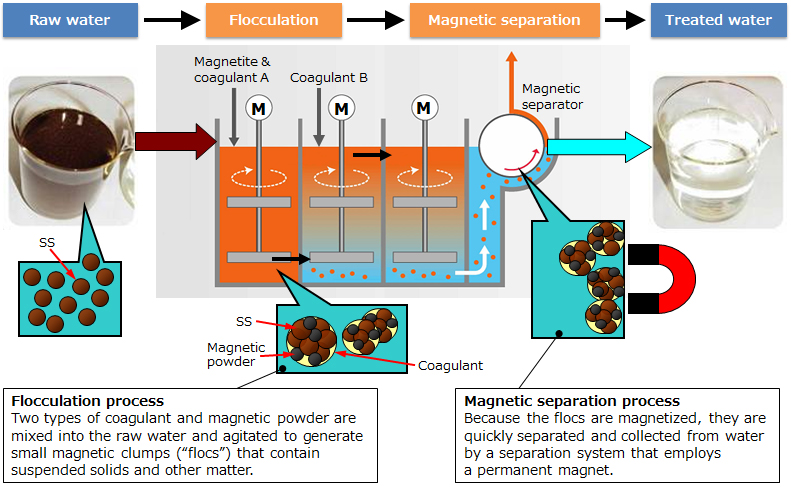

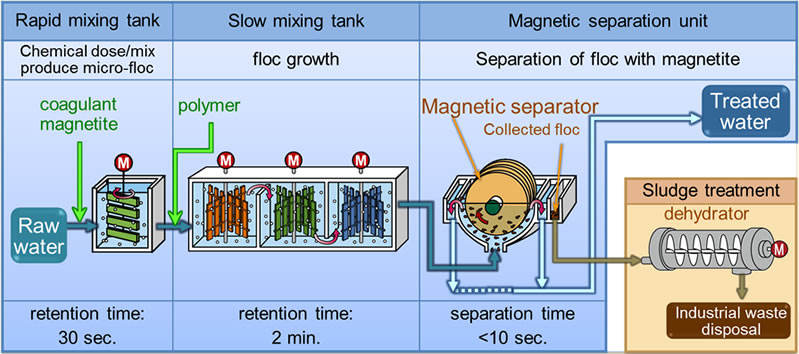

The Flocculation Magnetic Separation System, one of Hitachi's core technologies, quickly removes oil suspended solids and other matter from target water.

High-quality treated water can be delivered with less than five minutes retention time.

A wide variety of applications are available to meet the diverse needs of our customers.

In the Flocculation Magnetic Separation System, suspended solids (SS) within raw water are mixed with a flocculent that contains magnetic powder, flocculated, and then separated using a permanent magnet.

(In-house comparison)