We combine only the items that are absolutely necessary and most convenient.

Thus, the system supports user-friendly and intuitive operation.

The system not only displays easy-to-see and easy-to-understand symbols and changes colors according to each data item, but also allows users to easily understand the combined display of the current situation and operation state. The only thing users have to do is point to the device displayed on the screen. Thus, users can easily operate the system while still monitoring the whole plant.

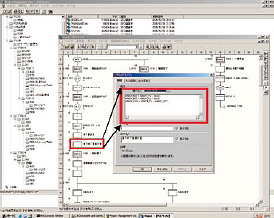

Since the system displays operation windows within a graphical interface, operators can prevent incorrect operations due to changes in the display position. Operating the function keys located across the bottom of the screen can quickly shift the display to the related facility and TAG screen. Since the production parameters and recipe are combined on-screen, the necessary information can be collectively displayed.

A plant flow can be created that takes into consideration the convenience of the operator, such as the characteristics of the plant and its operation. The use of a simple and easy-to-see graphical interface and colors of emphasis can prevent mistakes in operation.

An engineering screen can also be displayed in addition to the monitoring screen, in order to achieve advanced monitoring of operations.

Compliant with international standards IEC61131-3

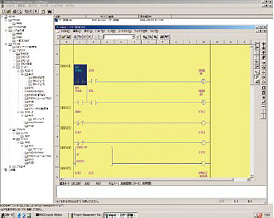

A graphical sequence description has been achieved.

Sequence control is indispensable in controlling plant production lines. The HIACS-AZ series system supplies three types of sequence controls: SFC (sequential function chart), ALD (AZ ladder), and DTS (decision table sequence). It also supports various sequence description methods to suit the characteristics of the processes involved.

The system graphically describes the sequences formerly composed in macro language, and its easy-to-understand method of description can improve the productivity of sequence programming on multiple recipe management and sequence control in batch processes. Furthermore, special processing can be described in the SFC box using C programming language and ladders.

The system is equipped with a ladder sequence function that can describe the program task processing in logic ladder sequences, such as "AND OR NOT", which can be widely used in electricity control and instrumentation control sequences.

ALD : AZ Ladder