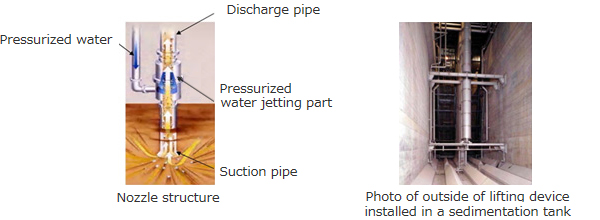

Odor-free closed pipe transport system for grit and screenings

Overview

Closed pipe transport system for grit and screenings saves space and provides odor-free working environment.

Features

- No drive motor in the water

Unlike a submersible pump, there is no drive motor part in the water, and there are no tangling or clogging difficulties because nozzles have no impellers.

- Improved working environment

Odors do not occur because grit and screenings are piped under pressure and transported materials are not exposed. Also, the work environment is hygienic with no spills or scattering since no conveyor is used in the pressure feeding pipe.

- Effective space utilization

Effective use of work space because there is no need for a bucket grit elevator or conveyor in renovation work.

- Reduction of maintenance work

Compared to a conventional sedimentation tank facility, a bucket grit elevator and belt conveyor are not necessary for the sediment discharge system. In addition, daily maintenance work is reduced because there is no need for a conveyor to the hopper for grit and screenings.

- Washing effect by nozzle internal pressure

Transfer of high pressure water injected into the nozzles enables washing of transported materials.

(In-house comparison)

System/Equipment Overview

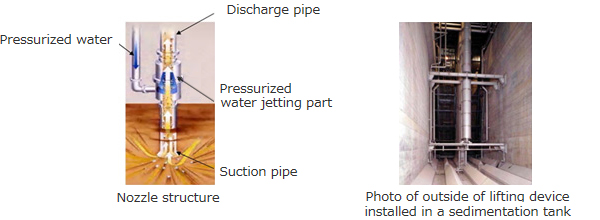

Pressurized water is supplied to the main unit by a pressurizing pump, and a negative pressure state is created on the suction side by the pressurized water.

Application fields

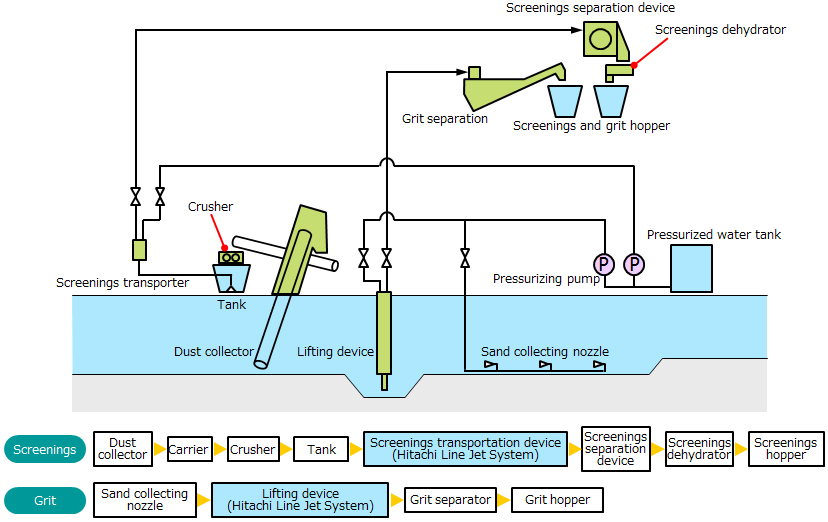

Various sedimentation tank facilities