COVER STORY:CONCEPT

Taking Advantage of Integral Architecture to Establish Effective Design Practices and Robust Supply Chains

It is not uncommon to hear people talking as if manufacturing is finished in Japan and that we are now entering the digital era. Not so, according to Professor Takahiro Fujimoto of the University of Tokyo, a pre-eminent figure in the field of manufacturing management. After a long and difficult struggle, manufacturing in Japan now finds itself in a position to take on the world. Professor Fujimoto talks about how manufacturing should adapt to the new normal, including where the strengths of Japanese manufacturing are to be found and what business strategies should be pursued amid the ongoing digital transformation.

——Please start by putting the current state of manufacturing in Japan in a historical context.

Takahiro Fujimoto

Takahiro Fujimoto

Professor, Graduate School of Economics, The University of Tokyo

Graduated in 1979 from the Faculty of Economics at the University of Tokyo and joined Mitsubishi Research Institute, Inc. in the same year. Past appointments include Research Associate at Harvard in 1989, Associate Professor at the Faculty of Economics, the University of Tokyo in 1990, Professor at the Graduate School of Economics, the University of Tokyo in 1998, and Executive Director of the Manufacturing Management Research Center in 2004. He is known for his studies of the Toyota Production System and other production management practices in manufacturing. His many publications include “Production Development Performance,” “An Evolutionary Theory of Production Systems,” “Capability Development Competition,” “Capability Building Competition.”

FujimotoDuring the 1980s, the final decade of the Cold War between East and West, Japan led the world in products such as cars and analog televisions (cathode-ray tube) for which an integral architecture, in the sense of being a monolithic black box, was a key design characteristic. To put it differently, this characteristic of being integrated (all the pieces fitting neatly together) was itself integral to the Japanese approach to design (product architecture). Japan achieved great success in this role as “America’s workshop,” overcoming the strong yen of the 1970s and late 1980s to become the world’s second largest economy by gross domestic product (GDP).

The 1990s, however, brought a completely changed world, one formed by the bursting of the economic bubble, the end of the Cold War, and the rise of China. China in particular established itself as the “workshop of the world” thanks to low labor costs and the mobilization of its vast rural workforce. This was a time when the ratio of the wage differential between Japan and China was 20 to 1. In other words, Japanese factories were at a 20-fold handicap. Buffeted by circumstances that included financial crisis and the very high yen, many Japanese companies moved their manufacturing plants to China.

A look at which Japanese industries experienced the greatest loss of competitiveness in the 1990s shows that not just globalization but the transition from analog to digital was a major factor behind this. The need to make detailed adjustments during development or production became less pressing with the advent of open and modular products that were largely produced by combining industry-standard parts and equipment with pre-defined interfaces between components and processes. Examples include digital televisions, personal computers, and dynamic random-access memory (DRAM) semiconductors. Many products such as home appliances and semiconductors inevitably did poorly as architecture no longer conferred as much of a comparative advantage on products and processes.

Automobiles, however, are by nature heavy objects that travel at high speeds on public roads. Driven by a very high level of demand for improvement in safety and reductions in raw materials used and the environmental footprint, the automotive industry saw ongoing innovation and relentless efforts to integrate different parts to achieve optimal design. This is why it was in the automotive industry that Japan, a country that for historical reasons has a high level of technical skills in the workplace, has been able to maintain the comparative advantage of architecture.

FujimotoThis situation has been gradually changing since around the turn of the century, a time when the relocation of manufacturing bases to China was proceeding at a rapid pace. There have been numerous instances over this period where Japan’s leading factories successfully boosted physical productivity multiple times over just a few years through the adoption of practices such as the Toyota Production System. Moreover, from around 2005, China’s wages rose at a rate that saw them double in value over five years, causing the 20-fold wage differential to shrink back to its current ratio of around three to five times. There were certain sectors where it was now Japan that had the advantage in terms of unit cost. By the beginning of 2010, Japanese manufacturers were no longer talking about always being at a cost disadvantage to China. This significant turning of the tide continued as the 2010s progressed.

YahiroI visited Dalian, China around 2008 as part of a survey by the Ministry of Economy, Trade and Industry where I was working at the time. When I spoke to the managers of Japanese companies there, they told me that the wage differential had shrunk so rapidly that when talented staff who have built up experience working in China are brought over to Japan, their salaries do not rise by very much and so they tend to go off to work for foreign companies. Even back then, this risk of losing staff was something that needed to be taken into account when employing Chinese workers.

FujimotoWhile this was going on, I believe most Japanese companies were also responding to these wage increases by taking action to improve workplace performance and boost productivity in their Chinese operations, including through support from “mother factories” in Japan. In any case, having made it through the tumult of the 1990s, Japanese manufacturing was gradually getting back to a normal competitive environment. Unfortunately, with the global financial crisis in 2008, the Great East Japan Earthquake in 2011, and the very high yen of the early 2010s, pessimism continued to pervade the air, leaving people feeling that manufacturing was a lost cause. Certainly, government figures record that the manufacturing workforce shrunk from around 15 million to around 10 million during the three decades of the Heisei era (1989 to 2019), with the number of companies falling by about half. Despite this, there was no commensurate fall in the total value added by Japanese manufacturing, with the figure hovering at a little over 100 trillion yen through all three decades. Maintaining total value added at around the same level while the workforce shrunk to two-thirds of its former size roughly equates to a nearly 1.5-fold improvement in productivity. Rather than the end of Japanese manufacturing, having made it through 30 difficult years, it can at last be said that Japan is getting back to normality and a position of global competitiveness.

——While Japanese manufacturing has made it to the start line in terms of global competitiveness, the digitalization of the 2010s represents a new challenge. How should Japan be making use of this digital technology?

FujimotoWhat I believe will be important in the future will be to establish a “winning” digital environment. For those types of plants or vehicles that required precise and high-speed control, the need in the past has been for real-time optimal control, utilizing a variety of different networks that include leased lines as well as the Internet. That is why the Internet of Things (IoT) with its implication of being limited to the Internet is something of a misnomer. A better characterization, I believe, would be Information from Things (IfT), meaning the acquisition of reliable information from the field and its forwarding to networks in real time. What is important in digital manufacturing is to attach accurate networked sensors to the various things found in the workplace and to acquire data and information in real time that, depending on the type of data, can then be analyzed either at the edge (at or near the site) or in the cloud to keep track of any variation between actual and planned performance. Accompanying this should be the use of techniques such as simulation to continually revise plans to maintain an optimal system-wide workflow.

Looking back to the time around 2018, about half of the case studies about IoT use were related to predictive maintenance (fault prediction) and its use to improve the utilization rate of individual pieces of equipment. While this is clearly an important application, it amounts to no more than selective optimization. As the strength of Toyota and Japan’s other leading manufacturers lies in production management for system-wide optimization to achieve good design and good workflows, the IoT and IfT first and foremost need to be deployed in ways that facilitate this. Unless it happens to be a bottleneck, improving equipment availability does nothing to help the overall production flow.

Achieving good workflows is essential for products made by integrating different parts and for agile manufacturing practices that can vary the type, quantity, and sequence of parts production. When the practice is to vary the type and quantity of the parts being produced, such as making five instances of one custom part following by 1,000 of another, it is important that production management is able to adapt to the circumstances and reduce holdups in the flow of work-in-progress. If plants are equipped with cyber-physical systems (CPSs) capable of the real-time monitoring of things like the progress of products through manufacturing, equipment utilization, and personnel deployment, it becomes possible to predict where holdups will occur 30 minutes later, for example. By allowing them to work together over a wider area, the on-site teams who are keeping track of this will be able to deal with such issues more effectively. As a platform for achieving this, use of the IoT and IfT in ways that make use of workplace know-how will be essential.

Jun Abe

Jun Abe

Vice President, Executive Officer, and CEO of Industry & Distribution Business Unit, Hitachi, Ltd.

Joined Hitachi, Ltd. in 1984. His appointments have included head of the database design department of the Software Division in 2001, Senior Vice President of Hitachi Data Systems in 2007, General Manager of the Software Division in 2011, General Manager of Business Relation Promotion Division, Social Innovation Business Project Division in 2013, Senior General Manager of the Control System Platform Division, Services & Platforms Business Unit (Omika Works General Manager) and the Service Platform Business Division, Information & Telecommunication Systems Group in 2016. He took up his current position in 2018.

AbeIn Hitachi’s Industry & Distribution Business Unit, I am currently just the person responsible for the division, which delivers system integration for customers in the manufacturing and distribution industries. Prior to this role, I previously spent around two years as General Manager of the Omika Works where we were already putting a lot of effort into efficiency improvement using such things as IT and radio-frequency identification (RFID) before terms like the IoT and big data gained currency. One of our first initiatives was aimed at visualizing the manufacturing workplace. This involved linking data together to understand the “where,” “in what order,” and “when” of what is happening at the plant.

What marked this work out in particular was the process of establishing goals and finding solutions to problems through collaborative creation with managers from customer businesses and others. This is because what matters most in DX is not the “D” of digital, but rather the “T” of what the transformation actually entails.

FujimotoI have visited Omika Works on several occasions for research surveys, gaining a sense of the ease of communications between the development and production teams, with helmeted factory staff going in and out of the design room. I recall from around 2010 that you had a focus on factory-wide workflow improvement, with an excellent IT system that plant staff found easy to use. I believe that people-led digital manufacturing suited to production practices that involve varying the type, quantity, and sequence of what is produced can be achieved by enhancing this in ways that deliver higher levels of real-time and general-purpose performance.

YahiroHaving also worked for an electrical machinery manufacturer other than Hitachi, I am conscious that all of these companies shared a Waigaya culture of informal and open discussions and meetings in the past and achieved their growth in a way that allowed for discussion between management and workforce. At one manufacturer, a project run directly by the company president that brought together staff from different departments led to numerous innovations, after management and factory staff discussed things in a way that transcended their different employment ranks. I am sad to say that this atmosphere has been lost and that a wider gap is opening up between managers and workers.

FujimotoI feel that too. It is because relying solely on vertical organizational structures and command hierarchies is not a recipe for success, something that is true also of government agencies.

YahiroBringing the two sides closer together is one of our jobs as a consulting company and we are currently seeking to improve workplace motivation through measures that include creating actual project management offices and revising key performance indicators (KPI) for workplace development so that they will be meaningful to both management and workers.

FujimotoAs you say, planning is likely best undertaken by cross-organizational special projects that are not impeded by the barriers between existing departments. Moreover, it is senior management that has the final say as to whether these measures will be adopted and it is by means of the instructions it issues to specific departments that the measures are implemented. This distinction between a horizontal organizational structure for planning and a vertical one for implementation is important. There have been instances in the past where putting the project in charge of both planning and implementation has impeded the planning process by putting them in conflict with existing operational departments. In that sense, the involvement of senior management will be essential to avoiding such conflict.

Toshihide Yahiro

Toshihide Yahiro

President, Hitachi Consulting Co., Ltd.

After studying investment banking in the IT sector and working first at the Long-Term Credit Bank of Japan and later in the digital content business of Sony Corporation, he went on to join the Ministry of Economy, Trade and Industry in its inaugural round of mid-career recruiting. After serving as the Director of the Information Economy Division of the Commerce and Information Policy Bureau, head of the Information Services Industry Office, and simultaneously as the Director for New Industry and Job Creation Policy in the Minister’s Secretariat and head of the New Business Policy Office, he left the ministry in 2010. He was subsequently employed by Sharp Corporation on work that included new cloud-based services, including positions as the Group General Manager, Cloud Computing Technology Development Group and as deputy manager of research and development. He left Sharp in 2012 and joined Hitachi Consulting as a director prior to taking up his current position in 2014.

YahiroSo, when it comes to using digital technology to consider business strategy in cross-organizational terms, it is important to have powerful data acquired from the IoT and IfT.

FujimotoYes. Practices that can vary the type, quantity, and sequence of what is produced and the production of a wide range of products that feature complex and intricate design along with their associated parts tend to be among the strengths of Japanese manufacturing operations that are skilled at coordination and adjustment. So they need to pursue digital manufacturing strategies that combine people and information and communication technology (ICT) in ways that further enhance competitive advantage. For example, while leading companies in places like China tend to manufacture standard products in high volumes on simple production lines and are moving in the direction of remotely operated plants that eliminate the need for people, Japanese companies should be following a different path. Something else that will be important in the future will be for IfT to have the broad scope to also encompass suppliers.

AbeThe challenge right now is how to respond flexibly to the diverse and complex demands of the market. This is a challenge that seems well matched by Japanese technology.

YahiroThe efficient production of custom products in varying types and quantities demands cross-organizational teamwork that also includes marketing, development, and finance departments.

FujimotoBecause integrated manufacturing has long been a strength of Japan. What is needed is to choose a “winning digitalization” that supports and enhances the teamwork of skilled craftspeople forged in Japan’s leading factories. I cannot agree with a path of simply imitating the leading ICT companies of Europe and America that takes us away from the crucial requirement of following strategies that play to our strengths and mitigate our weaknesses. This is because our underlying strengths are different.

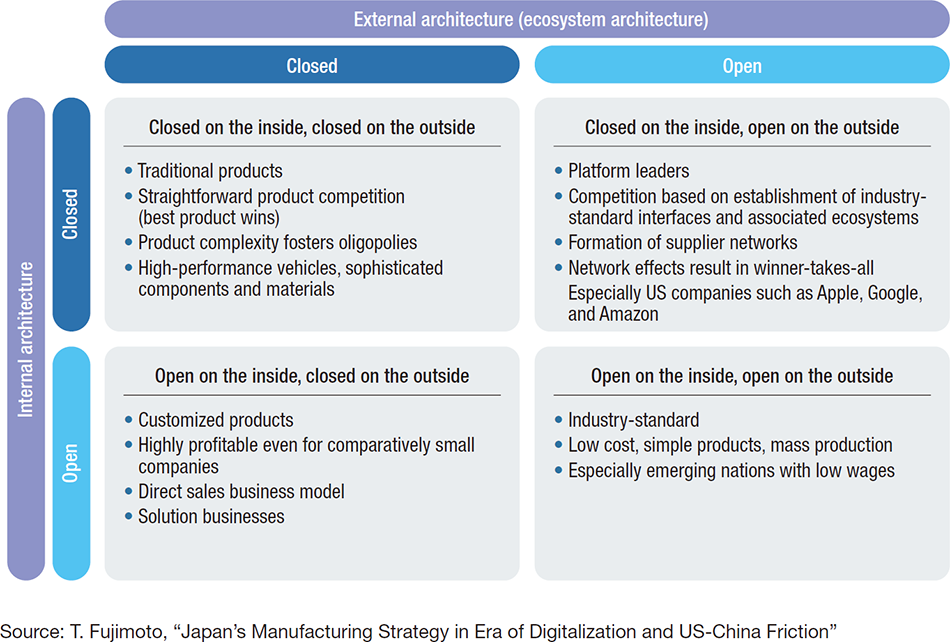

In terms of design, the direction we should be taking is one of establishing a clear architecture strategy. This involves balancing those aspects and design hierarchies where superior performance is maintained through integral and optimal design against those areas where proper use should be made of modular designs with standardized interfaces, and doing so on the basis of a clear distinction between these two approaches.

——Platform businesses, as exemplified by Google, Apple, Facebook, and Amazon (GAFA), have started to move into manufacturing. What sort of operational business strategies should Japan be following?

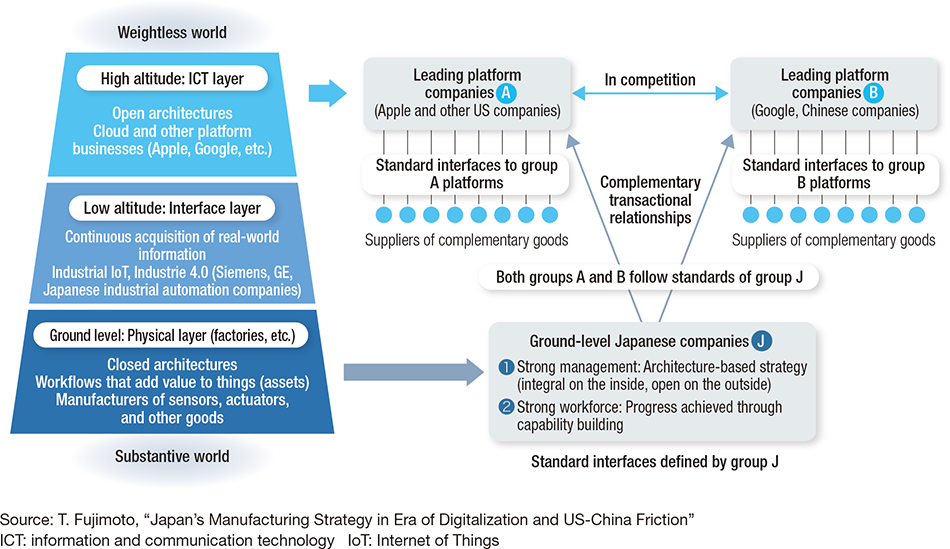

FujimotoWhere GAFA and other mega-platform businesses have become active is in the “weightless” cyber-to-cyber realm of the “high-altitude” cloud. While, in doing so, they have formed a giant ecosystem that brings in a wide range of complementary goods, enhancing asset utilization and the accuracy of their matching capabilities by means of big data and their overwhelming network power, they have also monopolized the data acquired in the process. However, this data monopoly has provoked increasingly harsh public scrutiny in recent years.

On top of this trend, the 2020s will also see an intensification of competition in the cyber-to-physical “low-altitude” cloud. Down in the physical realm, meanwhile, where objects have weight and physical laws hold sway, there is a need for precise and timely control of those objects that exist at ground level (assets, in other words) to prevent global warming and environmental degradation and to maintain human safety. In recent years, for example, there has been a growing realization that cloud-based approaches remote from the workplace can only go so far when what is needed is millisecond or micrometer control, and this has directed attention toward the “low-altitude” alternatives of edge computing and CPSs that are much closer to the ground. Furthermore, production of the complex machinery and parts that enable precise control is an area where many Japanese companies have long excelled.

Taking the automotive industry as an example, around 30% of the cars on the world’s roads were designed by Japanese companies. Elsewhere, Japanese companies supply a high proportion of the many machines and other assets that demand precise, high-speed control. Collaboration between customers who have a depth of knowledge about the control of their “ground-level” assets and the companies that manufacture these assets arises naturally as a means of providing better control through the collection of data from this customer equipment. This may well limit what can be achieved by platform businesses that operate in the cloud and so lack knowledge of these assets. This amounts to a struggle between those companies that pursue a data matching strategy and those based on control. As such, this practice by customers of collecting data from the assets they have installed to improve control may present a path to success for Japan’s capital goods manufacturers (see Figure 1).

Figure 1 | Japanese Companies’ Strategy of Complementing Platform Businesses

AbeCollecting and visualizing data from the physical world, and then utilizing it for control back in the physical world is certainly something that happens. We also supply control systems that are based on this approach.

FujimotoThat’s right. An increasing importance is being placed on achieving precise control through the use of edge computing and CPSs that process data in real time on “low-altitude” technology close to the ground level of the physical world. This requires standardization of the interfaces and communication protocols that can freely combine asset data from vehicles, appliances, and other equipment. I see this as another area where Japan can take the lead.

YahiroNot doubt the changes currently taking place in how people use cars give a hint of this future. As the world wakes up to electric vehicles, these companies recognize that it is no longer viable simply to manufacture and sell automobiles, leading them to start thinking about things like smart houses and smart cities. In other words, their business is targeting all aspects of users’ lifestyles, not just the time they spend in vehicles. The automotive industry is accelerating its acquisitions and collaborations in fields ranging from finance to artificial intelligence (AI) to establish next-generation service platforms. This applies across all industries, with the concern being that businesses will find their room to move has become constrained should they fail to pick up the pace of mergers and acquisitions (M&A) and deploy the logic of capital.

FujimotoWhat is important is for a variety of companies to work together and engage with the different facets of customers’ lives and the supply chain. There is only so much that individual companies can do by working away at their own particular solutions. Rather than closing off access to data, achieving this involves the corporate groups that deal with a variety of different assets making data from those assets that are already in place freely and openly available, including to competitors and companies from different industries. Even if it does not take the form of acquisition, it is desirable that this sort of collaboration and information sharing take place.

——What measures will be needed to lead the world through an organic interconnection between the physical world where objects have substance and the weightless realm of cyberspace?

FujimotoThe answer, I believe, is to solve the simultaneous equations formed when S, D, and G are combined. This entails a broader definition of these letters than in the United Nations’ Sustainable Development Goals (SDGs). Instead, an S-D-G perspective is one that takes simultaneous account of the three long-term trends of sustainability (S), digital technology (D), and globalization (G). While it is catchy attempts to address these separately from one another that gain attention, this is not the way to find solutions that will be sustainable in the long term. What is needed is to consider all three trends together and to find solutions that are optimal in terms of the problem as a whole. Hence the metaphor of simultaneous equations.

AbeWhile this is true for us also, rather than being about technology, this is about addressing societal challenges and contributing to a sustainable society.

FujimotoThat is right. Japan’s excellent manufacturing businesses still retain their high level of technical skills. Unfortunately, they tend to be weak when it comes to design concepts and business models that can leverage these skills. What allowed GAFA to gain their “air superiority” in the cyber realm of the cloud was the superior conceptual power of their design philosophies.

In terms of the future strategies available to “ground-level” Japanese companies, we have already discussed the one that involves the “low-altitude” technologies, and another we will get to shortly relates to the cloud. This latter strategy involves architectures in which companies’ own standards link directly from the ground up to the clouds of the platform businesses and other powerful companies that deal with related products. For example, Japanese companies have the leading share of the global market for the ceramic capacitors used widely in electronic and mechanical products such as smartphones, personal computers, and cars. This has come about because the manufacturing processes for these components are complex and difficult for their main overseas rivals to replicate. While each smartphone uses around 1,000 of these tiny electronic devices, they are vital components such that the failure of even a single one will affect phone performance. More than a trillion of these capacitors are produced annually, and even though most orders are from leading overseas smartphone manufacturers, they are all sold based on dimensions set by the Japanese companies that handle quality inspection. It is this that enables high-quality mass production. I describe this strategy as being integral (closed) on the inside and modular (open) on the outside. In other words, “integral-on-the-inside” products that competitors find difficult to imitate are sold as standardized “modular-on-the-outside” products. This is a strategy that is made possible by a high level of practical manufacturing capabilities and serves as an example of how manufacturing prowess ends up being more important than ever in this time of digitalization (see Figure 2).

Figure 2 | Map of Architecture Strategies Available to Japanese Companies

AbeAt Omika Works, it was only after we built up the requisite skills and know-how that digitalization finally bore fruit. What will be essential, however, as we enter an era when change is even more extreme, will be forms of digitalization that give a better view of the full picture. We also hope to contribute to DX across the entire value chain by providing customers with Lumada solutions that combine the latest IT, including AI and optimization, with the operational technology (OT) we have built up over many years in our own manufacturing operations.

FujimotoTo use self-driving cars as an example, optimal route calculation will be handled in the “high-altitude” cloud while the immediate area around the vehicle will be dealt with by “ground-level” technologies that include onboard sensors, electronic control units (ECUs), and embedded software comprising more than 100 million lines of code. Complimenting these, dynamic three-dimensional maps that update in real time will also be needed along with high-speed vehicle-to-everything (V2X) communications between vehicles and between vehicles and the roadside. In other words, there will be a need for advanced “low-altitude” CPSs to deal appropriately with oncoming vehicles when they are still hundreds of meters away, with pedestrian behavior, and with fallen objects or other obstacles. Or, to put it another way, advanced autonomous driving only becomes possible when control capabilities are put to work that cover all three layers.

YahiroCertainly, this is something that can be achieved by the Waigaya teamwork of Japanese craftspeople.

In particular, the trend among today’s younger generation is toward what can be called “connected experience,” meaning a state of being continually connected to someone or other. Maintaining an open line to friends while studying, for example. Bringing this approach into the manufacturing workplace has the potential to transform the current disconnected situation.

FujimotoWhile it remains important to maintain the trade skills and craftsmanship that have traditionally been a strength of Japanese workplaces, measuring these and utilizing AI and other digital technologies to transform them into structured knowledge should facilitate both automation and the transfer of skills to younger workers. What will also be needed in the future to continue developing these capabilities will be interaction between people and machines in the sense of an ongoing iterative process of acquiring skills and converting them into digital form.

AbeWe are also engaged in work aimed at helping to ensure product quality and facilitate the transfer of skills to young staff through the use of a Lumada solution to digitalize the actions of skilled engineers at the workplaces of manufacturing customers that can then be utilized to perform quantitative comparisons against the work of trainees.

FujimotoIn practice, because the best plants approach improvement from a scientific standpoint, they do not rely solely on inductive techniques that derive knowledge from large amounts of data that they have collected. Conventional big data analytics as practiced by the likes of GAFA frequently involves the use of such techniques, in effect telling users that such and such a result can be predicted once they have collected their big data, so there is no need to ask for scientific explanations. Unfortunately, these users tend not to accept what they are being told because the lack of a theory explaining why this is the case leaves them unconvinced. Rather, it is only when big data analytics is combined with abduction (hypothesis building) and deduction (logical reasoning) to complete the cycle of scientific reasoning and provide a convincing explanation to the people at the coalface that they will start to take action, giving rise to things like the Toyota practice of asking ‘Why?’ five times to drill down to underlying causes. Accordingly, I anticipate that the application of AI to continuous improvement in the workplace will involve a wide variety of techniques, including both induction and deduction.

Moving on to the ownership of data, the model that has prevailed to date in the cyber-to-cyber layer is one based on data monopolies by the organizations that monopolize the data for matching applications. My belief, however, is that this model will not work for competition and coordination between different companies at the cyber-to-physical layer, something that is set to increase in the realm of “low-altitude” technologies. The IfT data that capital goods manufacturers collect from the equipment they supply to customers only takes on significant meaning when, as part of their lives or trading practices, it is linked to similar asset data from other companies.

Accordingly, someone will establish standard interfaces for this data to allow for its sharing by the customers who own and are responsible for the appropriate control of assets and the capital goods manufacturers who design those assets, with this serving as a basis for open interconnection with other asset data in ways that suit customer workflows. Large numbers of the companies that control this equipment will enhance value collaboratively by interconnecting through data at this “low-altitude” layer and participating in cyber-to-physical platforms. I believe that an ecosystem with distributed ownership of data is better suited to the CPS era. Rather than a 100-fold increase in the stock price of the one company that holds a data monopoly, this sort of arrangement could, for example, see each of 100 companies with asset expertise gaining 10-fold shareholder value by coordinating data to assist customers.

YahiroThe establishment of a business ecosystem requires the setting of targets that will gain buy-in from other organizations around the world. This likely involves a common sentiment of wanting to make the world a better place and represents a way to achieve social innovation by solving the S-D-G simultaneous equations.

FujimotoA strength of many Japanese companies is the ability to address issues of sustainability (S) through detailed control, and the reason they are able to mobilize this strength is that a large number of companies who recognize what it is that society needs have sought to take responsibility for the control of physical assets. It will likely be more important than ever in the future for such companies to team up with one another by means of asset data.

AbeHitachi has many years of experience supplying mission-critical systems that underpin social infrastructure. It could be said that it has played its own part in taking responsibility for control in the physical realm. Right now, we are confronting a variety of societal challenges, not the least of which is the problem of the environment, and Hitachi intends to help establish sustainable ecosystems that will solve these issues.

——Finally, could you tell us what measures you see as being needed if Japanese manufacturing is to make progress, overcoming the coronavirus pandemic and the various other risks of the future?

FujimotoThe fact is that certain Japan-based plants rose in prominence during the current coronavirus pandemic. While obviously there were some that slowed down production temporarily in response to the fall in supply and demand, there were also quite a few that remained at close to full capacity right through 2020, even increasing their share of the global market.

Japanese production facilities also demonstrated their ability to recover or switch production following the Great East Japan Earthquake. The world was astonished at how Japan’s supply chain did not suffer major shutdowns, with numerous instances of plants going back into operation within two to three weeks and having sufficient stocks of many parts to cover this despite their just-in-time practices. In other words, while Japanese manufacturers already had an underlying resilience to large and visible disasters such as major earthquakes or floods, we have now seen that they also have the strength to cope with “invisible” global disasters like the current pandemic. This security of supply that they offer has come to be valued highly by corporate customers overseas. This supply chain robustness can also be seen as something that has been built up through past experience of overcoming major disasters.

YahiroWe are also starting to see moves by European and American companies to relocate factories, research centers, and other such operations away from China to other Asian locations such as Japan. In geopolitical terms, this is something that is currently working in Japan’s favor.

FujimotoJapan’s highly capable production facilities score highly on the four criteria of manufacturing skills, resilience, ability to shift production, and infection prevention. This is a consequence of Japan having retained its hubs of manufacturing expertise (what in Japan are called “tatakau [fighting] mother factories”) despite difficult times. Even as production was moving offshore, these highly experienced mother factories in Japan continued to serve as a base for knowledge transfer.

Despite the global crisis resulting from the coronavirus pandemic, I expect that Japan’s robust and flexible supply chains together with excellent factories that keep going to the very end, or if they do shutdown are the first to restart, will only rise in prominence within the global production system. In terms of international management that seeks to achieve the best overall outcomes globally and in the long term while continuing to use these facilities as hubs for knowledge transfer and capability building, I believe that the ongoing flexible adjustment and restructuring of the Asian supply chains of Japanese companies, especially the three-way balancing of Japan, China, and the Association of Southeast Asian Nations (ASEAN), will be an important challenge for manufacturing in the post-coronavirus era.

AbeThese are very thought-provoking ideas. Given the broad scope of Hitachi’s operations, I believe we can take on the role of bringing a variety of different customers together by serving as an intermediary who lays the groundwork for business ecosystems. Through the supply of digital solutions that incorporate Lumada, we intend to continue striving to enhance social, environmental, and economic value. Thank you for your time today.