Amid ongoing efforts to reduce CO2 emissions across a range of industries, the fact that transportation emissions of CO2 in logistics account for 17.7% of the total in Japan means that there is an urgent need for actions such as promoting green logistics and transitioning to EV trucks. Unfortunately, making the switch to EV trucks for distribution faces a number of challenges, including short range, which limits the area they can service, and the time taken for charging, which reduces their efficiency. To help create a sustainable society, Hitachi has developed an advanced logistics service provisionally named Hitachi Digital Solution for Logistics-EV that uses digital technology to address the practical challenges facing green logistics. This article describes the work being done in this area.

The Japanese government has set targets for reaching carbon neutrality by 2050 and a 46% reduction in greenhouse gas emissions by 2030 (relative to FY2013). A variety of carbon dioxide (CO2) emission reduction and other initiatives aimed at achieving these targets are underway across a range of industries. In logistics, there is an urgent need to reduce the amount of CO2 emitted by vehicles used for freight and to make the transition to practices that take account of the environment.

Since around 2006, the logistics industry has sought to address environmental problems by making the industry greener and more efficient through “green logistics.” Among the key pillars of green logistics are modal shift, joint delivery, and consolidation. Modal shift refers to replacing the transportation of freight by trucks or other vehicles with more environmentally friendly alternatives such as railways or ferries and other forms of shipping. Joint delivery means carrying freight from multiple consignors to a common destination in the same truck. Similarly, consolidation means improving the efficiency of delivery by combining geographically dispersed hubs and reorganizing the distribution network. What these have in common is that they have reduced CO2 emissions by changing how logistics services work. Across the industry as a whole, however, there is a limit to how much can be achieved by restructuring logistics services and this has led to growing momentum behind the switch from internal combustion engine (ICE) vehicles to electric or fuel-cell trucks.

Vehicle manufacturers, meanwhile, are also stepping up their action on the environment. In places like North America in particular, major logistics companies and electronic commerce businesses are among those adopting and transitioning to electric vehicle (EV) trucks. The adoption of EV trucks has also started in Japan, mainly by large logistics companies for use in last-mile delivery.

However, if the use of EV trucks is to be encouraged and become more widespread, there is an urgent need to overcome the problems they pose. These include short range, high up-front costs, and less efficient delivery.

This article describes work on a delivery scheduling solution that addresses these issues and is being undertaken as part of efforts to achieve sustainable logistics that cares for the environment.

The need for decarbonization is highlighted by the fact that transportation accounted for 17.7% of total CO2 emissions by Japan in FY2020, with freight vehicles making up 39.2% of this (6.9% of total emissions by Japan)(1). The Japanese government’s Green Growth Strategy Through Achieving Carbon Neutrality in 2050 sets a target of 100% of new light commercial vehicles being powered by electricity or non-carbon fuels by 2040, with heavy vehicles to follow(2). In line with this strategy, moves toward the adoption of small EV trucks for last-mile delivery are accelerating, including work on putting the charging infrastructure in place.

Unfortunately, the electrification of commercial vehicles is lagging behind that of passenger vehicles. Most existing EV trucks draw their electric power from onboard batteries that are charged using chargers. The carrying capacity of EV trucks is limited by the space taken up by the battery. Together with their long charging times and short range, this makes it difficult to use EV trucks for deliveries in the same way as ICE vehicles. Furthermore, because most delivery work happens during the day, with the vehicles being recharged at night, potential issues include a lack of chargers and the risk of exceeding the contracted level of electric power consumption. If vehicles are unable to fully recharge overnight, the effect this has on following-day deliveries incurs opportunity costs for the operator. In response, to make delivery by EV truck more efficient, Hitachi has developed and deployed a service that provides integrated management of both delivery and charging, including by planning routes in a way that takes account of charging and remaining battery capacity as well as vehicle operation.

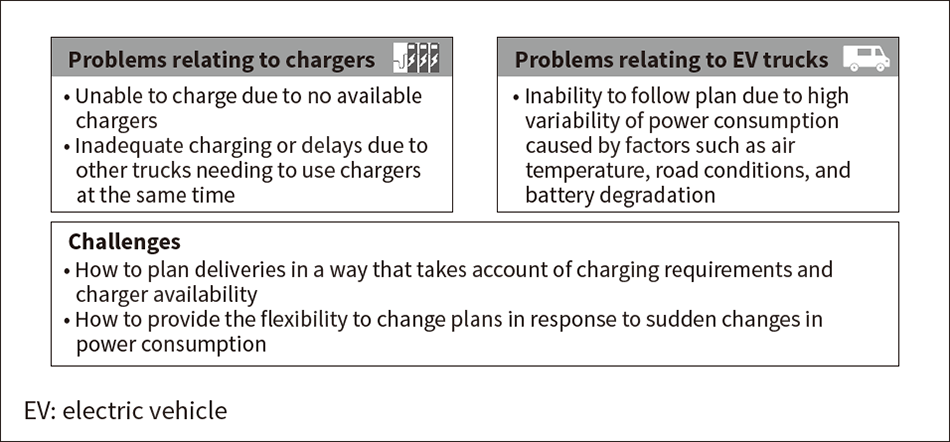

Figure 1 — Problems and Challenges when Using EV Trucks for Delivery The scheduling of deliveries by EV trucks needs to take account of power usage, which varies due to the weather and road conditions, as well as the availability of chargers.

The scheduling of deliveries by EV trucks needs to take account of power usage, which varies due to the weather and road conditions, as well as the availability of chargers.

Figure 1 illustrates some of the problems and challenges associated with delivery by EV truck.

EV trucks may need to have their batteries topped up during operating hours to extend their range if they are to avoid opportunity costs, such as when an EV truck has insufficient charge at the commencement of a delivery run or if it is required to travel distances in excess of 100 km. Unfortunately, the inadequate charging infrastructure currently available means that there may not be chargers available nearby to provide the needed top-up. Even if there are nearby chargers, they may be unavailable due to already being in use by other vehicles, leading to queuing and delivery delays. Accordingly, deliveries need to be scheduled in a way that pre-emptively takes account of charger availability and charging times.

Also, because the amount of power used by an EV truck varies widely depending on factors such as air temperature, road conditions, and battery degradation, the accuracy of power consumption prediction also needs to be improved through accurate tracking and monitoring of actual operations. The flexibility to modify schedules is also needed due to the risk of unplanned circumstances causing sudden changes in power consumption.

Hitachi Digital Solution for Logistics (HDSL) is a suite of advanced logistics services, one of which, HDSL-EV, is a delivery optimization service that supports EV truck scheduling. HDSL-EV was developed by Hitachi to overcome the challenges described above. The following sections describe HDSL and HDSL-EV.

HDSL, Hitachi’s suite of advanced services for collecting, storing, and analyzing customer data on logistics operations, currently offers the following services for delivery by ICE vehicle.

By automating vehicle dispatch, the delivery optimization service in particular can free companies from reliance on specific individuals. It is able to generate workable delivery schedules by combining the expertise of experienced staff with the analysis and use of data collected from actual deliveries.

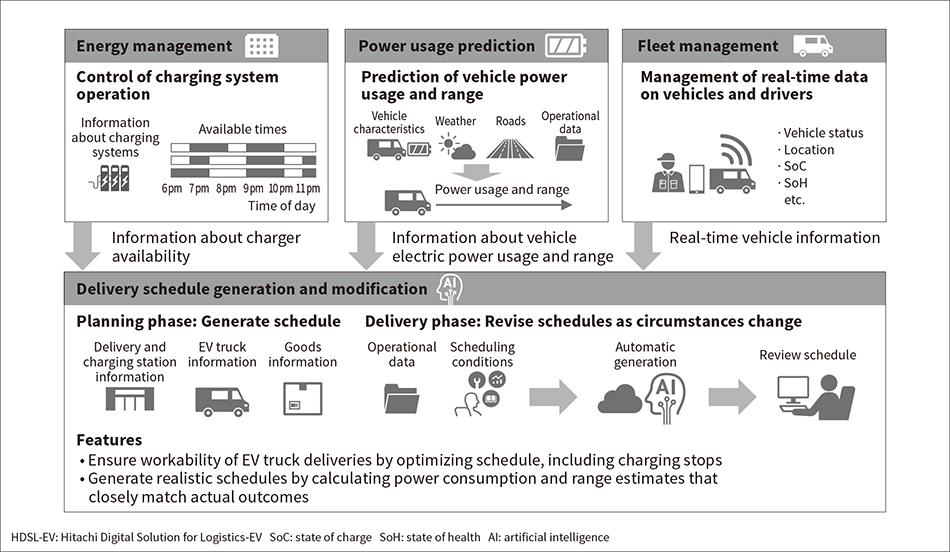

Figure 2 — Functions and Features of HDSL-EV HDSL-EV is equipped with functions for generating and modifying delivery schedules, predicting power consumption, and fleet management. In addition to coordinating these different functions, HDSL-EV can generate highly workable EV truck delivery schedules that keep any loss of efficiency to a minimum by using information from the energy management systems of local charging stations. It can also track what is happening in real time and adjust schedules accordingly.

HDSL-EV is equipped with functions for generating and modifying delivery schedules, predicting power consumption, and fleet management. In addition to coordinating these different functions, HDSL-EV can generate highly workable EV truck delivery schedules that keep any loss of efficiency to a minimum by using information from the energy management systems of local charging stations. It can also track what is happening in real time and adjust schedules accordingly.

The delivery optimization service for EV trucks (HDSL-EV) has functions both for generating delivery schedules from scratch at the planning phase and for revising schedules on the fly based on circumstances that arise during the actual delivery phase. In both cases, the schedules are generated automatically and factor in the charging of EV trucks (see Figure 2).

In practice, this allows EV truck deliveries to keep the loss of efficiency to a minimum by collecting information about the availability of chargers from the energy management systems (EMSs) of local charging facilities and optimizing deliveries in a way that allows for the need to stop at a charger. The routes, choice of charger, and charging schedules for EV trucks are adjusted to spread the load across the different charging facilities, avoiding situations where more than one EV truck needs to use a charger at the same time and thereby reducing waiting times and additional travel.

HDSL-EV also has a function for predicting power consumption based on a number of relevant vehicle and route parameter inputs. By doing so, it is able to generate highly workable schedules based on the calculation of power consumption and range estimates that closely match actual outcomes. Through interoperation with dynamic management functions that collect vehicle data such as battery state of charge (SoC) and state of health (SoH), Hitachi intends to provide the ability to determine what is happening in real time and adjust schedules accordingly.

Hitachi also plans to extend this function in anticipation of the future use of battery swapping systems by those EV trucks that are equipped to use them.

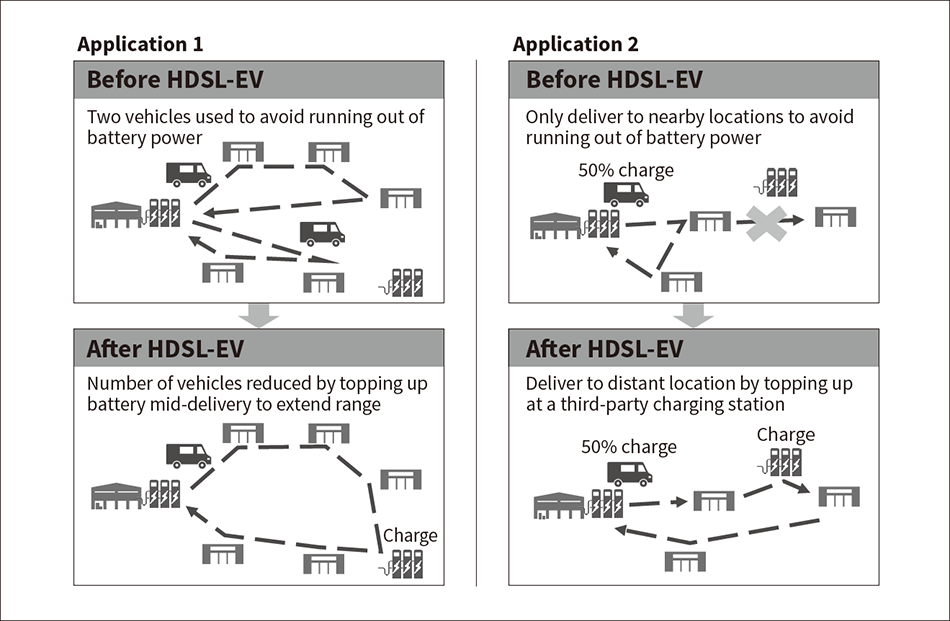

Figure 3 — Applications for HDSL-EV Because it allows for vehicles to extend their range by stopping to recharge during a delivery, the adoption of HDSL-EV reduces the total number of vehicles required and enables deliveries to distant locations.

Because it allows for vehicles to extend their range by stopping to recharge during a delivery, the adoption of HDSL-EV reduces the total number of vehicles required and enables deliveries to distant locations.

By providing automated delivery scheduling that keeps any efficiency effects to an absolute minimum, HDSL-EV supports the adoption of EV trucks by customers concerned about decarbonization. The following are two example applications for the service (see Figure 3).

The first involves a delivery run that stops at multiple destinations. If charging is only done at the depot, the shorter range of EVs compared to ICE vehicles limits the number of destinations that each vehicle can visit. By increasing the number of vehicles deployed, this decreases delivery efficiency. If HDSL-EV is adopted, it can extend vehicle range by optimizing the charging schedule and choice of charger, also minimizing additional working time for drivers and their vehicles. This enables deliveries to proceed with no loss of efficiency as the number of destinations visited can be increased to the extent that the carrying capacity of the EV truck allows.

The second application considers situations where the depot lacks sufficient charging systems. If ICE delivery vehicles are to be replaced by EV trucks, it is possible that there will not be enough electric power in terms of the number of chargers or the contracted level of electrical load. With HDSL-EV, however, it is possible for delivery operations to use third-party charging systems to make up for this electric power shortfall, and to do so in a way that keeps increases in the number of vehicles and operating time to a minimum.

Along with collecting, storing, and analyzing data on logistics operations, HDSL-EV can also incorporate data from other systems. For example, the collection and exchange of data on things like charging systems (either third-party or on-site), battery usage, and remaining charge in EV trucks allows the choice of charger and charging schedule to be coordinated, helping to avoid unnecessary waiting time, and spreading energy use. Plans for the future include interoperation with EMSs to spread energy usage on the basis of both how much electric power is used in the buildings that host charging systems and how much is used for EV truck charging, leading ultimately to the balancing of energy usage across society as a whole. Hitachi also intends to develop HSDL-EV into an ecosystem for green logistics while seeking to seamlessly bridge the “kiwa” (gaps) between different activities, especially in logistics, and make the supply chain as a whole greener and more efficient.