Accelerating Social Innovation through Global Open Collaborative Creation

Many industries and companies are realizing the importance of digital revolution, and as such they are now more aggressive in implementing digital solutions across their company. However, only a few of the companies are prepared or have what it takes to realize such a transformation. Through a collaborative creation methodology, and advanced analytics, Hitachi Europe Ltd. is supporting businesses across industries to realize digital transformations and solutions. In particular, Hitachi Europe has developed advanced algorithms for stationary and mobile asset management enabled by its own digital platform: a universal advanced telematics solutions platform. This article shows some of the advanced digital solutions Hitachi Europe provides to its customers that are now deployed on the universal advanced telematics solutions platform as a repeatable digital solution.

Automotive and Industry Laboratory, European R&D Centre, Hitachi Europe Ltd. Current work and research: Developing advanced telematics solutions for business use cases as a leader of the Automotive Team.

Automotive and Industry Laboratory, European R&D Centre, Hitachi Europe Ltd. Current work and research: Research and development of autonomous driving and telematics platform. Society memberships: The Institute of Electronics, Information and Communication Engineers (IEICE).

Automotive and Industry Laboratory, European R&D Centre, Hitachi Europe Ltd. Current work and research: Managing the Automotive and Industry Laboratory of the R&D Centre in Europe. Society memberships: Senior Researcher and member of IEEE.

Experience Design Laboratory, European R&D Centre, Hitachi Europe Ltd. Current work and research: Chief Designer and Advisor engaged in the development and application of new methods in the context of service design, design thinking and client engagement.

Currently, companies around the globe are seeking a digital revolution. Among established organizations, 89% of companies are either already adopting or planning to adopt a digital-first business strategy, with services (95%), financial services (93%), and healthcare (92%) at the forefront(1). As simply put by software engineer Oleksandr Tedikov, digital transformation is often viewed as an implementation of digital technologies into all areas of business in order to build more sustainable relationships and better understand the needs of customers(1). It involves discovering new frontiers and using innovation and technologies to push businesses. It is about finding new possibilities for an existing service in order to design and deliver a better experience for a customer. One of the biggest obstacles to becoming a digitally mature company is the lack of a digital transformation strategy. Another barrier is not having the enabling tools, such as artificial intelligence (AI) and machine learning (ML) capabilities, that drive digital transformation.

To bridge these barriers, Hitachi Europe Ltd. is offering a range of digital solutions to its customers using a well-defined methodology. This involves working together with customers to define (if non-exiting) and shape their digital revolution journey. Hitachi calls this methodology collaborative creation, meaning that the company creates and innovates a solution together with its customers by offering them a wide range of digital solutions and platforms to support a quick digital transformation. Hitachi supports its customers by identifying concrete business cases, and if necessary, the hardware and software required, and see to it that the identified business cases are realized. Hitachi Europe offers, for example, a range of well-established digital solutions ranging from conducting research and applying advanced analytics for rail maintenance and industry solutions to developing advanced algorithms for stationary and mobile asset management for cost reduction including digital platforms and support.

Digital transformation does not fall from the sky; to enable it, one needs put in place all the necessary digital infrastructure and tools. This includes hardware, software, and human resources. To achieve the business cases, advanced analytics realized by digital enablers such as AI and ML is inevitable. Data extraction, storage, transfer, and insightful analytics are part of the journey. Hitachi Europe has first-hand experience on how difficult it is to get all of these in one place in one company. This simply means that it might take some time for a company to start reaping the benefits of digitalization.

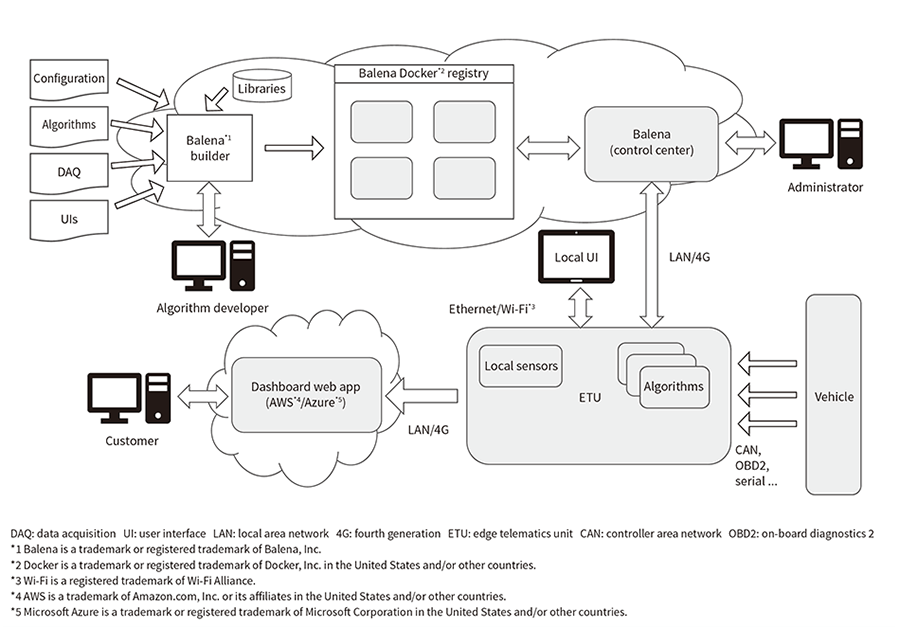

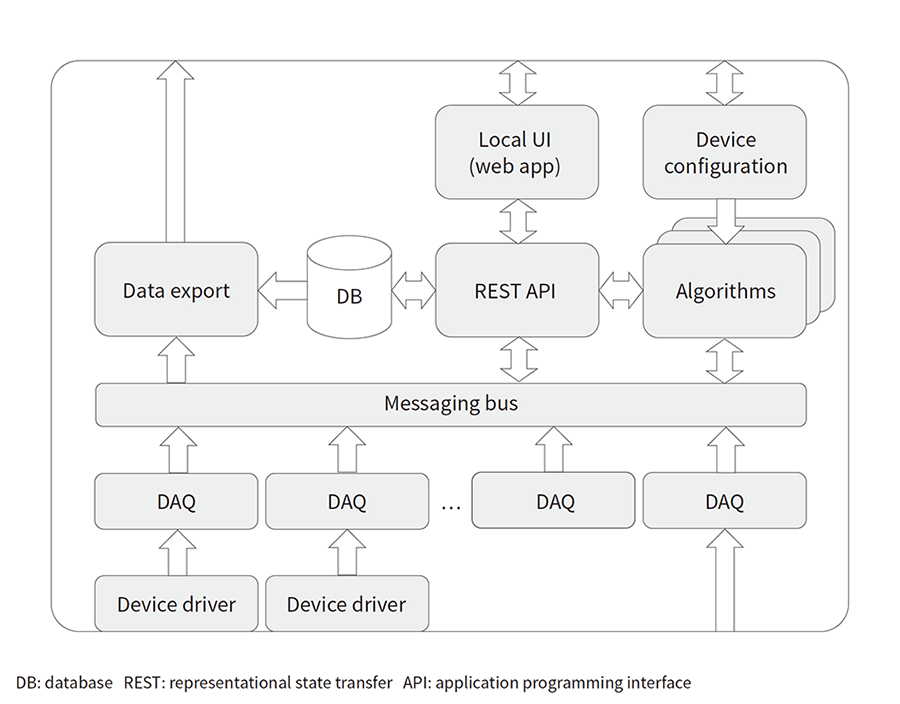

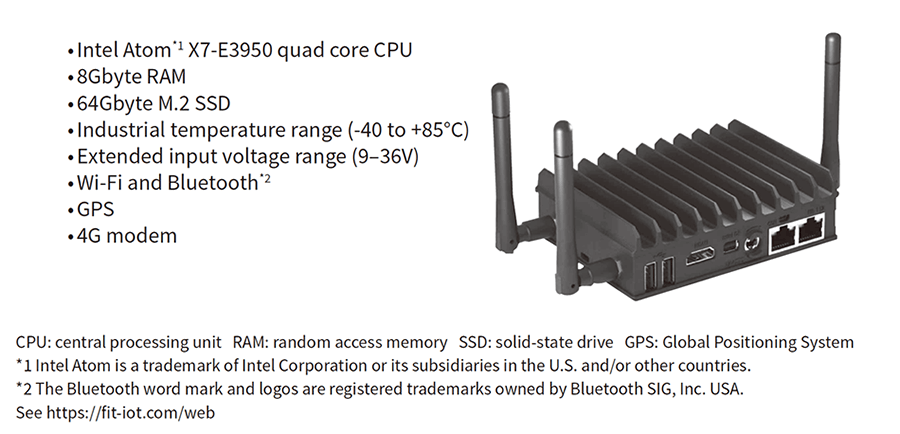

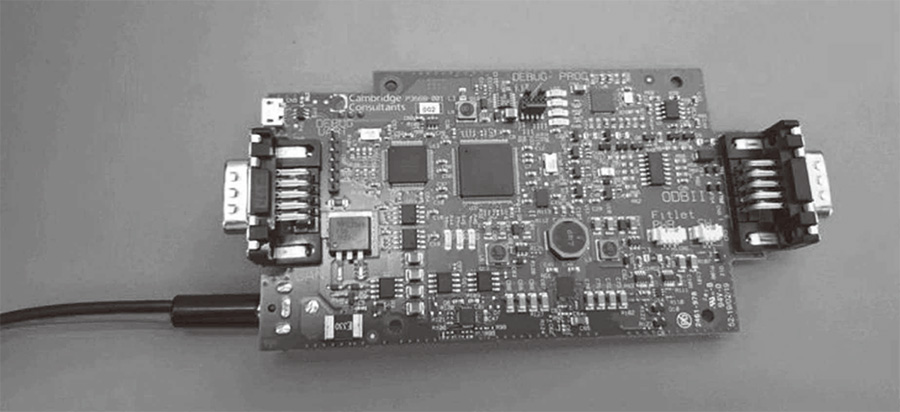

To address the above issue, Hitachi Europe has designed and developed a multi-interfaced mobile device that easily connects to any asset; can gather, store, and transfer data; performs advanced digital analytics both on the edge and in the cloud or center; and finally showcases results and key performance indicators (KPIs) on an interactive user interface both on the edge and in the center. Hitachi Europe calls this device the digital edge telematics unit (ETU). The overall system is called the universal advanced telematics solutions platform (UATSP) (see Figure 1, Figure 2, and Figure 3). UATSP includes in-built advanced algorithms, namely remaining-useful-life (RUL) estimation for brake pads, RUL estimation for tires, RUL estimation for stone crushers, RUL estimation for battery life, fuel optimization for ships, an energy production optimization module, and driving behavior and risk estimation. The UATSP has a customized printed circuit board (PCB) that includes additional sensors, such as vibration sensors and accelerometers (see Figure 4). The UATSP has been designed with the intention of shortening the time it takes to obtain the benefits of digitalization, and this is Hitachi's contribution to the Social Innovation Businesses.

Figure 1—UATSP System Overview The diagram presents a general overview of the universal advanced telematics solutions platform (UATSP), including the overall hardware and software architecture.

The diagram presents a general overview of the universal advanced telematics solutions platform (UATSP), including the overall hardware and software architecture.

Figure 2—Software components of the UATSP The diagram presents a general overview of the software architecture of the UATSP. The upper parts reside on the cloud or local network, and the lower parts represent the interface with sensors.

The diagram presents a general overview of the software architecture of the UATSP. The upper parts reside on the cloud or local network, and the lower parts represent the interface with sensors.

Figure 3—Digital ETU This is the off-the-shelf gateway used as a base for the edge telematics unit (ETU).

This is the off-the-shelf gateway used as a base for the edge telematics unit (ETU).

Figure 4—Customized PCB of UATSP The custom circuit board was designed to suit Hitachi Europe’s requirements (accommodating several business use cases and enabling fast deployment of advanced digital solutions).

The custom circuit board was designed to suit Hitachi Europe’s requirements (accommodating several business use cases and enabling fast deployment of advanced digital solutions).

This subsection shows one of Hitachi Europe's digital solutions now deployed on the UATSP and currently running as one of the advanced edge solutions. The next subsection describes a practical digital solution deployed on UATSP on the center side.

According to a report by the World Shipping Council (WSC) in 2008, fuel costs represent as much as 50–60% of total ship operating costs. Ocean carriers are required to recover these costs to maintain levels of service, meaning the price of shipping goods will continue to face upward pressures. Carriers have been responding to the high cost of fuel, according to WSC, by utilizing a range of operational adjustments. Considering that these operational adjustments have generally already been taken by shipping lines, there are limited additional operational measures that vessels can take to further reduce fuel consumption.

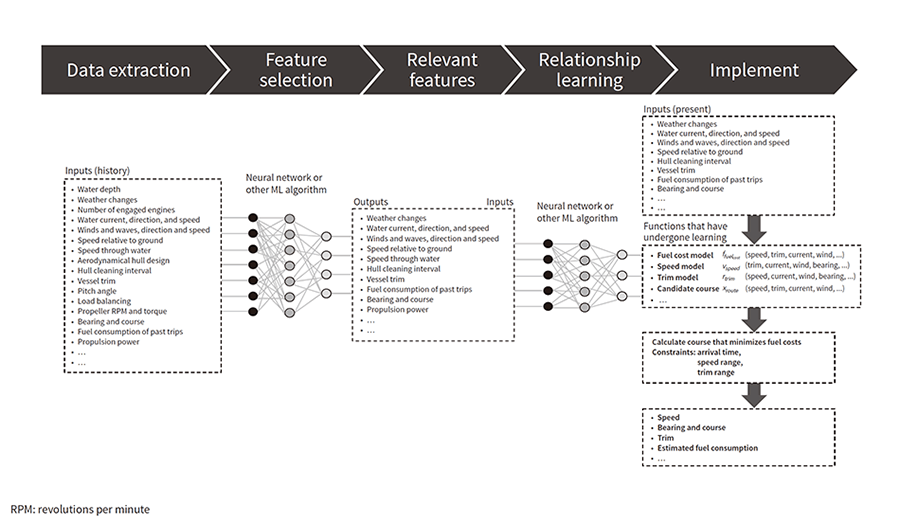

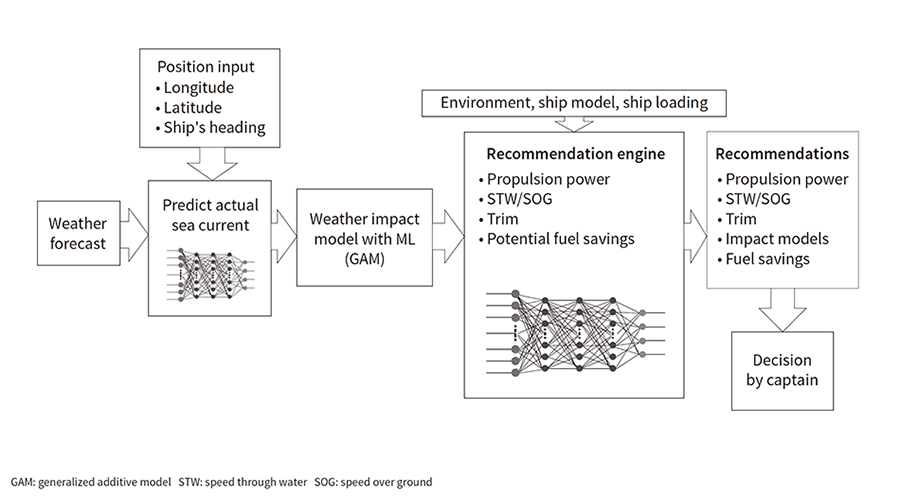

In response to the above challenge, Hitachi Europe used advanced analytics, including AI and ML to run collaborative creation projects with a European customer. Hitachi designed and developed an AI-assisted voyage planning technology to reduce fuel consumption and environmental impact in collaboration with the customer (see Figure 5, Figure 6, and Figure 7). This involved first utilizing data collected by the customer for AI learning and identifying the factors (feature values) that influence fuel costs. Next, fuel costs and other vessel operating parameters (such as speed, trim, and possible vessel courses) were modeled by using these feature values as a basis for AI learning. During actual operation, current data values are fed into the model and used to estimate the fuel costs and other vessel operating parameters at points along each possible course. The results of this are then used to determine which course will minimize fuel costs. In this digital revolution project and collaborative creation project, Hitachi Europe developed an AI-based algorithm that recommends, in real time, the speed and power necessary to navigate the vessel from its origin to destination in a fuel-efficient and environmentally desirable way, taking into consideration complex dynamic environmental factors such as changing winds and sea currents, waves and tides, and uneven sea depths. Ensuring that the vessel meets the expected time of arrival is used as a model constraint.

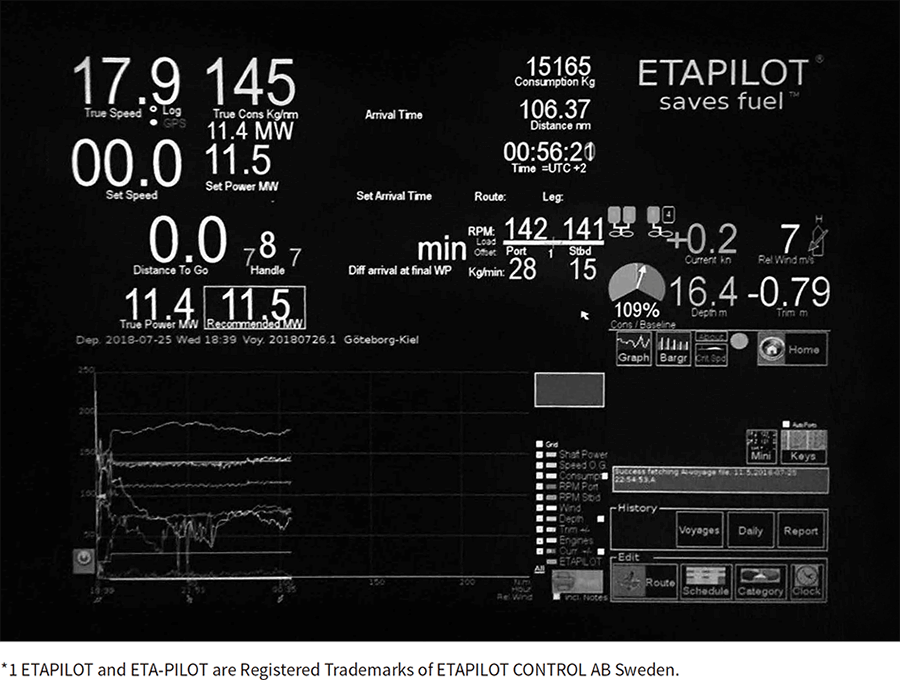

The technology was launched live on a customer vessel in August 2018 and the captains were happy with model performance. The technology promises savings in the range of 2-4% and is now deployed to run on the UATSP for easy deployment to a new environment such as a new vessel or a new customer with little effort.

Figure 5—AI and ML Pipeline and Approach The figure shows the pipeline and approaches of artificial intelligence (AI) and machine learning (ML).

The figure shows the pipeline and approaches of artificial intelligence (AI) and machine learning (ML).

Figure 6—AI Recommendation Engine Pipeline This figure shows the data flow pipeline of the modules developed for the recommendation engine used to determine optimal sailing parameters for the fuel optimization use case.

This figure shows the data flow pipeline of the modules developed for the recommendation engine used to determine optimal sailing parameters for the fuel optimization use case.

Figure 7—Live ETAPILOT*1 Dashboard Displaying Recommended Power This figure shows a live dashboard displaying the recommended power for fuel efficient sailing. The value of “11.5” indicated by the rectangle is the recommended power.

This figure shows a live dashboard displaying the recommended power for fuel efficient sailing. The value of “11.5” indicated by the rectangle is the recommended power.

As mentioned earlier, the UATSP has the beauty of being able to add new digital solutions and support real-time analytics both on the edge and at the center. This digital solution is being deployed on the UATSP to run on the center side.

Given that heat production in itself is very expensive and the fact that district heat demand and electricity prices fluctuate every day or even every hour, it is important that heat production and distribution companies develop a good model that predicts heat demand and optimizes its production. Complicating the problem is the fact that ever-changing weather conditions play an important role in determining the heat consumption of a given household or a building. To address the above challenge, Hitachi Europe and a renowned energy company decided to work together to identify potential optimization areas in the company.

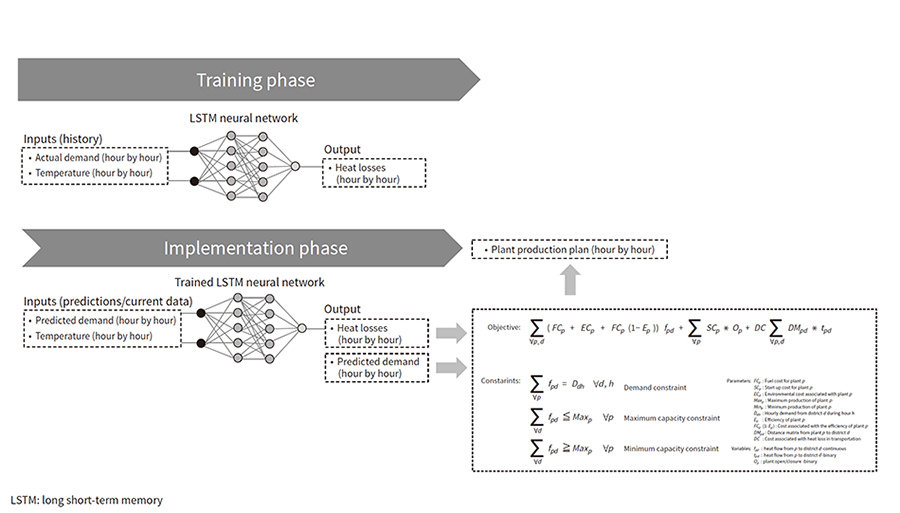

In this collaborative creation project, Hitachi Europe uses advanced analytics to design and develop AI- and ML-based technology to estimate the next-day hour-by-hour district heat forecast and an optimal production plan for the plants. It also introduced a novel AI-based heat loss estimation model (see Figure 8). This model sums the three major cost components and calculates the heat production plan that will minimize this total cost. The first cost is that of heat production, being made up of each heat production plant's fuel costs, environmental costs, and the losses in heat production. The second cost is that of plant startup, which quantifies how much it costs to start each plant. The third cost is that of heat transmission, representing the loss of heat along the distance from the plant to where the heat is to be delivered.

A live test was conducted in December 2018 that compared Hitachi Europe's model with the customer's current model. The result showed that the current customer's model can be improved by integrating models developed by Hitachi Europe. It has now deployed this model on the UATSP to run on the center or cloud. This is an example of the quick realization of a digital solution by a new customer with little effort.

Figure 8—AI Pipeline for Modeling Heat Loses The figure shows the design of a neural network for predicting heat losses during district heat transfer from plants to districts.

The figure shows the design of a neural network for predicting heat losses during district heat transfer from plants to districts.

This article has described two successful collaborative creation projects with the customers in Europe, projects that number among those deployed on the UATSP – a powerful platform for ensuring a quicker return on investment (ROI) in digitalization. Hitachi Europe is committed to contributing to Social Innovation Businesses through collaborative creation with customers.

The authors sincerely thank collaborative creation customers for their time and data used in achieving the results on business use cases described in this article.