Smart Life Solutions for People Everywhere

At the same time as the manufacturing industry is experiencing major changes brought about by factors such as the globalization of markets, worsening labor shortages, and reforms to working practices, another global trend within the industry is the considerable activity taking place in relation to the use of digital tools. This includes a variety of initiatives in Japan based on the concepts of Society 5.0 and the Industrial Value Chain Initiative. With an emphasis on cell production and using its Lifestyle Home Appliances Unit as a model, the Products Division of Hitachi Global Life Solutions, Inc. has been adopting Internet-of-Things systems based on the concepts of enhancing transparency and connectivity while reducing reliance on particular individuals to reform its manufacturing practices in ways that will enhance total supply chain management. This article describes these improvements.

While retaining an emphasis on cell production, the reforms to manufacturing practices at Hitachi Global Life Solutions, Inc. (Hitachi GLS) have combined greater transparency with cell automation and system-wide optimization of the links between individual processes as well as the enhancement of efficiency by getting rid of process steps that do not add any value or by making improvements or eliminating barriers and bottlenecks. The Monozukuri World No. 1 Project launched in FY2017 has involved the development of proprietary production techniques suitable for wider use and work on establishing optimal systems for high-volume production that facilitate increased sales. This work has been underpinned by the following three concepts.

The aim is to enhance manufacturing capabilities by using the Internet of Things (IoT) to put these concepts into practice.

In an environment where product lifecycles are short and where home appliances are produced in anticipation of future sales, the risks are that a slow response to changing sales trends will result in potential sales being lost when demand spikes or excess inventory building up when sales are lower than expected. The aim of cell production is to establish manufacturing practices that are both efficient and able to deal with fluctuations in production volumes, reducing the quantity of work in progress held between and within processes and minimizing both lost time when switching production between different models and holding costs when work in progress is held up.

The Lifestyle Home Appliances Unit at Hitachi GLS introduced cell production in earnest in 2003 and has achieved dramatic improvements in productivity by adopting the practice for all of its varied product range, which extends from washer/dryers to vacuum cleaners, cooking appliances, and lighting. The unit’s 15-plus years of experience with the practice has included winning a Nikkei Monozukuri Award in 2008 for a proprietary cell production technique for large home appliances such as front-loading washer/dryer cells and refrigerator and water heater cells.

Hitachi GLS has been running its Monozukuri World No. 1 Project at all of its sites since FY2017, including at overseas operations. The project seeks to improve production efficiency and reduce lead time, with the three key concepts listed above playing a central role. Phase two of the project, which commenced in FY2019, involves the use of automation and the adoption of new systems to improve efficiency so as to achieve the 2021 Mid-term Management Plan. The project is intended to raise the standard of manufacturing across Hitachi GLS by means of activities that run across all worksites and provide for the sharing of ideas as well as staff development and the fostering of an improvement-oriented culture through a workplace-led approach. This includes each of the sites presenting improvement activities at regular meetings attended by senior management and holding GLS Production Innovation (G.P.I.) working groups for workplace improvement.

Use of IT in the reform of manufacturing practices has in the past been done in a piecemeal manner, with activities seeking to provide more transparency in the manufacturing workplace, its management, the analysis of operations, and so on. However, there is a need to optimize operations across multiple sites and utilize IoT technology to enhance the production systems that monitor and automate all of the steps from the machining of parts to sub-assembly manufacturing, product assembly, inspection, and dispatch, as well as the management of the four elements of manufacturing (4M): men, machines, materials, and methods, based on orders and production planning. Hitachi GLS has consolidated the work being done on this within the Monozukuri World No. 1 Project under the banner of “manufacturing IoT.”

The aim is to develop systems that will maintain optimal safety, quality, delivery, and cost (SQDC) by automating the preparation and updating of production plans that depend on the expertise of specific members of staff; handling attendance management, which is complicated by the diversity of ways in which people are employed in the manufacturing workplace; sharing information for safety, quality, and efficiency improvement; and providing real-time information on things like equipment operation. Although system development is largely undertaken in-house, systems such as those for automatically generating production plans are developed jointly with the Center for Technology Innovation – Production Engineering of Hitachi Research & Development Group. In either case, the systems have been put in place through a bottom-up approach that is able to incorporate the knowledge held in the workplace in a flexible manner, taking account of compatibility with core business systems and the ability to be extended to other operations at the same site.

The following sections present examples modeled on the workplace where front-loading washer dryers are manufactured. These front-loading washer dryers are a major product for the Lifestyle Home Appliances Unit. The current intention is to extend this work to other products and other sites.

The system is intended to provide the flexibility to keep pace with fluctuations in market demand and the rate of production by automating the preparation and updating of production plans that previously depended on the expertise of specific members of staff and to rationalize auxiliary tasks.

A background factor was that, because the Lifestyle Home Appliances Unit had a large amount of on-site production machinery, a result of producing so many of its components itself, there was a heavy workload associated with the production planning needed to keep work in progress to a minimum while also ensuring a reliable flow of parts to the assembly line and maintaining a high level of utilization in the operation of this plant.

The solution to these challenges is the automatic production planning system, which is made up of an automatic detailed scheduling system that automatically generates production plans for finished products and an internal production scheduler that generates production plans for parts manufactured in-house.

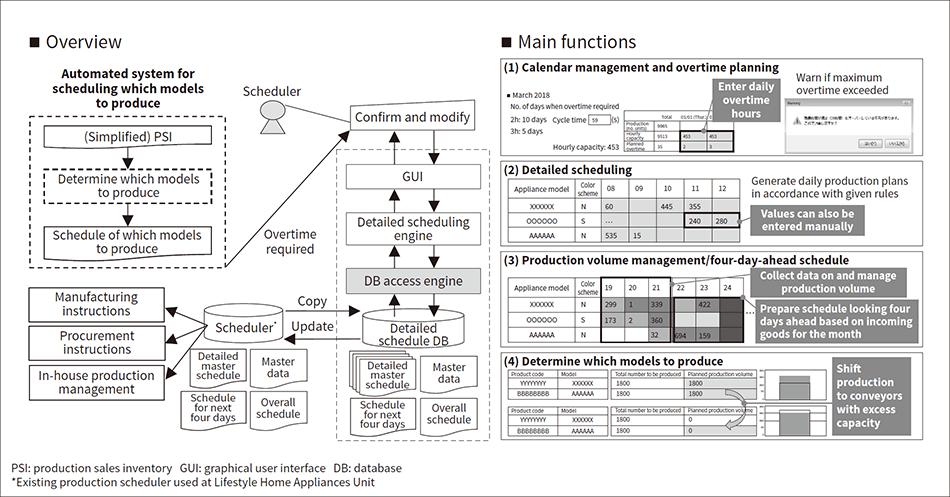

Fig. 1—Automatic Detailed Scheduling System The figure shows an overview of the system and its functions. To automate the process, the different scheduling methods used for different products are defined as parameters.

The figure shows an overview of the system and its functions. To automate the process, the different scheduling methods used for different products are defined as parameters.

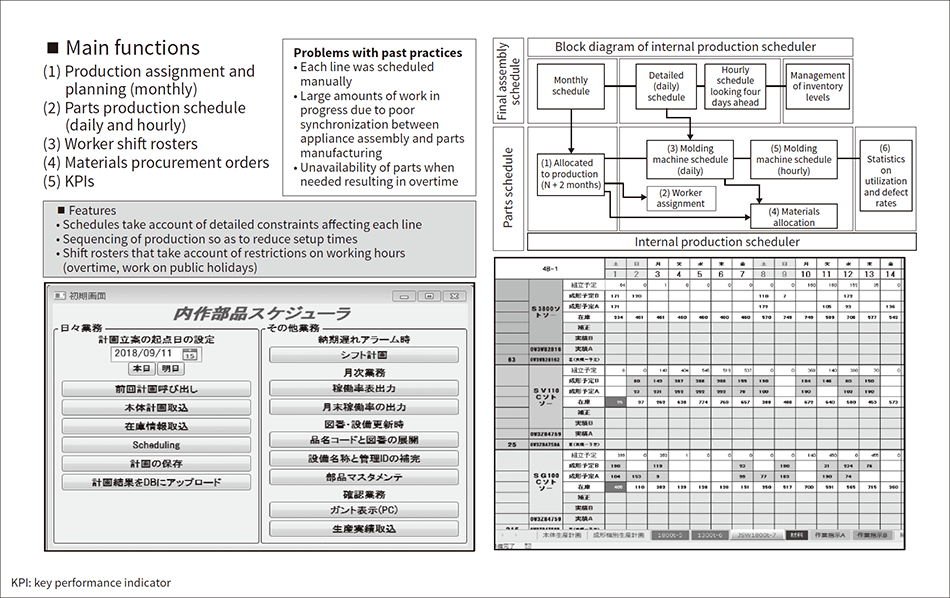

Fig. 2—Internal Production Scheduler The figure shows a block diagram of the internal production scheduler and example screens. In addition to work schedules, the system also generates shift rosters.

The figure shows a block diagram of the internal production scheduler and example screens. In addition to work schedules, the system also generates shift rosters.

This system is intended to automate attendance management and worker assignment. It shares information with a newly implemented attendance management system to provide better information about attendance and uses information on the skill sets of individual workers to automatically generate a staff reassignment map to deal with any worker absences.

Through the sharing of data with employment management systems, it has also rationalized the auxiliary tasks of attendance managers, such as collating overtime details and working through the approvals process.

This system is intended to shorten the time it takes increasingly diverse new employees to become proficient and to raise the level of worker training.

With the structure of the workforce being such that 70% or more of roles are outsourced, with high turnover and staff coming from an increasingly diverse range of national origins, shortening the time it takes new employees to become proficient in cell production tasks that take about 10 minutes per worker, without compromising safety, is a major challenge when seeking to improve efficiency.

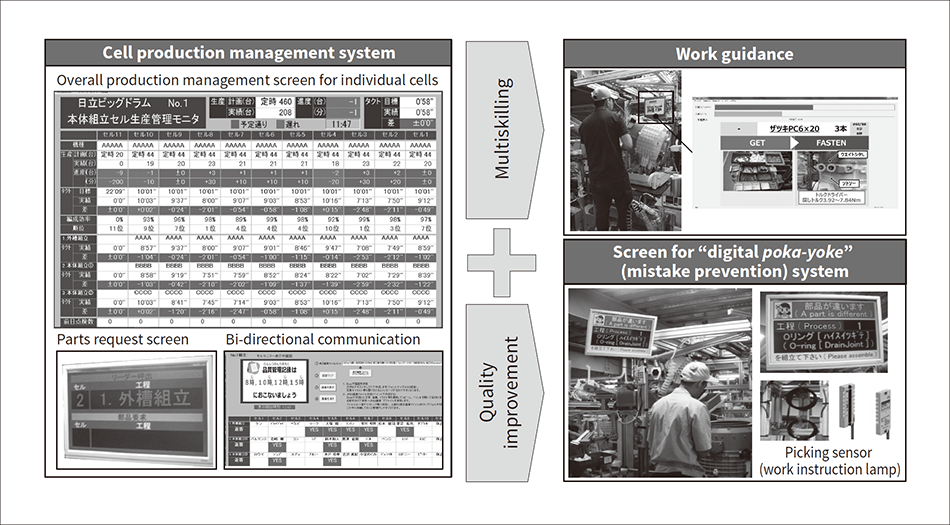

This system displays the information that cell workers need on a monitor installed directly in front of them, providing a wide variety of instructional information including images showing how work is to be performed, how to avoid mistakes such as forgetting to attach certain parts, and communication (see Figure 3).

Fig. 3—Cell Production Management System The system improves efficiency by interactively linking information on individual cells with the management of all areas of the cell assembly shop.

The system improves efficiency by interactively linking information on individual cells with the management of all areas of the cell assembly shop.

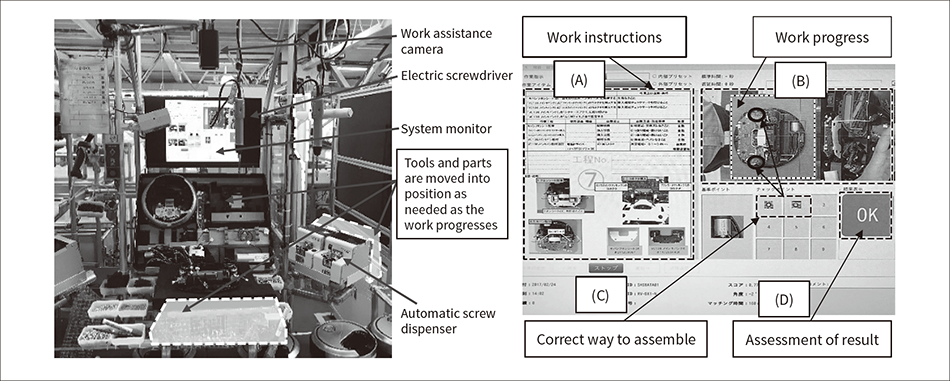

The production efficiency of an assembly cell for robotic vacuum cleaners was enhanced by putting in place a single-worker cell for a monitoring technique that combines the processing of images from a commercially available work assistance camera and a newly developed system. This was done to satisfy the requirements of a tightly packed design that features the same functions as competing models in half the volume, with a high component count and a complicated wiring harness (see Figure 4).

Fig. 4—Monitoring Cell The figure shows the functions and layout of the monitoring cell. As the worker carries out a task in accordance with instructions on the monitor (A), the system compares the actual work done (B) with data on how it is meant to be done (C). This prevents problems such as incorrect assembly or parts being left out by indicating whether or not the work has been done correctly (D).

The figure shows the functions and layout of the monitoring cell. As the worker carries out a task in accordance with instructions on the monitor (A), the system compares the actual work done (B) with data on how it is meant to be done (C). This prevents problems such as incorrect assembly or parts being left out by indicating whether or not the work has been done correctly (D).

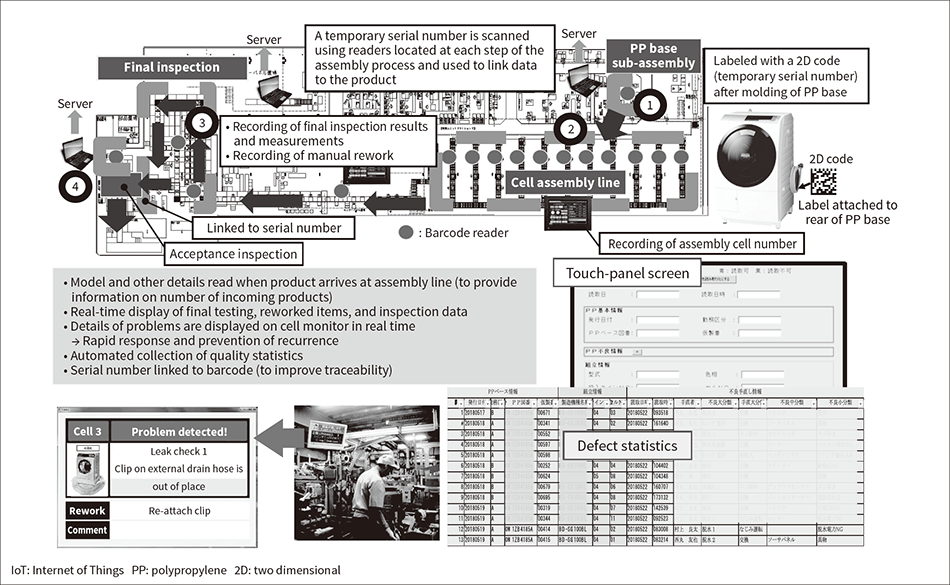

This system has been introduced into the appliance assembly process in a way that treats components manufactured internally and labeled with QR codes* as key parts. It is intended to make quality management more transparent, to provide real-time feedback, and to rationalize auxiliary tasks. Information is recorded for each appliance on whether products pass the post-assembly final inspection as well as on things like any rework or adjustments that were made. This information is linked to the serial number when acceptance inspection is performed. By doing so, use of the monitors installed in the assembly cells to display feedback about defects in real time when a problem is detected not only enables a quick response when the same defect recurs, but also improves traceability and automates the preparation of daily inspection reports and quality statistics (see Figure 5).

Fig. 5—Final Inspection IoT System The figure gives an overview of the final inspection IoT system and its main functions.

The figure gives an overview of the final inspection IoT system and its main functions.

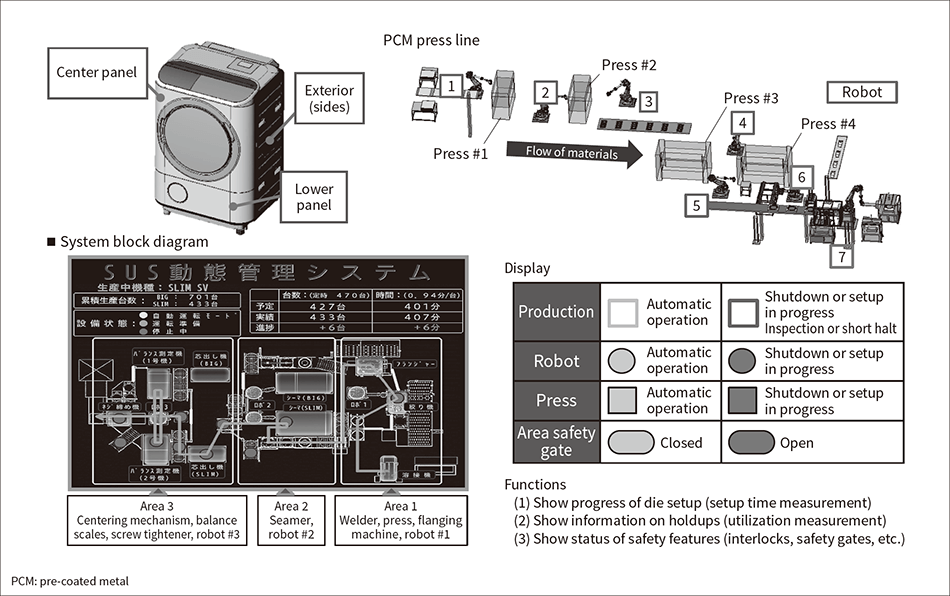

The shop where the exterior parts of front-loading washing machines are press-formed is equipped with a number of presses and robots, and operates as an unmanned production line. The equipment status management system acquires timely information about the equipment setup and any problems that occur. The intention is to shorten the time taken to restart from a shutdown and to increase equipment utilization and production volumes. A system for viewing what is happening on the line has been put in place by installing a number of large-screen monitors in the workplace and displaying the layout of the line as a whole, and the presses and robots in each unit (see Figure 6).

Fig. 6—Equipment Status Management System Color coding is used to indicate the operating status of each unit. By displaying the die status (whether setup is in progress or complete), time taken for setup, and the state of interlocks for each area so that whether the equipment gate is open or closed can be seen at a glance from anywhere, this significantly improves the performing of safety checks when restarting equipment. It also makes it easier to deal with problems and determine where delays are happening based on robot control signals such as when robots take hold of a workpiece.

Color coding is used to indicate the operating status of each unit. By displaying the die status (whether setup is in progress or complete), time taken for setup, and the state of interlocks for each area so that whether the equipment gate is open or closed can be seen at a glance from anywhere, this significantly improves the performing of safety checks when restarting equipment. It also makes it easier to deal with problems and determine where delays are happening based on robot control signals such as when robots take hold of a workpiece.

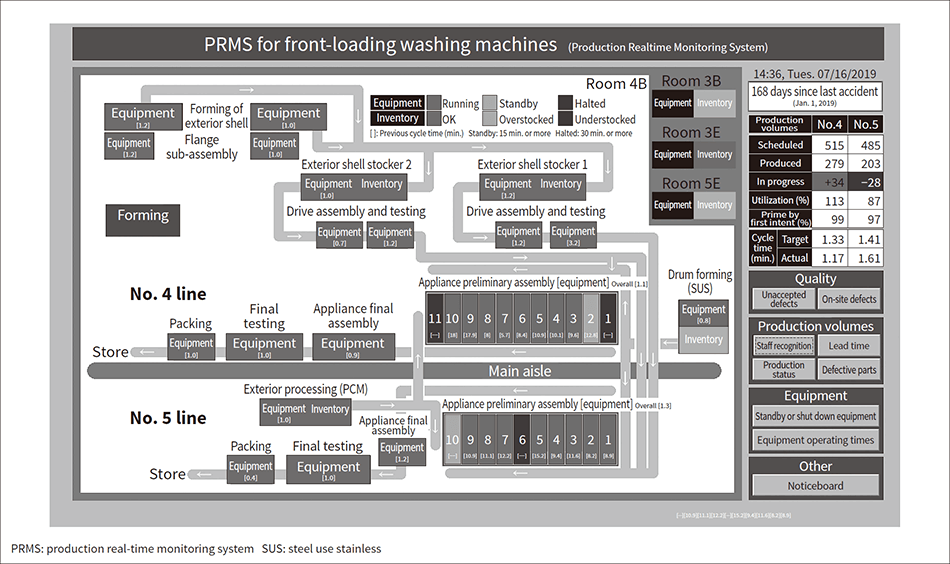

A production real-time monitoring system (PRMS) for providing information on all steps along the production process that is integrated with the systems mentioned avobe was installed to identify bottlenecks across the entire production process and to provide productivity information (prime by first intent and plant utilization) (see Figure 7). The same philosophy was adopted in the installation of a similar system on the refrigerator assembly line at HCPT. The system is used to make improvements aimed at reducing losses by providing information about what is happening on the refrigerator production line.

Fig. 7—Production Real-time Monitoring System Shows at a glance what is happening in the room and provides a dashboard for centralized management of different systems.

Shows at a glance what is happening in the room and provides a dashboard for centralized management of different systems.

Because the installation of IoT systems makes it possible to collect data from “things,” data can be shared between people, and between people and equipment. As anyone can make use of this data, it is possible to identify where the problems lie in a workplace, come up with the best possible solutions in an efficient manner, and implement improvement actions quickly.

By facilitating human resource management and training at manufacturing workplaces, where diversity is on the rise, these IoT systems are an important factor in enhancing SQDC.

The areas that Hitachi GLS plans to work on in the future are the upgrading of its core business systems by adopting integrated enterprise resource planning (ERP), the efficient allocation of design and manufacturing resources through the enhancement and integration of supply chain management (SCM) and engineering chain management (ECM), and the use of digitalization for better quality traceability. By achieving highly efficient workplaces, Hitachi GLS is aiming for the faster and more accurately targeted supply of value-laden products that suit the needs of individual consumers.