Corporate management has been called on over recent years to address a variety of challenges, notably decarbonization, rising energy prices, and a shrinking workforce. To address these challenges, Hitachi has been making progress on support for carbon neutrality measures along with utilizing its Lumada models to facilitate a transformation in the business processes associated with energy and facilities. It has also sought to help companies strengthen their core businesses by offering managed services that make the operation, maintenance, and asset management of energy-related equipment less burdensome. This article presents existing examples and future prospects for measures that help to enhance corporate value by taking on tasks that support customers’ core businesses, such as more sophisticated equipment management, in addition to the utilization of Lumada models to enable smarter energy use across multiple sites or areas.

The diverse challenges that confront today’s corporate management can be broadly divided into the following three categories.

However, as efforts that address these challenges on an ad hoc basis will find it difficult to resolve them in any fundamental or sustained manner, what is needed are enablers*1 that can provide comprehensive and ongoing solutions and support.

When embarking on work toward carbon neutrality, Hitachi first puts together a “to be” vision of what it wants to achieve so as to provide a clear indication of the direction and strategy, and also a portfolio and roadmap for doing so. Once agreement is reached with the customer, this is then used in subsequent progress monitoring. As this work proceeds over long periods of time, ongoing support is delivered using Lumada models.

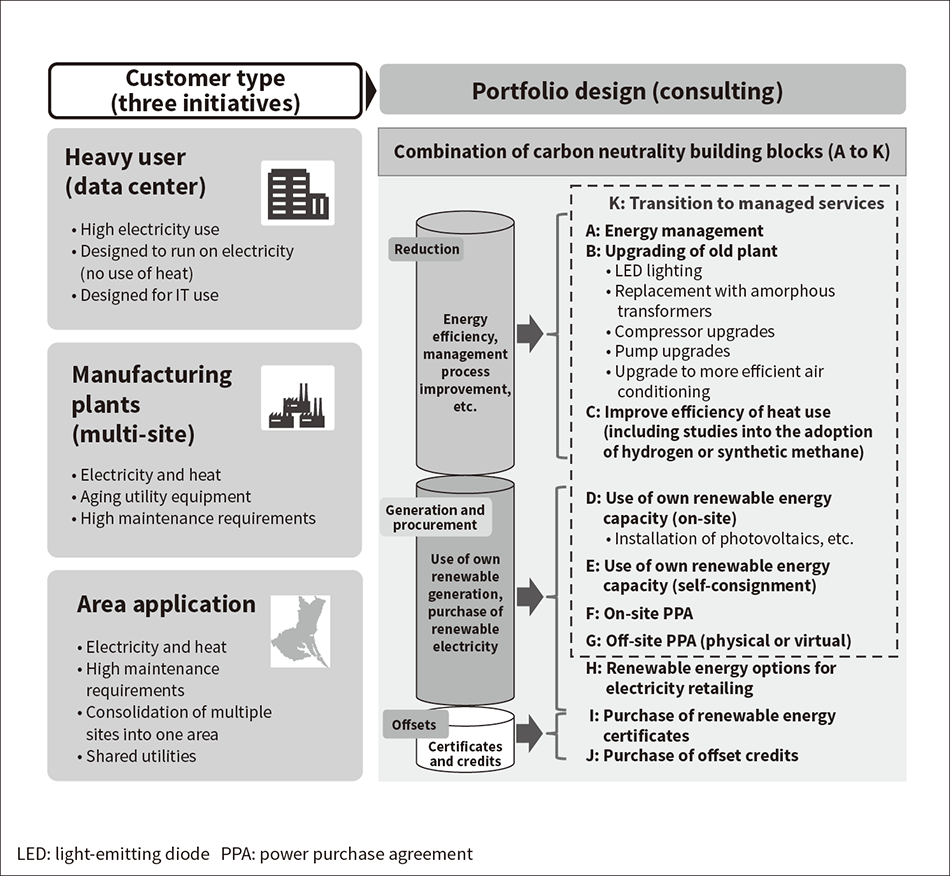

Figure 1 — Portfolio Design Portfolio design combines different solution building blocks based on what fits best with the customer’s energy usage characteristics.

Portfolio design combines different solution building blocks based on what fits best with the customer’s energy usage characteristics.

Portfolio design (consulting) categorizes measures for achieving carbon neutrality into “reduction,” “generation and procurement,” and “offsets,” setting targets based on the relative proportion of measures from each of these three categories.

To make this process work more effectively, Hitachi determines which model best fits a customer based on their energy use characteristics. To support rapid and flexible delivery, it treats the different solutions for achieving carbon neutrality as building blocks that can be combined as needed (see Figure 1).

The following are examples of how this use of solution building blocks might work.

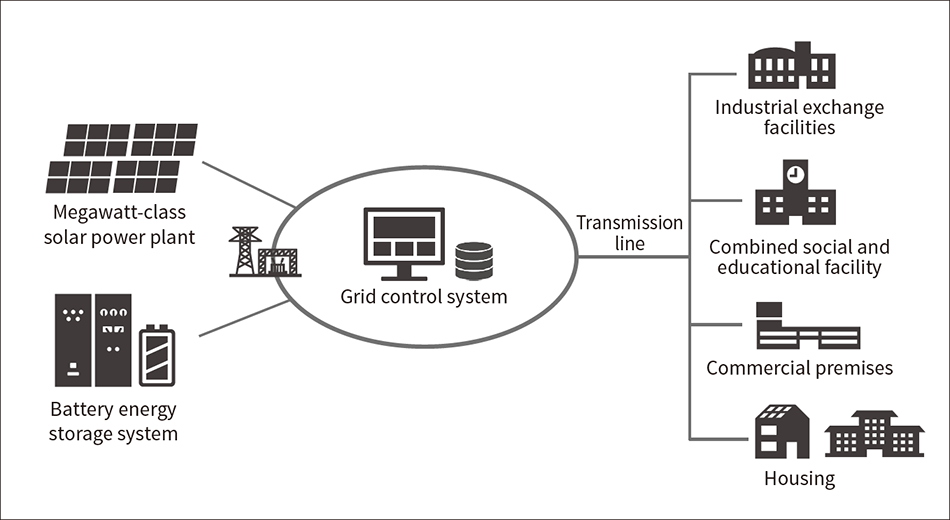

Figure 2 — Diagram of Shimonogami Smart Community Project Planned for Okuma Town, Futaba District, Fukushima Prefecture The project will use its own transmission lines to supply renewable energy generated by a megawatt-class solar power plant to consumers in the Shimonogami area around Ono Station in Okuma. Featuring a grid control system and battery energy storage, it will support the establishment of a system for the local sourcing of energy.

The project will use its own transmission lines to supply renewable energy generated by a megawatt-class solar power plant to consumers in the Shimonogami area around Ono Station in Okuma. Featuring a grid control system and battery energy storage, it will support the establishment of a system for the local sourcing of energy.

Following the 2020 announcement by the Japanese government of its 2050 Carbon Neutral Declaration, an increasing number of local government agencies around Japan have been making their own zero-carbon declarations.

It was against this background that Hitachi Power Solutions Co., Ltd. signed a memorandum of understanding on October 11, 2022 with Okuma Town in the Futaba District of Fukushima Prefecture for a project to build the Shimonogami smart community, Okuma having previously announced a zero-carbon declaration in February 2020.

The project includes plans to install a megawatt-class solar power plant, a battery energy storage system, its own transmission lines for delivering electric power to users, and a grid control system that provides optimal control of the overall network. By supplying electricity derived from renewable energy to the Shimonogami area around Ono Station in Okuma, it will support the establishment of a system for the local sourcing of energy.

The project will help Okuma in its goal of becoming a zero-carbon town through the use of locally generated renewable energy (see Figure 2).

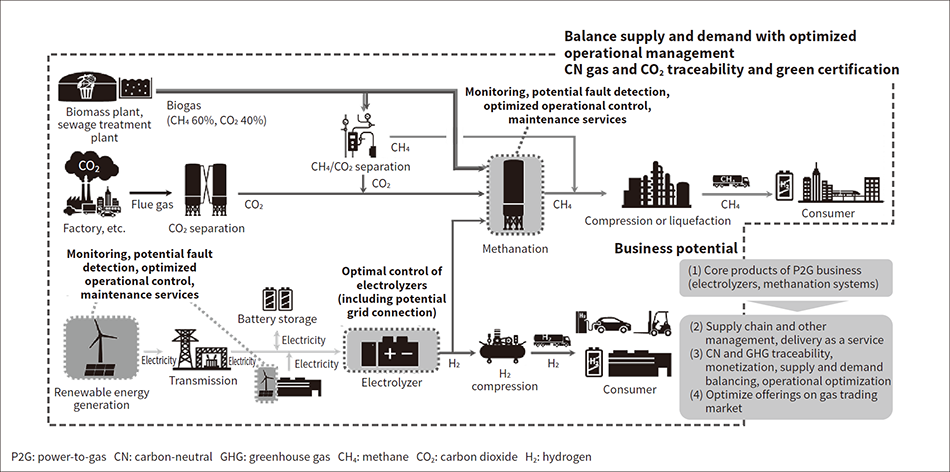

Figure 3 — P2G System for Hydrogen and Synthetic Methane The system can supply either synthetic methane or hydrogen by combining methanation with the use of excess renewable energy to power the production of hydrogen by an electrolyzer. Demand information is used for optimal system-wide energy management.

The system can supply either synthetic methane or hydrogen by combining methanation with the use of excess renewable energy to power the production of hydrogen by an electrolyzer. Demand information is used for optimal system-wide energy management.

Along with an increased proportion of energy coming from renewable sources, serious attention is being given in Japan and elsewhere to the adoption of power-to-gas (P2G) as part of the transition to a carbon-neutral society in 2050. This involves the use of excess renewable electric power to produce hydrogen. At companies, industrial complexes, and ports, a lot of work is currently going into the development of supply chains for the production, transportation, storage, and use of hydrogen, with the participants working together in ways that take advantage of their respective corporate strengths and local circumstances.

Hitachi is directing its efforts toward the production and use of hydrogen and synthetic methane in particular. To enable low-cost hydrogen production and build a hydrogen value chain, engineering work is focusing on high-voltage electrolyzers and hydrogen distribution control as well as on providing a hydrogen dual-fuel option for gas turbines and gas engines. As one way of using hydrogen is in the form of synthetic methane, Hitachi is helping Japan’s gas industry achieve its goal of 1% synthetic methane by 2030 and 90% by 2050, focusing on biomethanation and conducting studies aimed at commercialization. As well as supplying the key products for hydrogen and synthetic methane that serve as the heart of the overall P2G system, Hitachi is also looking to supply operational technology (OT) and IT for asset life cycle management, supply chain management, and the trading of carbon credits (see Figure 3).

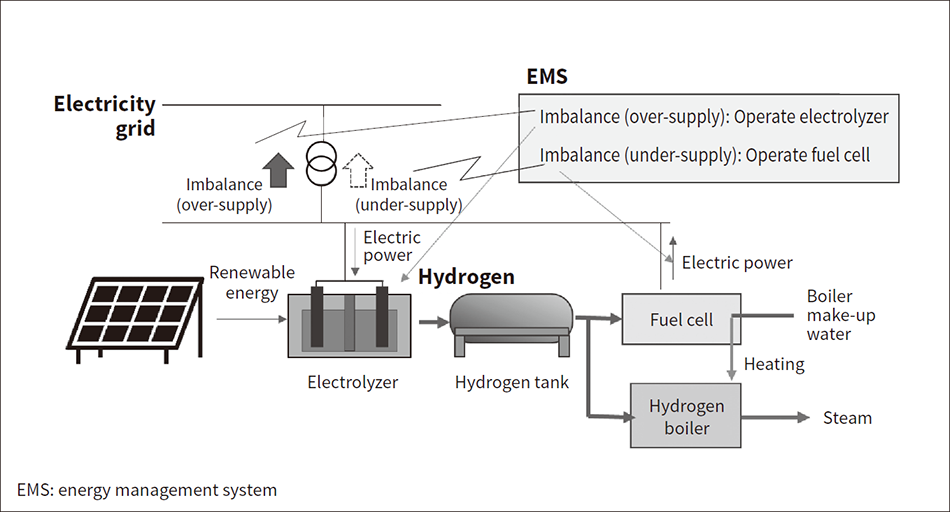

Figure 4 — Block Diagram of System for Carbon-neutral Supply of Heat The electrolyzer runs on electricity generated by photovoltaic panels and the hydrogen it produces is stored in tanks. By supplying the stored hydrogen to either a hydrogen boiler or a fuel cell, depending on whether there is an under- or over-supply of electric power, the system makes the power supply more reliable while also achieving carbon neutrality in the supply of heat.

The electrolyzer runs on electricity generated by photovoltaic panels and the hydrogen it produces is stored in tanks. By supplying the stored hydrogen to either a hydrogen boiler or a fuel cell, depending on whether there is an under- or over-supply of electric power, the system makes the power supply more reliable while also achieving carbon neutrality in the supply of heat.

The bulk of corporate CO2 emissions can be divided into those associated with electricity and those associated with heat. In other words, carbon neutrality needs to address not only the electricity-related CO2 emissions that can be reduced through measures such as renewable generation, but also emissions associated with the supply of heat. This section describes a project in which hydrogen was used to supply carbon-neutral heat.

The project involves a corporate group that is undertaking trials with assistance from the Ministry of the Environment FY2022 Subsidy for CO2 Emission Control Measures. As 50% of their CO2 emissions are attributable to electricity and the other 50% to heat, carbon neutrality cannot be achieved without also addressing the latter. Accordingly, the group decided to trial the use of hydrogen to supply carbon-neutral heat on the assumption that adequate supplies would be available in the future. To achieve high operational efficiency, the project involves setting up a cogeneration system in which green hydrogen produced from renewable energy is supplied to a hydrogen boiler and fuel cell. The project also plans to trial control practices based on an energy management system (EMS) that balances supply and demand by using an electrolyzer as a sink for electric power and a fuel cell as a source (see Figure 4).

By keeping imbalances in electric power to a minimum using the fuel cell and electrolyzer in tandem with generation equipment that is to be installed by Hitachi in the future, the goal is not only to achieve carbon neutrality in the supply of heat, but also to make the electricity supply more reliable. Hitachi has served as a long-term energy partner for the group, including by helping them to develop a roadmap for carbon neutrality and assisting with equipment installation. Hitachi also plans to utilize the know-how it has developed on this project in co-creation with other companies that have made a commitment to carbon neutrality.

Along with the use of digital technology for continuous monitoring, action on carbon neutrality also calls for ongoing progress accompanied by repeated analysis and testing. Because data appreciates (grows in value) over time whereas equipment depreciates (deteriorates), this gives rise to improvements in process (operations and maintenance).

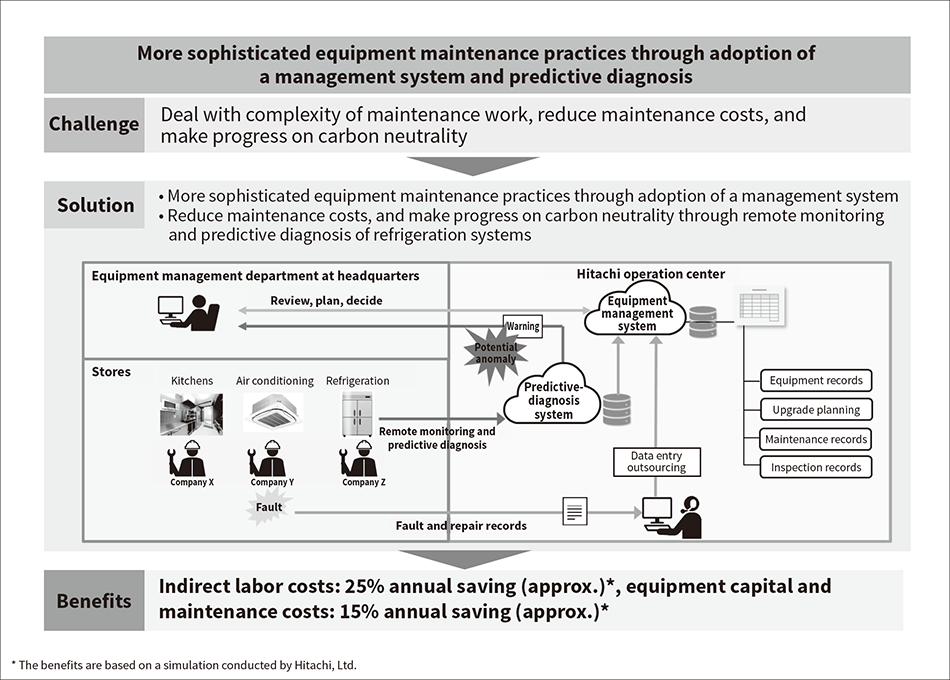

Figure 5 — Provision of Managed Services for Equipment Management to Retailer The figure illustrates the operational issues facing the food retailer, the solutions provided, and the benefits it has delivered. The solution took the form of an equipment management system and a predictive-diagnosis system combined as a single package.

The figure illustrates the operational issues facing the food retailer, the solutions provided, and the benefits it has delivered. The solution took the form of an equipment management system and a predictive-diagnosis system combined as a single package.

This section describes a solution for transforming equipment management that was supplied to a food retailer. The challenges that the company faced with regard to equipment operation were: (1) how to deal with the complexity of maintenance work while keeping costs low, and (2) how to make progress on carbon neutrality.

In response, Hitachi offered a package that combined the following two systems.

By combining carbon neutrality with more sophisticated equipment management, this will resolve the customer’s societal and environmental challenges while also extracting new value from data (see Figure 5).

Furthermore, by adopting consistent practices across different sites, it is anticipated that the service will deliver new benefits to the company as a whole by establishing not only an Internet of Things (IoT), such as equipment management systems, but also resource platforms for things like spare parts and maintenance staff. Beyond that, there is also scope for greater shared benefits by deploying resource platforms that transcend the borders between companies to encompass multiple sites, including those of other customers.

As the business environment in which companies operate becomes increasingly difficult, requiring that the investment of resources be focused on strengthening core operations, the time has come to reassess whether it is a good idea to continue keeping operations that support the core business (energy equipment and management) in-house, including measures for achieving carbon neutrality.

Hitachi’s goal is to contribute to the core business activities of its customers by enabling them to make the change from an ownership-based to a usage-based model by outsourcing these tasks on a comprehensive and ongoing basis.

By combining GX (including green electricity generation and energy efficiency) and DX (including energy management, asset management, and the IoT), Hitachi also aims to enhance the corporate value of customers.