Water Environment Solutions Based on Advanced Technology and Comprehensive Capabilities

The water supply and sewerage industry in Japan is facing very difficult business conditions, including fewer customers and lower revenues, rising demand for infrastructure upgrades, etc. One way of overcoming these difficulties is to operate the business as a public-private partnership. Hitachi intends to help achieve sustainable water supply and sewerage operations by supplying public-private solutions such as private finance initiatives and comprehensive maintenance services that are based on its many years of experience in supplying products for the water environment.

Construction & Operation Engineering Department, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: PPP business in the Japanese water industry. Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage.

Water Treatment Engineering Department, Social Infrastructure Systems Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Development of water supply and sewage treatment systems in Japan. Certifications: P.E.Jp (Professional Engineer, Japan) of Water Supply & Sewerage.

Water Treatment Engineering Department, Social Infrastructure Systems Division, Water Solutions Division, Water Business Unit, Hitachi, Ltd. Current work and research: Design of water supply and sewage machinery equipment systems in Japan.

Operation & Maintenance Department, Water Planning Division, Water Treatment Division, Hitachi Plant Service Co., Ltd. Current work and research: PPP business in the Japanese water industry.

After reaching a peak of 128.06 million in 2010, the population of Japan is now falling(1). This poses a major challenge for the water supply and sewerage industry, with consequences that include fewer customers and lower revenues as well as difficulties with passing on know-how due to an aging workforce and staff shortages. Numerous utilities are already coming up against these problems.

Another challenge is the need to upgrade aging water supply and sewerage infrastructure, with the peak demand for such upgrades likely to coincide for both water supply and sewerage. This is creating a need to allocate larger budgets and to handle these infrastructure upgrades in a coordinated manner. Moreover, the water supply and sewerage industry is facing increasingly difficult conditions, including the pressure to undertake a comprehensive reappraisal of disaster response management and the seismic resilience of infrastructure prompted by the Great East Japan Earthquake(2).

Meanwhile, the Ministry of Health, Labour and Welfare published its New Water Supply Vision in 2013 and the Ministry of Land, Infrastructure, Transport and Tourism published its New Sewerage Vision in 2014. These documents outlined the futures for water supply and sewerage and described the policies needed to achieve them. Public–private partnerships (PPPs) are one way to achieve sound and stable water supply and sewerage operations despite difficult business conditions, and it is believed that the adoption of measures that utilize private sector technical capabilities and know-how can help put water supply and sewerage operations on a stronger footing, including delivering a better quality of services and lower costs.

As part of Hitachi's marketing of its water environment solutions, this article describes an example of operations handled by PPPs as well as developments planned for the future.

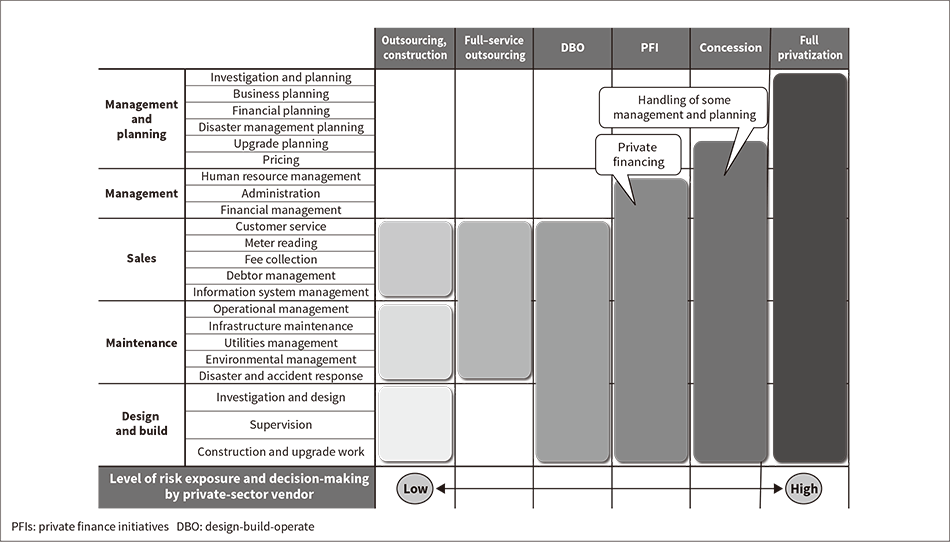

Business models for PPPs can take a variety of forms. Examples include partial outsourcing in which a limited range of activities, such as operations and management, are consigned to a private-sector or other organization; full-service outsourcing in which a wide range of maintenance work is consigned, not just operations and management; private finance initiatives (PFIs) in which the private-sector organization handles everything from design, construction, and financing through to the subsequent long-term maintenance of the infrastructure; and concessions (see Figure 1).

Hitachi is currently engaged in a wide variety of activities from partial outsourcing to PFIs with the aim of achieving sustainable water supply based on its many years of experience in supplying products and systems for the water environment, providing after-sales service, and developing technology(3).

Figure 1—Public–Private Business Models Offered by Hitachi As a partner of choice for water utilities, Hitachi supplies solutions in a variety of forms, from partial outsourcing to full-service outsourcing, PFIs, DBO contracts, and concessions.

As a partner of choice for water utilities, Hitachi supplies solutions in a variety of forms, from partial outsourcing to full-service outsourcing, PFIs, DBO contracts, and concessions.

The water infrastructure for Yubari City is made up of the Asahimachi system that supplies water drawn from the Asahimachi Dai-ichi Dam and Asahimachi Dai-ni Dam and treated by the Asahimachi Water Purification Plant, and the Shimizusawa system that supplies water drawn from Shimizu-no-sawa Dam and treated by the Shimizusawa Water Purification Plant. As of the end of FY2014, the systems supplied an average of 3,343 m3/day to a population of 9,314 people, with a coverage rate of 99.49%. The maximum daily supply volume was 6,766 m3.

The two main facilities in Yubari City's water system are the Asahimachi Water Purification Plant completed in 1967 and the Shimizusawa Water Purification Plant completed in 1969. Both are more than 40 years old and are now showing their age. Along with the expectation of lower revenue from water use and the need to downsize the infrastructure due to a falling population, issues such as rising workloads due to the lower number of people it employs mean that the sustainability of water services is posing a major challenge for the city.

In response, Yubari City formulated its Eighth Business Expansion Plan in July 2010 with the aim of maintaining a safe and reliable supply of water into the future, including a decision to use a PFI mechanism for the upgrading and reconstruction of water supply infrastructure.

The PFI project was the first of its type for water supply in Hokkaido and only the second in Japan to combine the construction and operational management of a water purification plant in a PFI package.

It was undertaken as a single project covering all aspects of operation and maintenance. Along with the construction of new purification plants on the same sites as the aging Asahimachi and Shimizusawa water purification plants, the operation of which would be managed by the vendors, this also included an infrastructure upgrade to update the off-site mechanical, electrical, and instrumentation systems; operation and maintenance of water infrastructure within the city; management of water quality; administration of water supply equipment; and services such as water meter reading, billing, and customer service.

The project used a build-transfer-operate (BTO) model that includes operation and maintenance, with ownership of the infrastructure being transferred to the city after design and construction are complete.

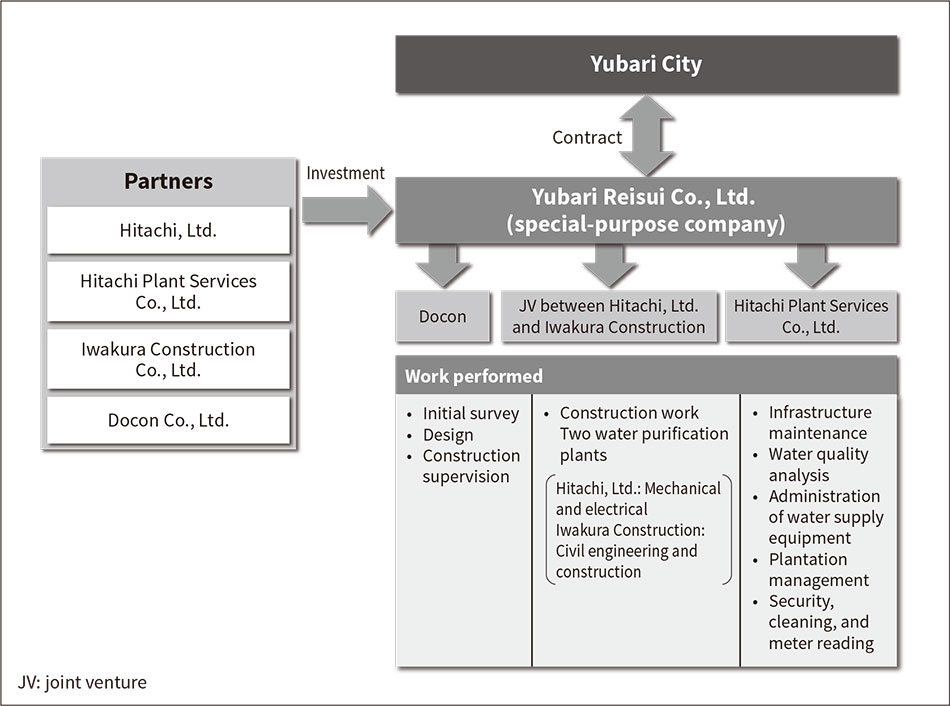

The vendor was Yubari Reisui Co., Ltd., a special-purpose company set up with investment from Hitachi and two other companies. The company signed a contract with Yubari City in March 2012 and work commenced in April of that year. (see Figure 2).

Figure 2—PFI Scheme The scheme involved Yubari Reisui Co., Ltd. contracting work to the respective partner companies, with Docon Co., Ltd. handing initial survey and design work and supervising construction, a JV between Iwakura Construction Co., Ltd. and Hitachi, Ltd. handling construction, and Hitachi Plant Services Co., Ltd. taking responsibility for maintenance.

The scheme involved Yubari Reisui Co., Ltd. contracting work to the respective partner companies, with Docon Co., Ltd. handing initial survey and design work and supervising construction, a JV between Iwakura Construction Co., Ltd. and Hitachi, Ltd. handling construction, and Hitachi Plant Services Co., Ltd. taking responsibility for maintenance.

The project involved downsizing at the new water purification plants. The new capacities were 3,100 m3/day for the Asahimachi Water Purification Plant (see Figure 3) and 4,100 m3/day for the Shimizusawa Water Purification Plant. Membrane filtration treatment was adopted for both plants because it takes up less space and is easier to maintain, provides the flexibility to adjust the amount of water supplied in response to demand by using measures such as changing the number of units in operation, and is able reliably to remove Cryptosporidium and other pathogenic protozoa to maintain water quality. A sediment settling tank was also installed as a pre-treatment measure to reduce the load on the membrane filters at times of high turbidity and the like. The tank is also used as the means to add activated carbon powder to deal with problems such as odors and organic materials (see Figure 4).

Because the source water quality and capacity of the two new water purification plants are similar, two near-identical plants were built with the same treatment sequence. In addition to simplifying maintenance by using the same type of plant with standardized equipment specifications and layout, the high degree of commonality in design and building work helped reduce construction costs.

Whereas the operational management of the water purification plants and off-site infrastructure under the old systems had been based on local controls that required staff to perform operation in person, a remote monitoring and control system was installed along with the upgrading of mechanical, electrical, and instrumentation systems for both the off-site equipment and the new water purification plants. This means that staff can now perform remote monitoring and control from the plants or from their city hall office.

The benefits also include facilitating security of water supply across the entire supply area while also boosting efficiency, including through the use of collected data to locate leaks.

Figure 5—Handover Ceremony This photo shows Mr. Chiba, President of Yubari Reisui Co., Ltd. (left), and Mr. Suzuki, Mayor of Yubari City (right).

This photo shows Mr. Chiba, President of Yubari Reisui Co., Ltd. (left), and Mr. Suzuki, Mayor of Yubari City (right).

The design and construction of the new Asahimachi and Shimizusawa water purification plants commenced in 2012, with the plants being completed and ownership transferred in June 2016 (see Figure 5). Active steps were also taken to improve the service to local residents, with economic revitalization through the proactive use of local companies for construction and repair work, deployment of dedicated staff with expertise in customer service and meter reading, and the provision of care for the elderly when reading meters. Other measures included a community participation activity (involving an environmental education program for elementary school children), employment creation through the local hiring of staff, and the fostering of people who could take over the role of looking after the local water supply system. Hitachi intends to continue contributing to regional revitalization through PFI projects in the future(4).

In FY2015, Toda City supplied water to 135,776 people, with 100% coverage and a maximum daily supply volume of 47,370 m3(5). The water is sourced from an aquifer (deep well) via the prefectural water supply from the Okubo Water Filtration Plant (Tone and Arakawa Rivers) of the Saitama Public Enterprise Bureau. The main infrastructure comprises the Seibu, Chubu, and Tobu water filtration plants (with capacities of 32,800 m3/day, 6,600 m3/day, and 24,400 m3/day respectively), 10 deep wells, and seven service reservoirs.

In contrast, sewerage reached only 89.4% of the region as of April 2017(6). Wastewater from the city goes to the sewerage system for the southern bank of the Arakawa River and is treated by the Arakawa Sewage Treatment Center (run by Saitama Prefecture and located in Toda City). Important infrastructure includes the Niizo and Shimotoda pumping stations and 11 facilities for dealing with stormwater.

While the population of Toda City has been rising over time, the daily consumption of water per person has been falling in recent years. Among the likely reasons for this are greater public awareness of the need to conserve water, the spread of products that use less water, and falling demand from major water users. A difficult business environment is foreseen in the future because falling water volumes mean lower revenue. Moreover, financing is also an issue with much of the system's mechanical and electrical equipment coming due for replacement, while civil engineering structures are also coming due for replacement at the same time as water volumes are falling.

For these reasons, Toda City looked at PPPs as one way of making its operations more efficient. It embarked on a study of full-service outsourcing arrangements in 2013, and in 2015 put out a request for tenders for a multi-year arrangement of this type that was to include customer service as well as management of water supply and sewerage infrastructure. The contract covered 48 different activities serving a population of 135,000 people (as of January 2016), making it the largest such full-service outsourcing arrangement for water supply and sewerage in Japan to date.

The full-service outsourcing arrangement took the form of a multi-year contract with performance criteria that covered a comprehensive range of activities with the aim of maintaining safe and reliable water supply and sewerage services while also upgrading the technology used to operate these services and improving service to residents by utilizing innovations from private-sector vendors to implement efficient procedures and maintenance practices for customer service and operational management of water supply and sewerage infrastructure that Toda City had contracted separately in the past (see Table 1).

A joint venture (JV) led by Hitachi, Ltd. that also included DK Corporation and Hitachi Plant Services Co., Ltd. signed a service contract with Toda City in January 2016, with operations commencing in April of that year.

Table 1—Overview of Full-service Outsourcing Arrangement The outsourcing arrangement covers 48 different activities.

The outsourcing arrangement covers 48 different activities.

Figure 6—Signing of Disaster Response Agreement This photo shows Mayor Jinbo of Toda City (left) and Mr. Nagakura (right), head of the Kanto Area Operation Kitakanto Branch.

This photo shows Mayor Jinbo of Toda City (left) and Mr. Nagakura (right), head of the Kanto Area Operation Kitakanto Branch.

Along with the rationalization of the duties of Toda City employees and cost savings made possible by utilizing innovations from the private-sector vendors to implement efficient procedures and maintenance practices, the benefits of the outsourcing contract also included notably better disaster response capabilities. Whereas work on water filtration plants, pumping stations, and customer service had been contracted separately in the past, the full-service outsourcing arrangement enabled a more rapid emergency response to disasters or accidents by centralizing the chain of command. One such initiative was the signing of a disaster response agreement between the city and the JV in October 2016 (see Figure 6). The objective of the agreement was to establish a cooperative framework to be invoked during emergencies in order to facilitate a rapid restoration of services. Specifically, it involved having the JV help provide water and handle telephone inquiries from residents when requested to do so by the city in the event of earthquake or storm damage. It also involved restoration of water supply and sewerage infrastructure or preventing it from being damaged.

Although the project has only just commenced, the intention is to contribute through the PPP with Toda City to improving service to residents and maintaining safe and reliable water and sewerage services, while also offering proposals for things like how to make maintenance highly efficient and the upgrading or replacement of infrastructure.

This article has described Hitachi's involvement in PPP solutions for water supply and sewerage and presented examples.

In the future, Hitachi intends to continue serving as the partner of choice for utilities, contributing to the provision of robust and sustainable water supply and sewerage services through the supply of solutions for the water environment.