Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.

Gas turbine clean combustion technology for next-generation

coal-fired thermal power generation

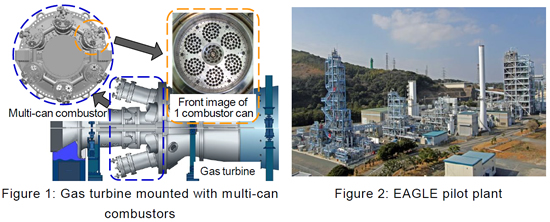

Pioneering demonstration of low NOx technology at the EAGLE pilot plant

Tokyo, April 11, 2013 - The New Energy and Industrial Technology Development Organization ("NEDO"), Japan and Hitachi, Ltd. (TSE:6501, "Hitachi") today announced the development of a new combustion technology reducing NOx*1 emission to less 10ppm without the addition of diluents (dry*2 single digit NOx*3), using gas turbine combustors being developed under the project for next-generation coal-fired thermal power generation*4 using CCS*5 - IGCC*6 at the EAGLE*7 pilot plant.

CCS-IGCC is next-generation coal-fired thermal power technology which is expected to drastically reduce CO2 emission. One issue, however, was in order to counteract the large amount of NOx produced when the coal-derived syngas*8 was combusted, a diluent was used to suppress NOx but this also reduced the efficiency of power generation.

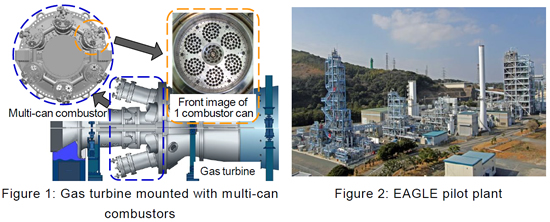

NEDO and Hitachi have developed a multi-hole co-axial jet burner*9 which is able to stably combust hydrogen containing fuel, a technology which meets environmental regulations, without the addition of diluents as well as drastically reducing NOx emission. Through tests at a Hitachi facility using a test fuel simulating coal-derived syngas, followed by this test at the EAGLE pilot plant using an actual gas turbine and syngas, it was confirmed that the technology suppressed NOx emissions below environmental regulation levels.*10

These results are the first supporting the possibility for achieving highly efficient power generation in practical operation as well as suppressing NOx below emission standards.

- (1)Business summary

This development was conducted under the "Innovative Zero-emission Coal Gasification Power Generation Project: Development of low NOx combustion technology for high-hydrogen syngas in IGCC" sponsored by NEDO (FY2008-FY2012). In July 2011, tests were conducted within a Hitachi facility using a single-can combustor with multi-hole coaxial jet burners and test fuel simulating coal-derived syngas. With the cooperation of the Wakamatsu Research Institute of the Electric Power Development Co., Ltd. (J-Power), further tests were on-site at the EAGLE pilot plant.

- (2)Achievements

Achievements of this development are as described below.

- Using an actual gas turbine mounted with a six-can combustor and coal-derived syngas, at the EAGLE pilot plant, a new combustion technology which does not require the addition of diluents was tested, and dry single digit NOx was achieved. This result verified the feasibility of the new technology with actual equipment and actual gas.

- A method was developed to stably run the gas turbine from start-up to maximum power output whereby after starting the gas turbine with oil fuel, the fuel source is switched to syngas and run by burning syngas until maximum power output is achieved. The feasibility of this method was verified with actual equipment and actual gas.

As a result of these pilot tests, the possibility for achieving highly efficient power generation in practical operation as well as suppressing NOx below emission standards was demonstrated. The next development will be to achieve the practical application of zero emission coal-fired thermal power generation, especially the optimization of gas turbine running methods.

Notes

- *1

- NOx: nitrogen oxides

- *2

- Dry/Wet: In order to suppress NOx emissions in conventional IGCC plant gas turbine combustors, the "wet" method which involves the injection of diluents such as water, steam or nitrogen into the combustor, is used. In contrast, processes which do not require the addition of such diluents are described as "dry".

- *3

- Single digit NOx: NOx emission of less than 10ppm; corrected to 16% O2.

- *4

- Project: "Innovative Zero-emission Coal Gasification Power Generation Project: Development of low NOx combustion technology for high-hydrogen syngas in IGCC" sponsored by NEDO (FY2008-FY2012). This project was supported by the Coal Division of the Natural Resources and Fuel Department, Agency for Natural Resources and Energy, Ministry of Economy, Trade and Industry (METI), Japan.

- *5

- CCS: Acronym for "carbon capture and storage." Technology which captures and stores CO2; preventing CO2, a green house gas, from being released into the atmosphere.

- *6

- IGCC: Acronym for "integrated coal gasification combined cycle." An efficient form of combined power generation using a gas turbine to generate power by reacting coal with water vapor to generate a gasified fuel, and then collecting the waste heat (steam) to generate additional power by running a steam turbine.

- *7

- EAGLE: Acronym of "coal Energy Application for Gas, Liquid and Electricity," for multipurpose coal gasification technology.

- *8

- Syngas: Abbreviation for synthesized gas. In this case, syngas is produced by the gasification of coal, and is a gas mixture of carbon monoxide, hydrogen and nitrogen.

- *9

- Multi-hole co-axial jet burner: A burner which has been concentrically configured so that the fuel pathflow and oxidant (such as oxygen) pathflow inject in same direction. Further, the flame is lifted and maintained at a distant position from the burner to facilitate dry low NOx combustion. The combustor incorporating this technology is mounted with a central burner encircled by 6 other burners.

- *10

- Environmental standard: Under the Air Pollution Control Act of Japan, the concentration of NOx emission is regulated at 70ppm (the O2 concentration in the exhaust gas set at 16%). However some municipal governments have established local by-laws for more stringent regulation.

About Hitachi, Ltd.

Hitachi, Ltd. (TSE: 6501), headquartered in Tokyo, Japan, is a leading global electronics company with approximately 326,000 employees worldwide. The company's consolidated revenues for fiscal 2012 (ended March 31, 2013) totaled 9,041 billion yen ($96.1 billion). Hitachi is focusing more than ever on the Social Innovation Business, which includes infrastructure systems, information & telecommunication systems, power systems, construction machinery, high functional material & components, automotive systems and others.

For more information on Hitachi, please visit the company's website at http://www.hitachi.com.