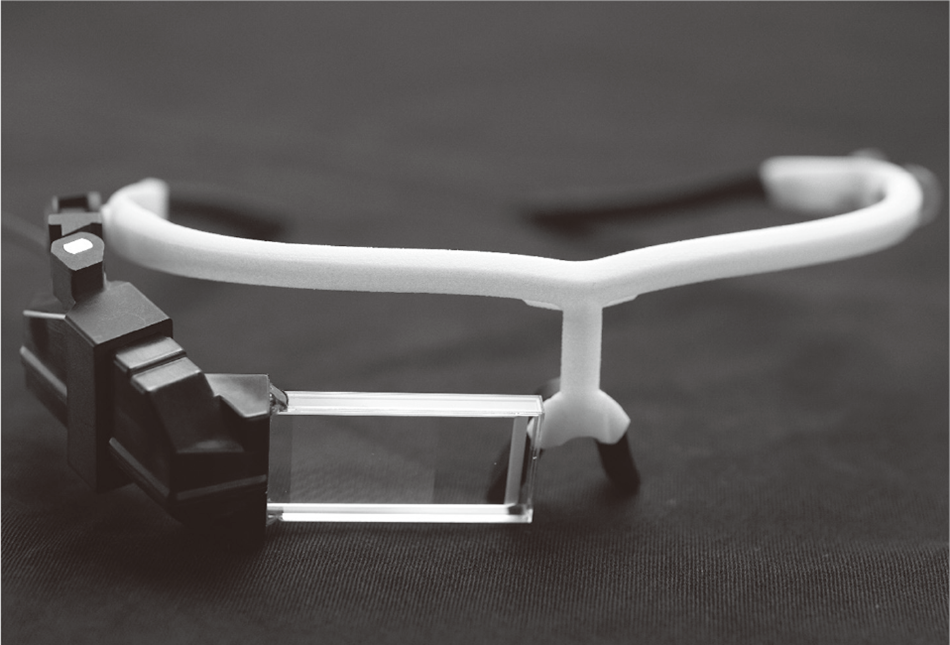

Figure 6 — AR Smart Glasses Made by Hitachi-LG Data Storage, Inc. The augmented reality (AR) smart glasses feature high luminance (5,000 nits or more) and high transparency (94%).

The augmented reality (AR) smart glasses feature high luminance (5,000 nits or more) and high transparency (94%).

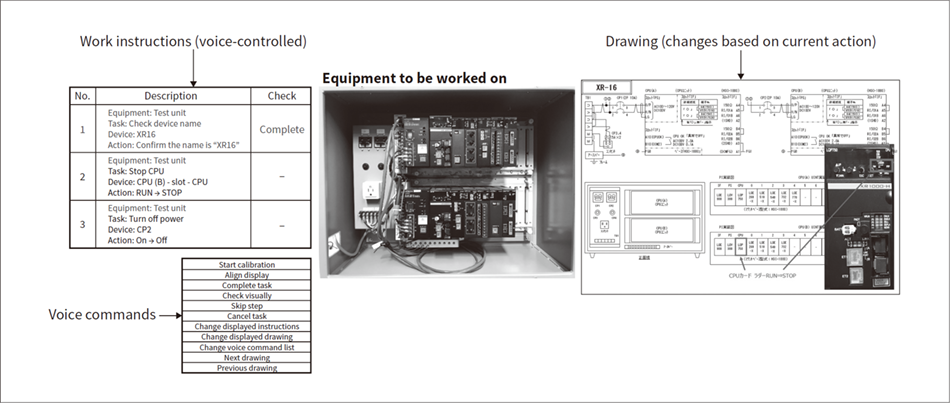

Figure 7 — Images Displayed in AR Smart Glasses On-site workers are able both to see what they are working on and to refer to work instructions and drawings on the smart glasses as they go about their task. Viewing of work instructions is voice-controlled (to finish viewing the document or change to a different one). It is also easy to resize or reposition the displayed documents and drawings.

On-site workers are able both to see what they are working on and to refer to work instructions and drawings on the smart glasses as they go about their task. Viewing of work instructions is voice-controlled (to finish viewing the document or change to a different one). It is also easy to resize or reposition the displayed documents and drawings.

Japan’s workforce is shrinking due to a low birthrate and aging population, estimated to fall from 64.04 million in 2020 to just 39.46 million in 2065(5). A lack of experienced staff has already become an issue within Hitachi, calling for the training of younger employees and the good use of those experienced staff who remain. Alongside this, the spread of COVID-19 has increased demand for remote working practices and for avoiding closed spaces, crowded places, and close-contact settings in the workplace.

With remote work support having attracted attention as a way to address this societal challenge, Hitachi is developing and implementing solutions that support commissioning, maintenance and inspection, and troubleshooting work.

Whereas past practice for on-site work was for this to be carried out by a two-person team, one to do the job and an experienced worker to check their work, a lack of such experienced staff makes it difficult to assign people with adequate expertise to every workplace. Moreover, having young and inexperienced workers perform such on-site work on their own risks human error due to impatience or lack of knowledge. To address this situation, Hitachi has introduced a remote operational support system.

Figure 5 shows an overview of the remote operational support system.

The sort of on-site work that in the past was performed by two people is instead done with one worker on site and another experienced person located remotely who checks the work. The on-site worker is equipped with smart glasses (see Figure 6) and a smartphone and is able to view work instructions (procedures) and drawings on the smart glasses as they go about their work (see Figure 7). The remotely located experienced worker (checker) watches the progress of the work as video sent via the smartphone and can provide the on-site worker with instructions as needed.

Future developments will include connecting to multiple sites so that work can proceed in parallel and enhancements to the remote monitoring functions to provide a more realistic experience. To achieve this, Hitachi plans to utilize its sensing and video analysis techniques to give access to more useful information by measuring distances at the site, audio information, and capturing the on-site worker’s movements and vital signs.

With the ongoing moves toward consolidation and joint operation in the water and sewage industries, practices such as the use of monitoring systems that operate over wide-area networks and the integration of multiple systems to make data available are becoming increasingly common. However, this interconnection of systems in turn raises concerns about cybersecurity(6).

The Ministry of Health, Labour and Welfare encourages utilities to implement robust cybersecurity, having stipulated in its 2020 revisions to the Ministerial Ordinance of Technical Standards for Water Supply Facilities(7) that cybersecurity measures [as defined in section two of Japan’s Basic Act on Cybersecurity (Act No. 104 of 2014)] be adopted to ensure that the electronic computers that manage the operation of infrastructure do not become a major risk to water supplies.

One recent incident occurred in February 2021 in the USA where a hacker gained unauthorized remote access to a monitoring and control system for a water treatment plant, instructing it to significantly increase the amount of sodium hydroxide added to drinking water(8). While quick action by operators, who noticed the change and restored the correct setting, prevented any harm to consumers, the incident highlighted the threat posed by cyberattacks.

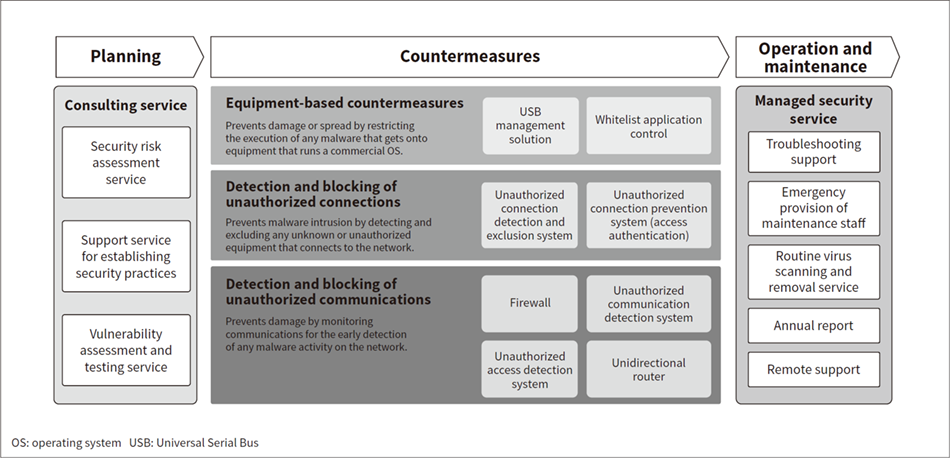

Hitachi supports cybersecurity in the water and sewage industries by drawing on its own experience and expertise in control security to provide comprehensive three-tiered support, covering planning, countermeasures, and operation and maintenance (see Figure 8).

The planning stage involves undertaking a risk assessment of security management and operation based on international standards and guidelines and recommending the establishment of organizations and systems capable of delivering the required security management and operation. The countermeasures phase involves solutions such as, (1) blocking the unauthorized use of unknown Universal Serial Bus (USB) memory devices to prevent malware intrusion, (2) specific measures involving the use of white-list application control to block the execution of unknown programs, thereby preventing any malware that does get into the system from spreading or performing any actions, and (3) installation of equipment for detecting unauthorized communications in an effort to ensure the early detection of any malware activity on the control network. Similarly, support for the operation and maintenance stage includes the prompt dispatch of emergency maintenance staff and assistance with the response when a security incident occurs as well as the use of remote access to enable an early resolution of problems.

Figure 8 — Security Solutions for Water and Sewage Hitachi provides support across the entire security life cycle of planning, countermeasures, and operation and maintenance.

Hitachi provides support across the entire security life cycle of planning, countermeasures, and operation and maintenance.

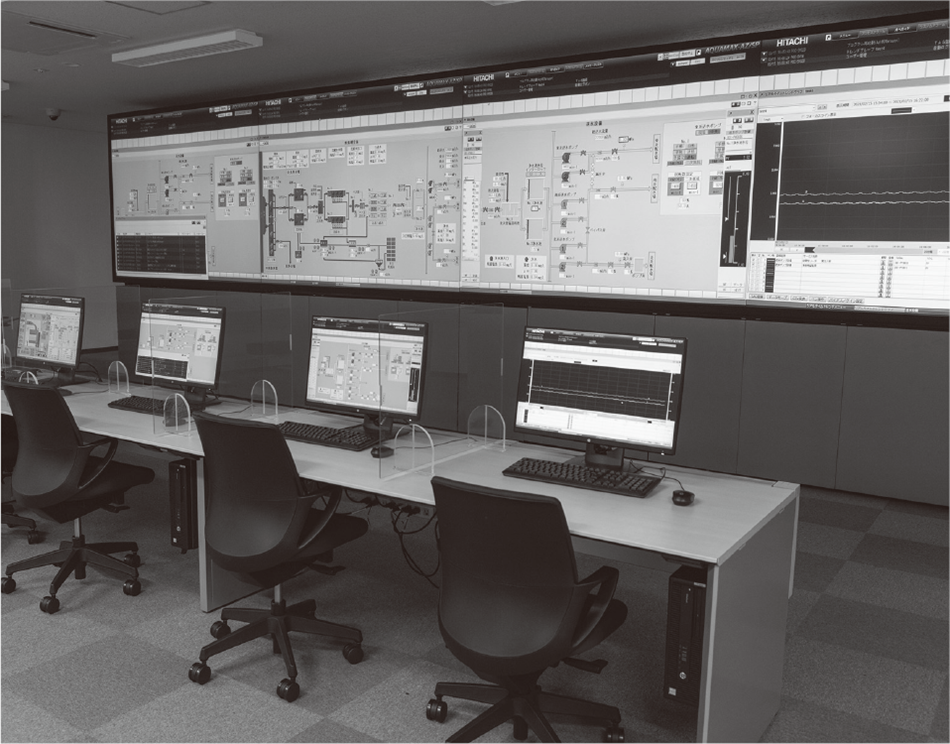

Figure 9 — Cybersecurity Training Facility Simulation Monitoring and Control System for Water and Sewage Trainees can participate in hands-on training in a realistic environment.

Trainees can participate in hands-on training in a realistic environment.

Security requires the strengthening both of the organization itself and of the practices by which IT and OT systems are maintained. In 2017, Hitachi established the Nx Security Training Arena (NxSeTA) at Omika Works (Hitachi City, Ibaraki Prefecture) to provide a venue for training exercises aimed at upskilling staff and organizations for the social infrastructure business(10). The facility replicates the sort of infrastructure systems supplied by Omika Works to provide a realistic environment for hands-on training and, since its inception, has hosted numerous personnel from Japan’s electricity and railway industries.

Training programs encompass lectures, workshops, hands-on exercises, and scenario drills. Moreover, by drawing on the control and information technologies and associated expertise built up by Hitachi over time, training can be flexibly customized to suit different customer policies and the skill level of the trainees. Hands-on exercises use a simulation of an information system or monitoring and control system to provide practical training in how actual attacks are perpetrated and what defensive measures to deploy when this happens. In scenario drills, trainees are put in charge of an IT or OT system and tasked with responding to a cyberattack. As separate scenarios are available for both system personnel and management, the exercises can also include decision making on whether or not to shut down operations based on the reports from system personnel. By assessing and providing feedback on organizational risk management as well as individual skill levels, the training contributes to personnel development by improving the response and decision-making capabilities of the organization as a whole.

To deal with movement restrictions put in place in response to COVID-19, Hitachi has also taken steps to offer training in a wider range of formats, including the introduction in April 2020 of a portable security training arena (that can be setup at a venue of the customer’s choosing) and remote security training arena (that uses remote access to conduct learning at a distance). The training facility was also upgraded in December 2020 with the addition of a simulation monitoring and control system for water and sewerage systems (see Figure 9). Hitachi also plans to further expand its range of training options for water and sewage utilities.

This article has presented examples of the use of AI and big data for long-term water demand prediction and to support planning, VPP projects that take advantage of DX in the water and electricity sectors, use of AR for smarter on-site maintenance practices, and security solutions that facilitate digitalization.

In the future, Hitachi intends to continue contributing to the resolution of societal challenges in the water and sewage industries through the development of technologies that utilize data to enhance OT and promote DX.