Efforts are being made on a global scale aimed at minimizing the temperature rise due to global warming. In particular, an increasing number of countries, regions, and companies are setting targets for 2030 and 2050 as they work toward reducing greenhouse gas emissions and achieving carbon neutrality. Companies are seeking to achieve carbon neutrality by reducing their own emissions (Scope 1 and Scope 2 emissions) and making the transition to renewable energy. However, they are also being called upon to achieve carbon neutrality in terms of emissions across the entire supply chain (Scope 3), including raw materials and the use of their products, and to audit the quantity of greenhouse gases emitted in the course of supplying their products and services. This article focuses on energy management systems and describes support for efforts to achieve carbon neutrality at the company level in particular (Scope 1 and Scope 2 emissions).

Efforts to curb the increasing severity of climate change have been growing, including an agreement to limit global warming to 1.5°C above pre-industrial levels by 2030, adopted at the 26th United Nations (UN) Climate Change Conference of the Parties (COP26)(1) held in Glasgow, UK from October to November, 2021. At the same time, alongside the adoption by national governments of policies aimed at achieving carbon neutrality by 2050, there are also rising expectations for voluntary action by society as a whole.

In Japan, the Fifth Strategic Energy Plan(2) was approved by the Cabinet in July 2018, in advance of COP26. The Sixth Strategic Energy Plan is now being formulated and includes the objectives of reducing emissions of greenhouse gases by 46% from 2013 levels by 2030 and achieving carbon neutrality by 2050.

Meanwhile, if companies are to live up to these societal expectations, they will need to make the transition to carbon neutrality not only in their own operations, but also across their entire supply chains. This article describes energy management systems that help to overcome the challenges associated with achieving carbon neutrality within individual companies.

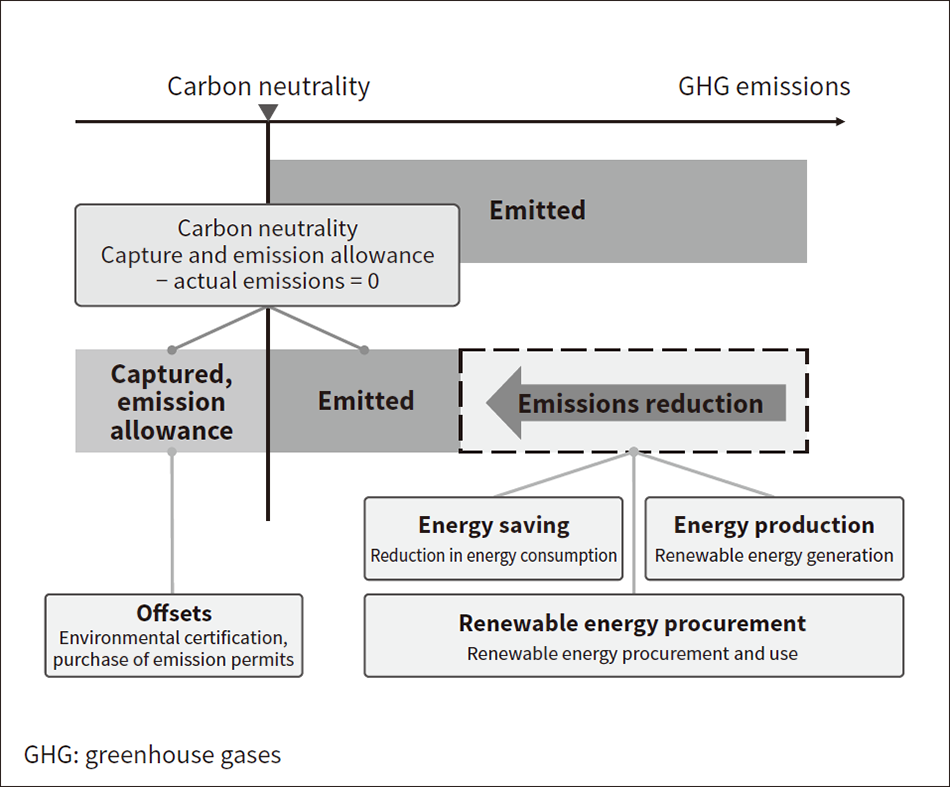

Figure 1 — Ways of Achieving Carbon Neutrality Achieving carbon neutrality will require a sensible mix of four different approaches.

Achieving carbon neutrality will require a sensible mix of four different approaches.

There are four different approaches that can be taken to achieving carbon neutrality. These are energy saving to reduce energy use at companies, energy production whereby companies generate their own carbon-free renewable energy, procurement of carbon-free renewable energy, and offsetting carbon emissions. Achieving carbon neutrality requires a sensible mix of these different approaches (see Figure 1).

Among these different approaches, energy saving is particularly important and warrants a high priority because, along with reducing the cost of implementing the other measures, it also frees up resources for doing so. At companies that have already put a lot of effort into energy saving, on the other hand, the issue that deserves prompt attention is when and how to install or purchase carbon-free energy.

Meanwhile, given the variability of renewable energy, the risk of imbalances in the supply and demand for electric power is rising. While renewable energy will need to become a major form of grid-connected electricity generation if society is to become carbon neutral, this will make the risk of imbalances in electricity supply and demand even higher than it already is, posing a challenge for society relating to the maintenance of grid stability.

Energy management in the past has often been no more than a tool for providing insight into what is happening or for investigating different ways of doing things, with the benefits only coming from work being put in on the ground. To achieve more intensive energy savings, however, the scope of these systems is increasingly being extended to include control, combining demand prediction and optimization techniques to also help implement such measures and reap their benefits.

There is a need to make energy management systems more sophisticated by combining the demand prediction and optimization techniques mentioned above with information such as renewable energy generation predictions and electricity market prices. As well as making full use of all renewable energy produced and avoiding curtailment, such systems can also be used to minimize the cost of purchased renewable energy.

An electricity balancing market was established in Japan in April 2021 to provide the adjustment capabilities (balancing capacity) needed for frequency control on electricity transmission and distribution networks and to balance supply and demand(3). This provides a mechanism for the grid-level procurement and operation of balancing capacity across multiple areas and a market for buying and selling demand response capacity in order to reduce balancing costs by promoting transparency and competition based on market principles. The establishment of this market has made it easier to cope with the fluctuating output of renewable energy.

While the output of renewable energy varies depending on weather conditions, the market allows the electricity transmission and distribution system to maintain grid stability by acquiring balancing capacity from electricity users in real time. As well as giving users the opportunity to play their part in addressing societal challenges, the provision of balancing capacity also generates revenue that users can reinvest in carbon neutrality. That is, whereas they would have received no compensation in the past, the market now allows users to sell whatever balancing capacity they have available.

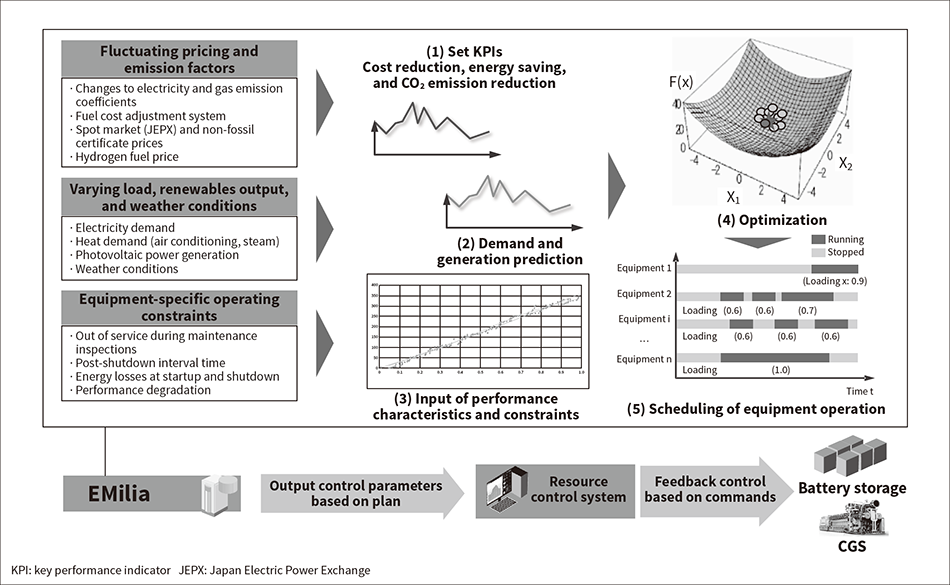

One system for achieving carbon neutrality as described above is the EMilia integrated management system for energy and equipment(4) that Hitachi has been supplying since 2017 (see Figure 2). To date, Hitachi has installed community energy management systems (CEMSs), factory energy management systems (FEMSs), and building energy management systems (BEMSs) (see Figure 3).

EMilia has functions that go beyond visualization, it is also equipped with functions for more intensive energy savings. In addition to demand prediction linked to the weather and production scheduling, it also incorporates an optimal operational planning function for minimizing costs and carbon dioxide (CO2) emissions that can control the operation of utility supply equipment and provide feedback to production scheduling.

When it comes to achieving carbon neutrality, there will likely be a limit to how much can be accomplished by past approaches to energy management that targeted energy savings made by eliminating waste and inefficiency.

EMilia, on the other hand, can maximize benefits by delivering more intensive energy saving, cost savings, and full utilization of energy production through the seamless integration of control with optimal operational planning based on ever-changing external circumstances (including energy prices and CO2 pricing and emission factors), energy demand, and the operational constraints and performance characteristics of utilities (see Figure 4).

EMilia is able to address more complex customer challenges because it combines the relevant functions in a single system in a way that best suits customer requirements. These include demand prediction for heat and power, calculation of how best to use equipment, and the scheduling and control of equipment operation.

Figure 4 — Energy Saving by Means of Optimal Operations Planning and Control The aim is to make energy savings by formulating an optimal operations plan and controlling equipment accordingly.

The aim is to make energy savings by formulating an optimal operations plan and controlling equipment accordingly.

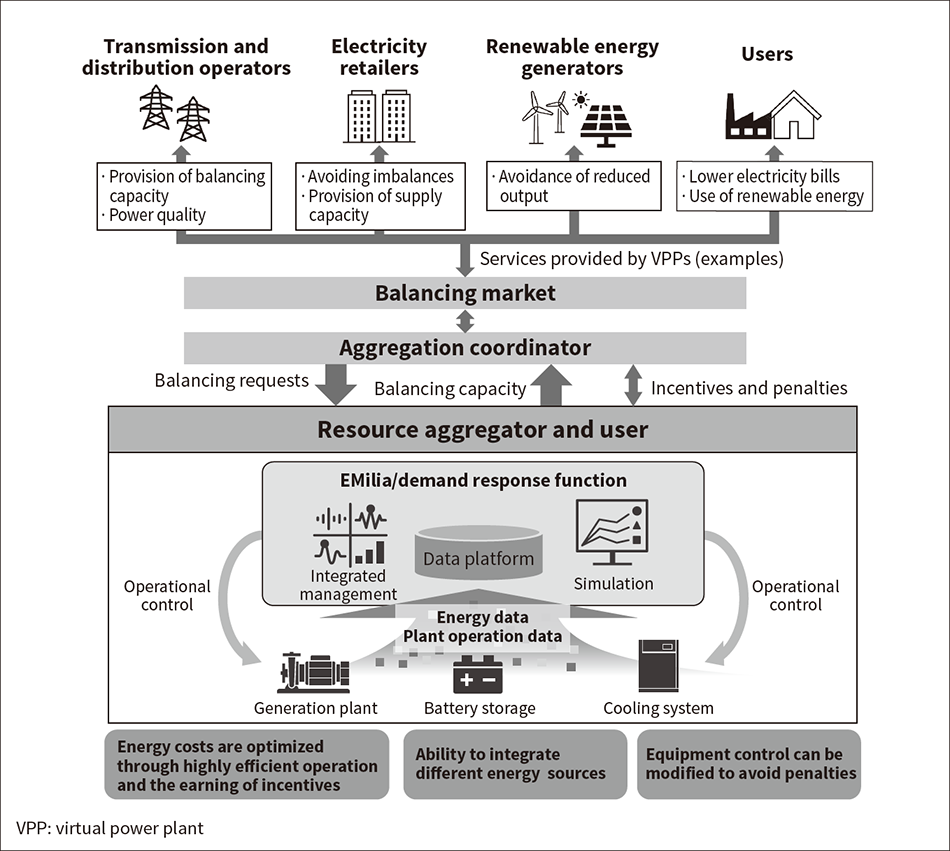

Figure 5 — EMilia Upgrades for Balancing Market An upgrade in FY2021 added functions for the balancing market to better serve customer needs and facilitate the transition to renewable energy as a leading source of electricity generation.

An upgrade in FY2021 added functions for the balancing market to better serve customer needs and facilitate the transition to renewable energy as a leading source of electricity generation.

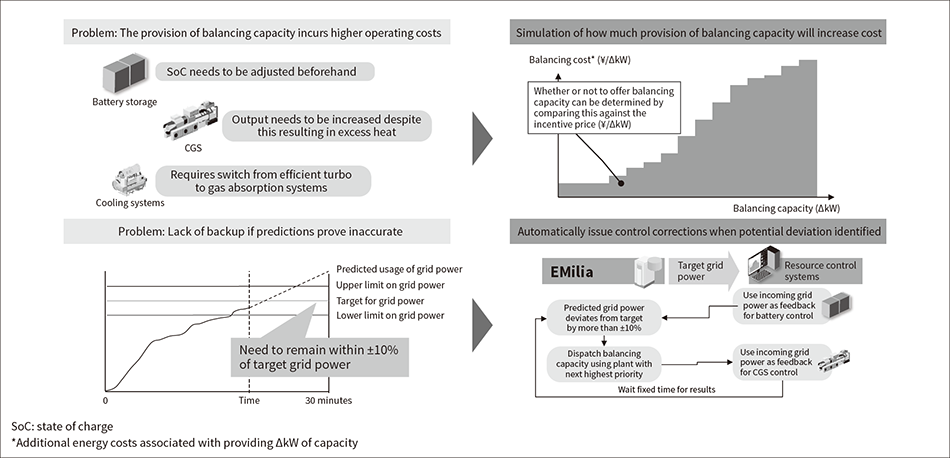

Figure 6 — Functions for the Balancing Market Functions are available for taking cost increases into account when predicting balancing capacity and also for making adjustments during operation.

Functions are available for taking cost increases into account when predicting balancing capacity and also for making adjustments during operation.

EMilia continues to evolve. An upgrade in FY2021 added functions for the balancing market to better serve customer needs and facilitate the transition to renewable energy as a leading source of electricity generation(5) (see Figure 5).

Aggregation coordinators (ACs) participate in the balancing market by bundling the balancing capacity (demand response) that can be provided by the resource aggregators (RAs) they represent. They offer this capacity on the market and, once a contract is agreed, determine how much each RA will adjust their electricity demand to meet balancing requests as they come in. The RAs, for their part, determine how much balancing capacity they can offer in each time period and inform the ACs of this at the bidding stage. When a contract is in effect, the RAs control their electrical loads to provide the amount of balancing capacity requested by the ACs. The ACs and RAs earn incentives for the balancing capacity they supply but must pay penalties for any failure to deliver on their capacity commitments.

EMilia supports the OpenADR 2.0b protocol for system interoperation with ACs and provides the following functions for the balancing market.

Things like the certification of carbon-free status and the calculation of carbon footprints require that the quantity of CO2 consumed or emitted in a production process be determined and that this quantity be linked to operational data.

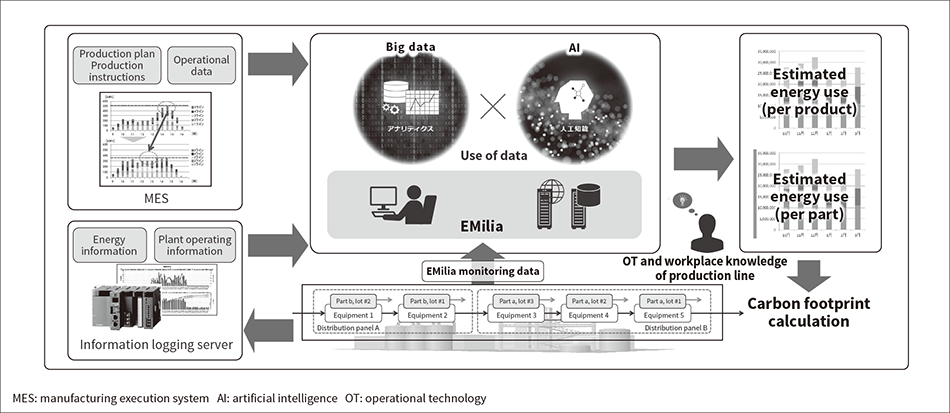

To meet these customer requirements, EMilia interconnects with external systems to link the time-series data it collects on energy consumption in production to the operational data held by the manufacturing execution system (MES) or other plant systems. By doing so, it is able to facilitate the calculation of carbon footprints by estimating how much energy is consumed on a per-product or per-part basis (see Figure 7).

There is growing demand from customers wanting to use carbon footprint information in their disclosures to stakeholders or as a way to identify potential improvements. As the need for energy management is only expected to increase in the future, it is anticipated that these systems will become an integral part of the management infrastructure at companies.

Figure 7 — How Carbon Footprints are Calculated EMilia supports the calculation of carbon footprints by linking operational data to data on energy use.

EMilia supports the calculation of carbon footprints by linking operational data to data on energy use.

This article has described how energy management systems can help customers in their efforts to achieve carbon neutrality. Achieving carbon neutrality is an urgent task for companies and it is something that needs to be addressed as part of business continuity.

Through the supply of its various solutions, Hitachi intends to continue its support for resilient businesses and sustainable growth by meeting the challenges that arise from the changing business circumstances faced by customers.