The problems posed by climate change have worsened globally over recent years, including natural disasters and the impact on ecosystems. This has led nations everywhere to accelerate their efforts to decarbonize, resulting in a rapid expansion in the installation of wind power generation capacity, one of the more effective means of doing so. Hitachi Power Solutions Co., Ltd. has since 1996 been operating its wind power business in partnership with the German wind turbine manufacturer Enercon GmbH and it has gained a large share of the Japanese domestic market for these systems. A feature of this business is that, by drawing on skills and expertise built up over many years, it can provide a one-stop service for its customers that extends from the earliest stages of a project to its completion. This article describes this one-stop service and presents examples of solutions based on wind power generation systems.

The problems posed by climate change have worsened globally over recent years, including natural disasters and the impact on ecosystems. This has led nations everywhere to accelerate their efforts to decarbonize, resulting in a rapid expansion in the installation of wind power generation capacity, one of the more effective means of doing so. Japan, too, is expected to see the ongoing installation of wind power generation, with the Sixth Strategic Energy Plan published in 2021 projecting an increase in onshore wind generation from the current 4.2 GW to 15.9 GW in 2030 (assuming strengthened policy measures)(1).

The cumulative total of wind generation system orders for Japan received by the Hitachi Group as of the end of December 2022 was 876 units, giving it a leading share of the domestic market. In particular, Hitachi Power Solutions Co., Ltd. has since 1996 been operating its wind power business in partnership with the German wind turbine manufacturer Enercon GmbH and has installed a total of 481 turbines as of March 2023.

The key feature of the wind power business of Hitachi Power Solutions is that it can support the operations of customers planning to install wind power generation across every step of the process, from the earliest stages of a project to construction, operation, and ultimately demolition. This takes the form of a one-stop service for the activities that are essential to a generation business: (1) identification and selection of sites for turbine installation, (2) business planning, including where to position turbines to get the best return, financing, and the acquisition of wind farm certification, (3) transportation and erection of generation equipment, (4) operational management to maintain and improve utilization post-commissioning, (5) maintenance to ensure equipment reliability, and (6) demolition and replacement.

This section describes each of the processes handled by Hitachi Power Solutions’ one-stop service.

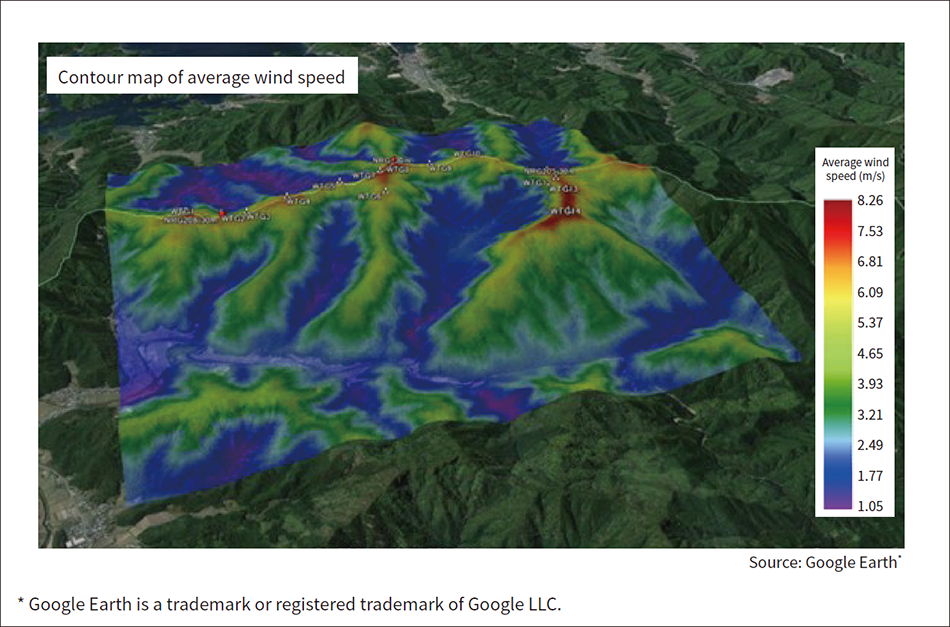

Figure 1 — Results of Wind Condition Simulation The color-coding indicates the wind speed distribution obtained by simulation. This information can serve as a basis for deciding where and how many turbines to install.

The color-coding indicates the wind speed distribution obtained by simulation. This information can serve as a basis for deciding where and how many turbines to install.

For onshore wind power generation, the site selection and business planning process extends from surveying potential sites and wind conditions to basic design, detailed design, and technical review(2).

The site selection stage that covers the steps from site survey to basic design involves surveying the site conditions (surrounding topology, presence of endangered species, and so on), identification of sites with favorable wind conditions, wind condition surveys, and surveys of social factors (distance from residences, gaining of consent for noise and impact on scenery, grid connection, and transportation routes).

Past practice when identifying sites with favorable wind conditions has been to make use of resources such as publicly available maps of wind conditions(3). To provide even better maps for site selection, Hitachi Power Solutions has developed its own proprietary wind maps in partnership with Hitachi, Ltd. using a data assimilation technique that combines atmospheric simulations with actual data collected from wind sensors located around Japan(4).

Business planning covers the detailed design and technical review. Site and geotechnical surveys are conducted based on the size of the proposed wind farm and used to assess the profitability of the project. This includes a detailed design that draws on a survey of wind conditions at the candidate site over a period of at least one year. The locations and total number of turbines are determined so as to increase total generation capacity, utilizing the results of the wind survey and wind conditions simulation to take account of the topology where the turbines are to be located and any disturbance caused by one turbine to another (see Figure 1).

As approximately 70% of Japan’s land area is mountainous, wind farms are significantly impacted by the turbulence characteristics of such terrain as well as by typhoons and other seasonal wind conditions. Accordingly, a conformance assessment is conducted based on the strength of the selected wind turbines and the likely wind conditions at the proposed site. This is then used to support the acquisition of wind farm certification.

Establishing working arrangements with local government and with local businesses is extremely important when installing wind power generation. To this end, Hitachi is taking steps to further strengthen the support it offers, predicating this on active involvement by local government and business through project structures that contribute to regional revitalization and are based on co-creation with the community. This extends from financing and engineering, procurement, and construction (EPC) to operation and maintenance (O&M) and the running of the business.

The size of wind turbines is growing as the technology advances and customers pursue higher generation efficiency (see Figure 2). Turbines supplied by Hitachi Power Solutions in the past have included the E-40 (40-m rotor diameter and 600-kW rated output) and E-70 (70-m rotor diameter and 2,300-kW rated output). Subsequently, the E-82 (82-m rotor diameter and 2,300-kW rated output) became the mainstream model from about 2009 onwards amid a trend toward turbines with larger diameters and higher outputs despite wind power generation being limited to flat sites with good wind conditions and sites located from the coast to inland. With the reduction in feed-in tariff (FIT) rates and the transition to the feed-in premium (FIP) system, Hitachi went on to launch the E-115 (115-m rotor diameter and 4,200-kW rated output) turbine featuring higher generation efficiency. The first E-115 commenced operation in April 2023 at Oga City in Akita Prefecture. The next-generation model currently under development is the E-138 (138-m rotor diameter and 4,200-kW rated output), which features even higher generation efficiency. Meanwhile, Hitachi has the advantage of being able to offer a 2,000-kW-class turbine like the E-82 when this better suits the topology and other site conditions. Hitachi also intends to contribute to maintaining and expanding wind generation capacity in Japan by offering the most suitable configurations and number of units for customers whose wind turbines are coming up for replacement.

The growth in wind turbine size and blade length poses challenges for the transportation of parts. The Eurus Kamikatsu-Kamiyama Wind Farm of Eurus Kamikatsu-Kamiyama Wind Energy Corporation that commenced operation in July 2022 is situated across a mountainous region at elevations of 1,000 m or more, making transportation across steep and narrow terrain unavoidable. Along with widening the mountain roads, this difficulty was overcome by using a special-purpose blade lifter that transports the blades at a tilted angle, allowing construction to be completed successfully in areas that would have been difficult to access using conventional transportation (see Figure 3). The knowledge gained from this project will be put to use in the future transportation of large turbines.

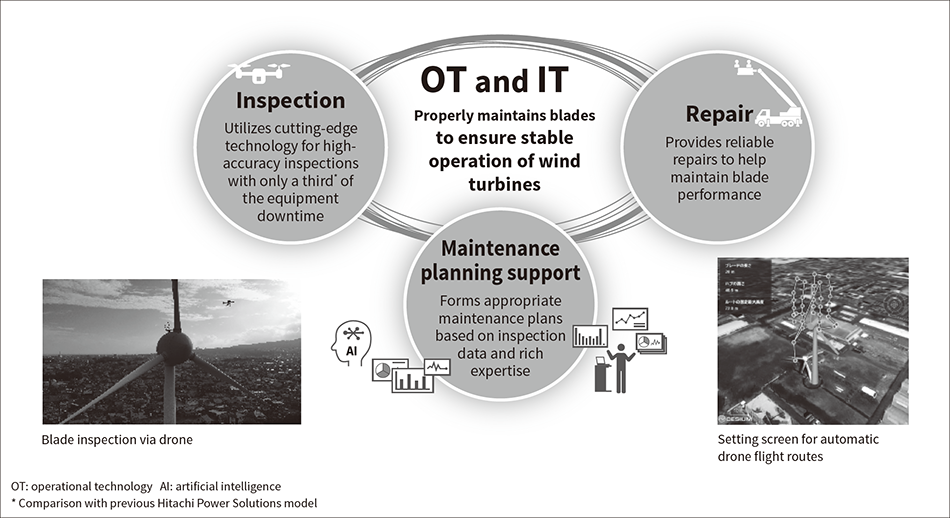

Figure 4 — Available Services and Benefits of Hitachi’s Total Service for Wind Turbine Blades The service provides customers with a one-stop shop, with capabilities that extend from blade inspection to maintenance planning and repair.

The service provides customers with a one-stop shop, with capabilities that extend from blade inspection to maintenance planning and repair.

By leveraging a combination of digital technology and expertise derived from its extensive industry experience, Hitachi Power Solutions is able to operate and maintain wind power generation systems in ways that meet the diverse needs of customers.

In April 2022, it launched a total service for turbine blades that provides enhanced equipment and operational safety(5). This operates as a one-stop service for blade inspection using drones and artificial intelligence (AI), maintenance planning, and repair of damage or wear and tear (see Figure 4). Benefits include reducing the amount of equipment downtime required for inspection to about one-third of previous levels. This improves profitability as less time lost to shutdowns means more time generating electric power for sale. The service is supplied as one of the solutions available on Hitachi’s Lumada digital platform. Further improvements in accuracy are also planned by collecting data on how turbine blades change over time and by making use of more advanced AI.

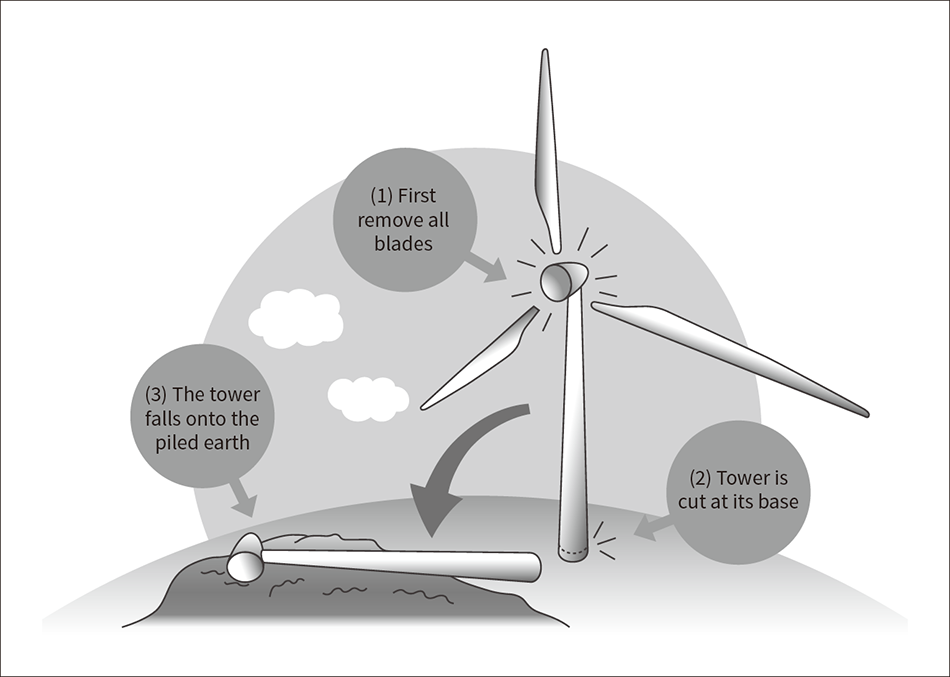

Figure 5 — Technique for Taking Down Wind Turbines for Demolition After the blades have been removed, the wind turbine tower is cut at its base and the tower is brought down onto a previously prepared pile of earth for disassembly. The procedure is very safe and it avoids the cost of having to transport and assemble a large crane.

After the blades have been removed, the wind turbine tower is cut at its base and the tower is brought down onto a previously prepared pile of earth for disassembly. The procedure is very safe and it avoids the cost of having to transport and assemble a large crane.

While onshore wind power generation capacity is expected to grow in the future, wind farms built in the early 2000s are now approaching the end of their lives. If this capacity is not to be lost, they will need to be replaced. Hitachi Power Solutions has entered into an agreement with Besterra Co., Ltd. to license their patented technique for taking down wind turbines for demolition(6). After the blades have been removed, the wind turbine tower is cut at its base and the tower brought down onto a previously prepared pile of earth for disassembly. The ability to accurately control the direction in which the tower falls means the procedure is very safe and it avoids the cost of having to transport and assemble a large crane (see Figure 5). The procedure is particularly suited to sites with only a small number of turbines and it cuts the cost by about half. Hitachi Power Solutions has built more than 480 wind turbines to date. As some of these are now approaching the end of their lives, having an efficient demolition technique encourages their replacement.

Hitachi Power Solutions draws on technology and expertise built up through its work on installing wind power generation systems to supply a range of solutions that meet the needs of customers. The following are some notable examples.

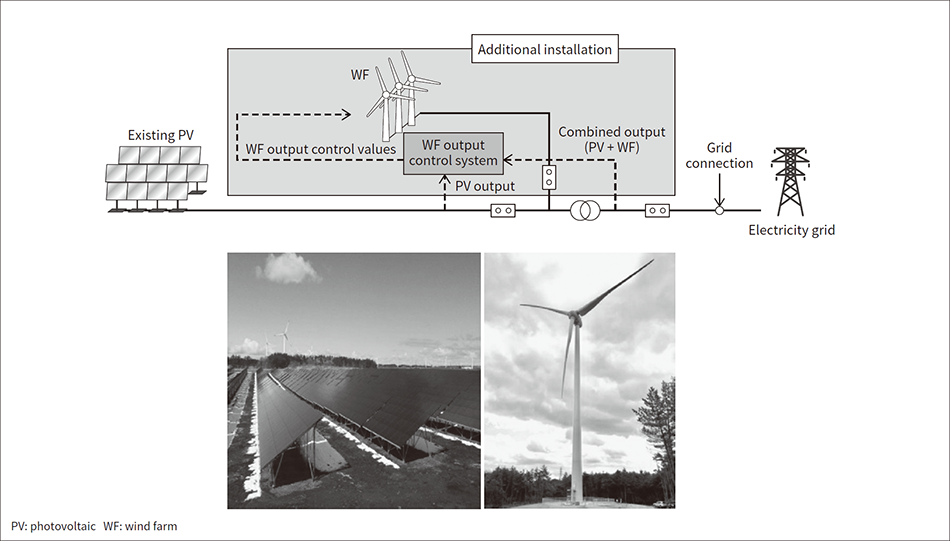

Figure 6 — Block Diagram and Photographs of Wind Power Generation System that Interoperates with Photovoltaic Power Generation The block diagram shows the system configuration (top) and the photographs show an operating photovoltaic power plant (bottom left) and a subsequently installed ENERCON wind turbine (bottom right).

The block diagram shows the system configuration (top) and the photographs show an operating photovoltaic power plant (bottom left) and a subsequently installed ENERCON wind turbine (bottom right).

Solid progress on making the transition to a decarbonized society is needed to address climate change, an area that has seen rapid growth in action over recent years. Use of renewable energy, as epitomized by wind power generation, is one effective means of helping to overcome this challenge. As described in this article, a characteristic of Hitachi Power Solutions is that it works in partnership with customers, providing a one-stop service for every step of the process from the early stages of a wind power generation project to operation and ultimately demolition. In the future, the company intends to contribute to the creation of a decarbonized society by holding true to this ethos and drawing on skills and expertise built up over many years to deliver wind power generation solutions that help to resolve challenges for customers and wider society.

Sensyn Robotics, Inc. provided considerable assistance with the inspection technique for turbine blades described in this article that uses drones and AI. Besterra Co., Ltd. likewise provided assistance with the technique for wind turbine demolition. The authors would like to take this opportunity to express their deep gratitude.