COVER STORY:ACTIVITIES 1

Ensuring Safety and Security through the Use of Existing Logistics Network and Hydrogen Storage Alloy

Japan overhauled its energy policy after the Great East Japan Earthquake in 2011. As a result, the use of natural energy sources such as solar and wind power as renewable energy sources has progressed. Such energy sources, however, are unlikely to serve as main sources of power due to their characteristics. For this reason, hydrogen is becoming popular as a new energy source. At present, various initiatives are being promoted nationwide to develop a hydrogen economy. One major such initiative is to build an integrated supply chain for the production, storage, and use of hydrogen. For this article, Hitachi Review spoke to key people involved in each project of a demonstration project in Tomiya City, Miyagi Prefecture, which is actively promoting the development of a low-carbon hydrogen supply chain.

Hirotoshi Wako

Hirotoshi Wako

Mayor of Tomiya City, Miyagi Prefecture

Born in Tomiya City, Miyagi Prefecture, he took over his family’s agricultural business, cultivated blueberries with friends and made them into a specialty of Tomiya. At the age of 31, he started a CAD system company. Then, he established a designated confirmation and inspection body. After opening a restaurant called “The Terrace,” he became involved in the Slow Food movement and served as both the first representative of Japan and a member of the International Council. After the Great East Japan Earthquake in 2011, he opened “Reconstruction Food Stall Village Kesennuma Alley,” a temporary restaurant district in Kesennuma City to rebuild the disaster-stricken area and help its residents. He also founded an electric power company, and built and operated a large-scale solar power plant called “Tomiya Solar Garden.” In 2015, he was elected Mayor of Tomiya Town, and then became Mayor of Tomiya City in 2016, when Tomiya became a city.

As the global energy situation is changing dramatically, the supply chains of major traditional energy sources such as petroleum and natural gas are also changing significantly and energy-related problems are emerging as pressing issues in many countries.

Under these circumstances, hydrogen is attracting attention as a new energy source. The shift to natural energy sources such as solar and wind power has been promoted worldwide to tackle global warming. However, these energy sources still present challenges for use as main power sources because the amount of energy generated from them fluctuate according to the season and weather conditions.

Hydrogen, on the other hand, can be extracted from water using electricity and also provides other production options, as it can be produced from a number of resources, including fossil fuels such as petroleum and natural gas as well as methanol and ethanol. Moreover, hydrogen can generate electricity by combining it with oxygen, and thermal energy can be extracted from it through combustion. Since hydrogen has the advantage of emitting no CO2 during its combustion, it is expected to significantly contribute to decarbonization, when combined with renewable energies such as biomass energy.

In December 2017, the Japanese government developed the first national strategy for hydrogen in the world. With a view to the goals of the Paris Agreement, Japan is promoting efforts in the mobility sector, such as the promotion of fuel-cell vehicles and hydrogen filling stations. The country is also accelerating its efforts to develop a hydrogen economy, including the establishment of an international hydrogen supply chain.

Yoichi Fujimoto

Yoichi Fujimoto

Senior Advisor, New Energy Business Development Department, Marubeni Corporation

Since he joined Marubeni in 1985, he has been steadily engaged in overseas sales in the energy sector. After investing in a mega-solar business, in 2012, which was the largest in Japan at that time, he set up the New Energy Business Development Department to develop hydrogen, fuel ammonia, and bio-jet fuel businesses, and now serves as its Senior Advisor.

Amidst these efforts, one local government, Tomiya City in Miyagi Prefecture, has been promoting an innovative effort to build a low-carbon hydrogen supply chain based on the concept of local production for local consumption. Tomiya City was originally a village when it was incorporated as a municipality with the introduction of Japan’s current municipality organization system in 1889. Adopting “The Best City in Japan to Live in” as its slogan, it continued to grow from a small town into a city. Since the 1960 census, it has been a growing city with the population increasing year by year.

Mayor Hirotoshi Wako explained why the city initiated such an effort:

“Even before I took office as Mayor, the city had been addressing environmental problems by establishing solar power plants in the private sector, for example. Especially after the Great East Japan Earthquake, we felt the increasing need to promote decarbonization and renewable energy. However, Tomiya City is not rich in natural energy sources such as wind power, hydropower, and geothermal energy. So we wondered if we could produce hydrogen from sunlight.”

Around that time, Mayor Wako was informed that the Ministry of the Environment (MOE) was inviting the public to enter its competition for hydrogen supply chain demonstration projects through the Environmental Policy Division, Miyagi Prefecture. He immediately secured the cooperation of Yoichi Fujimoto, a Senior Advisor in the New Energy Business Development Department, Marubeni Corporation. Hitachi also joined the team, as the company was planning to launch a joint carbon-neutral initiative with Marubeni through its power generation business in Kyushu. The three parties started discussions with the aim of having their project adopted as a demonstration project.

Marubeni has operated power and fuel businesses over many years. The company has a successful record leading various projects through long-term investments in engineering, procurement, and construction (EPC) and independent power producers (IPPs) in the electric power sector, liquefied natural gas (LNG) businesses in the fuel sector, and petroleum development projects. Hitachi also has a long history in the energy business, including electric power.

Unfortunately, however, the initial three-party proposal led by Tomiya City was not selected in the competition. Fujimoto, who was responsible for the future design of the project, explained the reason for the rejection:

“We were originally approached by the personnel of Tomiya City who were temporarily transferred to the Tokyo Office of Miyagi Prefecture. They wanted to discuss starting a hydrogen business project with us. Initially, we wanted to use the electricity and hot water produced from hydrogen in plastic greenhouses for growing blueberries, which are a specialty of Tomiya, and in institutions for the elderly. However, it was not a good idea to include so many things. We even approached the Kakuda Space Center of Japan Aerospace Exploration Agency (JAXA), which uses the largest amount of hydrogen in the Tohoku region, and asked JAXA’s Senior Vice President to use the hydrogen produced in Tomiya City. In the end, our proposal was rejected because we did not have a clear vision of its wider use for the future.”

Hidenori Ohara

Hidenori Ohara

Assistant Director, Environmental Management Office, Miyagi Consumer’s Co-operative Society and Co-op Tohoku Sunnet Business Federation

He joined the Co-operative Society in 1996. Two months later, he was appointed to study ISO 14001 exclusively. In 1997, the Miyagi Co-operative Society became the first cooperative to receive ISO 14001 certification in Japan. He was appointed as the chief internal environmental auditor to help other cooperatives nationwide to comply with ISO 14001 and conduct internal audits before taking his current position.

Although their first attempt failed, the three parties started discussing a new proposal. Through the process, they came up with the idea of asking Miyagi Consumer’s Co-operative Society to join the team to build a new supply chain. The new project was coordinated by Ryusuke Gotoda, General Manager of the Smart Utility Division, Environment Solutions Division, Water & Environment Business Unit, Hitachi, Ltd. He had the following to say about the project:

“Economy is ultimately the most important factor in developing a successful working supply chain. We needed to reduce the transport costs incurred to send the produced hydrogen to customers. So, we came up with the idea of asking the Miyagi Consumer’s Co-operative Society, which has a nationwide logistics network, to help us make the project successful.”

Miyagi Consumer’s Co-operative Society is the first consumers’ cooperative to receive ISO 14001 certification in Japan. Since it was first certified in 1997, the organization has been actively engaged in environmental conservation activities to solve four priority issues: reducing the total CO2 emissions in its cooperative services; reducing and recycling waste from its business operations; developing an environmentally friendly local community; and giving environmental consideration in its merchandise business. Hidenori Ohara, Assistant Director of the Environmental Management Office at Miyagi Consumer’s Co-operative Society, was responsible for the equipment operation and hydrogen delivery. He described the circumstances of his organization just before it joined the project:

“We used to promote environmental activities and suggestions within the scope of our businesses, based on the concept of ISO 14001. However, after we experienced the nuclear accident caused by the Great East Japan Earthquake, we shifted to our own promotion and expansion of renewable energy. In FY2021, we successfully reduced CO2 emissions by 70%, compared with 2013, the year the Paris Agreement was concluded. Then, after continuing activities such as working to procure electric power based on the ‘Renewable Energy 100% (RE100)’ initiative and renewable energy businesses such as biomass power generation, we were invited to participate in this project.”

Ryusuke Gotoda

Ryusuke Gotoda

General Manager, Smart Utility Division and Carbon Neutral Business Promotion Office, Environment Solutions Division, Water & Environment Business Unit, Hitachi, Ltd.

In 1987, he joined the Matsudo Research Laboratory, Hitachi Plant Engineering & Construction Co., Ltd. to research and develop air-conditioning equipment for buildings, plants, clean rooms, and other facilities. In 2015, he started developing hydrogen technologies. Since 2021, he has been engaged in the planning and development of carbon-neutral businesses as General Manager of the Smart Utility Division, Environment Solutions Division, Water & Environment Business Unit.

The four parties, including Miyagi Consumer’s Co-operative Society, resumed their activities aimed at the successful adoption of their proposal. The key point of the new proposal was the way of storing hydrogen.

“While there are many ways to store hydrogen, we thought that security and safety would be essential for promoting the wider use of hydrogen in society. So we have chosen a method that uses a hydrogen storage alloy cassette to store hydrogen, while making sure to keep the pressure inside the container lower than 1 MPa.” (Gotoda)

Hydrogen storage alloy cassettes are not classified as dangerous articles under the High Pressure Gas Safety Act and the Fire Service Act. Therefore, no qualification is required for handling them and they can be loaded on trucks together with water and foodstuffs, etc. Marubeni’s strength as a trading company was put to good use in importing the rare metals used as raw materials in the hydrogen storage alloy.

“One of Marubeni’s major tasks was to study the feasibility of the project and how to expand it in the future. Cost is a critical factor in commercialization. As the rare metals used as raw materials in the hydrogen storage alloy were produced in China, we investigated the situation during the demonstration project and found that three or four specialized trading companies in China were involved. For that reason, we negotiated the price of the metals directly with suppliers through Marubeni’s Beijing Branch. As a result, we managed to receive an inexpensive quote for bulk purchases, improving the future business feasibility of the project.” (Fujimoto)

One of the features of this supply chain is that it produces green hydrogen*1, rather than gray hydrogen*2 or blue hydrogen*3, which are derived from fossil fuels. To produce green hydrogen, which is a field in which Japan is lagging behind other countries, Miyagi Consumer’s Co-operative Society kindly provided the use of solar power generated on the roof of one of its buildings at the Tomiya Joint Purchasing and Logistics Center of Miyagi Consumer’s Co-operative Society, where a hydrogen manufacturing system and other equipment are installed.

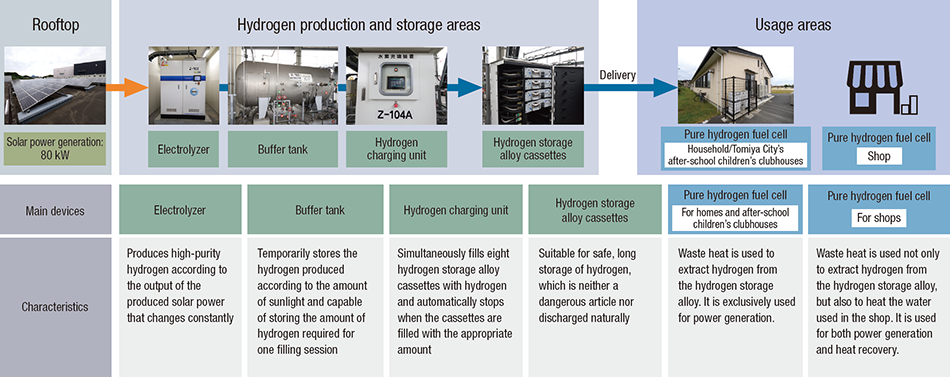

The newly proposed low-carbon hydrogen supply chain is as follows. First, solar power generation is used to produce high-purity hydrogen with a water electrolyzer. The produced hydrogen is stored in a buffer tank and loaded into hydrogen storage alloy cassettes in the hydrogen charging unit. From there, Miyagi Consumer’s Co-operative Society personnel deliver the cassettes to homes and Tomiya City’s after-school children’s clubhouses. Finally, the delivered hydrogen storage alloy cassettes are used to generate power (see Figure 1). This project was submitted to the MOE’s FY2017 Low-carbon Hydrogen Technology Demonstration Project in Cooperation with Local Government, and successfully adopted.

The entire series of demonstration equipment was completed in August 2018. The Tomiya Joint Purchasing and Logistics Center of Miyagi Consumer’s Co-operative Society held a ceremony to commemorate the start of its operation. Toru Doi, then State Minister for Reconstruction, Yoshihiro Murai, Governor of Miyagi Prefecture, and other concerned parties attended the ceremony, which garnered wide media coverage the following day and evoked a strong public response. Hitachi, which coordinated the project, had to work hard to get everything ready in time for the ceremony.

“The city insisted that the operation launch ceremony should be held in early August just before Sendai Tanabata Festival... (laugh) Considering how short the period was between the adoption and the ceremony, we thought it would be utterly impossible at first, but we managed to do it in the end.” (Gotoda)

With a wry smile, Mayor Wako explained the significance of the ceremony:

“I’m very sorry about that time (laugh), but the timing of the operation launch ceremony was very important for us to formally announce that we were about to start the low-carbon hydrogen supply chain in Tomiya City. Luckily, all major figures attended the ceremony with a splendid ribbon-cutting event. The footage of the delivery of hydrogen storage alloy cassettes filled with hydrogen to after-school children’s clubhouses also helped us announce the start of the operation to a wide range of people on a large scale. I believe that many people realized Tomiya City’s commitment to become an advanced hydrogen city through this demonstration project.”

Figure 1 | Overview of Hydrogen Supply Chain Equipment of Tomiya City

During the three-year demonstration project from FY2017 to FY2019, while the low-carbon hydrogen supply chain was in actual operation, various types of demonstration data were obtained for its commercialization. Originally, the project was supposed to end after three years and the related equipment removed, but the project began to show new promise.

As the demonstration continued, the project team developed a strong desire to operate the hydrogen supply chain and deliver a stable supply of hydrogen energy and proposed an enhancement plan to make the supply chain stronger by integrating a hydrogen mixed-combustion generator. As a result, the demonstration project was extended until 2021.

“While we have established a low-carbon hydrogen supply chain in the Tomiya model, in terms of resilience, for example, if the power grid were to go down, the supply chain would come to a halt. So we decided to add a hydrogen mixed-combustion generator, which generates electricity from the hydrogen stored as a backup or from the biofuel produced from waste, so that the supply chain could continue to operate without relying on the power grid in the case of a power failure.” (Gotoda)

In response to the idea of combining used deep-frying oil to support a business continuity plan (BCP), Ohara imagined how carbon neutrality should be treated in the future:

“When I heard about the idea of deep-frying oil, I thought that it was a great idea, and it also matched the resource recycling efforts being made by supermarkets and other shops. In addition to electric power, our goal is to achieve zero-carbon in vehicle fuels by 2040, including dealing with chlorofluorocarbons. I believe that ideas of adding something extra to hydrogen will expand the potential in various ways. Up to now, the reality has been that efforts to achieve decarbonization and resource recycling have been made separately. However, I think that efforts will be combined in various ways, including in parallel or multiple configurations.”

Tomiya City has been conducting many hydrogen promotion and awareness activities, such as symposiums and forums, and test-riding fuel-cell (FC) buses. The city has also actively allowed people to come and observe the low-carbon hydrogen supply chain, with nearly 500 observers from 83 companies by FY2021. The city has also pressed forward and launched a new initiative to promote carbon neutrality further.

Based on its 2050 Zero Carbon City declaration in 2021, Tomiya City is developing a strategy that incorporates initiatives required to fulfill the goal of achieving net zero CO2 emissions by 2050. Since 2022, the city has been taking action to realize this strategy. Our efforts, including a series of demonstration projects and other initiatives, have also led to the winning of several awards, such as the Grand Prize at the Seventh Annual Platinum Vision Awards hosted by the Platinum Society Network, and the Award for Excellence at the Zero Carbon Challenge Cup hosted by the MOE.” (Wako)

From the perspective of a trading company, Marubeni summarized the current outcomes so far:

“We believe that our project has had considerable influence both in Japan and overseas. It also has the advantage of having practical data obtained by operating the supply chain in a way that was enlightening while identifying issues for commercialization. I have heard that the national government is about to starting to create environmental values that will compensate for the cost of hydrogen, which is not exactly cheap at present. The Tomiya model will develop into locally adapted versions throughout Japan. We would like to continue operating our equipment and also try new things as well.” (Fujimoto)

Gotoda described one of their future visions:

“Tomiya City’s supply chain model is not a recycling model, but a single-path model in which hydrogen is produced from solar energy and consumed in fuel cells. Although it is an excellent model in terms of carbon neutrality, it is still lacking in terms of global resource recycling. How to extract energy from waste and return it to other applications will be the key to future success. If we can innovatively incorporate circular economy features into the Tomiya model, it will become a representative case of the first proper model that is run in a green way.”

Mayor Wako, who has led the project and also promoted carbon neutrality by signing the Global Covenant of Mayors for Climate and Energy in 2022, added:

“We must leverage this demonstration project and lead to the next step. However, that is not something we can do alone. We will need not only all the people of our city and companies, but also the people of Japan and the mankind to work as one to achieve this. If possible, Tomiya City is willing to be in its crucial vanguard.”

Hitachi will continue to actively obtain opinions from the concerned parties such as Tomiya City, Marubeni, and Miyagi Consumer’s Co-operative Society, and identify social needs to accelerate its commitment to carbon neutrality through the implementation of practical hydrogen supply chains.

The town of Namie, in Fukushima Prefecture, is one of the regions that was considerably damaged by the Great East Japan Earthquake that occurred on March 11, 2011. While there are still areas in the town where it is difficult to return home due to the impact of the accident at Fukushima Daiichi Nuclear Power Station, the town has been steadily making efforts to rebuild. In March 2020, Namie Town issued its 2050 Zero Carbon City declaration. Since then, the town has been moving toward developing a hydrogen-energy-based community with the goal of achieving net zero CO2 emissions by 2050. Hitachi is also participating in a hydrogen supply chain demonstration project in Namie Town, leveraging the knowledge that the company has acquired through another demonstration project to establish a low-carbon hydrogen supply chain in Tomiya City, Miyagi Prefecture.

Naka Shimizu

Naka Shimizu

Director, Industry Promotion Division, Namie Town Hall, Fukushima Prefecture

After graduating from a private university in Tokyo, he started working at Namie Town Hall in 1986. For the first 24 years of his employment there, it was an ordinary rural town hall with the same people all the time. However, since the earthquake 12 years ago, everything has changed significantly. As the chief secretary to the late Tamotsu Baba, Mayor of Namie Town, he met and worked beside the Mayor with many different people from all over Japan (through earthquake assistance, first, and then rebuilding work). He also visited many different places nationwide (to express gratitude for assistance, cheer up evacuees, and inviting companies to participate). Three months before the mayor passed away, he was appointed the Manager of the Industry Promotion Division to promote Namie Town’s industries (2018). Until his retirement, he will continue to strive to fulfill the two long-held goals that were set by the late mayor immediately after the earthquake: “Hydrogen Town—New Energy Town” and “Research Town Namie.”

Fukushima Hydrogen Energy Research Field (FH2R) is at the core of Namie Town’s efforts to realize a zero carbon city. FH2R uses 20 MW of solar power to electrolyze water with a hydrogen production system and produces as much as 1,200 Nm3 of hydrogen per hour. It is one of the world’s largest hydrogen production plants that can also store and supply such a large amount of hydrogen (see Figure 1).

Namie Town launched the “Hydrogen Town Namie”* plan to promote urban development based on hydrogen energy, aiming at net zero CO2 emissions by 2050. Since the opening of FH2R in March 2020, the town has been engaged in various efforts as a demonstration field for hydrogen applications in order to identify and solve issues that arise in the phases of creation, transportation, and utilization. Naka Shimizu, Director of Industry Promotion Division, Namie Town Hall, explained the current situation of the town’s commitment to the development of a zero carbon city and the use of hydrogen:

“To expand the use of fuel-cell vehicles, for instance, rapid hydrogen refueling is a must. We are currently building large demonstration refueling equipment for FC vehicles on the north side of FH2R and it will be completed soon. We also want to discuss and demonstrate what to do with the electric power used in hydrogen production.”

Although FH2R has 20-MW solar power generation equipment, it cannot continuously produce hydrogen on cloudy days or at night. Therefore, in the current situation, when solar power generation is not available, expensive electricity has to be purchased from the grid. Fortunately, however, Namie Town is rich in natural energy sources.

“Of course, we care about the cost, but Namie Town is also committed to green hydrogen, making efforts to introduce and expand the use of renewable energies such as mega-solar power generation, wind power generation, and hydroelectric power generation at the Ogaki Dam in the town. As the sea is rough in this region, we have also started conducting surveys and studies aimed at the social implementation of wave power generation.” (Shimizu)

Ryusuke Gotoda

Ryusuke Gotoda

General Manager, Smart Utility Division and Carbon Neutral Business Promotion Office, Environment Solutions Division, Water & Environment Business Unit, Hitachi, Ltd.

In July 2021, Namie Town, Marubeni Corporation, Hitachi, Panasonic Corporation, and Miyagi Consumer’s Co-operative Society signed a five-party agreement, the Cooperation Agreement Regarding Namie Town Revitalization Plan, Utilizing Hydrogen for Decarbonization. The purpose of the agreement is to promote the comprehensive restoration and revitalization of Namie Town by contributing to the town revitalization plan, the construction of an RE100 industrial park, invigoration of local industries, and digital transformation (DX). Based on the agreement, Hitachi has started a Demonstration Project for the Development of a Hydrogen Supply Chain for General and Industrial Use and Adjustment of Hydrogen Supply and Demand and is planning to construct its demonstration equipment in FY2022 (see Figure 2).

The planned hydrogen supply chain will transport hydrogen in small, light hydrogen cylinders for general use and supply electric power derived from hydrogen energy, using the existing distribution lines for industrial use, which consumes a large amount of power. The project team is also planning to control power generation remotely according to the demand through demand prediction based on past data about the electricity consumption of customers and use data measurement and block chain technology to demonstrate that the supplied electric power is derived from hydrogen energy.

Shimizu had the following to say about the project, which has just begun to take shape:

“In terms of transportation, small cylinders are light and not very costly so that we can probably implement them successfully in our community. However, if the frequency of cylinder swapping can be reduced from daily to only once or twice a week, then social implementation should be even more successful. In the demonstration for industrial use, on the other hand, we have not realized the advantages yet, and we may consider storing electric power in storage batteries.”

Ryusuke Gotoda, General Manager, Smart Utility Division, Water & Environment Business Unit, Hitachi, Ltd., responded to the comment:

“Storage batteries always discharge electricity. Although they are suited to storing energy for several hours, hydrogen is better if you need to store energy for longer than that. Storage batteries are generally used in the charging rate range from 20% to 80%, whereas hydrogen can be used at any rate in the range from 0% to 100%. In this sense, hydrogen is also better. Of course, hydrogen has some disadvantages such as an efficiency decline in the hydrogen conversion process. However, we still believe that there is some advantage in sending the energy derived from hydrogen through distribution lines.”

Gotoda continued by emphasizing key points in the demonstration project:

“It is very meaningful to evaluate the two supply chains quantitatively. One of our current challenges is how to link the supply and the demand. Once we solve the challenge, we will then use an energy management system (EMS), which adjusts the balance between the supply and demand, to promote the wide use of our product.”

In addition to the perspective of transportation, Namie Town is also interested in the use of a hydrogen mixed-combustion generator in Tomiya City, Miyagi Prefecture from the perspective of creation, as Namie has some neglected farmland.

“We must determine how we should use contaminated farmland, including mountainous areas. Since it is difficult to grow rice on such land, we face some farming challenges. We may need to grow a large area of pasture land for producing biofuel, while reducing the cultivation cost.” (Shimizu)

Based on the demonstration project in Tomiya City, Hitachi explained the advantages of hydrogen mixed-combustion generation:

“In hydrogen mixed-combustion generation, diesel oil and hydrogen are burned together, which reduces CO2 in proportion to the amount of hydrogen that is mixed in. If biodiesel is used instead of regular diesel oil, this method of generation can produce 100% renewable biomass energy. The mixed combustion of regular diesel oil and hydrogen will be only a half-measure after all. I think that the key point is to mix biofuel with hydrogen in combustion.” (Gotoda)

Namie Town is currently re-developing the area around Namie Station and making various efforts based on the “Master Plan for Grand Design of Namie Town Area,” which the town established to achieve carbon neutrality and RE100. In hope of successful re-development, Shimizu said:

“We are thinking of building and operating an EMS that mixes all kinds of renewable energy sources, including hydrogen mixed-combustion generation. Home, industry, and mobility are the three crucial sectors for promoting the wide use of hydrogen, and we would like to make achievements in those sectors, one by one, while also considering the use of hydrogen-based hybrid trains. I hope Hitachi will support us in this matter with its wide range of technologies.”

Hitachi will continue to support Namie Town’s reconstruction efforts and promote its commitment to developing a hydrogen economy in Japan.