In the water supply sector, the Water Supply Act was revised in 2018 to address issues such as declining demand for water due to the shrinking population, aging water supply facilities, and the shortage of skilled workers. The revised Water Supply Act sets forth efforts for the systematic updating of water supply facilities from a long-term perspective as a responsibility of water utilities, and clarifies the importance of facility consolidation and reallocation. This article presents the latest efforts by the Hitachi Group to address these issues, describes the current status and future prospects of digital technologies that replace the five senses and experiences of operators with IoT and AI, as well as operation support technologies for facilities and equipment.

In the water supply sector, the Water Supply Act was revised in 2018 to address issues such as declining demand for water due to the shrinking population, aging water supply facilities, and the shortage of skilled workers. The revised Water Supply Act sets forth efforts for the systematic renewal of water supply facilities from a long-term perspective as a responsibility of water utilities, and clarifies the importance of facility consolidation and reallocation.

When consolidation or reallocation of facilities is implemented to improve the efficiency of staff allocation, a centralized monitoring system will be established from an integrated site. The number of utilities switching to this centralized monitoring system at an integrated site is expected to increase, but there are concerns that the reallocation of personnel will result in increased workload per operator and reduced judgment performance of operators due to management by inexperienced operators. Also, since the number of skilled operators is decreasing, it is becoming more difficult to pass on knowledge and skills to less experienced operators.

This article presents the latest efforts of the Hitachi Group to address these issues, describes the current status and future prospects of digital technologies that replace the five senses and experiences of operators with the Internet of Things (IoT) and artificial intelligence (AI), as well as operation support technologies for facilities and equipment.

The flocculation and precipitation process in water purification plants is a highly individualized process, and when water quality fluctuates, the amount of chemicals injected is changed based on the knowledge and experience of skilled operators. However, in recent years, the number of skilled operators has been decreasing, making it difficult to pass on their knowledge and technology. Therefore, to better pass on chemical dosage technology, Hitachi is developing an operation support technology that uses AI to learn the operation records of skilled operators and automatically calculate the flocculant dosage, and a technology that uses sensors instead of an operator’s five senses to determine whether flocculation is acceptable or not.

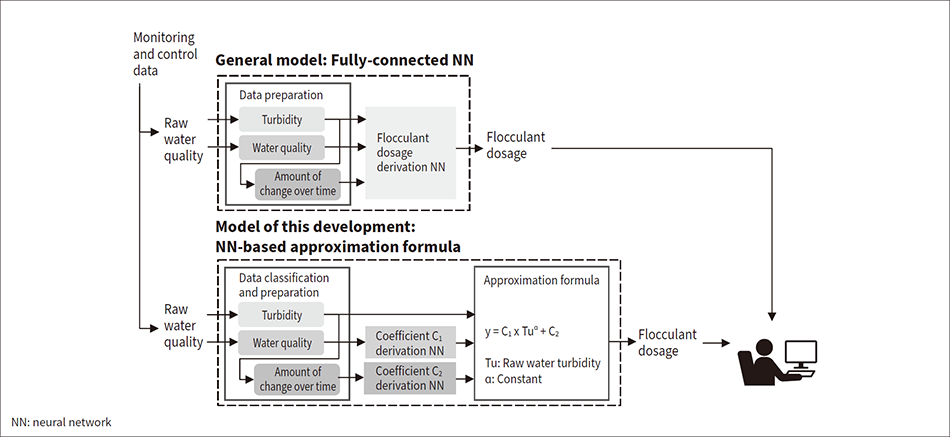

A neural network (NN) is an AI technology that can automatically extract and model the driving operation tendencies of skilled operators with high accuracy based on data. However, there is a concern that the margin of error could be large when the raw water quality is extrapolated beyond the data range of the training period. Another issue is that the readability of the calculation process is low and the obtained result is not easily explainable. Therefore, Hitachi built an NN-based approximation formula that combines NN with an approximation formula showing the relationship between raw water turbidity and flocculant dosage, which are major influencing factors (see Figure 1)(1). This formula was expected to maintain the relationship between the values of raw water turbidity and flocculant dosage even for extrapolated conditions and to prevent significant deviations in the values.

Also, a prediction model was developed to calculate the flocculant dosage using the raw water quality (turbidity, pH, water temperature, alkalinity, etc.) and the change in raw water turbidity over time as inputs. The monitoring and control data were divided into training and evaluation data. Figure 2 compares the predicted values of raw water turbidity, which is the main influencing factor, and the flocculant dosage calculated by the NN-based approximation formula. The predicted values of the fully-connected NN changed to a gradual downward trend when the turbidity exceeded the maximum turbidity (55 degrees) of the training data, whereas the NN-based approximation formula maintained an upward trend. This indicates that the correlation between raw water turbidity and flocculant dosage can be maintained by the approximation formula even when outside the range of the training data.

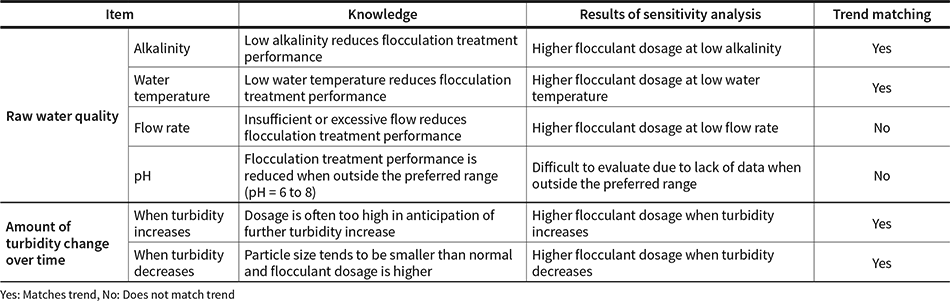

The sensitivity was evaluated to understand the influence of the rise and fall of raw water quality and raw water turbidity on the predicted results for the flocculant dosage in the NN-based approximation formula (see Table 1). Changes in the predicted flocculant dosage due to the rise and fall of the alkalinity, water temperature, and raw water turbidity were consistent with the findings, and this is expected to improve the explainability of the findings. It can be said that the NN-based approximation formula developed in this study was able to automatically find the operation based on the experience of skilled operators and apply it in the model.

Figure 1 — Overview of Operation Support System for Calculating Flocculant Dosage Hitachi provides an operation support technology that automatically calculates the flocculant dosage from the raw water quality. By combining an NN and an approximation formula that incorporates knowledge of the flocculation treatment process, operations based on the experience of skilled operators are automatically found and modeled.

Hitachi provides an operation support technology that automatically calculates the flocculant dosage from the raw water quality. By combining an NN and an approximation formula that incorporates knowledge of the flocculation treatment process, operations based on the experience of skilled operators are automatically found and modeled.

Table 1 — Comparison of Trend Extracted from Knowledge of the Flocculation Treatment Process and the NN-based Approximation Formula The trend obtained from the sensitivity analysis of the NN-based approximation formula is consistent with the knowledge of the flocculation treatment process, and this is expected to improve the explainability of the findings.

The trend obtained from the sensitivity analysis of the NN-based approximation formula is consistent with the knowledge of the flocculation treatment process, and this is expected to improve the explainability of the findings.

A convolutional neural network (CNN) is a machine learning technique widely used for image recognition, and when applied to images of flocs (particle clumps produced by flocculation), it enables modeling to evaluate whether flocs are in a flocculation state, which is conventionally done visually by skilled operators. Hitachi has developed a regression-type CNN model that predicts the sedimented water turbidity by using the raw water quality and operating conditions (turbidity, pH, water temperature, flocculant dosage, and intake flow rate) that affect the flocculation and precipitation process as well as floc images as inputs.

The regression-type CNN model was evaluated using floc images and monitoring and control data obtained from underwater monitoring cameras at an actual site during the summer season. The results showed that the prediction accuracy of sedimented water turbidity was improved during the period when the raw water quality was stable compared with the fully-connected NN estimation which only used the raw water quality and the operating conditions as input. This suggests that the floc images can be used to detect changes in the flocculation state that cannot be detected by the raw water quality and operating conditions alone. In this study, Hitachi will obtain floc images and monitoring and control data during the winter and snow-melting periods at the actual site to evaluate the prediction accuracy of sedimented water turbidity throughout the year.

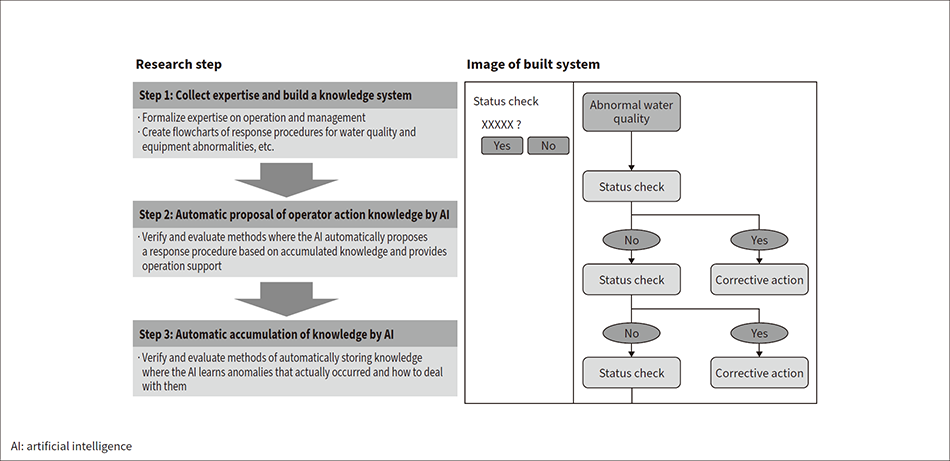

Figure 3 — Steps Taken in Joint Research with the Osaka Municipal Waterworks Bureau Hitachi aims to establish an operation support and human resource development method that utilizes AI technology and a knowledge system that formalizes operation expertise.

Hitachi aims to establish an operation support and human resource development method that utilizes AI technology and a knowledge system that formalizes operation expertise.

The flocculation and precipitation process as well as the operation and monitoring of water purification plants depend heavily on the individual skills of operators, but the number of skilled operators has been decreasing due to the declining birthrate and aging population, making it difficult to pass on knowledge and skills. This is what led Hitachi to start a joint research project with the Osaka Municipal Waterworks Bureau to build a knowledge system that formalizes the operation expertise of water purification plants and to automate operator action proposals and accumulation of expertise by using AI(2). The aim is to build a sustainable operation and management system with a small number of operators and utilize the knowledge system for human resource development.

This joint research aims to establish a knowledge system that formalizes operation expertise by using Hitachi’s Lumada to analyze a wide variety of data through statistical analysis, AI, and other methods, based on the wealth of knowledge and data obtained by the Osaka Municipal Waterworks Bureau in the operation and management of water purification plants to date. It also aims to establish an operation support and human resource development method using AI technology. The steps of the joint research are shown in Figure 3. First, in Step 1, formalization of operation and management expertise and flow of response methods for water quality and equipment anomalies are created. Next, in Step 2, Hitachi verifies and evaluates a method for providing operation support by using AI to automatically propose a response method based on accumulated knowledge. Finally, in Step 3, the AI automatically accumulates the relationships between “objects” including abnormalities and “items” such as related operations and operating conditions, and verifies that the accumulated results are effective as knowledge. Also, Hitachi examines how to use the knowledge in training programs and other applications for human resource development.

The water supply business is the business of supplying tap water to municipalities and other waterworks companies that supply water to general households. The Saitama Prefectural Public Enterprise Bureau acquires water sources through dam development to cope with rapid increases in population and delivers water treated at the water purification plant to the water tanks of water service companies. The environment where waterworks operate is expected to come under more severe conditions in the future, with declining water demand resulting in lower fee revenues, aging facilities, and the retirement of skilled engineers. Hitachi believes that it is important for the water supply business and the waterworks business to work together to improve the waterworks infrastructure (including consolidation and elimination), optimize its operation, and improve the efficiency of its maintenance and management throughout the entire region.

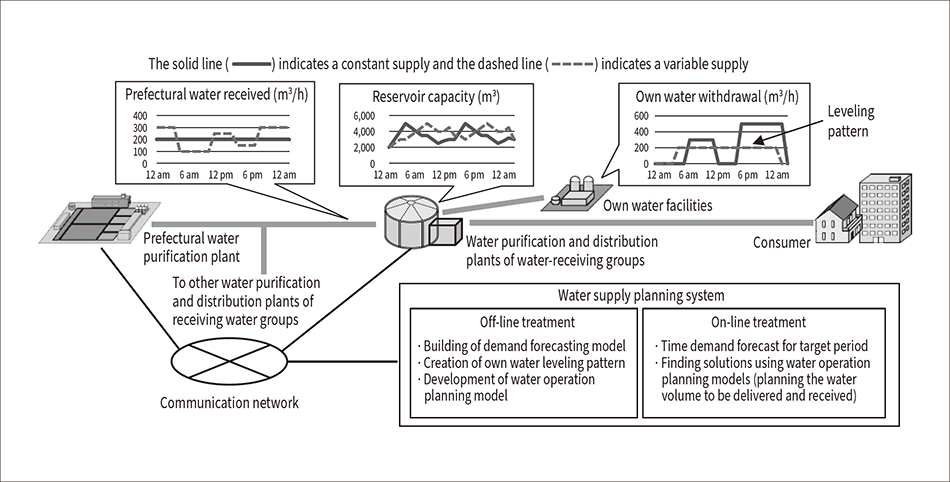

One method of efficient cooperation between the water supply business and the waterworks business is variable water supply. This is a method that modifies the current fixed-quantity supply of tap water to water-receiving organizations (municipal and other water utilities) and flexibly adjusts the amount of tap water supplied (amount of water received by municipalities) using the water distribution reservoirs at the water purification plants and water distribution plants of the receiving bodies as buffers. This reduces fluctuations in the amount of water that is withdrawn by the organization receiving water (its own water supply) in response to demand, and makes it possible to optimize (downsize) its own water supply facilities. Figure 4 shows an overview of the water supply planning system for enabling a variable water supply. Achieving a variable water supply for tap water will enhance the continuous maintenance of the water utilities by reducing the cost of updates by municipalities and other water utilities for their own water facilities and ensuring water supply demand for tap water by the water supply companies. A feasibility study of the variable water supply system is being conducted jointly with the Saitama Prefectural Public Enterprise Bureau(3).

Figure 4 — Overview of Water Supply Planning System for Providing Variable Water Supply Based on demand forecasting and water operation planning technology, a water operation plan is developed to meet various constraints such as projected water demand and upper and lower limits of reservoir storage capacity to develop its own leveled water supply pattern in advance. The leveling of a provider’s water supply enables downsizing of its own water facilities.

Based on demand forecasting and water operation planning technology, a water operation plan is developed to meet various constraints such as projected water demand and upper and lower limits of reservoir storage capacity to develop its own leveled water supply pattern in advance. The leveling of a provider’s water supply enables downsizing of its own water facilities.

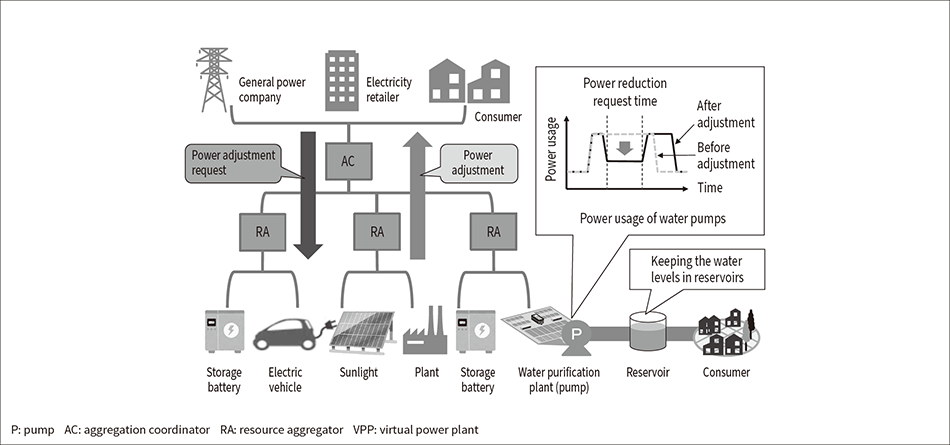

Figure 5 — Entry to VPP Market Using Water Supply Facilities In response to a power reduction request from the AC and RA, power adjustment is performed by adjusting the pump operation time while maintaining the water level in the distribution reservoir.

In response to a power reduction request from the AC and RA, power adjustment is performed by adjusting the pump operation time while maintaining the water level in the distribution reservoir.

With the growing awareness of global environmental issues, renewable energy equipment such as solar power generation and energy-saving devices are becoming more widespread and storage batteries are being installed to deal with power shortages. The concept of a virtual power plant (VPP) is one of the most efficient ways of using these devices and power sources. A VPP is a system that functions as a virtual power plant by bundling storage facilities such as storage batteries and electric vehicles (EVs) and treating them as a large power source, charging and discharging them according to the power usage of the market.

The structure of a VPP is shown in Figure 5. The VPP consists of a resource aggregator (RA), which controls power adjustment resources such as storage batteries, and an aggregation coordinator (AC), which distributes and coordinates surpluses or shortages of market power to the RA. The AC requests power adjustments as necessary according to market conditions, and the RA adjusts power by controlling the charging and discharging of power adjustment resources. Water supply facilities are assumed to be used as a power adjustment resource. Water utilities use a large amount of electricity to operate pumps and have distribution reservoirs for storing water. For this reason, significant adjustment performance can be obtained by controlling the operation time slots of water feed pumps while appropriately managing the amount of water stored in the distribution reservoirs.

Hitachi provides a water operation planning system that predicts water demand and formulates stable and efficient operation plans for pumping facilities according to the conditions of the water supply facilities. By applying this technology, water supply facilities can be used as power adjustment resources for VPPs, thereby contributing to a reduced environmental burden.

Going forward, Hitachi’s water business will incorporate information and control technology into its monitoring and control systems and Lumada’s comprehensive digital solutions for water and sewage utilities, and as a comprehensive water service provider, contribute to solving customer issues and creating a resilient social infrastructure.

The authors would like to express their deepest gratitude to the Osaka Municipal Waterworks Bureau, the Saitama Prefectural Public Enterprise Bureau, and others for their cooperation and support in its efforts to accumulate and utilize knowledge on the operation of water purification plants and to optimize water operation in the water supply business as described in this article.