As Japan strives to achieve carbon neutrality by the year 2050, in addition to the use of renewable energy, there is a demand to use nuclear power to the maximum extent possible over the long term to supply electric power. For this purpose, it is necessary to achieve both effective utilization of plutonium resources and the disposal of radioactive waste, and fast reactor fuel cycle technology contributes to this through the reduction in volume and toxicity of high-level radioactive wastes and maximization of resource use. In order to achieve early demonstration of a fast reactor fuel cycle, Hitachi-GE Nuclear Energy, Ltd. is moving forward with the development of PRISM and metal fuel cycle technologies. By adopting the use of metal fuel, the PRISM offers inherent safety while at the same time providing passive safety through the use of air cooling, natural circulation, and passive components. By combining the PRISM with the metal fuel cycle, it is possible to reduce the volume and toxicity of high-level radioactive wastes while at the same time offering a high level of nuclear proliferation resistance.

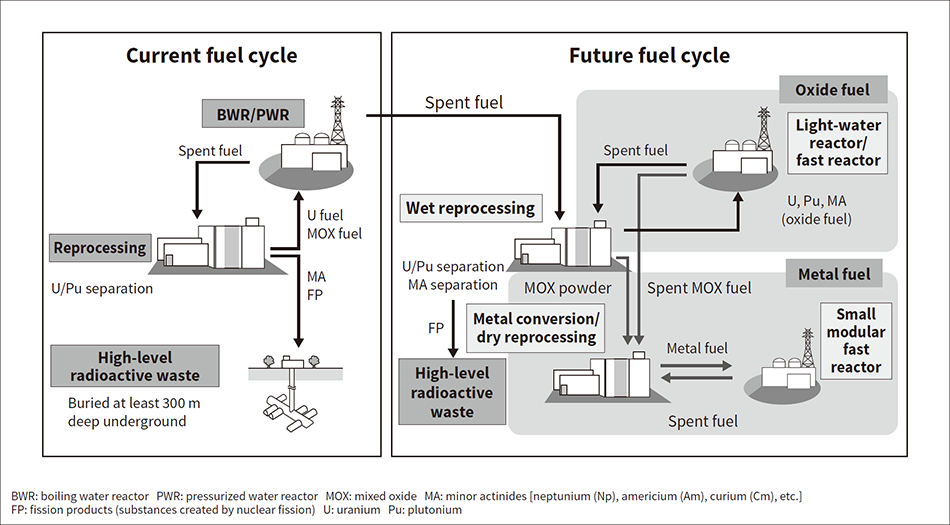

To help Japan achieve carbon neutrality by the year 2050, not only renewable energy, but also nuclear power needs to be utilized over the long term. Figure 1 shows the current fuel cycle as well as the fuel cycle to aim for in the future to achieve a reduction in volume and toxicity of high-level radioactive wastes and maximize resource use. The high-level radioactive waste generated from the reprocessing of spent fuel includes minor actinides (MAs) that continue to retain their radioactivity and pyrogenicity. In a future fuel cycle, it will be possible to recover MAs from high-level radioactive waste and burn it as fuel in a fast reactor to reduce the radioactivity and heat quantity of high-level radioactive waste, thereby reducing the burden placed on disposal sites. Hitachi-GE Nuclear Energy, Ltd. is working toward early realization of this fast reactor fuel cycle of the future by developing technologies for the power reactor innovative small module (PRISM) and the metal fuel cycle.

In the USA, the PRISM concept has been adopted by the versatile test reactor (VTR) program, as well as by the Advanced Reactor Demonstration Program (ARDP), which is a collaboration between GE Hitachi Nuclear Energy (GE Hitachi) and TerraPower, LLC to build the Natrium* nuclear reactor. ARDP plans to start operations in the USA with the Natrium around the year 2030. Utilizing this track record of designing and building these advanced fast reactors, it will be possible to proceed with development towards a goal of introducing them domestically while demonstrating fast reactor fuel cycle technology at an early stage. PRISM can be demonstrated at an early stage in this way, and can be flexibly expanded to support the necessary scale while providing value in the areas described below.

Hitachi-GE Nuclear Energy is considering the feasibility of introducing a metal fuel fast reactor fuel cycle that is compatible with domestic oxide fuel cycles, while studying and developing scenarios that involve reducing the volume and toxicity of high-level radioactive waste by burning the MAs generated in the oxide fuel cycle in a metal fuel fast reactor.

This article describes the state of this development work.

Figure 1 — Current Fuel Cycle and Fuel Cycle to Aim for in the Future Hitachi-GE Nuclear Energy is working toward the early realization of the fast reactor fuel cycle of the future by developing the power reactor innovative small module (PRISM), an innovative small modular sodium-cooled reactor, as well as technology for the metal fuel cycle.

Hitachi-GE Nuclear Energy is working toward the early realization of the fast reactor fuel cycle of the future by developing the power reactor innovative small module (PRISM), an innovative small modular sodium-cooled reactor, as well as technology for the metal fuel cycle.

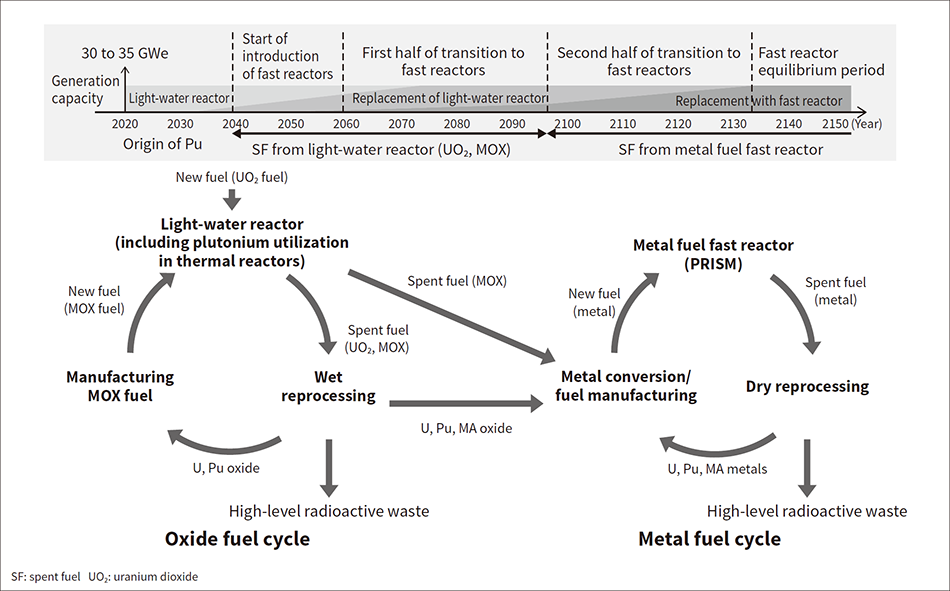

Hitachi-GE Nuclear Energy is considering scenarios for the introduction of the PRISM and the metal fuel cycle in Japan. The current light-water reactor fuel cycle is comprised of the oxide fuel cycle, which includes the oxide fuel reactor core, oxide fuel manufacturing, and wet reprocessing, and the introduction of the PRISM and its use of metal fuel, along with its metal fuel cycle, must be rationally and efficiently implemented in a way that conforms with domestic nuclear fuel cycle policies. Figure 2 shows the oxide fuel cycle and the metal fuel cycle.

The U, Pu, and MA oxides recovered in the oxide fuel cycle are converted to metals that are burned in a metal fuel fast reactor. Dry reprocessing technology with a high level of nuclear proliferation resistance is used to reprocess the spent fuel generated in a metal fuel fast reactor. Fast reactors, which consume fissile materials as fuel by using fast neutrons, have the potential to achieve high breeding ratios, and have a high level of flexibility with respect to fuel composition. For the future fuel cycle, in addition to multi-recycling using metal fuel, the spent MOX fuel that will be generated through future plutonium utilization in thermal reactors will be used as raw material for metal conversion and dry reprocessing, after which the results will be used as metal fuel with the goal of reducing the accumulation of spent fuel. Also, since U, Pu, and MA are recovered simultaneously during dry reprocessing, by combining a metal fuel fast reactor with dry reprocessing it will be possible to reduce the toxicity of high-level radioactive waste.

Figure 2 — Domestic Introduction of Metal Fuel Cycle Hitachi-GE Nuclear Energy is considering the domestic introduction of the PRISM. The MAs generated by the oxide fuel cycle are burned in the metal fuel cycle to reduce the volume and toxicity of high-level radioactive wastes.

Hitachi-GE Nuclear Energy is considering the domestic introduction of the PRISM. The MAs generated by the oxide fuel cycle are burned in the metal fuel cycle to reduce the volume and toxicity of high-level radioactive wastes.

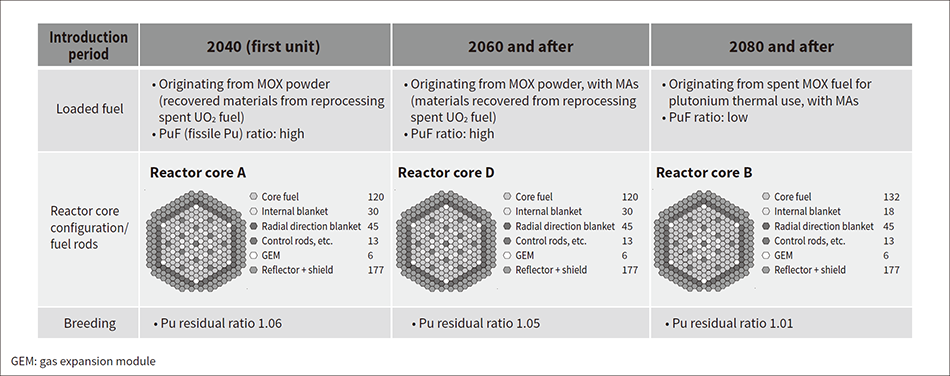

Figure 3 — Reactor Core Configurations According to Introduction Period The reactor core is configured based on the composition of the spent fuel that serves as raw material for the metal fuel, whether or not there are MAs, and the introduction period scenario. As the Pu residual ratio (the ratio between Pu amounts before and after burning) is > 1, Pu breeding and effective resource utilization are possible.

The reactor core is configured based on the composition of the spent fuel that serves as raw material for the metal fuel, whether or not there are MAs, and the introduction period scenario. As the Pu residual ratio (the ratio between Pu amounts before and after burning) is > 1, Pu breeding and effective resource utilization are possible.

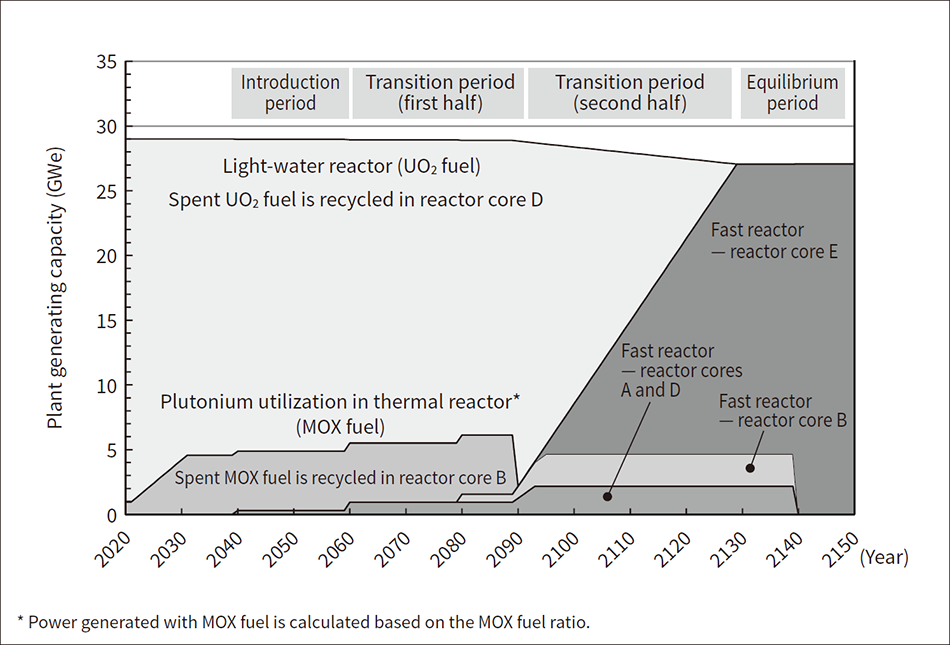

Figure 4 — Power Plant Capacity after Domestic Introduction of PRISM Generation capacity is set for each reactor core based on a consideration of the balance between accumulated spent fuel and Pu, and the raw materials for metal fuel.

Generation capacity is set for each reactor core based on a consideration of the balance between accumulated spent fuel and Pu, and the raw materials for metal fuel.

In the domestic introduction of the metal fuel cycle based on the PRISM, Hitachi-GE Nuclear Energy is considering multiple fast reactor cores based on the ratio of fissile plutonium (PuF) in the Pu of spent fuel produced domestically. To construct transition scenarios to the fast reactor equilibrium cycle, the company considered multiple fast reactor core introduction paces and the feasibility and effectiveness of domestic introduction.

Envisioning a gradual transition from light-water reactors to fast reactors, Hitachi-GE Nuclear Energy is considering scenarios involving the introduction of metal fuel fast reactors that conform to the oxide fuel cycle. Figure 3 shows the characteristics of reactor core A, which uses metal fuel with MOX as raw materials made from reprocessed and recovered spent fuel from domestic light-water reactors, reactor core D, which uses metal fuel including MAs, and reactor core B, which uses metal fuel with spent MOX fuel as raw materials. For any of these cores, the Pu residual ratio (ratio of the amount of Pu before and after burning) is 1 or higher, which means that the prospects are good for sustainability in the effective utilization of resources through Pu breeding.

Nuclear power plant capacity and the pace of introduction for fast reactors were set based on a consideration of factors such as the Strategic Energy Plan(1). Core specifications for light-water reactors and thermal reactors utilizing plutonium were set while referring to bibliographical values, etc.(2) Figure 4 shows the results of evaluating the pace of fast reactor introduction. The thinking concerning the pace of fast reactor introduction envisions the introduction of the first unit in 2040, followed by halting plutonium utilization in thermal reactors in 2090 or later, and replacing light-water reactors with fast reactors. Figure 5 shows the accumulation of spent fuel, as evaluated based on these domestic introduction scenarios. Since the accumulation of spent fuel does not become a negative value, this means the outlook is good for securing the necessary amount of Pu from domestic spent fuel until the equilibrium period for the domestic introduction of the PRISM, and this indicates feasibility for the domestic introduction of the PRISM from the viewpoint of Pu balance. The plan is to continue studying domestic introduction scenarios while considering Pu balance based on the latest information.

MAs that are radionuclides with a long half-life will need to be burned in order to reduce the volume and toxicity of high-level radioactive wastes. PRISM is a fast reactor that can burn MAs, and so if a metal fuel has an MA concentration of up to around 5%, it is thought to be feasible for use as a fuel due to the wealth of experimental information that has been accumulated. Also, dry reprocessing using molten salt electrolysis can recover MAs along with Pu, and past testing results evaluated the MA recovery rate at approximately 99.5%. Figure 6 shows the result of evaluating MA stockpiles based on the balance of MA recovery amounts and supplies of MA metal fuel in domestic introduction scenarios. While the number of fast reactors introduced is still low, since the pace of recovering MAs through wet reprocessing is faster, a temporary MA stockpile will be necessary, but as fast reactors are introduced, MAs will be gradually loaded into fuel, and it is expected that the need for an MA stockpile will diminish.

Based on the above, Hitachi-GE Nuclear Energy has successfully verified prospects for achieving the impact of the fast reactor cycle, which is the reduction in volume and toxicity of high-level radioactive wastes and maximizing resource use, through the domestic introduction of PRISM and the metal fuel cycle.

Hitachi-GE Nuclear Energy has considered the feasibility of a metal fuel fast reactor fuel cycle that conforms with domestic nuclear fuel cycle policies, and has determined that the prospects are good for compliance after domestic introduction. The company will continue working to develop small modular fast reactors and the metal fuel cycle based on these innovative technologies.