1. HMI Enhancement and Prevention of Cyberattacks on Nuclear Power Plants

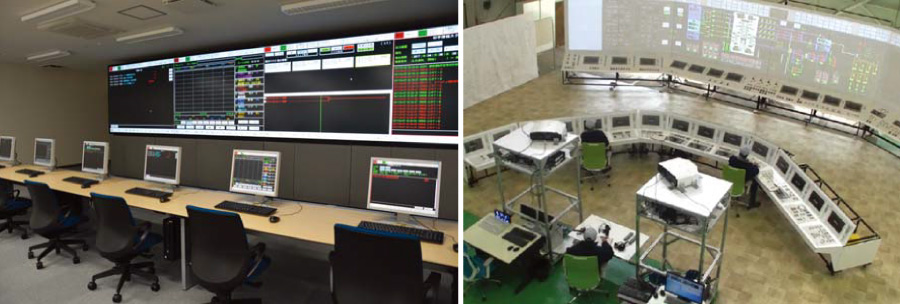

Recognizing the emergence of new threats to digital systems and cyberattacks against them, Hitachi's Services & Platforms Business Unit has established a facility for conducting security training and verification for nuclear power plants with the objectives of improving the defensibility of their control systems, strengthening the organizational structures and practices used for system operation, and developing human resources. By drawing on the business unit's expertise in designing control systems for critical infrastructure and utilizing its advanced information and telecommunications technologies, the facility will provide an environment that is very similar to that of an actual plant.

In response to recent expectations for human factors engineering (HFE) applied in the design process for the human machine interfaces (HMIs) in nuclear power plants, Hitachi-GE Nuclear Energy, Ltd. has developed full-size mock-ups and conducted HFE assessments as part of its main control room panel design activities.

The company is also seeking to make comprehensive plant safety improvements and produce better HMI designs by establishing design processes in which testing is able to be performed in ways that combine human operation with mechanical, control, and plant dynamics. This is being done using a plant simulator for design evaluation that is currently under development.

(Hitachi-GE Nuclear Energy, Ltd.)

1. Facility for conducting comprehensive security training and verification against cyberattacks, and the use of a central control room mock-up for design evaluation