Water and sewage pipe assets, which account for the majority of the assets of water utilities in Japan, were mostly constructed during the post-World War II period of rapid economic growth, and consequently, there are growing concerns that they are aging. Moreover, the aging of the workforce and reduced staff numbers are also issues that require urgent measures to provide safe and secure water supply and sewage systems. This article presents five examples of solutions developed to solve issues faced by water and wastewater utilities in their pipes. All of these solutions are effective in enabling appropriate pipe maintenance and management operations and can be widely used by water and sewage utilities.

The majority of the assets of water utilities in Japan are water and sewage pipe assets that were mostly constructed during the period of rapid economic growth after World War II, and consequently, there are growing concerns that they are aging. As a result, urgent measures are required to provide safe and secure water supply and sewage systems. On the other hand, the aging of the workforce and staff shortages have become issues, and there is a strong need to pass on skills and improve the efficiency of maintenance and management operations. In this context, Hitachi is working daily to develop and commercialize services for more effective operations of utilities by combining the digital technologies and products that it has developed on its own.

This article describes five of these efforts that are considered to be widely and commonly utilized in the maintenance and management departments of utilities. First, this article presents Hitachi’s leak detection service and pipe management support system for improving the efficiency of water pipe maintenance and management. This is followed by the use of drones for inspecting pipes, which have been difficult to inspect by humans, fiber-optic multi-sensing for providing a reliable power supply, and a rainwater pump operation support system as a flood prevention solution that takes into account the structure of the pipe during localized heavy rains.

This section presents Hitachi’s leak detection service and pipe management support system, which are provided as maintenance and management support services for waterworks.

The leak detection service constantly monitors water pipes using a proprietary ultra-sensitive vibration sensor, and consists of a leak detection sensor with communication functions and a monitoring platform in the cloud(1).

Specifically, a sensor installed on a water control valve of a water pipe measures the vibrations propagated from the point of leakage, and assigns a score to the result from analysis of the measured data. The score is transmitted from the sensor to the monitoring platform and displayed on a screen to visualize the presence or absence of suspected leaks. This service enables utilities to remotely monitor the status of underground pipes without having to go to the site. Also, since the scope of suspected leaks can be narrowed down, the service is expected to improve the efficiency of investigation work for confirming the point of leakage.

This service was awarded the Minister of Education, Culture, Sports, Science and Technology Prize at the 51st Japan Industrial Technology Awards organized by Nikkan Kogyo Shimbun, Ltd.(2) and is scheduled to be widely deployed in Japan and abroad as a service that contributes to achieving a safe, secure, and resilient social infrastructure.

Since pipes were installed in a concentrated manner during certain periods of time in the past (around 1975, 1998, etc.) to increase the water supply coverage, it is expected that the pipe replacement period will also be concentrated during certain periods of time in the future. As a result, the annual investment in updating pipes is expected to be extremely high only during certain periods, making long-term update planning difficult.

The pipe management support system that is presented here helps to resolve this issue by calculating the base year for pipe renewal and leveling the amount of investment related to pipe renewal, thereby supporting the preparation of pipe renewal plans.

Specifically, information on underground pipes made of various materials and joints, as well as actual leakage incident data accumulated from the above-mentioned leak detection service monitoring platform, are added to evaluate the incident rate of pipes using a proprietary method of statistical analysis and to calculate the base year for pipe renewal. Based on the calculated base year for pipe renewal, the amount of investment in pipe renewal is leveled by making the annual investment in pipe replacement by each utility as uniform as possible. The leveling of the investment amount is based on an amount that minimizes the life cycle cost (LCC, the total cost of the pipe, including initial installation, maintenance, and management) as much as possible.

The system automatically calculates the amount of investment in pipe renewal for each fiscal year, which contributes to higher efficiency for the person preparing the pipe renewal plan, and it is also important to emphasize that this system can contribute to the transparency and accountability of the utility’s operations. Utilities of a highly public nature are expected to be able to use the information from this system to provide clearer and more persuasive explanations not only internally, but also to representative assemblies and citizens during the budget formulation and approval process.

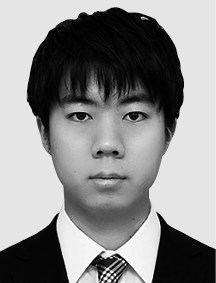

Going forward, Hitachi will provide this pipe management support system as a data lake that will help utilities optimize and advance their water pipe maintenance and management by consolidating and utilizing all pipe-related data (see Figure 1).

Figure 1 — Services to Support Maintenance and Management of Water Pipes This figure shows the data flow and examples of use.

This figure shows the data flow and examples of use.

Next, this section introduces available solutions to support the maintenance and management of sewer pipes, such as Hitachi’s sewer pipe investigation service, which uses drones, multi-sensing using optical fiber, and pump operation support during rainwater events.

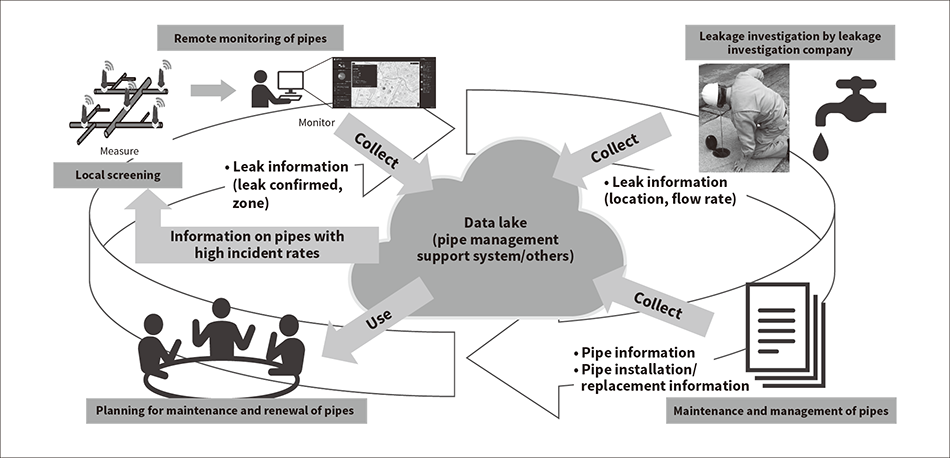

Figure 2 — Drone, Simulated Crack, and Flight Conditions The drone is shown at the top left, the simulated crack at the top right, and the flight conditions in the sewer pipe in the bottom image.

The drone is shown at the top left, the simulated crack at the top right, and the flight conditions in the sewer pipe in the bottom image.

Up to now, the maintenance and management of sewer pipes have been conducted primarily through visual inspections by humans or by video camera equipment. However, the high water levels, high flow rates, and high concentration of hydrogen sulfide in some sewer pipes make them difficult to investigate because of the high risks they entail for humans. To address this issue, Hitachi is developing a sewer pipe investigation solution using drones in collaboration with the Bureau of Sewerage Tokyo Metropolitan Government and the Tokyo Metropolitan Sewerage Service Corporation. Specifically, the system consists of (1) a drone specialized for flying inside sewer pipes and photographing the inside surface of pipes, and (2) an installation device for getting the drone into and out of the ground. The drone can be operated on the ground without a person entering the sewer pipe while images taken from the front of the drone are viewed on a monitor to enable images of the inside of the sewer pipe to be taken safely.

The main functions of each system component are as follows.

Using this drone and the installation device, Hitachi conducted a recorded flight to a maximum distance of 224 m away from the base in an in-service combined trunk sewer (cross-sectional width 5.0 m, height 4.5 m, depth 25–30 cm) and confirmed that the drone could fly back and forth stably without touching the walls, ceiling, or water surface, and could capture images of a simulated crack (5 mm wide black line drawn on a blank sheet of paper) equivalent to damage rating an A from the Bureau of Sewerage Tokyo Metropolitan Government. Despite the high humidity inside the pipe compared to the ground, there was no condensation on the investigation camera due to pre-heating and other measures, and the camera was able to capture images of good quality.

This solution enables the safe inspection of the inside of sewage pipes even in environments that are difficult for humans to investigate. Since the sewer pipes in such environments are more likely to be deteriorated, the solution will contribute to more accurate planning of repair and reconstruction work. In the future, Hitachi plans to conduct recorded flights of sewer pipes of various shapes and sizes to further clarify issues and apply the results in actual operation. Furthermore, Hitachi intends to combine the system with image processing technology that automatically identifies potential areas of deterioration from the recorded images to support more efficient investigation work (see Figure 2).

For maintenance and management of sewer pipes, visualization is required to assess the water level, water quality, and even the environment inside the pipe using gas sensors and to manage such information. However, when sensors and transducers are permanently installed in a pipe for visualization, there is no continuously available power source, and a means of communication is also required. This led Hitachi to focus on the use of optical fibers installed in sewer pipes. Hitachi resolved this issue by using optical fiber not only as a general communication channel, but also as a supply channel for sensing power using power-over-fiber (PoF) technology.

Sewer optical fiber is an optical fiber cable laid in sewer pipes for communication between sewer facilities. The installation of fiber-optic cables is proceeding for the purpose of upgrading and improving the efficiency of sewer facility management, and as of the end of FY2020, a total of approximately 2,227 km of fiber-optic cables have been installed nationwide, mainly in urban areas such as Tokyo(3). Also, because the optical fiber is buried underground, it is highly secure in the event of a disaster. Even during the Great East Japan Earthquake, there were no communication failures, and they played a major role in communicating among facilities and monitoring facility status conditions(4).

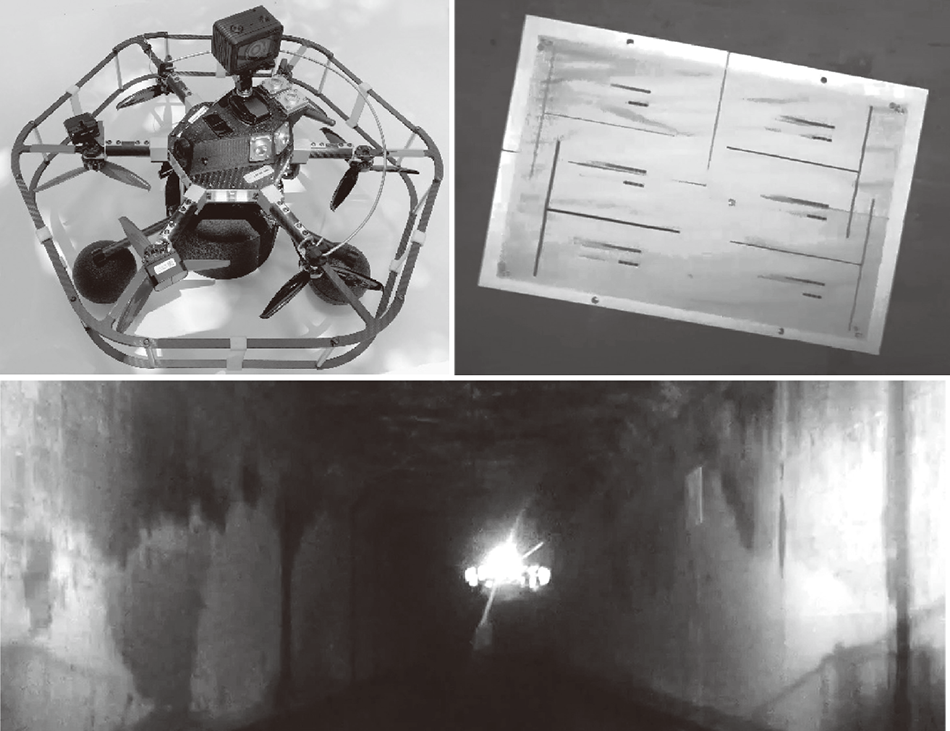

Figure 3 — Fiber-optic Multi-sensing System Real-time monitoring of sewage pipe conditions through sensing using fiber-optic communication and power-over-fiber (PoF).

Real-time monitoring of sewage pipe conditions through sensing using fiber-optic communication and power-over-fiber (PoF).

The system consists of field nodes, controllers, and a gateway, and uses PoF technology to provide power and communication from the controllers to the field nodes via a single optical fiber using wavelength division multiplexing communication (see Figure 3).

Up to four sensors (detachable with waterproof connectors) can be connected to each field node to measure the status conditions of pipes. The sensors include water level, conductivity, pH, and gases (hydrogen sulfide and cyanide).

For example, water-level meters and conductivity meters can be used to determine rainwater inflow, and pH meters can be used to determine abnormal water quality. The measurement of hydrogen sulfide using a gas sensor provides important information for identifying the source of foul odors in building cesspits and for managing corrosion in sewer pipes. The field node is in a waterproof housing so that it can be installed in locations where it may be submerged in water. This configuration enables the building of a flexible system capable of connecting up to five field nodes within a total length of 10 km to a single fiber-optic cable. The gateway accumulates the measurement data and provides it to a control center, sewage treatment plant system, or other location. The system is equipped with a measurement data analysis function in the gateway, and is capable of detecting unknown water, abnormal water quality, early rainwater, etc., and sending out e-mail alerts.

Pump stations in combined sewer systems that handle both sewage and stormwater must give priority to preventing flooding in the sewage treatment area by quickly removing rainwater that has fallen in that area. However, depending on the level of rainfall, operation must also address risks such as submerging sewage pump stations and increasing the environmental pollution load due to untreated simple effluent(5). Even now, there are cases where pumps are operated manually by skilled operators due to difficulties in automatic operation such as localized heavy rainfall, but there is concern that such expertise may be lost in coming years due to the mass retirement of skilled operators as a result of the declining birthrate and aging population in Japan.

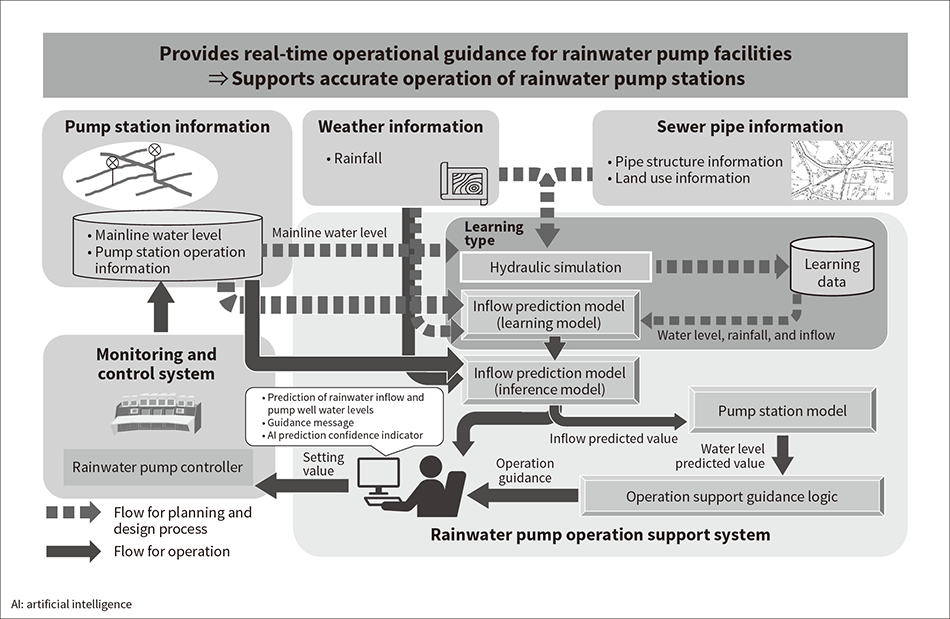

To address the above issues, Hitachi is developing a rainwater pump operation support system that uses artificial intelligence (AI) to predict inflow and provide operators with appropriate plans for starting and stopping rainwater pumps.

The frequency of rainfall at which rainwater pumps operate is not sufficient as training data for AI. Therefore, hydraulic simulations based on actual data on mainline water levels and rainfall, as well as sewage pipe information such as land use and pipe structure, are used to calculate inflows for various rainfall patterns, which are then used as training data (see Figure 4).

During planning and design, actual data from pump station operation (starting/stopping of pumps/generators, amount of effluent/water delivered, opening of water gates, etc.), mainline water level (collected by fiber-optic multi-sensing system, etc.), rainfall (rainfall radar), and data generated by hydraulic simulation are used as learning data to create an inflow prediction model (learning model).

During operation, the system predicts the inflow rate by inputting real-time data using the learned model as the inference model, predicts the pump well water level and other parameters using the pump station model, and provides the timing of pump startup and shutdown from the operation support guidance logic according to the prediction results. The operation support guidance logic, which applies the expertise of experienced operators, can select and provide guidance in accordance with the operation policy, such as prioritizing water level or effluent quality. The accuracy of the inflow rate prediction will be improved by continuously adjusting the parameters based on the data accumulated through the usage of the operation support system.

This system helps visualize the reliability of AI predictions and is equipped with a human machine interface (HMI) that allows the operator to intervene as needed, enabling the operator to achieve pump operation in which the AI and the operator cooperate with each other while keeping the certainty of the AI predictions in mind.

Figure 4 — Rainwater Pump Operation Support System In addition to actual data, hydraulic simulation results are also used as training data to create an inflow prediction model (learning model).

In addition to actual data, hydraulic simulation results are also used as training data to create an inflow prediction model (learning model).

This article has presented examples of digital solutions developed for the maintenance and management of water and sewage pipes. These solutions are currently being developed for water utilities in Japan, but Hitachi will devise ways to provide services in a more flexible manner based on the unique circumstances of each customer. Also, with an eye on international expansion, all of those involved in this project will work together to build services that can be used by more customers and to continuously improve the quality of these services.