EcoAssist-Pro/LCA

Supporting the Decarbonization of

Supply Chains

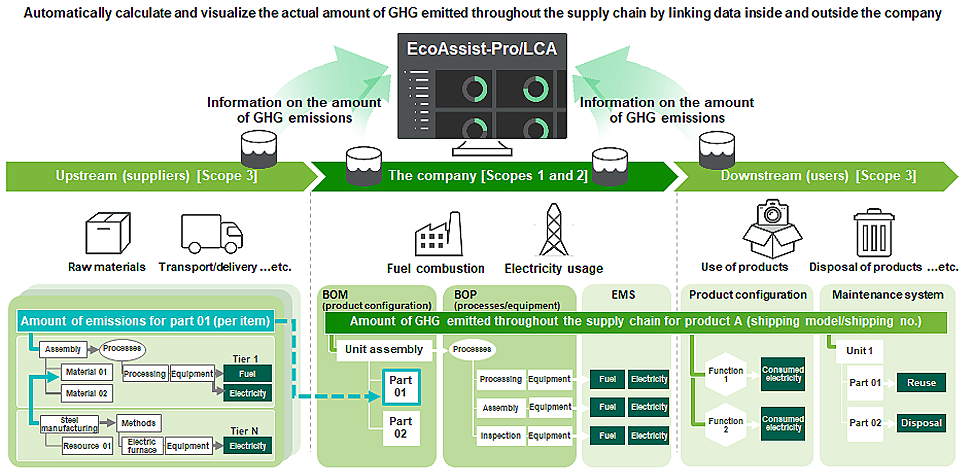

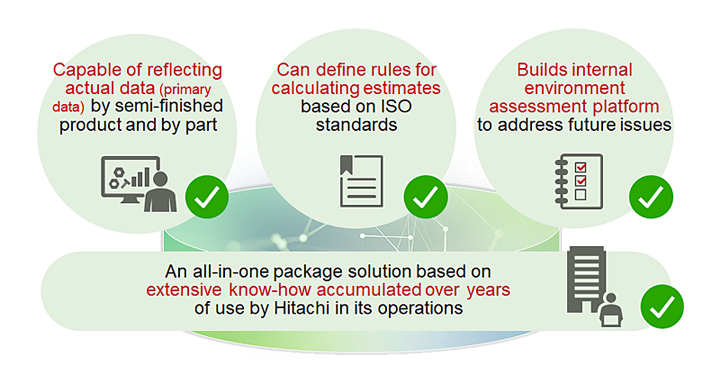

This solution quantitatively analyzes the environmentally hazardous substances related to each product based on the concept of life cycle assessment (LCA) and visualizes the amount of emitted greenhouse gases (GHG) and other information.

Detailed assessments can be easily made through calculations using a cumulative formula based on the bill of materials (BOM).

Until now, companies have been working to visualize the amount GHG emitted by each of their businesses in an effort to comply with the Act on Promotion of Global Warming Countermeasures and the Act on Rationalizing Energy Use. Going forward, with the adoption of the Eco-design for Sustainable Products Regulation (ESPR)*1 followed by the Carbon Border Adjustment Mechanism (CBAM)*2 in the EU, companies will need to quantitatively calculate the amount of emissions for each of their products.

EcoAssist-Pro/LCA provides a system for cumulatively calculating the amount of GHG emissions for each product based on the product's BOM and information on its materials, parts, and manufacturing processes.

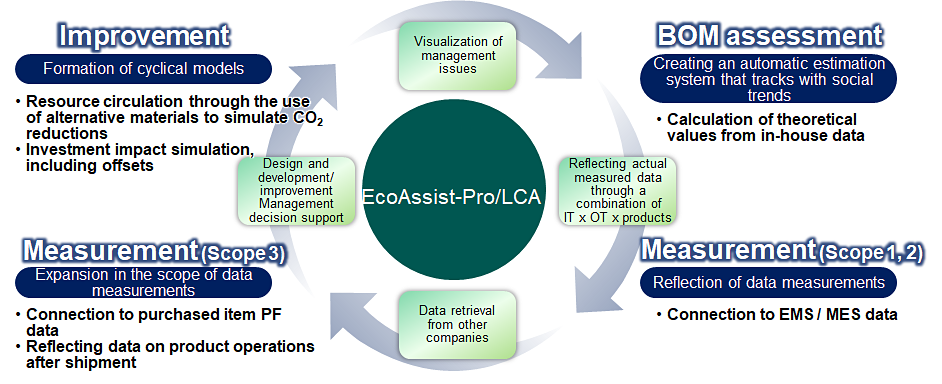

To provide more detailed calculation results, it is important to replace theoretical values with actual measured values. (Regarding the calculation of theoretical values, based on BOM information, some parts with relatively high environmental impact are calculated by applying the basic unit of parts. For other materials, the processing process for each material is estimated and calculated.)

In addition to performing calculations based on theoretical values, EcoAssist-Pro/LCA links with other systems and services to replace theoretical values with measured values. It also implements APIs*3 to link to suppliers' data on measured values.

In this way, through detailed calculations on and visualization of the environmentally hazardous substances of each product, the solution helps companies reduce their GHG emissions. For a stronger response to decarbonization needs, we plan on providing an enhanced version in March 2024.

EcoAssist-Pro/LCA helps automate the calculation of GHG emissions throughout an entire supply chain by linking systems inside and outside the company.

Based on the results of this calculation, companies can formulate plans for continued improvements, visualize the results of such improvements, and make assessments in line with the Carbon Disclosure Project (CDP)*6 and other investor demands.